Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

50 viewsHoneywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Honeywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Uploaded by

christianjatayuHoneywell Sensors Switches Oil Rig

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- R Student CompanionDocument351 pagesR Student CompanionJUDGE100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Training PPT June 2023Document10 pagesTraining PPT June 2023Atif IjazNo ratings yet

- Coupled Tanks - Workbook (Student) INGLÉS PDFDocument34 pagesCoupled Tanks - Workbook (Student) INGLÉS PDFDanielaLópezNo ratings yet

- MarpolDocument3 pagesMarpolAbu NawshadNo ratings yet

- EdtpaDocument7 pagesEdtpaapi-310967404No ratings yet

- Modified M.SC SyllabusDocument27 pagesModified M.SC SyllabusAbhishekBanerjeeNo ratings yet

- Mathematics OF Investment: Cavite State UniversityDocument14 pagesMathematics OF Investment: Cavite State UniversityAlyssa Bianca AguilarNo ratings yet

- SANITARY PERMIT YampleDocument6 pagesSANITARY PERMIT Yamplekimmy100% (1)

- Week 06Document70 pagesWeek 06HawJingZhiNo ratings yet

- Tabel Faktor Pengali PDFDocument2 pagesTabel Faktor Pengali PDFKHALIFATUL AZWINNo ratings yet

- The Pitch Method Business Model CanvasDocument26 pagesThe Pitch Method Business Model CanvasRenata MasseroniNo ratings yet

- Shi2016 PDFDocument43 pagesShi2016 PDFm.knoeri habibNo ratings yet

- PeopleSoft Applications Portal and WorkCenter PagesDocument18 pagesPeopleSoft Applications Portal and WorkCenter PagesLydie StevensNo ratings yet

- Activity Sheet For Constant Pressure Calorimetry PDFDocument5 pagesActivity Sheet For Constant Pressure Calorimetry PDFSheryl Jane MitanteNo ratings yet

- Chapter 10 (6) - BDocument52 pagesChapter 10 (6) - BMahfuzur RahmanNo ratings yet

- I, Hereby Declare That The Research Work Presented in The Summer Training Based Project Report Entitled, Study of Compotators of Frooti JuiceDocument98 pagesI, Hereby Declare That The Research Work Presented in The Summer Training Based Project Report Entitled, Study of Compotators of Frooti Juiceaccord123No ratings yet

- Slurry Pumps Ar1 PDFDocument40 pagesSlurry Pumps Ar1 PDFsanjayagrawal70-1No ratings yet

- Purchase ManagementDocument32 pagesPurchase ManagementManjula Ashok100% (1)

- Pile RockDocument31 pagesPile RockpandianNo ratings yet

- E SRKRPORTALuploadsSyllabus ModelPapersModel R17 B.tech MECH 69Document33 pagesE SRKRPORTALuploadsSyllabus ModelPapersModel R17 B.tech MECH 69prasadNo ratings yet

- Agreements and Disclosures UbsDocument88 pagesAgreements and Disclosures UbsAxeliiNilssonNo ratings yet

- 1804 08330Document6 pages1804 08330Nhat VienNo ratings yet

- S/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDocument75 pagesS/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDianPramana100% (2)

- Section A-A: Quaife Design & Development. Drg. No. Used inDocument1 pageSection A-A: Quaife Design & Development. Drg. No. Used instefan.vince536No ratings yet

- Appian QuestionsDocument2 pagesAppian QuestionsAnuragNo ratings yet

- Membrane Desalination and Water ReuseDocument484 pagesMembrane Desalination and Water ReuseHassanKMNo ratings yet

- Manual FOR Whirling of Shaft Apparatus: WWW - Elshaddaiengineering.inDocument3 pagesManual FOR Whirling of Shaft Apparatus: WWW - Elshaddaiengineering.insindhu elshaddaienggNo ratings yet

- The Central Excise Act, 1944Document10 pagesThe Central Excise Act, 1944sandeep1318100% (3)

- General Exhaust (Dilution) Ventilation Systems General ExhaustDocument5 pagesGeneral Exhaust (Dilution) Ventilation Systems General ExhaustmadbakingNo ratings yet

- Recruitment AdvertisementDocument1 pageRecruitment AdvertisementDeepanjan MandalNo ratings yet

Honeywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Honeywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Uploaded by

christianjatayu0 ratings0% found this document useful (0 votes)

50 views2 pagesHoneywell Sensors Switches Oil Rig

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHoneywell Sensors Switches Oil Rig

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

50 views2 pagesHoneywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Honeywell Sensors Switches Oil Rig Applications 000756 4 en Highres

Uploaded by

christianjatayuHoneywell Sensors Switches Oil Rig

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

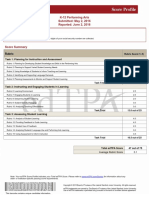

Sensors and Switches in Oil Rig Applications

A Measure weight on drill line via cable tension

Crown Block Load cells: 41, RM

Measure oil, water, and hydraulic fluid

B pressure

Power Pressure sensors: FP2000, MLH, IP IS,

Generation PX2, PX3, SPT

Unit Emergency shutdown

Switches for ESD: WOI

D Measure inlet/outlet pressure with high accuracy

Accumulator Pressure sensors: FP2000, STJE

Unit

Control/monitor operations activity

MICRO SWITCH basic switches: BZ, V7,

V15W, SX

E MICRO SWITCH toggle switches: TL, NT,

Drilling Cab TS, TW, ET, AT

Key, rotary, and e-stop switches: custom

Limitless™ operator interface: WOI

Measure hydraulic pressure, weight, force/strain

F or movement, monitor raising or lowering deck for

Rig Hydrau- directional drilling

lic Lift Pressure sensors: FP2000, IP IS

Load cells: 41

Measure torque, load/weight/position while guiding

H pipe into position

Drawworks Load cells: 41, RM

MICRO SWITCH switches: BX, LSX

Measure torque while attaching pipe using hydraulic

I pressure or load measurements

Iron Load cells: 41

Roughneck

Pressure sensors: FP2000, IP IS

M Measure tank liquid levels

Water/ Switches: HDLS, WLS non-contact

Storage Pressure sensors: MLH, LL-V, SPT, PX2

Tank

Monitor torque/twisting movement to ensure right

amount of force is applied

Torque sensors: custom

Measure weight on drill bit

N Load cells: 41

Top Drive Measure hydraulic pressure and feed

information into control system

Pressure sensors: FP2000, 811FM

On/off control and operator alerts to enhance safety

Limitless™ operator interface: WOI

O Measure weight on the drill line via cable tension

Traveling Load cells: 41

Block

R Measure tension on deadline/drilling line cable

Deadline Load cells: 41, RM

Anchor

T Measure valve position/choke valves

Choke MICRO SWITCH hazardous area switch:

Manifold CX, VPX

U Measure drilling mud pressure to monitor and control

Mud Return mud flow

Line Wing Union sensors: 434, 435, 437

V Position sensing or on/off applications

Mud Shaker Switches: HDLS, WLS, WOI

Z Measure direct and indirect loads Measure drilling fluid pressure

W Position sensing or on/off applications Winch Canister load cells: MPB, 3130, 3156, 3127 Pressure sensors: FP2000

AE

Mud Cleaner Limit switches: HDLS, WLS, WOI

Monitor RAM position via hydraulic volumetric or Fluid Wing Union sensors: 434, 435, 437

Measure pressure and flow of mud media AB

pressure behind the piston Manifold Measure valve position

Wing Union sensors: 434, 435, 437 BlowOut

(“pinch offs”) Limit switches: CX, WCX, VPX

Preventor Pressure sensors: A-105, TJE

On/off or emergency start/stop applications

Y Measure tank liquid levels

Limitless™ operator interface: WOI Measure pressure or differential pressure at high AF

Mud Pump AD Pressure sensors: FP2000, IP IS, SPT

Mud pump stroke count, position sensing, or on/off temperature and pressure ranges Mud Tank/

Drill Bit Pressure sensors: S Monitor tank valve position

applications Reservoir

Limit switches: BX, LSX, HDLS, WLS

MICRO SWITCH limits: EX, BX, HDLS

Sensors and Switches in Oil Rig Applications Load Cells

Model 41

• Rugged, low profile pancake style

Pressure Sensors • All-welded stainless steel with double diaphragm design

• Load ranges of 5 lb to 500,000 lb; Accuracy: ±0.1 %

FP2000 Series • Low sensitivity to extraneous loads

• All-welded, stainless steel construction • Intrinsically safe option available

• Gage, absolute, barometric, vacuum, differential pressure

• Range: 0.5 psi to 10,000 psi

Model RM

• Accuracy range of 0.1 % or 0.25 %

• Rod end in-line tension load cell

• Intrinsically safe options available

• Rugged design with stainless steel, all-welded construction

• Load ranges from 2000 lb to 200,000 lbs; ±0.22 % to 0.29 % accuracy

MLH Series

• Low sensitivity to extraneous loads

• All metal wetted parts for use in wide variety of fluid applications

• No internal elastomeric seals mean no o-ring compatibility issues

• Range: 50 psi to 8000 psi (inclusive) Model MPB

• Accuracy: ±0.25 %FS BFSL • High capacity load measurements in a small size load cell

• Rated IP65 or better for protection from harsh environments • Rugged stainless steel construction

• Load ranges from 15,000 lbs to 2,000,000 lbs

IP IS Series • Accuracy: ±0.25 % full scale

• Rugged, all-welded stainless steel and Hastelloy® wetted parts for durability

• Compatible with a wide variety of media Model 3130

• Range: 7 bar to 350 bar | 100 psi to 5,000 psi • Carbon steel, fatigue-resistant load cell

• Accuracy: ±0.15 %, ±0.25 % BFSL • Extremely resistant to extraneous bending and side loading forces

• Fully configurable • Load ranges of 500,000 lbs to 1,000,000 lbs

• Accuracy: ±0.30 % full scale

PX2 and PX3 Series

• Cost effective, highly configurable and highly durable

Model 3156

• Compatible with a wide variety of harsh media

• Carbon steel, fatigue-resistant load cell

• Broad compensated temperature range with industry-leading Total Error Band

• Extremely resistant to extraneous bending and side loading forces

• Range: 1 bar to 46 bar | 100 kPa to 4.6 MPa | 15 psi to 667 psi (PX2)

• Load ranges of 25,000 lbs to 150,000 lbs

• Range: 1 bar to 46 bar | 15 psi to 667 psi (PX3)

• Accuracy: ±0.30 % full scale

• Accuracy ±0.25 %FSS; TEB ±2 %FSS (-40 °C to 125 °C [-40 °F to 257 °F])

SPT Series Model 3127

• Rugged, stainless steel in a small size package • Carbon steel, fatigue-resistant load cell

• Absolute, gage, sealed gage, vacuum gage • Extremely resistant to extraneous bending and side loading forces

• Range: 0 psi to 3 psi, 0 psi to 5000 psi; ±0.25 % accuracy • Load ranges up to 2,000,000 lbs.

• Reliable semiconductor technology, NEMA 4 design • Accuracy: ±0.30 % full scale

• Calibrated and temperature compensated

MICRO SWITCH Basic Switches

Model TJE

• Rugged, all-welded, stainless steel construction MICRO SWITCH Premium Large Basic Switches, BZ Series

• Built for applications requiring high accuracy and temperature stability • Accepted as the world-wide standard snap-action switch

• Unique “true gage” design hermetically sealed against atmospheric contamination • Best suited for high cost-of-failure applications

• Range: 1 psig/a to 60000 psig/a; accuracy: ±0.10 % • Designed for 100k operations at full load or 10M for mechanical life

• Intrinsically safe available • Current ratings from 10 A to 25 A

• UL/CSA, CE, ENEC approvals

Super TJE Series

• Ultra precision pressure sensors with up to ±0.05 % accuracy MICRO SWITCH Premium V-Basic Switches, V7 Series

• True gage, absolute and differential (wet/wet) • Best suited for higher cost-of-failure applications

• Durable, stainless steel for use in rugged environments • Designed for 100k operations at full load or 10M for mechanical life

• Range: 10 psig to 7500 psig (pressure); 50 psid to 750 psid (differential) • Current ratings from 0.1 A to 25 A

• Intrinsically safe options available • UL/CSA, ENEC approvals

811FM Series MICRO SWITCH Premium Miniature/Subminiature Basic Switches, SX Series

• All-welded, stainless steel construction for use with liquid, gas or corrosive vapors • Best suited for higher cost-of-failure applications

• Range: 2 psig/a to 10000 psig/a • Small size and light weight

• Accuracy: ±0.25 % • Current ratings from 0.1 A to 25 A

• Dual pipe thread pressure fitting for easy bulkhead mounting • UL/CSA, ENEC approvals

• Explosion proof

MICRO SWITCH Watertight Miniature Switches, V15W Series

Model S

• Miniature-sized basic switch designed for harsh-duty, wash down areas

• Rugged, high-frequency stainless steel

• Rugged, highly accurate machine control for turning circuits on and off

• Extremely small size, fits into tight spaces

• Compact, lightweight, and long-lasting

• Range: 100 psig to 15,000 psig

• UL, cUL, ENEC, CQC approvals

• Operating temperature range: -54 °C to 149 °C [-65 °F to 300 °F]

• Accuracy: ±1.0 %

MICRO SWITCH Limit Switches

Model A-105

MICRO SWITCH Hazardous Area Switches, BX and LSX Series

• Rugged, unitized stainless steel design with heavy sidewalls

• Designed specifically for dangerous indoor or outdoor locations

• Thin diaphragm design able to measure low pressures

• Superior reliability and repeatability

• Flush mount design with miniature footprint

• Explosion-proof design with flame path to contain and cool escaping hot gases

• Can be used in corrosive fluid environments

• O-ring seals render switches weather-proof, water-tight, dust-tight

• Range: 100 psig to 15,000 psig; accuracy: ±0.5 %

• UL, CSA (BX, LSX Series); ATEX, IEC EX, NEPSI, European approvals (BX Series)

LL-V Series

MICRO SWITCH Hazardous Area Switches, CX Series

• Designed for vertical entry into a tank

• Hazardous atmosphere outdoor use – watertight, dust-tight

• Complete fluid submersion; corrosion resistant to most fluids

• Superior reliability and repeatability

• True gage design with all welded stainless steel construction

• Rotary converts in seconds to clockwise, counter-clockwise, or both-way operation

• Range: 20 inH2O to 50 psig; accuracy: ±0.1 %

• IP66; NEMA 1, 3, 4, 4X, 6, 6P, 13 sealing

• UL, CSA, ATEX, IEC Ex approvals

Models 434, 435, 437 Wing Union Pressure Sensors

• Rugged design with Inconel® X-750 or NACE-compliant Inconel® 718 wetted parts

MICRO SWITCH Hazardous Area Valve Position Indicator, VPX Series

• Built to provide durability with abrasive or corrosive media

• Certified for ATEX, IEC Ex, CE, and cULus specifications for global applications

• Accuracy: ±0.1 %FSS BFSL (Model 435) high accuracy, or

• Die-cast aluminum housing and various sealing (NEMA 4, 4X, 6, and 13)

±0.2 %FSS BFSL (Model 434, 437) standard accuracy

• Versions available in both snap-action switches and intrinsically safe inductive

• Wide port aperture (Model 437) for use with more viscous media

proximity switches

• Compatible with WECO® 1502, 2002, 2202; intrinsically safe option available

• Versions of the VPX with proximity switches carry an Intrinsically Safe (IS) rating

• Protective cage option (Model 434, 435, 437)

MICRO SWITCH Hazardous Area Switches, EX Series

Torque Shafts • Designed for dangerous indoor or outdoor locations

• Superior reliability and repeatability

Custom Torque Shaft

• Smallest UL-listed housings available for use in hazardous locations

• Modify/design existing top drive shafts to measure torque

• O-ring seals render switches weather-proof, water-tight, dust-tight

• Strain-gauge the complex large shafts found in top drives

• UL, CSA, ATEX, IEC EX approvals

• Calibrating to torque levels required on a top drive

• Modify/adapt the calibration rig flanges to the custom flanges on a top drive shaft

MICRO SWITCH Heavy-Duty Limit Switches, HDLS Series

• Three series offer rugged, die-cast body and epoxy coating

• Boss-and-socket head design for secure head-to body retention

Operator Controls • Multiple mounting and actuator options

• UL, CSA, CE, CCC approvals

Rotary Switches

• 3- and 4-position options

• May be engineered with lever or knob actuator

Limitless™ Wireless Solutions

• Integral connectors (Metripak 280 and Sumitomo)

Limitless™ Wireless Operator Interface, WOI Series

• Environmentally sealed design

• Enables operator indication from locations where wiring is too costly or not pos-

sible

• Flexible operator type options (push button, rotary or key switch, etc.)

e-Stop Switches

• Reduces installation/maintenance costs with no wires, conduit, connectors, etc.

• Provides positive contact closure and opening when the switch is operated

• Eliminates issues with wire connection integrity on moving equipment

• Environmentally sealed design (IP67 sealing)

• UV-resistant knob for outdoor use

• Knob available in a variety of colors Limitless™ Wireless Non-Contact Switches, WLS Series

• MICRO SWITCH HDLS heritage combined with the latest wireless technology

MICRO SWITCH Toggle Switches (Sealed and Unsealed), • Enables presence/absence detection where wiring is an issue or not feasible

TL, NT, TS, TW, ET, AT Series • Reduces installation/maintenance costs due to no wires, conduit, connectors, etc.

• Broad product range meets a variety of electrical and load requirements • Eliminates wire connection integrity issues on moving equipment

• Sealed models built to withstand harsh, wet, dusty, and dirty environments

• 2 or 3 position, momentary and/or maintained action; 1-, 2- or 4-pole circuitries

• IWTS (integrated wire termination system) for ease of assembly & maintainability

Honeywell Sensing and Productivity Solutions

9680 Old Bailes Road

Fort Mill, SC 29707 000756-4-EN IL50 GLO Printed in USA.

January 2017

honeywell.com © 2017 Honeywell International Inc. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- R Student CompanionDocument351 pagesR Student CompanionJUDGE100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Training PPT June 2023Document10 pagesTraining PPT June 2023Atif IjazNo ratings yet

- Coupled Tanks - Workbook (Student) INGLÉS PDFDocument34 pagesCoupled Tanks - Workbook (Student) INGLÉS PDFDanielaLópezNo ratings yet

- MarpolDocument3 pagesMarpolAbu NawshadNo ratings yet

- EdtpaDocument7 pagesEdtpaapi-310967404No ratings yet

- Modified M.SC SyllabusDocument27 pagesModified M.SC SyllabusAbhishekBanerjeeNo ratings yet

- Mathematics OF Investment: Cavite State UniversityDocument14 pagesMathematics OF Investment: Cavite State UniversityAlyssa Bianca AguilarNo ratings yet

- SANITARY PERMIT YampleDocument6 pagesSANITARY PERMIT Yamplekimmy100% (1)

- Week 06Document70 pagesWeek 06HawJingZhiNo ratings yet

- Tabel Faktor Pengali PDFDocument2 pagesTabel Faktor Pengali PDFKHALIFATUL AZWINNo ratings yet

- The Pitch Method Business Model CanvasDocument26 pagesThe Pitch Method Business Model CanvasRenata MasseroniNo ratings yet

- Shi2016 PDFDocument43 pagesShi2016 PDFm.knoeri habibNo ratings yet

- PeopleSoft Applications Portal and WorkCenter PagesDocument18 pagesPeopleSoft Applications Portal and WorkCenter PagesLydie StevensNo ratings yet

- Activity Sheet For Constant Pressure Calorimetry PDFDocument5 pagesActivity Sheet For Constant Pressure Calorimetry PDFSheryl Jane MitanteNo ratings yet

- Chapter 10 (6) - BDocument52 pagesChapter 10 (6) - BMahfuzur RahmanNo ratings yet

- I, Hereby Declare That The Research Work Presented in The Summer Training Based Project Report Entitled, Study of Compotators of Frooti JuiceDocument98 pagesI, Hereby Declare That The Research Work Presented in The Summer Training Based Project Report Entitled, Study of Compotators of Frooti Juiceaccord123No ratings yet

- Slurry Pumps Ar1 PDFDocument40 pagesSlurry Pumps Ar1 PDFsanjayagrawal70-1No ratings yet

- Purchase ManagementDocument32 pagesPurchase ManagementManjula Ashok100% (1)

- Pile RockDocument31 pagesPile RockpandianNo ratings yet

- E SRKRPORTALuploadsSyllabus ModelPapersModel R17 B.tech MECH 69Document33 pagesE SRKRPORTALuploadsSyllabus ModelPapersModel R17 B.tech MECH 69prasadNo ratings yet

- Agreements and Disclosures UbsDocument88 pagesAgreements and Disclosures UbsAxeliiNilssonNo ratings yet

- 1804 08330Document6 pages1804 08330Nhat VienNo ratings yet

- S/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDocument75 pagesS/4HANA Configuration Case Phase I - Handbook: Product Motivation PrerequisitesDianPramana100% (2)

- Section A-A: Quaife Design & Development. Drg. No. Used inDocument1 pageSection A-A: Quaife Design & Development. Drg. No. Used instefan.vince536No ratings yet

- Appian QuestionsDocument2 pagesAppian QuestionsAnuragNo ratings yet

- Membrane Desalination and Water ReuseDocument484 pagesMembrane Desalination and Water ReuseHassanKMNo ratings yet

- Manual FOR Whirling of Shaft Apparatus: WWW - Elshaddaiengineering.inDocument3 pagesManual FOR Whirling of Shaft Apparatus: WWW - Elshaddaiengineering.insindhu elshaddaienggNo ratings yet

- The Central Excise Act, 1944Document10 pagesThe Central Excise Act, 1944sandeep1318100% (3)

- General Exhaust (Dilution) Ventilation Systems General ExhaustDocument5 pagesGeneral Exhaust (Dilution) Ventilation Systems General ExhaustmadbakingNo ratings yet

- Recruitment AdvertisementDocument1 pageRecruitment AdvertisementDeepanjan MandalNo ratings yet