Professional Documents

Culture Documents

External Circlip

External Circlip

Uploaded by

Divyang MistryOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

External Circlip

External Circlip

Uploaded by

Divyang MistryCopyright:

Available Formats

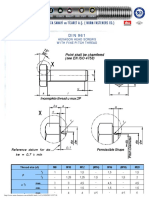

EXTERNAL CIRCLIPS

All Dimensions in millimeters

FOR d1= 170 AND

FOR d1 UPTO 9 ABOVE DETAIL AT X

DETAIL AT X

EXPANDED FOR ASSEMBLY

UNEXPANDED

FOR d1= 10 to 165

DETAIL AT X

CIRCLIP GROOVE FOR

SHAFT SUBJECT TO

STANDARD SEATING AXIAL LOAD

DIRECTION OF LOAD

CIRCLIP GROOVE DATA

Shaft

Dia Tol. D4 Tol. Axial

d1 S a b d 3 d5 M1 M2 N

D3 OnTol ON

Expan d2 On Force

h11 Max Approx Min H13 min min

D3 d 3 dedMin d2 Kgf

8 0.8 3.2 1.5 7.4 +0.09

+ 0.0615.2 7.6 0.9 1.0 120

- 0.12 0.8 1.2 7.2

9 1.7 8.4 -0.18 16.4 8.6 138

0.6

10 9.3 +0.15 17.6 1 9.6 153

3.3 -0.30 1.5

1.8

11 10.2 18.6 10.5 210

0.75

12 11 19.6 11.5 230

1 h11 1.1 1.2

13 3.4 2 11.9 20.8 12.4 300

0.9

14 3.5 2.1 12.9 22.0 13.4 325

+0.18 1.7

15 3.6 13.8 23.2 14.3 1.1 400

2.2 -0.36

16 3.7 14.7 24.4 15.2 490

1.2

17 3.8 2.3 15.7 25.6 16.2 520

18 2.4 16.5 26.8 17.0 690

3.9

19 2.5 17.5 27.8 18.0 725

20 4.0 2.6 18.5 29.0 19.0 1.5 770

21 4.1 2.7 19.5 30.2 20.0 805

1.2 1.3 1.4

22 4.2 2.8 20.5 31.4 21.0 845

24 22.2 33.8 2.0 22.9 1010

4.4 3.0

25 23.2 +0.21 34.8 23.9 1.7 1060

26 4.5 3.1 24.2 -0.42 36.0 24.9 1100

28 4.7 3.2 25.9 38.4 26.6 1500

2.1

29 4.8 3.4 26.9 39.6 27.6 1560

30 5.0 3.5 27.9 41.0 28.6 1620

1.5

32 5.2 3.6 29.6 43.4 30.3 2100

1.6 1.7 2.6

34 5.4 3.8 31.5 45.8 32.3 2220

35 3.9 32.2 +0.25 47.2 33.0 2670

5.6

36 4 33.2 -0.50 48.2 34.0 3.0 2760

38 5.8 4.2 35.2 50.6 36.0 2910

40 6.0 4.4 36.5 53.0 37.5 3810

42 1.75 6.5 4.5 38.5 56.0 39.5 1.85 2.0 4000

45 6.7 4.7 41.5 42.5 3.8 4300

2 670

+0.39 59.4

-0.78 2.5

48 6.9 5 44.5 62.8 45.5 4600

38 5.8 4.2 35.2 50.6 36.0 2910

Tolerance

40

Shaft

Shaft

42

6.0

6.5

4.4

4.5

36.5

CIRCLIP

38.5

EXTERNAL

53.0

56.0

CIRCLIPS

39.5

37.5 GROOVE DATA 3810

4000

1.75 1.85 2.0

Dia

Dia Tol. D4 d4 Tol. Tol Axial

45 S a a

6.7 b b

4.7 41.5 d 5 d5 Ex-

42.5 M1 m1M2 m2 3.8

N n 4300

d1 OnTol Expan

D3 d3+0.39 ON

59.4 d2 d 2On on Force

d1 h11 Max

MaxApprox

Approx Min Min H13 H13

min MinminMin

D3 d 3 ded

2.5panded

-0.78 d2 d2 Kgf

48 5 44.5 62.8 45.5 4600

50 6.9 5.1 45.8 64.8 47.0 h12 5700

52 7.7 5.2 47.8 67.0 49.0 5950

55 7.2 5.4 50.8 70.4 52.0 6300

56 7.3 5.5 51.8 71.6 53.0 6400

2.0 2.15 2.3 4.5

58 5.6 53.8 73.6 55.0 6650

60 7.4 5.8 55.8 75.8 57.0 6900

62 7.5 6.0 57.8 78.0 59.0 6930

63 7.6 6.2 58.8 79.2 60.0 7020

65 7.8 6.3 60.8 +0.46 81.6 62.2 7500

68 8.0 6.5 63.5 -0.92 85.0 65.0 6 900

7840

70 8.1 6.6 65.5 87.2 67.0 8050

72 8.2 6.8 67.5 89.4 69.0 8300

2.5 3.0 2.65 2.8

75 8.4 7.0 70.5 92.8 72.0 8600

78 7.3 73.5 96.2 75.0 9000

8.6

80 7.4 74.5 98.2 76.5 5.3 10700

82 7.6 76.5 101 78.5 11000

8.7

85 7.8 79.5 104 81.5 11400

88 8.0 82.5 107 84.5 11900

8.8

90 3.0 8.2 84.5 109 86.5 3.15 3.3 12100

95 9.4 8.6 89.5 115 91.5 12800

100 9.6 9 94.5 +0.54 121 3.5 96.5 13500

105 9.9 9.3 98.0 -1.08 126 101 16200

110 10.1 9.6 103.0 132 106 17000

+ 0.54

115 10.6 9.8 108.0 138

- 1.08 111 17800

120 11.0 10.2 113.0 143 116 18500

125 11.4 10.4 118.0 149 132 121 6 19300

130 11.6 10.7 123.0 155 126 20100

135 11.8 11 128.0 160 131 20900

140 12.0 11.2 133.0 165 136 21700

145 12.2 11.5 138.0 171 141 22500

150 11.8 142.0 177 145 28900

13.0

155 4.0 12.0 146.0 +0.63 182 150 4.15 4.3 30000

160 13.3 12.2 151.0 -1.26 188 155 31000

165 13.5 12.5 155.5 193 160 32000

170 12.9 160.5 197 165 32900

175 Max 165.5 202 170 33800

4.0 7.5

180 13.5 170.5 208 175 h13 34500

185 Max 175.5 213 180 33800

190 219 185 33500

180.5

195 185.5 224 190 32700

200 190.5 229 195 31900

14.0

210 Max 198 +0.72 239 204 48800

220 208 -1.44 249 214 51200

9.0

230 218 259 224 53500

240 228 269 234 52900

250 238 279 244 50300

5.0 5.2 5.3

260 245 293 252 54400

270 255 303 262 52500

16.0 12.0

280 265 +0.81 313 5.0 272 50800

Max

290 275 -1.62 323 282 49100

300 285 333 292 47300

Material: Spring steel HRC = 47 to 52 or HV = 480 to 558 kp / mm2 up to 38 mm bore diameter

HRC = 44 to 49 or HV = 440 to 510 kp / mm2 from 40 to 200 mm bore diameter

HRC = 40 to 45 or HV = 392 to 453 kp / mm2 from 210 to 300 mm bore diameter

You might also like

- 2.dsi M78 6-SpeedDocument151 pages2.dsi M78 6-SpeedAnonymous LaDv2vy100% (5)

- MB G100-12Document4 pagesMB G100-12rowan0% (1)

- Single Motor Double Door MechanismDocument34 pagesSingle Motor Double Door MechanismKanagarajan100% (1)

- Thread Specification SAE SAE J512 - 230312 - 115822Document2 pagesThread Specification SAE SAE J512 - 230312 - 115822kartikrjNo ratings yet

- Marco o Ring Size Chart Japanese PDFDocument12 pagesMarco o Ring Size Chart Japanese PDFraymond ngoNo ratings yet

- Mtu 16V 4000 M90Document1 pageMtu 16V 4000 M90jack donaldson100% (1)

- Ee101 FDZN20 30 FRMDocument34 pagesEe101 FDZN20 30 FRMberkay arıkanNo ratings yet

- Model 53R Rigid Planetary AxleDocument2 pagesModel 53R Rigid Planetary AxleMarek WyszatyckiNo ratings yet

- 1 2312 PDFDocument4 pages1 2312 PDFFrancisco CarrascoNo ratings yet

- International Standard: Synchronous Belt Drives - PulleysDocument6 pagesInternational Standard: Synchronous Belt Drives - PulleysBrunoNo ratings yet

- IMF IMF IMF IMF: Solutions For Pressure RegulationDocument8 pagesIMF IMF IMF IMF: Solutions For Pressure RegulationMohamed MahmoudNo ratings yet

- Saab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptDocument2 pagesSaab Official Service Manual: 900 16 Valve: 1985-1993 - ExcerptBentley PublishersNo ratings yet

- Series 2A CatalogueDocument26 pagesSeries 2A Cataloguemerv2a100% (6)

- Gator PE3242 PartsDocument8 pagesGator PE3242 PartsAshik Rahaman100% (1)

- Pins and KeysDocument12 pagesPins and KeysSam GillilandNo ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- Section Q: Splined Hubs, Drive KitsDocument8 pagesSection Q: Splined Hubs, Drive KitshaggNo ratings yet

- Bollhoff Rivkle Blind Rivet NutsDocument40 pagesBollhoff Rivkle Blind Rivet NutsAce Industrial Supplies100% (1)

- Tech in Fast Catalogue EnglishDocument42 pagesTech in Fast Catalogue Englishsharklasers12No ratings yet

- 복사본 볼트규격표Document20 pages복사본 볼트규격표임동섭No ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Iso 228 1 2000Document9 pagesIso 228 1 2000Ulvi NebiyevNo ratings yet

- Wrench ClearancesDocument2 pagesWrench Clearancescamohunter71No ratings yet

- Parallel Key Calculation According To DIN 6892Document21 pagesParallel Key Calculation According To DIN 6892zahirshah1436923No ratings yet

- Din 7623Document2 pagesDin 7623Racha Amel100% (1)

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- List of DIN Standards - 2006-04-20 PDFDocument4 pagesList of DIN Standards - 2006-04-20 PDFSerggie TabanaoNo ratings yet

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPNo ratings yet

- Asme 18 6.3Document1 pageAsme 18 6.3Andres Byke SepulvedaNo ratings yet

- RJR PMMTDocument16 pagesRJR PMMTArun PrasadNo ratings yet

- Carl Stahl UAE CatalogDocument64 pagesCarl Stahl UAE CatalogsuhailpmNo ratings yet

- Iso 4017Document1 pageIso 4017Nuno Miguel TorcatoNo ratings yet

- Images 1 - LefleatsDocument11 pagesImages 1 - LefleatsJeric Judalena SevillanoNo ratings yet

- Tabla Torqueo de PernosDocument1 pageTabla Torqueo de PernosErnesto LinaresNo ratings yet

- Parallel Helical Reducer RF97A: Sew-Eurodrive, IncDocument1 pageParallel Helical Reducer RF97A: Sew-Eurodrive, Inccarlos aguileraNo ratings yet

- Hollow Steel Catalog PDFDocument44 pagesHollow Steel Catalog PDFaiyubi2No ratings yet

- 1570 (Part II)Document20 pages1570 (Part II)Kaushik SenguptaNo ratings yet

- ARPCatalog PDFDocument128 pagesARPCatalog PDFAnonymous wpUyixsjNo ratings yet

- AISI Steel GradesDocument1 pageAISI Steel GradessanoopvkNo ratings yet

- Din 908Document2 pagesDin 908Dani Quirante Flaaut EtcNo ratings yet

- Synchronous Belt Drives - Automotive PulleysDocument14 pagesSynchronous Belt Drives - Automotive Pulleystv-locNo ratings yet

- ISO 2338 B / SN 212771 B: Dowel Pins, SteelDocument8 pagesISO 2338 B / SN 212771 B: Dowel Pins, SteelSirbu Vasile Liviu100% (1)

- 25CrMo4 (EN 10083 3)Document2 pages25CrMo4 (EN 10083 3)mohsen_267No ratings yet

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- Dowel 2011Document5 pagesDowel 2011nikhilpathak16674No ratings yet

- Iso 261-1998Document8 pagesIso 261-1998Pippo LandiNo ratings yet

- ASME B18.9 TabDocument2 pagesASME B18.9 TabmarceloNo ratings yet

- Din en Iso 2338Document1 pageDin en Iso 2338Janak MistryNo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- Metric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityDocument5 pagesMetric DIN 6797 Tooth Lock Washers: Visit Our For Product AvailabilityShrikant DeshmukhNo ratings yet

- Material Specification: Specification: Revision Date: Revision LevelDocument2 pagesMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDocument4 pagesISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNo ratings yet

- 701 Steel InclusionRating DIN-50602Document1 page701 Steel InclusionRating DIN-50602ksathisNo ratings yet

- Part List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)Document4 pagesPart List Rga-2315h1jt-11 2-La4-E1 (GB Cv05)restu yanuar salamNo ratings yet

- Renault Truck - KDocument16 pagesRenault Truck - KPaul FisherNo ratings yet

- Conical Seat Spherical Washer Is 4297Document6 pagesConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- Nylock Nut TDocument2 pagesNylock Nut Taiyubi2No ratings yet

- Carriage Bolt Square Neck Round Head ScrewsDocument1 pageCarriage Bolt Square Neck Round Head ScrewsBalaji Kanduri100% (1)

- Hexagon Head Screws With Fine Pitch ThreadDocument3 pagesHexagon Head Screws With Fine Pitch ThreadRolffoTelloNo ratings yet

- ASTM F593: MaterialsDocument1 pageASTM F593: MaterialsBilly DNo ratings yet

- Equivalent Grades of Gray IronDocument2 pagesEquivalent Grades of Gray Ironsujay13780100% (1)

- P1TF114 S4Document12 pagesP1TF114 S4finanzasNo ratings yet

- Whitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)Document2 pagesWhitworth Parallel Pipe Thread DIN ISO 228 (DIN 259) BSPP (British Standard Pipe Parallel)aldoNo ratings yet

- Joh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290Document6 pagesJoh. Heinr. Bornemann GMBH Postfach 1162, D-31676 Obernkirchen Phone: +49 5724 390-0 Fax +49 5724 390 290vuthanhNo ratings yet

- Theory of MachineDocument11 pagesTheory of MachineUnknown MajorsNo ratings yet

- Perhitungan Praktik Pengujian TanahDocument100 pagesPerhitungan Praktik Pengujian Tanah16Hikia Hanifam MuslimaNo ratings yet

- 6) Before, During, After WeldingDocument7 pages6) Before, During, After WeldingDivyang MistryNo ratings yet

- 2) Welding Process, SMAWDocument128 pages2) Welding Process, SMAWDivyang MistryNo ratings yet

- 3) Welding Process GTAWDocument11 pages3) Welding Process GTAWDivyang MistryNo ratings yet

- Roller Chain Sprokets (Matrin)Document39 pagesRoller Chain Sprokets (Matrin)Divyang MistryNo ratings yet

- About Design Review, Verification and ValidationDocument1 pageAbout Design Review, Verification and ValidationDivyang MistryNo ratings yet

- Engine Disassembly Procedure: Step 2 Step 1Document3 pagesEngine Disassembly Procedure: Step 2 Step 1lmjNo ratings yet

- KTA50 Engine Parts CatalogueDocument213 pagesKTA50 Engine Parts CatalogueGaly Hossam100% (4)

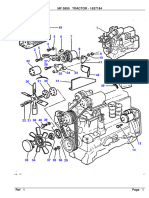

- Massey Ferguson MF 3650 TRACTOR Service Parts Catalogue Manual (Part Number 1637184)Document16 pagesMassey Ferguson MF 3650 TRACTOR Service Parts Catalogue Manual (Part Number 1637184)qlb898316100% (1)

- Wiring Diagram O500m 1725 PDFDocument60 pagesWiring Diagram O500m 1725 PDFDanielValbuenaAriasNo ratings yet

- FerrariDocument38 pagesFerrariJirayu MmNo ratings yet

- 13 51 017 Removing and Installing - Replacing High Pressure Pump (N57 D30 O - T 1)Document1 page13 51 017 Removing and Installing - Replacing High Pressure Pump (N57 D30 O - T 1)Tapciuc ciuc Florin VirgilNo ratings yet

- Southwire - ACSRDocument3 pagesSouthwire - ACSRMRLezamaNo ratings yet

- 2020 Fulcrum Catalog Rev00 PDFDocument116 pages2020 Fulcrum Catalog Rev00 PDFSucitroman AdeNo ratings yet

- Calado Árbol de Levas VW t4Document4 pagesCalado Árbol de Levas VW t4Radulf PugnusNo ratings yet

- Suggested Starting Torque Values: ASTM A307Document3 pagesSuggested Starting Torque Values: ASTM A307Vinayak PotdarNo ratings yet

- Actobotics Assortment Pack IncludesDocument8 pagesActobotics Assortment Pack Includesanon_937334650No ratings yet

- C400HDocument147 pagesC400HKINTOLOBONo ratings yet

- Doosan Engine de 12 Maintenance ManualDocument10 pagesDoosan Engine de 12 Maintenance ManualJoseph100% (57)

- 3 03 2Document1 page3 03 2wanpudinNo ratings yet

- Hardness Test Quality Control and Inspection Report FormDocument17 pagesHardness Test Quality Control and Inspection Report FormAlif Rahmat Febrianto0% (1)

- Mechanical DryerDocument2 pagesMechanical Dryerrafael velardeNo ratings yet

- Ch. 1 Spur Gears MCQDocument6 pagesCh. 1 Spur Gears MCQSantosh bansodeNo ratings yet

- 4 Stroke VinoDocument298 pages4 Stroke VinoFeiming HuangNo ratings yet

- Main Spindle Assy - Camlock - Xplod 1Document1 pageMain Spindle Assy - Camlock - Xplod 1NewNo ratings yet

- Elvindo ProdukDocument6 pagesElvindo Produkburhanuddin nNo ratings yet

- Mazda 62622 If 2Document20 pagesMazda 62622 If 2Marshall Jnr MaðzingaNo ratings yet