Professional Documents

Culture Documents

Titan 1M

Titan 1M

Uploaded by

Pranav Satpute0 ratings0% found this document useful (0 votes)

117 views1 pageThis document provides setup instructions for machining an aluminum part using 5 different tools. It lists the tool descriptions and part numbers. Setup notes specify using parallels in hard jaws and zeroing the axes.

Original Description:

Original Title

TITAN 1M

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides setup instructions for machining an aluminum part using 5 different tools. It lists the tool descriptions and part numbers. Setup notes specify using parallels in hard jaws and zeroing the axes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

117 views1 pageTitan 1M

Titan 1M

Uploaded by

Pranav SatputeThis document provides setup instructions for machining an aluminum part using 5 different tools. It lists the tool descriptions and part numbers. Setup notes specify using parallels in hard jaws and zeroing the axes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Operation & Set Up Sheet

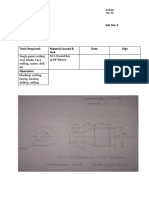

P/N: TITAN-1M Material: Alum Size: 1 x 2 Bar Cut 4.1 +.03 / -.0 Date:

Company: Program Name: REV:

Operation #: 1 Set Up Time: Run Time:

Tooling Box: Initials:

Tool List:

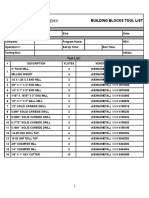

DESCRIPTION FLUTES VENDOR PRODUCT ID

3" FACE MILL 4 (KENNAMETAL) MM# 5673338

1

MILLING INSERT 4 (KENNAMETAL) MM# 5665949

2 3/8" X 1" X 3" END MILL 3 (KENNAMETAL) MM# 3870468

3 1/4” CHAMFER MILL 2 (KENNAMETAL) MM# 6464004

4 0.1772" SOLID CARBIDE DRILL 2 (KENNAMETAL) MM# 4150202

5 10-32 UNC ROLL TAP 4 (KENNAMETAL) MM# 5945352

NOTES

*USE PARRALLELS INSIDE OF HARD JAWS

*MATERIAL IS 1.0 HIGH – HOLD .100 TO .200 IN THE HARD JAWS – MAKE SURE YOU HAVE

ENOUGH STOCK ABOVE THE JAWS TO PROFILE AROUND THE PART AT Z-.76 DEEP WITHOUT

HITTING THE TOOL INTO THE JAW *** NOTE = SOFT JAWS WILL ALSO WORK

*X AXIS ZERO IS LEFT EDGE / MOVE IN .050 FROM ROUGH STOCK AND RE-ZERO

*Y AXIS IS ON THE BACK DEAD JAW / MOVE IN Y-.025 AND RE-ZERO

*Z AXIS IS TOP OF PART / ZERO TOP AND DROP Z-.02 FOR FACING OP

You might also like

- Press Tool - I Notes - Documents-1Document145 pagesPress Tool - I Notes - Documents-1Sourav Vashisth98% (43)

- Manual Do Sax Yamaha PDFDocument144 pagesManual Do Sax Yamaha PDFIlmar Ferreira100% (4)

- Belin Tools PDFDocument40 pagesBelin Tools PDFdoc_nebulaNo ratings yet

- Building Blocks Tool List v2Document2 pagesBuilding Blocks Tool List v2BoopathiNo ratings yet

- Pin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListDocument3 pagesPin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListtallerNo ratings yet

- Pin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListDocument3 pagesPin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListtallerNo ratings yet

- Pin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListDocument3 pagesPin-On Bucket (3.5 Yd ) (Z-Bar) ( - 618133) - ST156361: Parts ListtallerNo ratings yet

- Xtra ReportDocument9 pagesXtra ReportStjepan CrnkovićNo ratings yet

- 34 Solid Carbide Thread MillsDocument2 pages34 Solid Carbide Thread Millslintang madi sudiroNo ratings yet

- Avio Print J-3 Cub User Guide 1.1Document28 pagesAvio Print J-3 Cub User Guide 1.1Sauli KlaavuNo ratings yet

- Caledyne Hest ManualDocument8 pagesCaledyne Hest ManualGade JyNo ratings yet

- Catalog Insert BowlsDocument63 pagesCatalog Insert BowlsahmedNo ratings yet

- Report 10675153058754062757Document4 pagesReport 10675153058754062757Cotar S.A de C.V.No ratings yet

- 878-Tool Design and Drawing: Part - ADocument17 pages878-Tool Design and Drawing: Part - AsandhuNo ratings yet

- c006b MDocument28 pagesc006b MVignesh WaranNo ratings yet

- Shell RollinggDocument26 pagesShell RollinggwenigmaNo ratings yet

- Product InformationDocument56 pagesProduct InformationJose Enrique Mendoza RodriguezNo ratings yet

- Chain Puller Is One of Yamaha Vega RDocument7 pagesChain Puller Is One of Yamaha Vega Recep nugrahaNo ratings yet

- PRM Bench Mill Drill ManualDocument56 pagesPRM Bench Mill Drill ManualMatthew MattesonNo ratings yet

- Taladro Magnetico Rotabest Mini 36-50 Manual OperacionDocument12 pagesTaladro Magnetico Rotabest Mini 36-50 Manual OperacionAtahualpa Bulganin Infante YañezNo ratings yet

- Shop - Machine Shop Job No-1 Name of The Job-: Tools Required: Material Issued & Size Date SignDocument17 pagesShop - Machine Shop Job No-1 Name of The Job-: Tools Required: Material Issued & Size Date SignDifferent wayNo ratings yet

- Issue3 2Document7 pagesIssue3 2Crafty SeedNo ratings yet

- Procees Sheet Name of Job:-K 38 Lop Body Name of Industry: - LAXMI OIL & PUMPSDocument2 pagesProcees Sheet Name of Job:-K 38 Lop Body Name of Industry: - LAXMI OIL & PUMPSSikander GirgoukarNo ratings yet

- PARAT ToolpostDocument26 pagesPARAT ToolpostSebNo ratings yet

- 1 ToleranceDocument8 pages1 ToleranceRaymond LO OtucopiNo ratings yet

- Perrin High Pressure Valves For Hydrogen ServiceDocument12 pagesPerrin High Pressure Valves For Hydrogen ServiceKunming Wang100% (1)

- T7 PartsDocument86 pagesT7 PartsUmar ShamsudinNo ratings yet

- Tube Bender HMP 200 FinalDocument18 pagesTube Bender HMP 200 Finaltigre_fiel100% (1)

- Nitto Kohki Power Tools PDFDocument28 pagesNitto Kohki Power Tools PDFAnonymous E8YIWa4i6yNo ratings yet

- Art. No. ISO Body Size Ls ΦD Hs TDocument2 pagesArt. No. ISO Body Size Ls ΦD Hs TSyaifulIslamNo ratings yet

- Pig Launchers Pig ReceiversDocument3 pagesPig Launchers Pig ReceiversMurli ramchandran0% (1)

- DT 750 MOMF 5 Parker Check ValveDocument3 pagesDT 750 MOMF 5 Parker Check ValveMROstop.comNo ratings yet

- I XmillDocument8 pagesI XmillVladimir Pereira MacielNo ratings yet

- FUJI FRONTIER 340E - PartslistDocument172 pagesFUJI FRONTIER 340E - Partslistvitprint22No ratings yet

- Lithonia RSALPDocument2 pagesLithonia RSALPaario1No ratings yet

- TI Manual SJX Elevator-2Document11 pagesTI Manual SJX Elevator-2Alex MillerNo ratings yet

- Lealfet AirtoolsDocument2 pagesLealfet Airtoolsamirouche15No ratings yet

- Tugas Si SadeDocument25 pagesTugas Si SadeNabil SatriaNo ratings yet

- Thread MillDocument40 pagesThread MillferNo ratings yet

- Tangless 8pp en (Recoil Insert)Document8 pagesTangless 8pp en (Recoil Insert)WK SinnNo ratings yet

- Parts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Document40 pagesParts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Maks ProstNo ratings yet

- Met 103Document65 pagesMet 103xxforever510No ratings yet

- Beamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/ΜsDocument3 pagesBeamtool Scan Plan Inspection Layout: 25Mm 200Mm 100Mm 0Mm Steel 1020 3.24Mm/Μs 5.89Mm/Μsநந்த குமார் சம்பத் நாகராஜன்No ratings yet

- Eje 590SL Ser 2Document4 pagesEje 590SL Ser 2Leon Mercado RNo ratings yet

- MaxWell 4.5in Casing CuttingtoolDocument3 pagesMaxWell 4.5in Casing Cuttingtooljunbo duNo ratings yet

- Milling MachinesDocument48 pagesMilling MachinesAliah IzzahNo ratings yet

- MT HW2 Muratbekov Miras Anpdoy PDFDocument13 pagesMT HW2 Muratbekov Miras Anpdoy PDFMiras MuratbekovNo ratings yet

- Certificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiDocument51 pagesCertificate: Shri Leeladhar Pal, JR - Officer Plate Mill (Elect.), Bhilai Steel Plant, BhilaiAditya SinghNo ratings yet

- EMCO F1 ManualDocument308 pagesEMCO F1 ManualClinton Koo100% (1)

- Engg 2Document8 pagesEngg 2ganesan 0011No ratings yet

- Opera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachineDocument34 pagesOpera Ting Manual: HQ400/3A - HQ400/3B - HQ400/3L Multi - Purpose MachinerianrureNo ratings yet

- Milling Process: IE 337: Materials and Manufacturing Processes Lab # 4Document4 pagesMilling Process: IE 337: Materials and Manufacturing Processes Lab # 4Revanth ViswanadhaNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Modelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleFrom EverandModelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleNo ratings yet

- Turning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelFrom EverandTurning Wood with Carbide Tools: Techniques and Projects for Every Skill LevelRating: 4.5 out of 5 stars4.5/5 (3)