Professional Documents

Culture Documents

A 299 - A 299M - 09 (2014) PDF

A 299 - A 299M - 09 (2014) PDF

Uploaded by

أسامة وحيد الدين رمضانOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 299 - A 299M - 09 (2014) PDF

A 299 - A 299M - 09 (2014) PDF

Uploaded by

أسامة وحيد الدين رمضانCopyright:

Available Formats

Designation: A299/A299M − 09 (Reapproved 2014)

Standard Specification for

Pressure Vessel Plates, Carbon Steel, Manganese-Silicon1

This standard is issued under the fixed designation A299/A299M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope amination of Steel Plates

2

1.1 This specification covers manganese-silicon carbon A578/A578M Specification for Straight-Beam Ultrasonic

steel plates for use in welded boilers and other pressure vessels. Examination of Rolled Steel Plates for Special Applica-

tions

1.2 Plates under this specification are produced in two

grades. The specified minimum yield strength decreases for 3. General Requirements and Ordering Information

thicknesses over 1 in. [25 mm].

3.1 Plates supplied to this product specification shall con-

1.3 The maximum thickness of plates is limited only by the form to Specification A20/A20M, which outlines the testing

capacity of the composition to meet the specified mechanical and retesting methods and procedures, permitted variations in

property requirements; however, current practice normally dimensions and mass, quality and repair of defects, marking,

limits the maximum thickness of plates furnished under this loading, and ordering information.

specification to 8 in. [200 mm].

3.2 In addition to the basic requirements of this

1.4 For plates produced from coil and furnished without specification, certain supplementary requirements are available

heat treatment or with stress relieving only, the additional where additional control, testing, or examination is required to

requirements, including additional testing requirements and the meet end use requirements. The purchaser is referred to the

reporting of additional test results, of Specification A20/A20M listed supplementary requirements in this specification and to

apply. the detailed requirements in Specification A20/A20M.

1.5 The values stated in either inch-pound units or SI units 3.3 Coils are excluded from qualification to this specifica-

are to be regarded separately as standard. Within the text, the tion until they are processed into finished plates. Plates

SI units are shown in brackets. The values stated in each produced from coil means plates that have been cut to

system are not exact equivalents; therefore, each system must individual lengths from coil. The processor directly controls, or

be used independently of the other. Combining values from the is responsible for, the operations involved in the processing of

two systems may result in nonconformance with the specifi- coils into finished plates. Such operations include decoiling,

cation. leveling, cutting to length, testing, inspection, conditioning,

heat treatment (if applicable), packaging, marking, loading for

2. Referenced Documents shipment, and certification.

2.1 ASTM Standards:3 NOTE 1—For plates produced from coil and furnished without heat

A20/A20M Specification for General Requirements for Steel treatment or with stress relieving only, three test results are reported for

Plates for Pressure Vessels each qualifying coil. Additional requirements regarding plates from coil

A435/A435M Specification for Straight-Beam Ultrasonic are described in Specification A20/A20M.

Examination of Steel Plates 3.4 If the requirements of this specification are in conflict

A577/A577M Specification for Ultrasonic Angle-Beam Ex- with the requirements of Specification A20/A20M, the require-

ments of this specification shall prevail.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, 4. Materials and Manufacture

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.11 on Steel Plates for Boilers and Pressure Vessels. 4.1 Steelmaking Practice—The steel shall be killed and

Current edition approved March 1, 2014. Published March 2014. Originally shall conform to the fine austenitic grain size requirement of

approved in 1947. Last previous edition approved in 2009 as A299/A299M – 09. Specification A20/A20M.

DOI: 10.1520/A0299_A0299M-09R14.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SA-299/SA-299M in Section II of that Code. 5. Heat Treatment

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Plates 2 in. [50 mm] and under in thickness are normally

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on supplied in the as-rolled condition. Plates may be ordered

the ASTM website. normalized or stress relieved, or both.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A299/A299M − 09 (2014)

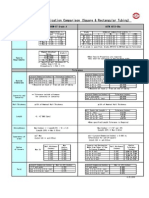

TABLE 1 Chemical Requirements TABLE 2 Tensile Requirements

Elements Composition, % Grade A Grade B

Carbon, max:A Tensile strength, ksi [MPa] 75–95 [515–655] 80–100 [550–690]

1 in. [25 mm] and under 0.26 Yield strength, min,A ksi [MPa]:

Grade A 0.28 1 in. [25 mm] and under 42 [290] 47 [325]

Grade B Over 1 in. [25 mm] 40 [275] 45 [310]

Over 1 in. [25 mm] 0.28 Elongation in 8 in. [200 mm], min, %B 16 16

Grade A 0.30 Elongation in 2 in. [50 mm], min, %B 19 19

Grade B A

Determined by either the 0.2 % offset method or the 0.5 % extension-under-load

Manganese:

method.

1 in. [25 mm] and under B

See the Elongation Requirement Adjustments subsection in the Tension Tests

Heat analysis 0.90 to 1.40

section of Specification A20/A20M.

Product analysis 0.84 to 1.52

Over 1 in. [25 mm]

Heat analysis 0.90 to 1.50

Product analysis 0.84 to 1.62

Phosphorus, maxA 0.025

Sulfur, maxA 0.025

Silicon: 7. Mechanical Properties

Heat analysis 0.15 to 0.40

Product analysis 0.13 to 0.45 7.1 Tension Test Requirements—The plates, as represented

A

Applies to both heat and product analyses. by the tension test specimens, shall conform to the require-

ments given in Table 2.

5.2 Plates over 2 in. [50 mm] in thickness shall be normal- 8. Keywords

ized.

8.1 carbon steel plate; pressure containing parts; pressure

6. Chemical Composition vessel steels; steel plates; steel plates for pressure vessel

6.1 The steel shall conform to the requirements given in applications

Table 1.

SUPPLEMENTARY REQUIREMENTS

Supplementary requirements shall not apply unless specified in the purchase order.

A list of standardized supplementary requirements for use at the option of the purchaser is included

in Specification A20/A20M. Those that are considered suitable for use with this specification are listed

below by title.

S1. Vacuum Treatment, S7. High-Temperature Tension Test,

S2. Product Analysis, S8. Ultrasonic Examination in accordance with Specifica-

S3. Simulated Post-Weld Heat Treatment of Mechanical tion A435/A435M,

Test Coupons, S9. Magnetic Particle Examination,

S4. Additional Tension Test, S11. Ultrasonic Examination in accordance with Specifica-

S5. Charpy V-Notch Impact Test, tion A577/A577M,

S6. Drop Weight Test (for Material 0.625 in. [16 mm] and S12. Ultrasonic Examination in accordance with Specifica-

over in Thickness), tion A578/A578M.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 2

You might also like

- Business Communication Essentials Canadian 4th Edition Bovee Test BankDocument38 pagesBusiness Communication Essentials Canadian 4th Edition Bovee Test Bankangiohereoutu68ec100% (19)

- Catalogue Indium CorporationDocument5 pagesCatalogue Indium CorporationPhilippe GuillemetNo ratings yet

- ASTM A270-98ae1Document5 pagesASTM A270-98ae1NadhiraNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Molybdenum: Standard Specification ForDocument3 pagesPressure Vessel Plates, Alloy Steel, Molybdenum: Standard Specification ForالGINIRAL FREE FIRENo ratings yet

- A204A204M-12 Standard Specification For Pressure Vessel Plates, Alloy Steel, MolybdenumDocument3 pagesA204A204M-12 Standard Specification For Pressure Vessel Plates, Alloy Steel, MolybdenumDiego Egoávil MéndezNo ratings yet

- Steel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements ForDocument9 pagesSteel, Strip, Carbon and High-Strength, Low-Alloy, Hot-Rolled, General Requirements FormuhammadNo ratings yet

- Astm A513 A513m 18Document10 pagesAstm A513 A513m 18Thị Hồng Vỹ LêNo ratings yet

- Hexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)Document15 pagesHexagon Head Screws With Metric Fine Pitch Thread - Product Grades Aandb (First Revision)kumar QANo ratings yet

- SB 271Document4 pagesSB 271AnilNo ratings yet

- Asme Sa 213 Grade t92 TubesDocument1 pageAsme Sa 213 Grade t92 TubesFerroPipENo ratings yet

- Astm A756 PDFDocument3 pagesAstm A756 PDFCristian OtivoNo ratings yet

- A588a588m 6956Document3 pagesA588a588m 6956Jaleel ClaasenNo ratings yet

- Astm B633 98Document5 pagesAstm B633 98radziNo ratings yet

- ASTM A213-A213M-05cDocument12 pagesASTM A213-A213M-05cNadhiraNo ratings yet

- Asme Section II A-2 Sa-688 Sa-688mDocument10 pagesAsme Section II A-2 Sa-688 Sa-688mAnonymous GhPzn1xNo ratings yet

- ASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtDocument17 pagesASTM A29-16 Standard Specification For General Requirements For Steel Bars, Carbon and Alloy, Hot-WroughtMalaz Abdul JalilNo ratings yet

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- A493 00 PDFDocument3 pagesA493 00 PDFJohano AraújoNo ratings yet

- Astm A827-14Document3 pagesAstm A827-14Артем Титов100% (1)

- A 941 - 04 QTK0MQDocument7 pagesA 941 - 04 QTK0MQTrầnHữuHòaNo ratings yet

- SB 308Document8 pagesSB 308AnilNo ratings yet

- A794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-RolledDocument3 pagesA794A794M-12 Standard Specification For Commercial Steel (CS), Sheet, Carbon (0.16 % Maximum To 0.25 % Maximum), Cold-Rolledtjt4779No ratings yet

- Astm A666 - 10Document9 pagesAstm A666 - 10MuhammedNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary TubingDocument6 pagesSeamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary TubingnaimNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument12 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General Applicationsist93993No ratings yet

- Seamless and Welded Ferritic Stainless Steel Feedwater Heater TubesDocument7 pagesSeamless and Welded Ferritic Stainless Steel Feedwater Heater TubesMina RemonNo ratings yet

- Astm A161Document2 pagesAstm A161TeoTyJayNo ratings yet

- Astm B111Document9 pagesAstm B111mmlingNo ratings yet

- Welded, Unannealed Austenitic Stainless Steel Tubular ProductsDocument4 pagesWelded, Unannealed Austenitic Stainless Steel Tubular ProductsDarwin DarmawanNo ratings yet

- Bolts PDFDocument13 pagesBolts PDFDario SangiovanniNo ratings yet

- A266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel Components PDFDocument5 pagesA266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel Components PDFManuel Antonio Santos VargasNo ratings yet

- A 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFDocument7 pagesA 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFTiến Lượng NguyễnNo ratings yet

- A 500 - 03 Qtuwmc1sruqDocument7 pagesA 500 - 03 Qtuwmc1sruqtran_lamNo ratings yet

- Material & StdsDocument2 pagesMaterial & Stdssajjan sutharNo ratings yet

- Cupola Malleable Iron: Standard Specification ForDocument4 pagesCupola Malleable Iron: Standard Specification Forali ahmedNo ratings yet

- A500 Vs A513Document2 pagesA500 Vs A513Angelo CubillosNo ratings yet

- Astm A 572 A 572m 15pdfDocument4 pagesAstm A 572 A 572m 15pdfKartik DoblekarNo ratings yet

- Astm A568 A568m 09Document10 pagesAstm A568 A568m 09Shailendra SharmaNo ratings yet

- Astm B16 2010Document5 pagesAstm B16 2010brunobassottiNo ratings yet

- 30 CR Ni Mo 8Document2 pages30 CR Ni Mo 8Amy GriffinNo ratings yet

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistanceDocument4 pagesSteel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistancePham Huu Loc Ho100% (1)

- Sa 325 PDFDocument12 pagesSa 325 PDFMo'men Abu-SmaihaNo ratings yet

- ASTM A480-A480M-04aDocument24 pagesASTM A480-A480M-04aNadhiraNo ratings yet

- Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServiceDocument7 pagesSeamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServicedgkmurtiNo ratings yet

- Precipitation Hardening Nickel-Copper-Aluminum Alloy (UNS N05500) Bar, Rod, Wire, Forgings, and Forging StockDocument6 pagesPrecipitation Hardening Nickel-Copper-Aluminum Alloy (UNS N05500) Bar, Rod, Wire, Forgings, and Forging StockraulNo ratings yet

- Astm-A270 PipeDocument6 pagesAstm-A270 PipeMiguel David Celis QuinteroNo ratings yet

- A403A403M gsvs8524Document8 pagesA403A403M gsvs8524mdracula2848No ratings yet

- SB 151 PDFDocument6 pagesSB 151 PDFAnilNo ratings yet

- Sae J1392 2001Document10 pagesSae J1392 2001henrychtNo ratings yet

- Standard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessDocument4 pagesStandard Specification For Steel Sheet Zinc Coated Galvanized or Zinc Iron Alloy Coated Galvannealed by The Hot Dip ProcessarchahmedassafNo ratings yet

- A304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsDocument48 pagesA304 - 20 Standard Specification For Carbon and Alloy Steel Bars Subject To End-Quench Hardenability RequirementsAlejandro Valdes100% (1)

- 219-Asme-Sec-Ii-B-Sb-211 Alu AlloyDocument14 pages219-Asme-Sec-Ii-B-Sb-211 Alu AlloyGRIPHOLD Engineering ServicesNo ratings yet

- Determining The Inclusion Content of Steel: Standard Test Methods ForDocument20 pagesDetermining The Inclusion Content of Steel: Standard Test Methods ForoslatNo ratings yet

- A176 PDFDocument2 pagesA176 PDFmahmoud hanafiNo ratings yet

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDocument17 pagesLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjNo ratings yet

- Ansi b17 2 Woodruff Keys Flat Bottom Type 1Document3 pagesAnsi b17 2 Woodruff Keys Flat Bottom Type 1rbagriNo ratings yet

- ASTM A299A299M-17 Standard Specification ForDocument3 pagesASTM A299A299M-17 Standard Specification Formarcio de rossiNo ratings yet

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceSama UmateNo ratings yet

- Astm A299 A299m 17 2022Document2 pagesAstm A299 A299m 17 2022عبد المالك بن شليغمNo ratings yet

- Pressure Vessel Plates, Carbon Steel, High Strength, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon Steel, High Strength, For Moderate and Lower Temperature ServiceSama UmateNo ratings yet

- A 455 - A 455M - 12a PDFDocument3 pagesA 455 - A 455M - 12a PDFأسامة وحيد الدين رمضانNo ratings yet

- A 254 - A 254M - 12 PDFDocument4 pagesA 254 - A 254M - 12 PDFأسامة وحيد الدين رمضانNo ratings yet

- A 435 - A 435M - 90 (2012) PDFDocument2 pagesA 435 - A 435M - 90 (2012) PDFأسامة وحيد الدين رمضانNo ratings yet

- A 249 - A 249M - 16a PDFDocument10 pagesA 249 - A 249M - 16a PDFأسامة وحيد الدين رمضانNo ratings yet

- A 247 - 17 PDFDocument13 pagesA 247 - 17 PDFأسامة وحيد الدين رمضانNo ratings yet

- Astm A242-13 PDFDocument3 pagesAstm A242-13 PDFsingaravelan narayanasamyNo ratings yet

- A 232 - A 232M - 05 (2011) E1 PDFDocument4 pagesA 232 - A 232M - 05 (2011) E1 PDFأسامة وحيد الدين رمضانNo ratings yet

- A 234 - A 234M - 17 PDFDocument9 pagesA 234 - A 234M - 17 PDFأسامة وحيد الدين رمضانNo ratings yet

- A 184 - A 184M - 06 (2011) PDFDocument3 pagesA 184 - A 184M - 06 (2011) PDFأسامة وحيد الدين رمضانNo ratings yet

- A 182 - A 182M - 16a PDFDocument15 pagesA 182 - A 182M - 16a PDFأسامة وحيد الدين رمضانNo ratings yet

- A 203 - A 203M - 12 PDFDocument3 pagesA 203 - A 203M - 12 PDFأسامة وحيد الدين رمضانNo ratings yet

- A 109 - A 109M - 16 PDFDocument9 pagesA 109 - A 109M - 16 PDFأسامة وحيد الدين رمضانNo ratings yet

- The Laboratory Mouse: A Guide To The Location and Orientation of Tissues For Optimal Histological Evaluation 1st Edition Jennifer Johnson (Author)Document54 pagesThe Laboratory Mouse: A Guide To The Location and Orientation of Tissues For Optimal Histological Evaluation 1st Edition Jennifer Johnson (Author)james.young746100% (1)

- Magnus EffectDocument324 pagesMagnus EffectTommaso Massai0% (1)

- Astm D 6546 - 00Document9 pagesAstm D 6546 - 00Khan ShahzebNo ratings yet

- FWRefDocument470 pagesFWRefbalajivangaruNo ratings yet

- Unit 3: Properties of ExponentsDocument10 pagesUnit 3: Properties of ExponentsLuis RiveraNo ratings yet

- Netquote Inc. v. Byrd - Document No. 157Document3 pagesNetquote Inc. v. Byrd - Document No. 157Justia.comNo ratings yet

- 2014 KS2 L6 Mathematics Paper 1Document16 pages2014 KS2 L6 Mathematics Paper 1Anonymous SrBcs9uXNo ratings yet

- SAMPLE - Booking A Hotel - Traveling in English - ESL LibraryDocument10 pagesSAMPLE - Booking A Hotel - Traveling in English - ESL LibrarySeow Hui100% (1)

- EN Innovator Agreement - Version 5 5Document4 pagesEN Innovator Agreement - Version 5 5jh41740No ratings yet

- Gonzales V Court of AppealsDocument2 pagesGonzales V Court of Appealsmarmiedyan9517No ratings yet

- KEEX-1100 User's Guide: Industrial 3.5" Embedded SBC With Intel® Atom D510Document49 pagesKEEX-1100 User's Guide: Industrial 3.5" Embedded SBC With Intel® Atom D510Péter CsörgőNo ratings yet

- GFR CatalogDocument137 pagesGFR CatalogironeousNo ratings yet

- 12 Diamond v. DiehrDocument49 pages12 Diamond v. DiehrAimee Grace GarciaNo ratings yet

- Trade Mark Process in India and Across The GlobeDocument4 pagesTrade Mark Process in India and Across The Globekumar PritamNo ratings yet

- Foundation Medicine ComplaintDocument11 pagesFoundation Medicine Complaintantonio_regalad352No ratings yet

- Nareg - Still FlexinDocument2 pagesNareg - Still FlexinLevani JavakhadzeNo ratings yet

- Strategies in Action: Strategic Management: Concepts & Cases 13 Edition Fred DavidDocument17 pagesStrategies in Action: Strategic Management: Concepts & Cases 13 Edition Fred DavidChris Nicole LaigueNo ratings yet

- De Re MilitariDocument3 pagesDe Re MilitariAbu SuhaibNo ratings yet

- F2988-12 Standard Specification For Commercial Coffee BrewersDocument5 pagesF2988-12 Standard Specification For Commercial Coffee BrewersRafael Obusan IINo ratings yet

- Jinjiangshisiluliangpinjinchukoumaoyi v. Schedule A - ComplaintDocument5 pagesJinjiangshisiluliangpinjinchukoumaoyi v. Schedule A - ComplaintSarah BursteinNo ratings yet

- Industrial Design NoteDocument10 pagesIndustrial Design Noteshrutiagarwal9229No ratings yet

- Road Closures GraphicsDocument1 pageRoad Closures GraphicsLive 5 NewsNo ratings yet

- Bream Gives Me HiccupsDocument5 pagesBream Gives Me Hiccupswamu885No ratings yet

- (Example) AIP Conference Proceedings License Agreement-ICMScE 2021-Lilit RusyatiDocument2 pages(Example) AIP Conference Proceedings License Agreement-ICMScE 2021-Lilit Rusyatianis mugitsahNo ratings yet

- Hydraulic Breakers BrochureDocument8 pagesHydraulic Breakers BrochureEndraNo ratings yet

- ProfTrainCertPolicy PDFDocument20 pagesProfTrainCertPolicy PDFLane MedaNo ratings yet

- Iq Mind BendersDocument213 pagesIq Mind BendersAkash PushpNo ratings yet

- IEEE Standard Definitions For Use in Reporting Electric Generating Unit Reliability Availability and ProductivityDocument78 pagesIEEE Standard Definitions For Use in Reporting Electric Generating Unit Reliability Availability and ProductivityDimas100% (1)

- Homer - The Iliad (Webster's Korean Thesaurus Edition) (2006)Document429 pagesHomer - The Iliad (Webster's Korean Thesaurus Edition) (2006)ravin66741No ratings yet