Professional Documents

Culture Documents

Special Application of Asphaltic Concrete For Dam Water Barrier Construction

Special Application of Asphaltic Concrete For Dam Water Barrier Construction

Uploaded by

Alberto GaxiolaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Application of Asphaltic Concrete For Dam Water Barrier Construction

Special Application of Asphaltic Concrete For Dam Water Barrier Construction

Uploaded by

Alberto GaxiolaCopyright:

Available Formats

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE.

For personal use only; all rights reserved.

Special Application of Asphaltic Concrete for Dam

Water Barrier Construction

Dipl,-Ing Reinhard Frohnauer’

STRABAG Tie&u GmbH

This report deals with two pumped storage schemes in Southern Germany which

have been rehabilitated afier 20 and 40 years of service. Their upper reservoirs

have received nc\v asphaltic concrete linings applied in extremely wide horizontal

paving lanes using the latest techniques of bridge pavers.

The 13s MW power generation scheme Reisach Rabenleite was commissioned in

1955. Its upper t-eseryoir with a capacity of 1 S million m’ underwent a complete

rehabilitation in I’+>3 - 1994. Its original lining consisting of a concrete facing on

the reservoir slopes and a heavy bituminous felt membrane on the reservoir bot-

tom has failed, ivith the result of increasing seepage in the past years. The defec-

tive lining has been replaced by a new asphahic concrete lining of 6-8 cm binder

and 8 cm impervious layer. In addition, an extensive monitoring system has been

installed.

Relying on technologies common at the time of construction, concrete slabs, non

reinforced, 7 x 7 III and 20 cm thick, were used to seal and secure the internal

slopes on the kidney shaped reservoir, The bottom of the reservoir was sealed

with a so-called _mammoth skin“ consisting of three layers of bituminous roofing

sheets reinfoj-ccd with glass fibre fleece and partly with thin copper foil in ad-

dition The embankment crest was secured by a solid parapet wall made of con-

c,rete,

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

According to today’s safety rules, the complete lack of monitoring instruments

was a significant weak point of the design,

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

Mer a few years of operation the first major faults appeared. In the course of 40

years nearly all concrete panels became cracked and most joints were leaking. The

bottom lining showed numerous cracks, especially at the interface with the con-

crete structure, Regular maintenance and repairs managed to fix these faults in the

short term, however, this work reflected the susceptibility of the system. Despite

all improvements the water losses increased to mof-e than 40 l/set, as could be

observed at the foot of the embankment. In fact, the cohesive components of the

dam fill had taken over the Cm&ion of a barrier.

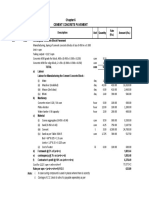

The redesign for the 120,000 m2 reservoir surface involved an 8 cm thick as-

phahic concrete seal to be placed on a 6 cm (bottom of the basin) or 8 cm (slope

of the basin) asphaltic concrete binder. In order to measure seepage water from

the asphaitic concl-ete lining a drainage layer and a bentonite membrane were

placed below to fat-m a second sealing level. A new control gallery in the center

of the basin is deter-mined to collect seepage water, if’any.

bottom transition slope

mastic seal coat

impervious asphalt

concrete 8 cm

binder layer 6 cm binder layer 6 cm

bentonite membrane

porous concrete 20 cm

Rabenleite: New Design of Asphaltic (‘oncrete Lining

A principal rule for the demolition work was to re-use as much of the existing

material as possible The entire demolished concrete as well as additional rock

excavation was processed and re-used as drainage material. Significant milestones

in the constl-uction schedule were the construction of a new access ramp to the

2 Frolmaw

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

r b ae a a o nts n d ta eedA ed t c tmrfr mi o c h vpt e tp

v a f 1 o m ot is 4 hi ’ t f bre r , ra T o sew d e 0t ,d h t t ie m r0 e o

n a e l t gi i t a e o r m sg hT n xm i p o h s eh di i a c r i b k e n

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

t r b h we b o i ea i sa r c t n na mest o ur t a bn prh i k su o s i d vae n

t d r h ro i e ow n a n g d s . t

T s o t r h d l r f h ia ne aop e w

e n e m t pr ec h bg w ah eot xe e e te hf i

d f w r a o A a fe m ot f n s ora ht s t e arel g el ew m si e o

w S ew p O o t iao t l e O n o gsf ah aa sm $ p lh se c Ae b i ai e

d l w rb u ao t a sa u p yw n o 5s tik i c e i p 0T angl u e o r t , h ba t s m f

s g wt v hr ta p e eta s o bs r dt lhvt lf i o u- pehe oo l t ry

w p i e n r t i e o r d

O t c a c n h fr o e oe n us c nt r

d b s aa a se e ts ua r i pm v o p e n o

-

f t a co h ss or e pe n ha c- al r

A s f yr a en b it r nh i fe

m i p oe ts la vn h as et e c- r e

p c h b ot a i no l n c t d r i e

s t tu e h rp d e ep g ne e gr

a c g A p r a r a i e c n c k s a

c b i op ae a s nl sa mqervious

ca asphaltic m concrete r8c cm ee

reinforcement

f e i s l n u e i b m s s e h t

t p hh rp ee ea a vr v ia y op

w T p a c h r l o i e l n s c . c a r

b i r e a s es a n m

o m d o v

a a l t l s cw o hl l ch eo o e e w p s n s e s

b r e e i q n u g i r

R N Da o D e C eb f a w r se

T a c h su f ot re s p l o hn i eec h i ro cecds so b a n f oi em a l

a c g a n r s g ln a ut a a r i ds t isb n n emgt u l hi d dg ear r

6 S t 5 f ub a e d , ’ aii n cs e o stwn c d ot no r inapedt a ns s u bhrhe

c l o a aa n w no pb ft at dbo po rir sh tw rr ona e

d s te m u i h n oa pM n T e t ft eU u s e A re r n t c ar v i

h b c i wi u of gt sta s m no( hho uls t e fi tri e r g om od ax e n d o pe

c Ro c o et m a o c f gh p sm n w o c ue a p io t a n a l c hxu r

b a t a o m t h p s a t oi t ej l pw n h nax mh oa l h h d i woe bn a a e n ba

o t p t c h ep h o r ree n o ar s u ti t

Av e ae e c s n r s f o w e c dyy f n t a b a r o s oit oh s o l e f t chr

b u 6 c ba sc m

a si 8 c i do a n ni mcn eu s dT nd a og nr p h es n s

w p u ah l c s sri a of i F og cc im n iw ah poe n p g n a d em di

f b r o r y u a vr o r b n Tim d l co b d hb e ja l ol e er d oi e

w c r e aa r e r r na e - te t e rdc - l h do h fb uc c a e o e uy l

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

the EAAW’ This re-heating is absolutely necessary to obtain a suff%zient bond

and the required density at the interface of the two adjacent lanes.

The use of a high capacity bridge paver on the slopes allows the placement of

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

large homogeneous lining sections, thus avoiding most of the usual paving joints

The quality and consequently also the lifetime of such homogeneous linings by far

exceeds those resulting from traditional working methods. It is especially im-

portant that the upper slope surfaces which are often exposed to the air can be

finished as a homogenous blanket up to the crest

The stopes at Rabenleite reservoir have a total length of 42 m in&ding the radial-

ly curved section towards the bottom. The construction width chosen for the

bridge paver was 2 1m so that slope paving could be managed in an upper and a

lower horizontal placing lane, Thanks to the adjustable main support and the

bendable scl-eed, also the curved section of the slope could be constructed by this

method. At the upper end, a smaller radial section was formed to join up with the

crest. One after- the other, drainage layer, binder and dense asphaltic concrete

were completed in the shortest possible construction titne. As the bridge paver

worked 24 hours a clay, it was possible to finish each section in approx. 4S hours,

+586,15 storage level

mastic sea1 coat

impervious asphaM concrete 8 cm

binder layer 8 cm

drainage layer: stabilized crushed stone 25 cm

Kabenlcite: Bridge Paver working at LJpper Slope Section

Both the contractor’s and the owner’s quahty control teams confirmed that the

required liner thickness and especially the void content of the dense asphaltic con-

crete of CI3% had been adhered to all over the surfaces

Frohnmcr

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

At the end the entire asphaltic concrete lining on the slope was sealed with 2

kg/n? of hot bituminous mastic. Mastic is an extremely economical and efficient

protection against weathering of asphalt with a lifetime of normally IO to 15

years. It can then easily be renewed at little cost.

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

After impounding of the reservoir only small amounts of seepage water (0.1 l/see)

are measured, most of it in the vicinity of the inlet tower.

Kabenleite: Bridge Paver Working at Lower Slope Section

The I68 MW pumped storage power station Langenprozelten was commissioned

in 1975. It provides a peak power supply to the German railway Deutsche Bahn.

The entire power station complex is located in a nature park The upper reservoir

with a capacity of 1.565 million m3 is lined with a continuous asphaltic concrete

sealing layer, After less than 20 years of operation major defects started to appear

in the lining, resulting in increasing water seepage.

The owner decided to carry out extensive rehabilitation. The slopes were pro-

vided with a new asphaltic concrete lining, The bottom of the reservoir showing

less damage was repaired at individual locations as required.

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

,5‘ i t u u t

T e s h sx s l e he i t fy o aas s h os l dl t t e lt ~ ii r le e nn u om

- 2 c d 0l m cr a o c oa l yf r ni i e u sn m r s ia e h sg

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

- 6 c a c m s b o p i n h n c a d r l e e t r

- 7 c i am m c s lp o p i e n h n r c a ei r l ro

- 4 k b g m i s ( / 2 al t e i m a

s u a n * ty m l ie i cr n

T a ch s l wo e i p i o ant ns h n i nv shc s l al e 5 nmer w

e t o l ra e a pri t n

u r f s A

o t i c i o tta h d n r t n fl hd be a i e h u

g ia e um

sa sp e p n g t h ta ea t e r

m o c a b f o d l n eo c c r k e s t

T f bh od w ae o l e e s bl f r i so e ec ew c mi t

- c j ot p os noo a i p np r n l ee a ti cn p t t e

T r rh e b t eem g y h p qa r h ne r u

bi oc a o oo i n eu da t g r tu t e

o o t a i r n o en n Tl g x s c h

y r t p u o ef o e aa f mi u n wr f pl t

i t d n l h r t a e a o y i e n r a . g

- c j o c o n r i s a n t c t r k s u e

T c h j o r e oi nt ul o

sni hs hin s f no let dnn a t pc t rp o ei u d o s lou en p

s d Tt r e w nth l e fw a uoe oTs r ea s i c l nhe e ct n t o gir s te

i o t s n a f ahp t gen e r on c rd o fl r o g ca s r t c

L a ( , an DI Cj atgb

pa o

r P n e emL ei a d n tna ns v pw n tt

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

- b l i s t e

B h b pl c a e b i ai a d i te y smsr l u i n t hn f e pt ao s n h e o a elu yf

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

d p l a oem W u t e f a a t t h mw n x - or ot h es p pat p s fl h e nu s rh o

r i w ve w n ac as b h i tta c pu l o it n heu o ol i f ci ers u rt s

B w a lo e a l t ib s t bl s hcs s t b - poe o eat e o y e rvv eu r r

e b tn s l e a th t de a t b n heel ra v y wt i od e arj al i e he n p oiy i

a t p T t w h a h bea wcr w i e ys aact dh s n v t poh i t i

t o l j h Tp wa oe e het adn in n oenh ctie nt b o n e eav te l t

b a p u sl r l t t so t o l o l r fof h tg i uo a ur e hr n ns y co

- w o m e s f a a e s t a t h l i e

D t

t a u o os h bm e(f e me s ap t a ha n e sr b hr l as on to e ee

n a n e t cs e a t ws h h o ct t hl uewe if f eh e ie rdet pU se x n f ro

t e o t hw f i fp h ee ff n T a e c a er t f h r a t coh r it u h

c t b d h a o be e a i f n t r s s wl p r d h e e t a s o ea ar y m

A as i t s f p S n h wi e a T t pi ea cas pR o srs lsd i k r A te de a

i w t r no t i l h e fhg t i e p e’ h n a e i r

T r w t h ep eo t h e b pl o t rn ph e a as f ha e tr e n Cs nti in ho l i urn

i r n T s e o tv hr c p f hwe e w o b o eso a h f a p a r tr s ao s

l o w s :

- d o p e a e a omfn n t xr v a fco e da i st i t cul pw ne a o erri

r o a d

- s m o tu e i h f hr sx ld n t efm l i d l o io 4o c ae os e i w nf mca pt

- r o e c f l i 7 co t a ui n b mn hp s sn s r c ia p ii t i

- r o s e c e ai fc o ao stn o nl u ts n i n t rt n c

- a o h m

p s fo pa et ls a it l ci

G t m d i h ro e v o e t e rp m e s f h qpeu as n t - e uo m nt o

c l c o d to r h a n f u o oaw i a ln s a ec f d as tn ed t l o t e egv a l n

f a t ll s t ih udi - ua P c8e cpnr r m e0 tiobe f B uflri a

w s a ta b e P s chs ci l b m w ae t on e e B ci n e pd tc t ht mee ht t

c b o T m i s n dh a t to v i e i jt u r r c e f a n oh mee c n f r

r w ae d i T ind a at h myou Pm ahd ep pfc map loh r r e rB g

m f o ta z a i c f th w o tt no o l u e i ni h l n i r t g e e d t ne hu

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

‘ D t e i s n i g g

asphalt concrete 4 cm

crushed gravel 20 cm

gravel base 35 cm

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

mastic seal coat

T asphaltic concrete binder layer 6 cm

\

crushed gravel drain layer 20 cm

asphalt concrete

existing asphaltic concrete 4 cm

crushed gravel 20 cm

gravel base 35 cm

new asphaltic concrete binder layer 10 cm

crushed gravet drain layer 20 cm

existing asphaltic concrete binder tayer 6 cm

existing impervious asphalt concrete, milled down to 4 cm

Langcnprozelten: Design of Asphahic Concrete Lining

The rehabilitation concept was based on the principle of an asphahic concrete seal

with a minimum number of joints.

The slope Lning was installed in 2 sections in tine with the geometry of the reser-

voir basin

- an upper section with a lane width of 22 m including curved section of crest

- a lower section with a lane width varying between I4 m and I8 m,

Rehabilitation of the access ramp was carried out using the conventional vertical

installation method,

The asphahic mix was brought to the site using 35 t semitrailers, This bulk trans-

port provided for the maintenance of a high

- temperature potential. A feeder vessel

with a capacity of40 t was instaHed in the basin for inter&ediate storage, A wheel

loader with a’load capacity of 6 t transported the mix from there to the paving

uliit on the slope

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

The asphalt was then installed as already described above for the Reisach-

Rabenleite project.

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

- ‘.

.#!

langenprozelten: Paving of Lower Slope Section

A construction pet-iod of 77 calendar days was available for perfor-mance of the

rehabilitation work It was possible to keep to this deadline by working 24-hour

shifis and sometimes also on weekends, The contractually agreed penalty which

was to be avoided was unusually high.

The new surface lining installed in the Langenprozelten upper reservoir is an un-

qualitied success in technical terms. Following installation reliable and trouble-

free operation of the reservoir is once again guaranteed.

Following successful rehabilitation the Langenprozelten and Rabenleite reservoirs

are now equipped with tidly functional and reliable sealing systems which were

constructed in accordance with state-of-the-art hydraulic asphalt technology. A

service life of between 30 - SO years or more can be expected provided that these

sealing systems undergo qualitied maintenance, in particular of the mastic seal to

protect against UV rays.

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

1. B~lhnann, Fritz. kenhut, Kurt

Downloaded from ascelibrary.org by Universidad Nacional Autonoma de Mexico on 03/09/15. Copyright ASCE. For personal use only; all rights reserved.

Re-Consttxtction of the Reservoir Group Jansen (in Gertnan language)

Water Management 84 (1994) 4

2. Dressier, Joachim

Re-Constt-uctiort of the Upper Reservoir

Reisach-Rabenleite (in German language)

Water Management 8S ( 1995) 7/8

3, Frohnauer, Reinhard

Upper Reservoir Rabenleite in a New Dress

S~vedC~~L,I~-S~~tnl)osilttn( 1996), Repair and Upgrading of Dams

4, Grdger, Manfred; Kuhimann, Willy

Refkbishment of Asphahic Concrete Lining at the Upper Reservoir

of Langenprozehen I+m~ped Storage Plant

(in Gertnan language)

Bitutnen 1 (1994)

5. STRABAG 13rochure No. 51 (1996)

Asphahic Conct-ete for Hydraulic Structures

Asphahic Conct-ete Reservoirs

Copyright ASCE 2004 Waterpower 1999

Waterpower '99

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Construction Quality Control For Asphalt Concrete Hydraulic BarriersDocument5 pagesConstruction Quality Control For Asphalt Concrete Hydraulic BarriersAlberto GaxiolaNo ratings yet

- Review of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaDocument26 pagesReview of Practices For Improving Ride Quality and Periodical Renewal of Bituminous Pavements in IndiaProf. Prithvi Singh Kandhal100% (2)

- Ajgs D 17 01351 - R1Document25 pagesAjgs D 17 01351 - R1Alberto GaxiolaNo ratings yet

- Closet 1Document1 pageCloset 1Alberto GaxiolaNo ratings yet

- Sintesis de Nanofibras Polimericas (Chinchillas)Document5 pagesSintesis de Nanofibras Polimericas (Chinchillas)Alberto GaxiolaNo ratings yet

- Fiber-Reinforced Asphalt-Concrete - A ReviewDocument7 pagesFiber-Reinforced Asphalt-Concrete - A ReviewAlberto GaxiolaNo ratings yet

- Evaluation and Design of Fiber-Reinforced Asphalt MixturesDocument9 pagesEvaluation and Design of Fiber-Reinforced Asphalt MixturesAlberto GaxiolaNo ratings yet

- 18th May 2020Document181 pages18th May 2020VenkataLakshmiKorrapatiNo ratings yet

- IPS CTB Cement Treated BaseDocument82 pagesIPS CTB Cement Treated BaseBIJAY KRISHNA DAS100% (2)

- IRC 37 2018 Guidelines For The Design of Flexible Pavements PDFDocument3 pagesIRC 37 2018 Guidelines For The Design of Flexible Pavements PDFKhairul HoqueNo ratings yet

- Professional ElectiveDocument4 pagesProfessional ElectiveMayank ShrivastavaNo ratings yet

- Modified Kodad - Revoor Road RenewalsDocument418 pagesModified Kodad - Revoor Road RenewalsSRIHARINo ratings yet

- 23ed0006 - Sitio Rubia - JulyDocument202 pages23ed0006 - Sitio Rubia - JulyELMERNo ratings yet

- Comparison of Rutting Resistance of Stone Mastic Asphalt With Convention MixDocument7 pagesComparison of Rutting Resistance of Stone Mastic Asphalt With Convention MixUIJRT United International Journal for Research & TechnologyNo ratings yet

- Saic-Q-1035 Sub-Base & Base CourseDocument4 pagesSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNo ratings yet

- Chapter 4Document28 pagesChapter 4singhconstNo ratings yet

- Working Examples of Pavement DesignDocument2 pagesWorking Examples of Pavement DesignSafdar Khan100% (2)

- Unit V Evaluation and Maintenance of Pavements 8Document7 pagesUnit V Evaluation and Maintenance of Pavements 8Rajha RajeswaranNo ratings yet

- Northampton Paving Memo and MapsDocument8 pagesNorthampton Paving Memo and MapsGreg SaulmonNo ratings yet

- KHRI Webinar Schedule PDFDocument1 pageKHRI Webinar Schedule PDFTanuj1122No ratings yet

- 13a. Road Construction MethodsDocument18 pages13a. Road Construction MethodsSheeraz AhmedNo ratings yet

- AOR Conc Blocks 450x300x150 M30Document1 pageAOR Conc Blocks 450x300x150 M30Daljeet SidhuNo ratings yet

- Asphalt Base, Binder and Wearing Course - Adm Part SpecDocument9 pagesAsphalt Base, Binder and Wearing Course - Adm Part SpecRolando de GuzmanNo ratings yet

- Lafarge 2014 PriceListDocument2 pagesLafarge 2014 PriceListjgreenguitars0% (1)

- CE 6505: Structural Design of Pavements (3.0 CR) : Course OutlineDocument27 pagesCE 6505: Structural Design of Pavements (3.0 CR) : Course Outlinemunna 00170No ratings yet

- RA Khonsa PWDDocument43 pagesRA Khonsa PWDsatpuraNo ratings yet

- Adair: Un-Terminated, Grouped by Primary CountyDocument407 pagesAdair: Un-Terminated, Grouped by Primary Countyalvaro almendarezNo ratings yet

- Southern Tier Bridges - Steuben CountyDocument13 pagesSouthern Tier Bridges - Steuben CountyGeorge StockburgerNo ratings yet

- Typical Cross Section 24mDocument1 pageTypical Cross Section 24mManoj AhirwarNo ratings yet

- Spesifikasi Umum 2018 - Divisi 6 Perkerasan AspalDocument104 pagesSpesifikasi Umum 2018 - Divisi 6 Perkerasan AspalAkhmad RifandyNo ratings yet

- A Critical Review of Bituminous Paving Mixes Used in IndiaDocument20 pagesA Critical Review of Bituminous Paving Mixes Used in IndiaHimagiriNo ratings yet

- Road WorkDocument4 pagesRoad WorkAshesh Mariners ChakrabortyNo ratings yet

- General ManagerDocument7 pagesGeneral Managerოთო აბაშიძეNo ratings yet

- Kajian Kuat Tekan Dan Infiltrasi Pada Beton Non PasirDocument7 pagesKajian Kuat Tekan Dan Infiltrasi Pada Beton Non Pasireffendi najibNo ratings yet

- Laboratory Evaluation of Asphalt Mixtures Containing Various Percentages of Reclaimed Asphalt PavementDocument8 pagesLaboratory Evaluation of Asphalt Mixtures Containing Various Percentages of Reclaimed Asphalt PavementprmraoNo ratings yet

- Tender Drawing of Package NCB S 13Document64 pagesTender Drawing of Package NCB S 13Malik BilalNo ratings yet