Professional Documents

Culture Documents

Kerf On Site Guide

Kerf On Site Guide

Uploaded by

Enkhmend-Od UlziibatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kerf On Site Guide

Kerf On Site Guide

Uploaded by

Enkhmend-Od UlziibatCopyright:

Available Formats

Kerf saw cuts in porcelain tiles.

Kerf saw cut at edges of porcelain tiles are essential for their use as facade cladding with butech’s vf concealed anchoring sys-

tem.

The number and type of slots depends on the porcelain tile format.

The kerf saw cut characteristics, as well as its tolerances, are listed in Appendix I of the on-site cutting and kerf saw cutting

manual.

Portable machine for kerf saw cutting porcelain tiles.

This type of portable machine for slotting porcelain tiles is the easiest and most practical way for making cuts on the sides of

porcelain tiles. The features of this machine are the following:

• No load speed: 11,000 rpm.

• Cutting disc: Porcelain wet cutting disc 4” (100 mm)

• Fast adjustment of different milling depths. Maximum slot depth: 3/4” (20 mm)

• Micrometer screw for position adjustment: 6 types

• Adjustable angle from 0° to 90°

• Water cooling.

Cutting procedure

2. Make mark at desired kerf location. 1. Check User Manual and Instructions.

3. Check blade is in good condition. 4. Adjust tool based on final position of kerf and

thickness of panel.

* All measurements in inches are approximate due to the connection from metric to imperial system

butech building technology, s.a.

Ctra. Vila-real - Puebla de Arenoso (CV-20), Km. 2.5 · Apartado de Correos 297 · 12540 Villarreal, Castellón - Spain.

Teléfono (+34) 964 53 62 00 · Fax: (+34) 964 53 00 34 · E-mail: butech@butech.es · www.butech.es

5. Turn tool on and check water cooling system 6. Position panel.

works correctly.

7. Check position and dimensions of kerf match 8. Produce new kerfs as per manufacturer instructions.

guidelines shown in this document.

butech building technology, s.a.

Ctra. Vila-real - Puebla de Arenoso (CV-20), Km. 2.5 · Apartado de Correos 297 · 12540 Villarreal, Castellón - Spain.

Teléfono (+34) 964 53 62 00 · Fax: (+34) 964 53 00 34 · E-mail: butech@butech.es · www.butech.es

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dewalt - Acc Catalogue en MasterDocument188 pagesDewalt - Acc Catalogue en MasterМаркоNo ratings yet

- Tri TronicsProduct Catalogue - Online UPSDocument11 pagesTri TronicsProduct Catalogue - Online UPSPrerana singhNo ratings yet

- Visonic Smarthome Secure Link Installation GuideDocument32 pagesVisonic Smarthome Secure Link Installation Guidekpcakes1No ratings yet

- 500-650 Hci 750 PDFDocument2 pages500-650 Hci 750 PDFlucas ronaldo coronel mendozaNo ratings yet

- 1.1 About 33/11Kv Substation, Midc, ButiboriDocument20 pages1.1 About 33/11Kv Substation, Midc, ButiboriParitoshik KharadNo ratings yet

- Brochure AlfaRomeo - US 4C - 2015-v2Document9 pagesBrochure AlfaRomeo - US 4C - 2015-v2aleNo ratings yet

- Vector Scorer Service Parts CatalogDocument27 pagesVector Scorer Service Parts CatalogNathan BukoskiNo ratings yet

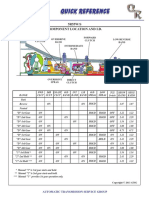

- Quick Reference: 5R55W/S Component Location and I.DDocument7 pagesQuick Reference: 5R55W/S Component Location and I.DAyhan Ümit100% (3)

- Capacitor Leakage Adaptor For DMMsDocument10 pagesCapacitor Leakage Adaptor For DMMsSerhii HolykNo ratings yet

- Fan Merk Kruger Model CCDDocument4 pagesFan Merk Kruger Model CCDKarin Aca OviNo ratings yet

- OpenPCR Build InstructionsDocument76 pagesOpenPCR Build InstructionstitojankowskiNo ratings yet

- Elgin Hydrocyclone Cut Sheet 2019Document1 pageElgin Hydrocyclone Cut Sheet 2019Andrew GoadNo ratings yet

- 6WG1 ECU PinoutDocument3 pages6WG1 ECU Pinouttruong.fb.04No ratings yet

- Arar-33kV Cable Sizing Calc 30.10Document13 pagesArar-33kV Cable Sizing Calc 30.10srigirisetty208100% (1)

- What Causes Error 199 When Using Modsoft and Modbus? - FAQs - Schneider Electric BrazilDocument4 pagesWhat Causes Error 199 When Using Modsoft and Modbus? - FAQs - Schneider Electric BrazilpararexistrarNo ratings yet

- Avolta RC User Manual PDFDocument16 pagesAvolta RC User Manual PDFabdulla2012No ratings yet

- Banda Wollard PDFDocument852 pagesBanda Wollard PDFedgar espinosa100% (1)

- Kyocera FS C5020 30NDocument216 pagesKyocera FS C5020 30NwergyNo ratings yet

- Atomic 3000 LED: User ManualDocument44 pagesAtomic 3000 LED: User ManualGiovani AkNo ratings yet

- Cat 793FDocument4 pagesCat 793Fyoungk225812No ratings yet

- Electrical Machine - Ga - 1Document8 pagesElectrical Machine - Ga - 1rahulmeenameenarahul26No ratings yet

- Runcam New Swift 2: User ManualDocument11 pagesRuncam New Swift 2: User ManualTomas PilkaNo ratings yet

- Servo Motor Selection For UAVDocument9 pagesServo Motor Selection For UAVUAV Society100% (1)

- Dcim-B02 832 01 07 02Document12 pagesDcim-B02 832 01 07 02ОлександрNo ratings yet

- SpecsDocument309 pagesSpecsNarendra GoudNo ratings yet

- 04 Diagrama Hidraulico-NeumaticoDocument100 pages04 Diagrama Hidraulico-NeumaticoLc NoéNo ratings yet

- User GuideDocument68 pagesUser GuideВладимир МурушкинNo ratings yet

- Gr18rapport2021 02Document46 pagesGr18rapport2021 02umair saifNo ratings yet

- Karthi CVDocument4 pagesKarthi CVKarthi MarxNo ratings yet

- HVDC TransmissionDocument78 pagesHVDC Transmissiondhay aliNo ratings yet