Professional Documents

Culture Documents

SAP Logistics Optimization With Handling Unit Management

SAP Logistics Optimization With Handling Unit Management

Uploaded by

amitava_bapi0 ratings0% found this document useful (0 votes)

131 views17 pagesThe document discusses logistics optimization through handling unit management. Key points include receiving, inventory management, shipping, and transfers using handling units; handling units in production, warehousing, and quality management; packaging; integration across functions; and lessons from implementations. Handling units can simplify and accelerate supply chain operations by integrating material flows and packaging information across SAP functionality.

Original Description:

Original Title

SAP Logistics Optimization with Handling Unit Management

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses logistics optimization through handling unit management. Key points include receiving, inventory management, shipping, and transfers using handling units; handling units in production, warehousing, and quality management; packaging; integration across functions; and lessons from implementations. Handling units can simplify and accelerate supply chain operations by integrating material flows and packaging information across SAP functionality.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

131 views17 pagesSAP Logistics Optimization With Handling Unit Management

SAP Logistics Optimization With Handling Unit Management

Uploaded by

amitava_bapiThe document discusses logistics optimization through handling unit management. Key points include receiving, inventory management, shipping, and transfers using handling units; handling units in production, warehousing, and quality management; packaging; integration across functions; and lessons from implementations. Handling units can simplify and accelerate supply chain operations by integrating material flows and packaging information across SAP functionality.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 17

Logistics Optimization with Handling Unit Management

Logistics Optimization with HUM by

Anil Kumar

Agenda

• Overview of Handling Units.

• Receiving Handling Units.

• Handling Units & Inventory Management.

• Shipping Handling Units.

• Interplant and Intercompany Transfers with Handling

Units.

• Handling Units in Production.

• Warehouse Management and Handling Units.

• Quality Management and Handling Units.

• Packaging.

• More of HU Integration.

• Lessons from Go-Live.

• Summarizing Handling Unit Management.

Logistics Optimization with HUM by

Anil Kumar

What is a Handling Unit?

Logistics Optimization with HUM by

Anil Kumar

What is a Handling Unit?

• A Handling Unit(HU) can be thought of as a system representation

of a real world grouping of materials.

• Location/Status information of a group of individual materials

assigned to a HU can be tracked by recording the HU move.

• A Handling Unit has a unique number identifying it. The unique

number can be formed to the specifications of industry standards

such as EAN 128 or SSCC. The HU grouping of materials is

generally tagged with the scannable HU identifier.

• The HU data entity can contain additional information such as

volume, weight, dimensions, packaging material, status etc.

• A HU can maintain a historical record enabling backward traceability

and can thus assist in product recalls.

Logistics Optimization with HUM by

Anil Kumar

Receiving with Handling Units

• An Inbound Delivery with pallet/packaging information can be

verified and received using Handling Units.

• Handling Units can be reused eliminating the need to reassociate a

group of materials with a new handling unit and a corresponding

new tag as it moves through the supply chain.

• HUs eliminate the need to use less efficient forms of pallet/package

identification in container load shipments.

• An ASN sent by a vendor can automatically create HUs along with

the Inbound Delivery document.

• Seamless accounting of returnable containers/packaging.

Logistics Optimization with HUM by

Anil Kumar

Handling Units & Inventory

Management

Non HU HU Manage

SLoc SLoc

• Handling Unit Management (HUM) is specified at the organizational

unit of “Storage Location”.

• At a HUM location all stocks need to be associated with at

• least one Handling Unit.

• A HUM location requires a partner non-HUM location. Any

unpacking at a HUM location automatically moves the inventory into

the non-HUM location.

• Movement of material in a HUM location requires a Handling Unit to

be specified.

Logistics Optimization with HUM by

• Handling Units enable fast and efficient material movement.

Anil Kumar

Shipping Handling Units

• HUs can be picked whole, or partially via Pick-HUs.

• Eliminates the need to explicitly specify packaging information at time of

shipment.

• ASNs sent to customers can include packaging information.

• Package volumes, weights and dimensions are available for shipment

planning.

• Backward traceability available thus helping with the resolution of product

issues.

• Delivery picking can be restricted to only certain package types, based on

individual customer specifications.

• Seamless accounting of returnable containers/packaging.

Logistics Optimization with HUM by

Anil Kumar

Interplant/Intercompany Transfer w/ HUs

• Picking of groups of materials via HU picks.

• HU information automatically updated in Outbound Delivery.

• HU information automatically updated in Inbound Delivery.

• Putaway of groups of materials via HU put away.

• HUs & HU tags reusable across different facilities.

• Record of activities with respect to HU throughout its life within

the organization. Helps with traceability requirements.

Logistics Optimization with HUM by

Anil Kumar

Handling Units in Production

• Packing information can be specified and recorded at time of production

rather than at time of shipping.

• Order independent staging of HU to non-HU location. Material backflushed

and/or issued like in non-HU environments.

• Order independent staging of HU, and HU issued to production order. Or

HU assigned to order and backflushed.

• Order specific staging and issue to production order.

• Order based, repetitive and process manufacturing supported.

• Goods receipt by HU.

• HU can be assigned to a sales order at time of production*.

Logistics Optimization with HUM by

Anil Kumar

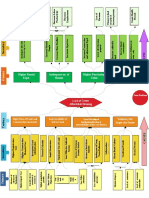

Warehouse Management and HUs

Logistics Optimization with HUM by

Anil Kumar

Warehouse Management and HUs

Logistics Optimization with HUM by

Anil Kumar

Warehouse processes to be considered within traceability scope

Logistics Optimization with HUM by

Anil Kumar

Handling Units in Quality

Management

• Inspection lots are assigned to Handling

Units.

• Samples can be at HU or inspection lot

level.

• Usage decision and transfer posting by

HU

Logistics Optimization with HUM by

Anil Kumar

Packaging

• At least one packaging material is

required for creating a HU. The

required packaging material is

identified as a load carrier.

• Packaging conditions can be

created when consistent packs

are being delivered to customers

and received from vendors.

• Automatic and/or semi-automatic

creation of HUs possible.

• Business processes involving

returnable packaging functions

are supported.

Logistics Optimization with HUM by

Anil Kumar

More of HU Integration

• Serial numbers of products can be associated with a HU. Thus

tracking of serialized products becomes considerably easier with

the association to a HU.

• Batch information is stored along with the product in a HU.

• Handling Units nicely dovetail into the functionality of Value

Added Services(VAS).

• HUs are used to represent Trucks/Containers in Yard

Management.

• Physical and Cycle Inventory can be conducted at HU level.

• Baseline RF transactions for HUs are included.

• SCM EWM makes extensive use of handling units with some

functions such as process layout functionality requiring the use

of Handling Units.

Logistics Optimization with HUM by

Anil Kumar

Lessons from Go-Lives and

Implementations

• Complexity and effort required in the conversion of inventory

into a HUM environment is frequently underestimated creating

bottlenecks and issues during cutover.

• Not enough retraining planned for experienced SAP users.

• Change of thought paradigm required particularly in

environments not used to SU concepts.

• Lack of adequate testing on-site with hardware such as label

printers and RF equipment included in the test.

• Not enough cross functional involvement and ownership. HUs

affect multiple functional processes and thus require

involvement from multiple areas.

Logistics Optimization with HUM by

Anil Kumar

Summarizing Handling Unit

Management

• Handling units can simplify and accelerate movement of goods

through supply chains.

• Handling units integrate through most of SAP’s functionality.

• Implementation of HUM in an environment with movement of

packaged material provides a compelling return on investment.

• Handling units facilitate a higher velocity of material flows.

• HUs provide proven functionality and value in environments

where packing information is materially relevant.

• Handling units are intrinsic to many new functional

developments from SAP and thus provide strategic value in

environments where SAP products form the backbone of the

enterprise software systems.

Logistics Optimization with HUM by

Anil Kumar

You might also like

- SAP S/4HANA Retail: Processes, Functions, CustomisingFrom EverandSAP S/4HANA Retail: Processes, Functions, CustomisingRating: 3 out of 5 stars3/5 (1)

- Marketing Audit ExampleDocument35 pagesMarketing Audit ExamplejanakaedNo ratings yet

- SAP IS-Retail Interview Questions, Answers, and ExplanationsFrom EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsRating: 3 out of 5 stars3/5 (11)

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- 1 Batch Specific UoM and Active Ingredient ManagementDocument2 pages1 Batch Specific UoM and Active Ingredient ManagementpoojaNo ratings yet

- Fundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFDocument17 pagesFundamentals of SCM Ewm A Step by Step Guide 2011 of SCM Ewm Rajesh PDFVinayak RaoNo ratings yet

- Handling Unit Management in SAP - Packing During Outbound ProcessDocument48 pagesHandling Unit Management in SAP - Packing During Outbound ProcessBabu Pon Immanuel Gnanadhas86% (7)

- SAP-WM Training: Introduction To Warehouse ManagementDocument4 pagesSAP-WM Training: Introduction To Warehouse Managementrajkumaraei40% (5)

- SCM 601 - Theoretical ContentDocument6 pagesSCM 601 - Theoretical ContentroccatNo ratings yet

- Warehouse Management System in SAPDocument10 pagesWarehouse Management System in SAPWaaKaaWNo ratings yet

- Quantitative Economics With Python PDFDocument945 pagesQuantitative Economics With Python PDFcarlos ortizNo ratings yet

- Packing in Outbound DeliveryDocument10 pagesPacking in Outbound DeliveryIshan AgrawalNo ratings yet

- Cycle Counting Configuration, Process Flow and Implementation by Rajen Patel in SAP ERP Logistics Materials Management (SAP MM)Document6 pagesCycle Counting Configuration, Process Flow and Implementation by Rajen Patel in SAP ERP Logistics Materials Management (SAP MM)gong688665No ratings yet

- Cycle Counting in SAP MMDocument10 pagesCycle Counting in SAP MMPMPROIT100% (3)

- Logistic Unit: Iebach Ogistics RoupDocument8 pagesLogistic Unit: Iebach Ogistics RoupMANISH.sikNo ratings yet

- WM TcodesDocument15 pagesWM TcodesbtbsapmmNo ratings yet

- Sap WM Interview Questions and AnswersDocument1 pageSap WM Interview Questions and AnswersRakesh Reddy Gopi ReddyNo ratings yet

- WM Printing SettingsDocument4 pagesWM Printing SettingsWaaKaaWNo ratings yet

- Cross Docking in SAP Warehouse Management - One Step - SAP BlogsDocument9 pagesCross Docking in SAP Warehouse Management - One Step - SAP Blogsnik100% (1)

- Cross Docking WMDocument8 pagesCross Docking WMShyam ChelluriNo ratings yet

- Understanding The Packing Function in SAPDocument3 pagesUnderstanding The Packing Function in SAPsushma_311819No ratings yet

- Expertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsDocument6 pagesExpertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsArun PadhiNo ratings yet

- Material Management by Using SAP in Real Estate Construction SectorDocument6 pagesMaterial Management by Using SAP in Real Estate Construction Sectorcodertutorial comNo ratings yet

- Bulk Strategy - PutawayDocument11 pagesBulk Strategy - PutawayEKTA SIMARIANo ratings yet

- Batch ManagementDocument6 pagesBatch ManagementChandra Sekhar PNo ratings yet

- LO530 4.6 - Basic Processes in WMDocument337 pagesLO530 4.6 - Basic Processes in WMamitava_bapi100% (3)

- Understanding EWM Process Oriented Storage ControlDocument15 pagesUnderstanding EWM Process Oriented Storage Controlnina861430% (1)

- Prepared by G.V.Shivakkumar Sap-Mm/WmDocument11 pagesPrepared by G.V.Shivakkumar Sap-Mm/WmJITUL MORANNo ratings yet

- WM CustomizingDocument37 pagesWM CustomizingAlessandra Coletti100% (2)

- Storage Location Reference in SAP WMDocument4 pagesStorage Location Reference in SAP WMMohammed Savad50% (4)

- WM Storage Location ControlDocument4 pagesWM Storage Location ControlPradeep Kumar Reddy NaraNo ratings yet

- Handling Units in Production OrdersDocument3 pagesHandling Units in Production OrdersBLNo ratings yet

- Create Material Master MRP Views and Assign MRP TypesDocument12 pagesCreate Material Master MRP Views and Assign MRP Typesdudhmogre23No ratings yet

- Create Transfer Order - DirectDocument3 pagesCreate Transfer Order - Directmehboob hafizNo ratings yet

- 1.1.1.SAP MM Material Master Tutorial - Free SAP MM TrainingDocument11 pages1.1.1.SAP MM Material Master Tutorial - Free SAP MM TrainingManickath Mani NairNo ratings yet

- Sap Production Planning (Old)Document100 pagesSap Production Planning (Old)Nina PagkatipunanNo ratings yet

- Handling Unit Management in SAP Packing During Outbound ProcessDocument48 pagesHandling Unit Management in SAP Packing During Outbound ProcessmohannaiduramNo ratings yet

- Reservation - Internal Order With Material To Material Transfer PostingDocument10 pagesReservation - Internal Order With Material To Material Transfer PostingmeddebyounesNo ratings yet

- 3 - 9 - Material Master Data - Sap WM ViewsDocument4 pages3 - 9 - Material Master Data - Sap WM Viewsrajesh98765100% (1)

- Sap Master Data in Materials ManagementDocument13 pagesSap Master Data in Materials Managementedmondo77No ratings yet

- Sap SD Availability Check PDFDocument17 pagesSap SD Availability Check PDFSandip SharmaNo ratings yet

- Production With HU-IntellectDocument17 pagesProduction With HU-IntellectSameer BagalkotNo ratings yet

- Fernando Vladimir Soliz Mejia: Contact InformationDocument16 pagesFernando Vladimir Soliz Mejia: Contact InformationfsolizmNo ratings yet

- Availability Check: Check Against ATP Quantities 2. Check Against Product Allocation 3. Rule Based Availability CheckDocument65 pagesAvailability Check: Check Against ATP Quantities 2. Check Against Product Allocation 3. Rule Based Availability CheckksubratkumarNo ratings yet

- Wave Picking in SAP WMDocument1 pageWave Picking in SAP WMShobhit Bajaj100% (1)

- SAP WM Putaway and Removal Strategies in WMDocument8 pagesSAP WM Putaway and Removal Strategies in WMShwetha SNo ratings yet

- Handling Unit ManagementDocument15 pagesHandling Unit Managementinpbm06330100% (2)

- WM D ProcessDocument70 pagesWM D Processkumar N100% (1)

- WM Implementation Introduction G.V.Shivakkumar, CTS, Venkatesansivakumar@yahoo - Co.inDocument26 pagesWM Implementation Introduction G.V.Shivakkumar, CTS, Venkatesansivakumar@yahoo - Co.insrinuNo ratings yet

- Configuration Guide Pre-Numbered Invoicing in SAPDocument14 pagesConfiguration Guide Pre-Numbered Invoicing in SAPGustavoGDANo ratings yet

- Stock Transfer Between Plant Using STO With DODocument36 pagesStock Transfer Between Plant Using STO With DOAnubhav SharmaNo ratings yet

- Physical Inventory in WMSDocument25 pagesPhysical Inventory in WMSJagadish JaganNo ratings yet

- SAP CatchweightDocument32 pagesSAP Catchweightsanthoshinou100% (1)

- SAP PP - IntroductionDocument8 pagesSAP PP - IntroductionKoustubha KhareNo ratings yet

- Batch Determination in SapDocument13 pagesBatch Determination in SapVivek KalchuriNo ratings yet

- Sap SCM PLMDocument22 pagesSap SCM PLMchandu.sap100% (4)

- 25 Stock Transfer & Transfer PostingDocument14 pages25 Stock Transfer & Transfer PostinglymacsauokNo ratings yet

- QM Master Data and Testing HUM PDFDocument15 pagesQM Master Data and Testing HUM PDFstrokesdivisionNo ratings yet

- SAP Warehouse Management: Duration StatusDocument3 pagesSAP Warehouse Management: Duration StatusNikhil RaviNo ratings yet

- Detailed SAP Interface Design Fundamental DocumentDocument4 pagesDetailed SAP Interface Design Fundamental Documentamitava_bapiNo ratings yet

- LO530 en 46C Warehouse ManagementDocument349 pagesLO530 en 46C Warehouse Managementamitava_bapiNo ratings yet

- Inbound and Outbound Idoc ConfigurationDocument13 pagesInbound and Outbound Idoc Configurationamitava_bapiNo ratings yet

- 944 Warehouse Stock Transfer Receipt AdviceDocument21 pages944 Warehouse Stock Transfer Receipt Adviceamitava_bapiNo ratings yet

- LO530 4.6 - Basic Processes in WMDocument337 pagesLO530 4.6 - Basic Processes in WMamitava_bapi100% (3)

- TCW Module 3 Pre FinalDocument21 pagesTCW Module 3 Pre FinalMark Jade BurlatNo ratings yet

- Analyzing Farming Systems DeterminantsDocument12 pagesAnalyzing Farming Systems Determinantsadmirechawaz100% (1)

- Topic: 1.1 What Is Accounting? 1.2 Who Uses The Accounting Data 1.3 The Basic Accounting EquationDocument6 pagesTopic: 1.1 What Is Accounting? 1.2 Who Uses The Accounting Data 1.3 The Basic Accounting EquationAnn Ameera OraisNo ratings yet

- DSP App - Dspfinance - Com - A Document Received As Part of A Job Scam, Likely A Cheque Fraud NetworkDocument3 pagesDSP App - Dspfinance - Com - A Document Received As Part of A Job Scam, Likely A Cheque Fraud NetworkJames BarlowNo ratings yet

- Statemant HSBCDocument1 pageStatemant HSBCVera DedkovskaNo ratings yet

- Suli LK TW Iii 2017Document91 pagesSuli LK TW Iii 2017J KNo ratings yet

- CFAS - Statement of Changes in Equity and Notes To FS - Quiz 4 - SY2019 2020Document19 pagesCFAS - Statement of Changes in Equity and Notes To FS - Quiz 4 - SY2019 2020Ivy RosalesNo ratings yet

- Concept Paper ThesisDocument5 pagesConcept Paper ThesisSteven Z. CondeNo ratings yet

- Job Opportunities Kenya October 10 - October 15Document305 pagesJob Opportunities Kenya October 10 - October 15Ngugi KariukiNo ratings yet

- CBMEC 1 BSOA Lesson 1 Introduction To Production and Operations ManagementDocument7 pagesCBMEC 1 BSOA Lesson 1 Introduction To Production and Operations ManagementPeach DefsoulNo ratings yet

- After Sales Services of Selected Car Insurance Companies - Chapter 1 5 - RevisedDocument68 pagesAfter Sales Services of Selected Car Insurance Companies - Chapter 1 5 - RevisedMariel AdventoNo ratings yet

- Akun Impor Ud BuanaDocument1 pageAkun Impor Ud BuanaYusnita dwi kartikaNo ratings yet

- 21-01-21 Siang Bahan Paparan BIM - Herry VazaDocument33 pages21-01-21 Siang Bahan Paparan BIM - Herry Vazaeryanto mrNo ratings yet

- Test Bank For Essentials of Marketing Management 1st Edition MarshallDocument92 pagesTest Bank For Essentials of Marketing Management 1st Edition MarshallXolani MpilaNo ratings yet

- Finance WC AnkurDocument67 pagesFinance WC AnkurshobhnaNo ratings yet

- Mea Assignment WordDocument23 pagesMea Assignment WordNabila Afrin RiyaNo ratings yet

- Unit 12 Strategic Option PDFDocument15 pagesUnit 12 Strategic Option PDFPradip HamalNo ratings yet

- Foreign Exchange Market: Presentation OnDocument19 pagesForeign Exchange Market: Presentation OnKavya lakshmikanthNo ratings yet

- Abm 1-W6.M2.T1.L2Document5 pagesAbm 1-W6.M2.T1.L2mbiloloNo ratings yet

- Problem Tree 1Document1 pageProblem Tree 1bhbfc project-1No ratings yet

- SAP Fioneer ESG WhitepaperDocument12 pagesSAP Fioneer ESG WhitepaperOphiuchus0% (1)

- World ScaleDocument2 pagesWorld Scalekeerthi86No ratings yet

- MBA-AFM Theory QBDocument18 pagesMBA-AFM Theory QBkanikaNo ratings yet

- OBE SYLLABUS - GOVT ACCTG ACCTG FOR NPOs FAT 41 - SUMMERDocument10 pagesOBE SYLLABUS - GOVT ACCTG ACCTG FOR NPOs FAT 41 - SUMMERAngela DizonNo ratings yet

- Barber & Odean - The Internet and The InvestorDocument14 pagesBarber & Odean - The Internet and The Investoronat85No ratings yet

- B 20170522Document94 pagesB 20170522larryNo ratings yet

- InvoiceDocument1 pageInvoiceshiv kumarNo ratings yet

- Review Questions - OVWL 2023Document8 pagesReview Questions - OVWL 2023zitkonkuteNo ratings yet