Professional Documents

Culture Documents

MES ST 1002 - Saddle

MES ST 1002 - Saddle

Uploaded by

Darshan PanchalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MES ST 1002 - Saddle

MES ST 1002 - Saddle

Uploaded by

Darshan PanchalCopyright:

Available Formats

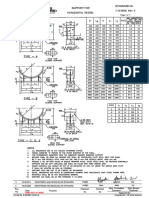

L3 MAX. LOAD APPROX. WT.

150 D LB H L1 L2 TYPE PER SADDLE PER SADDLE

(M.TON) (KGS.)

T.L.

ts D 10 10

300 260 300 50 200 A 4.4 17

120° P.)

18

(TY

(Min.) R50

D/

EARTHING

LUG 350 280 325 55 210 A 4.8 18

t3 -10]

H

te

[N

o 400 330 350 75 250 A 4.5 20

CL WRAPER 450 370 375 95 300 A 3.6 22

NOTE-6

t1 t1

REFER

t2

PLATE

500 450 450 125 370 A 14.9 40

L1 L1

Ø26 HOLES FOR 170

L2 M20 BOLTS

600 560 500 175 470 A 13.2 50

= =

LB

30 (NOTE-11) 700 650 550 225 570 A 11.0 55

TYPE - A PARALLEL TO VESSEL

800 750 600 275 670 A 10.6 65

26

AXIS (TYP)

SLOT HOLE FOR SLIDING BASE PLATE 900 850 650 300 760 A 11.0 75

1000 950 700 330 820 B 12.3 85

1200 1100 800 375 960 B 19.4 130

2-Ø6 VENT HOLE

TYP. (REFER NOTE-5)

1400 1250 900 465 1150 B 19.7 140

ts D R50

L3

(TYP.) CL WRAPER PLATE

120° 1600 1450 1000 370 1300 C 23.3 165

18

(Min.)

D/

EARTHING

LUG

t1 1800 1600 1100 410 1450 C 39.1 260

t3 -10]

H

ote 110 110

[N

2000 1750 1200 445 1600 C 43.5 290

2200 1950 1300 495 1800 D 49.1 295

NOTE-6

t1

REFER

t2

2400 2150 1450 545 2000 D 53.5 390

L1 L1 140

Ø26 HOLES FOR

L2 M20 BOLTS 250 2600 2300 1550 585 2150 D 52.9 440

= LB =

30 (NOTE-11) 2800 2500 1650 620 2300 E 52.7 475

TYPE - B

PARALLEL TO VESSEL

26

AXIS (TYP)

3000 2670 1750 670 2500 E 64.9 600

SLOT HOLE FOR SLIDING BASE PLATE

3200 2800 1850 710 2600 E 63.8 620

3400 3000 1950 760 2800 E 64.9 630

2-Ø6 VENT HOLE 3600 3200 2050 830 3000 F 60.5 725

TYP. (REFER NOTE-5)

ts D R80

L3 3800 3350 2150 845 3150 F 61.0 745

(TYP.) CL WRAPER PLATE

120°

18

(Min.) EARTHING

4000 3550 2250 895 3300 F 60.6 820

D/

LUG

t3 -10] t1

H

ote 110 110

[N

TYPE t1 t2 t3 L3

REFER

NOTE-6

t1 A 10 10 12 170

t2

B 10 12 12 250

L1 L1 L1 140

Ø30 HOLES FOR

L2 M24 BOLTS

C 12 16 16 300

250

= =

LB D 16 20 20 350

30 (NOTE-11)

TYPE - C, D, E & F E 20 20 20 400

PARALLEL TO VESSEL

30

AXIS (TYP)

F 25 25 20 450

SLOT HOLE FOR SLIDING BASE PLATE

01 10-JUN-2016 REVISED & REISSUED AS STANDARD DRAWING SMP SGB RGO

00 25/07/2008 ISSUE FOR IMPLEMENTATION AKV AND AKG

REV DATE DESCRIPTION BY CHKD. APPD.

STANDARD NO. REV.

SUPPORT FOR

L&T Hydrocarbon Engineering MES-ST-1002 01

HORIZONTAL VESSEL

SHEET 1 OF 2

Notes :-

1. All dimensions are in mm unless otherwise specified.

2. Vessel diameter 'D' refers to the outer diameter of the shell.

3. For intermediate diameters take dimensions of next higher diameter`s data.

4. Welding shall be done all around and shall be continuous fillet weld. Weld size shall be 6mm for vessels

upto Ø 1400mm & 8mm for vessels above Ø 1400mm.

5. Provide two numbers of Ø 6mm vent holes in saddle wrapper plate. These holes shall be provided

diagonally be provided diagonally opposite and be left unplugged and shall be filled with hard grease only.

6. Where earthing lug cannot be put at an elevation of 400mm above the saddle base plate it shall be

located as high as possible.

7. Earthing lug shall be as per standard drawing MES-ST-1026.

8. Detail, dimensions and notes in datasheet take precedence over those shown here.

9. Materials shall be as per data sheet.

10. Wrapper plate thickness shall be smaller of shell thickness(ts) and "t3"

11. Minimum slot hole length shall be ensure with respect to equipment`s thermal expansion.

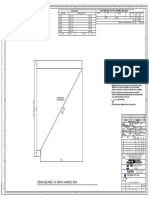

01 10-JUN-2016 REVISED & REISSUED AS STANDARD DRAWING SMP HAS RGO

00 25/07/2008 ISSUE FOR IMPLEMENTATION AKV AND AKG

REV DATE DESCRIPTION BY CHKD. APPD.

STANDARD NO. REV.

SUPPORT FOR

L&T Hydrocarbon Engineering MES-ST-1002 01

HORIZONTAL VESSEL

SHEET 2 OF 2

You might also like

- WICKED LibrettoDocument49 pagesWICKED LibrettoCatalina Moreno100% (2)

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanNo ratings yet

- HMT Training ReportDocument43 pagesHMT Training ReportNajvan MuhammedNo ratings yet

- 16 B 06 HDocument20 pages16 B 06 HVaibhav Bhoir0% (1)

- IPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ADocument3 pagesIPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ANikhil KarkeraNo ratings yet

- 03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantDocument40 pages03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantmahmoudNo ratings yet

- Double Walled Vessel IntroductionDocument14 pagesDouble Walled Vessel IntroductionChanchal GuptaNo ratings yet

- Tbe For Osbl (SBS)Document5 pagesTbe For Osbl (SBS)benidbb100% (3)

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- VP 3209 e 031a 02 0013 Rev.dDocument254 pagesVP 3209 e 031a 02 0013 Rev.dSuryaprakashNo ratings yet

- Dimensioning A Heat Exchanger Flange: About P3 EngineeringDocument22 pagesDimensioning A Heat Exchanger Flange: About P3 EngineeringVilas AndhaleNo ratings yet

- API 650 Storage Tank 2400Document34 pagesAPI 650 Storage Tank 2400PANOLI PROJECTNo ratings yet

- Notes:: TAG# SV-01Document1 pageNotes:: TAG# SV-01omarNo ratings yet

- Specific Size Agitator Selection Process & Specification PDFDocument141 pagesSpecific Size Agitator Selection Process & Specification PDFParth ThakarNo ratings yet

- ESR0055024ACAL1004 0cDocument24 pagesESR0055024ACAL1004 0ckayaltharanNo ratings yet

- PVM Su 1322 H.1 PDFDocument22 pagesPVM Su 1322 H.1 PDFJEEVITHANo ratings yet

- DT & DP - Flange Rating and Pipe Sizing R2 PDFDocument11 pagesDT & DP - Flange Rating and Pipe Sizing R2 PDFroyNo ratings yet

- PU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDocument8 pagesPU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDDA7No ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- V 21302 - Rev.2 CDocument133 pagesV 21302 - Rev.2 Cpandiangv100% (1)

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Document1 pageTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNo ratings yet

- A.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018Document6 pagesA.1) Verification Statement For Pvelite Calculations, As Per Asme Section Viii Div.1 2018ToniNo ratings yet

- AES Floating HeadDocument8 pagesAES Floating HeadArjun Singh AroraNo ratings yet

- Damper SelectionDocument11 pagesDamper SelectionJKKNo ratings yet

- Engineering Standard: IPS-E-PR-410Document19 pagesEngineering Standard: IPS-E-PR-410محمد نصیریNo ratings yet

- Flange Mawp Reduction PV Elite PDFDocument8 pagesFlange Mawp Reduction PV Elite PDFDarshan PanchalNo ratings yet

- Ring Joint DimensionsDocument1 pageRing Joint DimensionsDuane HodgsonNo ratings yet

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNo ratings yet

- Stratification OT 3536-22 ScrubberDocument31 pagesStratification OT 3536-22 ScrubberbecemNo ratings yet

- V1121 FLPC MS Ga 6024017 PDFDocument219 pagesV1121 FLPC MS Ga 6024017 PDFDarshan PanchalNo ratings yet

- Drum SizingDocument48 pagesDrum SizingVikram Sharma100% (1)

- Ario Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001Document5 pagesArio Damar - Sriwijaya Oil & Gas Development: Document No. CT-F17795-TE2-31-E-002-001idilfitriNo ratings yet

- 6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiDocument15 pages6684-EQS-101-CA-0001 - 000 - 03 - Contractor's Scope of Work - Static EquiAvinash ShuklaNo ratings yet

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDocument1 pageHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgNo ratings yet

- Evaporative Condenser PDFDocument2 pagesEvaporative Condenser PDFDemetrius100% (2)

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Catalyst Final CalculationsDocument47 pagesCatalyst Final CalculationsPrable SekhriNo ratings yet

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTORONo ratings yet

- Pressure Vessel Design Old (Eugyene F Megysey)Document31 pagesPressure Vessel Design Old (Eugyene F Megysey)David FonsecaNo ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- ETHANOL (6.0D X 8.825 H), Rev. 0Document26 pagesETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaNo ratings yet

- B ABK 5000 1 API 650 Calculation ReportDocument50 pagesB ABK 5000 1 API 650 Calculation ReportZackNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- 16-77-03 Field Welding of Fusion Welded PanelsDocument3 pages16-77-03 Field Welding of Fusion Welded PanelsJKKNo ratings yet

- TQ - Air Fin Cooler (CS) - ModificationDocument6 pagesTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNo ratings yet

- MD1-0-T-030-05-00070 - 3 ITP For Field Erected TankDocument14 pagesMD1-0-T-030-05-00070 - 3 ITP For Field Erected TankTran Khuynh100% (1)

- 8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDocument26 pages8015-0151-SECL-00-000-ME-BD-00004 - 02 - Design Basis For Rotating and Package Equipment PDFDamiano Tondelli100% (1)

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- Basic Engineering Design Basis For Sour Water Stripper Unit (SWS) (UNIT 08)Document10 pagesBasic Engineering Design Basis For Sour Water Stripper Unit (SWS) (UNIT 08)mohsen ranjbarNo ratings yet

- PO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFDocument57 pagesPO6258 RFI+for+S60133-0504+ (GTG+PKG) PDFmyungkwan haNo ratings yet

- 107 CNT D 202Document3 pages107 CNT D 202luis m hueto castilloNo ratings yet

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNo ratings yet

- 2A P220 Accumulator Process Data Sheet PDFDocument3 pages2A P220 Accumulator Process Data Sheet PDFAhmed MusallamNo ratings yet

- Cryogenic Standard Tanks PDFDocument12 pagesCryogenic Standard Tanks PDFprakash07343No ratings yet

- Cold Insulation Thickness TableDocument1 pageCold Insulation Thickness TableZeeshan AhujaNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNo ratings yet

- 7-12-0002 Rev5 - Support For Horizontal VesselDocument1 page7-12-0002 Rev5 - Support For Horizontal VesselSachinNo ratings yet

- Bar Bending Schedule Indian Standard v3.2 - English - XLSMDocument8 pagesBar Bending Schedule Indian Standard v3.2 - English - XLSMdjebaili1993No ratings yet

- Transportation - Bearing LoadDocument3 pagesTransportation - Bearing LoadDarshan PanchalNo ratings yet

- Sr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCDocument3 pagesSr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCDarshan PanchalNo ratings yet

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDocument3 pagesPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNo ratings yet

- Design Notes and AssumptionsDocument19 pagesDesign Notes and AssumptionsDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDocument4 pagesVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDocument270 pagesVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNo ratings yet

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Document1 pageB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNo ratings yet

- Champion Jointing SheetDocument5 pagesChampion Jointing SheetDarshan PanchalNo ratings yet

- Spec. Number Suffixes: US Based On US Codes and Standards, ON Applicable For Onshore Projects, M&U Units UsedDocument28 pagesSpec. Number Suffixes: US Based On US Codes and Standards, ON Applicable For Onshore Projects, M&U Units UsedDarshan PanchalNo ratings yet

- Gaskets App 2Document6 pagesGaskets App 2Darshan PanchalNo ratings yet

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalNo ratings yet

- Design Philosophy - StaticDocument61 pagesDesign Philosophy - StaticDarshan PanchalNo ratings yet

- Process Equipment Design: Machine A PDF Writer That Produces Quality PDF Files With Ease!Document1 pageProcess Equipment Design: Machine A PDF Writer That Produces Quality PDF Files With Ease!Darshan PanchalNo ratings yet

- Btech Syllabus For Gndec LudhianaDocument38 pagesBtech Syllabus For Gndec Ludhianaਅਰ ਜੋਤNo ratings yet

- 16 Bit Carry Select Adder With Low Power and AreaDocument3 pages16 Bit Carry Select Adder With Low Power and AreaSam XingxnNo ratings yet

- Conveyance 15 ExercisesDocument9 pagesConveyance 15 Exercisespriyankasadashiv21No ratings yet

- G.R. No. L-48176 PDFDocument7 pagesG.R. No. L-48176 PDFAj SobrevegaNo ratings yet

- FT096 20191112 Iso A4Document64 pagesFT096 20191112 Iso A4Jeff Zeitlin100% (4)

- NORTH NEGROS SUGAR CO V HIDALGO FULL TEXTDocument29 pagesNORTH NEGROS SUGAR CO V HIDALGO FULL TEXTKiethe MyraNo ratings yet

- Soco Assignment 2Document4 pagesSoco Assignment 2Lara LavanyaNo ratings yet

- Dextra - Marine Tie RodsDocument6 pagesDextra - Marine Tie Rodspangalengan zaxNo ratings yet

- Sample Letter of Intent To Transfer FundsDocument2 pagesSample Letter of Intent To Transfer Fundsnavid kamravaNo ratings yet

- Gun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintDocument41 pagesGun Rights Groups Sue Over California Carry Permit Requirements - CRPA v. LASD ComplaintAmmoLand Shooting Sports NewsNo ratings yet

- Performance of Recron-3s Fiber On Black Cotton SoilDocument6 pagesPerformance of Recron-3s Fiber On Black Cotton SoilInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Studentzone 02 2017Document3 pagesStudentzone 02 2017YahiaEl-obidyNo ratings yet

- November 2023 Timetable Zone 2Document12 pagesNovember 2023 Timetable Zone 2Horror666No ratings yet

- Astm D 3948-05Document12 pagesAstm D 3948-05JorgeMunizNo ratings yet

- Full Download Strategic Management A Competitive Advantage Approach Concepts and Cases 14th Edition David Test BankDocument27 pagesFull Download Strategic Management A Competitive Advantage Approach Concepts and Cases 14th Edition David Test Banksuidipooshi100% (29)

- Harminder Singh SAP ID-500073564: Social BondsDocument5 pagesHarminder Singh SAP ID-500073564: Social Bondsharminder singhNo ratings yet

- Life Below Water: Verlin Andre Africa Simon Marquis Lumbera Rhona Mae Panopio Ais1ADocument14 pagesLife Below Water: Verlin Andre Africa Simon Marquis Lumbera Rhona Mae Panopio Ais1ASimon Marquis LUMBERANo ratings yet

- On Commercial Aviation Safety: AUTUMN 2000Document26 pagesOn Commercial Aviation Safety: AUTUMN 2000Alex AlonsoNo ratings yet

- ITS 2016 Boston - Tugconomy PaperDocument6 pagesITS 2016 Boston - Tugconomy PaperPietGebruikerNo ratings yet

- ENGINEERING DESIGN GUIDELINES Reboiler Rev1.3web PDFDocument12 pagesENGINEERING DESIGN GUIDELINES Reboiler Rev1.3web PDFSamit MitraNo ratings yet

- Math Test 2 DR - EhsanDocument9 pagesMath Test 2 DR - EhsanNərmin ŞahverdiyevaNo ratings yet

- SPC SpreadsheetDocument10 pagesSPC SpreadsheetSpyros IliakisNo ratings yet

- Shivam Digital MarketingDocument85 pagesShivam Digital Marketingssbharadwaj294No ratings yet

- CB-8466 ECF ClearFire Economizer PDFDocument16 pagesCB-8466 ECF ClearFire Economizer PDFAbdul RazzaqNo ratings yet

- Sikatia 2Document12 pagesSikatia 2Kaushlendra OmNo ratings yet

- Summon FormDocument2 pagesSummon FormmichaelNo ratings yet

- EH - UK - Employers - Basics of UK Payroll GuideDocument10 pagesEH - UK - Employers - Basics of UK Payroll GuidexiibzzxNo ratings yet

- China Freezing Air Conditioning Equipment Mfg. Industry Profile Cic3573Document8 pagesChina Freezing Air Conditioning Equipment Mfg. Industry Profile Cic3573AllChinaReports.comNo ratings yet