Professional Documents

Culture Documents

Spun Pile - Further Instruction

Spun Pile - Further Instruction

Uploaded by

Mark Fash0 ratings0% found this document useful (0 votes)

85 views1 pageThe document provides instructions for repairing structure and maintenance to a jetty at Pandan Terminal. The contractor will clean the circumference of a pile cap to inspect for cracks, and clean and route identified fissures. If no cracks are found deeper than 0.1mm after routing, the contractor will take photos and seal the surface. If deeper cracks appear, the contractor will mark, photograph, and seal the cracks before sealing the surface.

Original Description:

Spun Pile Repair Works

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides instructions for repairing structure and maintenance to a jetty at Pandan Terminal. The contractor will clean the circumference of a pile cap to inspect for cracks, and clean and route identified fissures. If no cracks are found deeper than 0.1mm after routing, the contractor will take photos and seal the surface. If deeper cracks appear, the contractor will mark, photograph, and seal the cracks before sealing the surface.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

85 views1 pageSpun Pile - Further Instruction

Spun Pile - Further Instruction

Uploaded by

Mark FashThe document provides instructions for repairing structure and maintenance to a jetty at Pandan Terminal. The contractor will clean the circumference of a pile cap to inspect for cracks, and clean and route identified fissures. If no cracks are found deeper than 0.1mm after routing, the contractor will take photos and seal the surface. If deeper cracks appear, the contractor will mark, photograph, and seal the cracks before sealing the surface.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Structure Repair & Maintenance to Jetty at Pandan

PROJECT TITLE REPORT NO.

Terminal

CLIENT Shell Eastern Petroleum Pte Ltd DATE

JOB NO. P03P4159 DRAWING NO. Please find the attached

EQUIPMENT NO. Spun Pile Crack Repair - C117 East AREA Shell Jetty Walkway @ Pile Cap 63

Contractor will clean

the circumference at

500mm below pile cap

500mm bottom. Contractor to

report to the

consultant/engineer if

found any visible crack.

Contractor to clean the surface of the two

This is the surface fissures till the level of +1.2mCD, which is

fissure/crack, likely to be about ~1.5m from the bottom of the pile cap.

the washout of cement

along both the formwork Contractor to rout alone the two fissures with

joints when spinning. max depth of 10mm. After routing, the

This was reported on all contractor to exam the routed surface

the piles during the last carefully if any crack/fissure.

repair of Shell Pandan

a) If not finding any crack/fissure, the

contractor to take photos evident and mark

on drawing "no further crack or deeper crack

1. Spun Pile C117E- Before Cleaning 2. Spun Pile C117E- After Cleaning & Cutting

less than 0.1mm wide for spun pile Pxxx"

The contractor to seal back the routed

surface with the approved epoxy.

b) if visible crack was found beyond the

routing depth, the contractor to highlight the

crack line with marker and take photos

evident. Contractor to draw the crack on

sketch, also to indicate the width & length.

The contractor to seal the crack and seal

back the routed surface with the approved

epoxy.

3. Spun Pile C117E- After Cleaning & Cutting - No real crack 4. Spun Pile C117E- Cutting Wider - No real crack

5. Spun Pile C117E- Cutting Wider cleaned with water - No real crack

COMPLETED BY CONTRACTOR MAIN CONTRACTOR CLIENT THIRD PARTY

COMPANY MIGHTY ROTARY/E9000 SEPL

SIGNATURE

NAME

DATE

You might also like

- Group 17 Body, Doors and WindowsDocument57 pagesGroup 17 Body, Doors and Windowsapi-3802918100% (3)

- Site Installation Manual: Aco DrainDocument22 pagesSite Installation Manual: Aco Draindonaji123No ratings yet

- Tips & Installation InstructionsDocument2 pagesTips & Installation InstructionsAthul T.NNo ratings yet

- Spe 96810 MS PDocument10 pagesSpe 96810 MS PSlim.BNo ratings yet

- Temp Fencing & GateDocument12 pagesTemp Fencing & GateMark Fash0% (1)

- Joska Muchelle WambuaDocument2 pagesJoska Muchelle Wambuamutisoshadrack082No ratings yet

- Item Description Unit Qty Rate Amount Proposed Piggery Project in Busuju Bill No 1. Element: Preliminaries Tools and PlantsDocument8 pagesItem Description Unit Qty Rate Amount Proposed Piggery Project in Busuju Bill No 1. Element: Preliminaries Tools and PlantsRucho ConstructioncompanyNo ratings yet

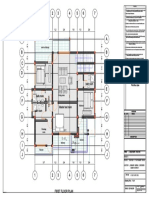

- First FloorDocument1 pageFirst FloorMBONYUMUVUNYI AnatholeNo ratings yet

- Daily Report 26-11-2021Document7 pagesDaily Report 26-11-2021Ahmed MohammedNo ratings yet

- Smartcare Damp Proof Ultra PDFDocument2 pagesSmartcare Damp Proof Ultra PDFramachandran_chem100% (1)

- Ekene Semi Detached StructuralDocument18 pagesEkene Semi Detached StructuralNwachukwu PrinceNo ratings yet

- SH-12 TankDocument1 pageSH-12 Tankdigvijay singhNo ratings yet

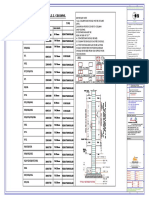

- Details of RCC ColumnDocument1 pageDetails of RCC ColumnRavi Kumar RaiNo ratings yet

- C10487-04 Revb PDFDocument1 pageC10487-04 Revb PDFBharat AryalNo ratings yet

- C10487-04 Revb PDFDocument1 pageC10487-04 Revb PDFjinesh shahNo ratings yet

- C10487-04 Revb PDFDocument1 pageC10487-04 Revb PDFjinesh shahNo ratings yet

- 12 Phase 1: Front ViewDocument1 page12 Phase 1: Front ViewMAXWELL ERIPONNo ratings yet

- Avions Marcel Dassault: Fan Jet Falcon Maintenance ManualDocument4 pagesAvions Marcel Dassault: Fan Jet Falcon Maintenance ManualSergio VázquezNo ratings yet

- 33-11KV SUBSTATION BoQDocument37 pages33-11KV SUBSTATION BoQRicky ChangNo ratings yet

- Method Statement For Repairs - Repair Procedure: Surface PreparationDocument3 pagesMethod Statement For Repairs - Repair Procedure: Surface PreparationAnonymous cG5MyHMNo ratings yet

- Proofex Engage Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument3 pagesProofex Engage Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureJyoti Shree NepalNo ratings yet

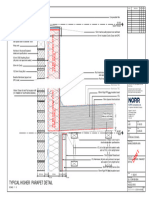

- Bbasn NRR A1 ZZ DR A 00309 Typical Higher Parapet DetailDocument1 pageBbasn NRR A1 ZZ DR A 00309 Typical Higher Parapet DetailNiemNo ratings yet

- Investigation ReportDocument9 pagesInvestigation ReportAditya PrajasNo ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- Annex BDocument3 pagesAnnex BNaveed KhanNo ratings yet

- Method Statement For Concrete RepairingDocument13 pagesMethod Statement For Concrete RepairingMihirdutta100% (4)

- Renderoc S: Constructive SolutionsDocument2 pagesRenderoc S: Constructive SolutionsMuhammad.FaisalNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- CP 300 (A) - QCP-007 Repair of Concrete Structures Rev. 03Document10 pagesCP 300 (A) - QCP-007 Repair of Concrete Structures Rev. 03tarekNo ratings yet

- FBS Ii enDocument10 pagesFBS Ii enunsalNo ratings yet

- Highway Structure Drawings 4Document1 pageHighway Structure Drawings 4Martin ScottNo ratings yet

- Mdrs Harti Hostel All Lintel & Staircase (1) - Model3Document1 pageMdrs Harti Hostel All Lintel & Staircase (1) - Model3sishelpolicepatilNo ratings yet

- AE RemarkDocument7 pagesAE Remarklnmtlkotanh27No ratings yet

- 4012 Plans and NotesDocument9 pages4012 Plans and Notesamit kumawatNo ratings yet

- RENDEROC-S - Merged SDSDocument11 pagesRENDEROC-S - Merged SDSKannan Sasidharan PillaiNo ratings yet

- Construction Methodology - Access Hole - Rev03Document4 pagesConstruction Methodology - Access Hole - Rev03Rommel AntonioNo ratings yet

- Cement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDocument8 pagesCement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDanish KhanNo ratings yet

- Mason E0010Document24 pagesMason E0010SandeepNo ratings yet

- Conbextra EP40 UAEDocument2 pagesConbextra EP40 UAEjasonNo ratings yet

- Excavations and TrenchingDocument12 pagesExcavations and TrenchingtrishNo ratings yet

- Saltel Patch Successfully Restores CasingDocument1 pageSaltel Patch Successfully Restores CasingAbdulrhman Nabil ShahinNo ratings yet

- Design and Performance of A 15m Deep Excavation For A Wagon TipplerDocument5 pagesDesign and Performance of A 15m Deep Excavation For A Wagon TipplerlingamkumarNo ratings yet

- Apex Duracast Pebbletex TDSDocument2 pagesApex Duracast Pebbletex TDSsudhakarrrrrrNo ratings yet

- Surface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1Document1 pageSurface Excavation & Rock Support General Notes: AFRY.4649.00.102 P1அம்ரு சாந்திவேலுNo ratings yet

- Fig. 10-8 Fig. 10-10: Pipe End As A Pipe Cutter Leaves ItDocument7 pagesFig. 10-8 Fig. 10-10: Pipe End As A Pipe Cutter Leaves ItWilly UioNo ratings yet

- HR 7Document1 pageHR 7MAXWELL ERIPONNo ratings yet

- 33KV PTDocument1 page33KV PTRushi VariaNo ratings yet

- CPWD Cube SpecificationDocument2 pagesCPWD Cube SpecificationkumarchemNo ratings yet

- Footing ChecklistDocument3 pagesFooting ChecklistvasudevumNo ratings yet

- Repair of Concrete Pavement - RestorationDocument2 pagesRepair of Concrete Pavement - RestorationRana MahatoNo ratings yet

- Mud Hopper (K1050-20-41) User ManualDocument4 pagesMud Hopper (K1050-20-41) User ManualTony100% (1)

- Spe 11499 MsDocument8 pagesSpe 11499 Msjavidan ibrahimliNo ratings yet

- Renderoc HS PDFDocument2 pagesRenderoc HS PDFMuhammed KunnappillyNo ratings yet

- Concete Work RMC PumpDocument3 pagesConcete Work RMC PumpKoneti JanardhanaraoNo ratings yet

- Technical Proposal: (Application of Belzona Tank Preformed Patch Repair)Document8 pagesTechnical Proposal: (Application of Belzona Tank Preformed Patch Repair)Bambang IrawanNo ratings yet

- Apex Duracast FinetexDocument2 pagesApex Duracast FinetexKeyur PatelNo ratings yet

- Single Part DrawingsDocument65 pagesSingle Part DrawingsMAXWELL ERIPONNo ratings yet

- No Change: Method Statement Page 1Document6 pagesNo Change: Method Statement Page 1Shaun WongNo ratings yet

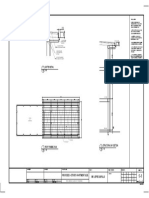

- Gutter Detail: 3" PVC Pipe W/wire Basket Strainer Down SpoutDocument1 pageGutter Detail: 3" PVC Pipe W/wire Basket Strainer Down SpoutBj GutierrezNo ratings yet

- Method StatementDocument16 pagesMethod StatementMark FashNo ratings yet

- Master Schedule, Manpower & Equipment ListDocument21 pagesMaster Schedule, Manpower & Equipment ListMark Fash100% (2)

- Summary From SI ReportDocument1 pageSummary From SI ReportMark FashNo ratings yet

- Seo Services in DelhiDocument9 pagesSeo Services in DelhiSunil KumarNo ratings yet

- Switching Theory and Logic DesignDocument2 pagesSwitching Theory and Logic DesignManjunath BadigerNo ratings yet

- TSL3223 Eby Asyrul Bin Majid Task1Document5 pagesTSL3223 Eby Asyrul Bin Majid Task1Eby AsyrulNo ratings yet

- #SyallabusDocument33 pages#SyallabusSandeep B MNo ratings yet

- Belt Conveyour Safetyv2Document24 pagesBelt Conveyour Safetyv2Luis MecNo ratings yet

- Catalogue Phonics2017Document32 pagesCatalogue Phonics2017jNo ratings yet

- Introduction To Naming and Drawing of Carboxylic Acids and EsterDocument38 pagesIntroduction To Naming and Drawing of Carboxylic Acids and Esterkartika.pranotoNo ratings yet

- DS PD Diagnostics System PD-TaD 62 BAURDocument4 pagesDS PD Diagnostics System PD-TaD 62 BAURAdhy Prastyo AfifudinNo ratings yet

- Champschicken Com Seocheck 2020 12 17Document17 pagesChampschicken Com Seocheck 2020 12 17Dayanand baraNo ratings yet

- Rightline 176529 Parts ManualDocument8 pagesRightline 176529 Parts ManualSean CarvalhoNo ratings yet

- Oblicon Reviewer Q and ADocument13 pagesOblicon Reviewer Q and ARussel SirotNo ratings yet

- Week 9Document10 pagesWeek 9shella mar barcialNo ratings yet

- Lab 27Document3 pagesLab 27api-239505062No ratings yet

- 33 05 13 Manholes and Structures 10Document4 pages33 05 13 Manholes and Structures 10salamNo ratings yet

- OpAudCh02 CBET 01 501E ToraldeMa - KristineE.Document4 pagesOpAudCh02 CBET 01 501E ToraldeMa - KristineE.Kristine Esplana ToraldeNo ratings yet

- Development of 22-kV Distribution Systems and Switchgear: Shuichi Kikukawa Kenji Tsuchiya Satoru Kajiwara Akira TakahamaDocument7 pagesDevelopment of 22-kV Distribution Systems and Switchgear: Shuichi Kikukawa Kenji Tsuchiya Satoru Kajiwara Akira TakahamaDave ChaudhuryNo ratings yet

- 66 - Series Singer 66 Sewing Machine ManualDocument16 pages66 - Series Singer 66 Sewing Machine ManualCynthia PorterNo ratings yet

- Num MethodsDocument160 pagesNum Methodsnoreply_t2350% (1)

- CC Pinwheel BWDocument1 pageCC Pinwheel BWTariq ZuhlufNo ratings yet

- Bacteria KSUDocument2 pagesBacteria KSUsentryx1No ratings yet

- Present Perfect LINGODADocument31 pagesPresent Perfect LINGODAThayrone NeryNo ratings yet

- BOQ Cum Price Schedule (Annexure-I)Document22 pagesBOQ Cum Price Schedule (Annexure-I)Akd Deshmukh100% (1)

- SRS Template ExampleDocument16 pagesSRS Template ExampleabcNo ratings yet

- Case Study On Akshaya Patra Group-1Document9 pagesCase Study On Akshaya Patra Group-1swaroopNo ratings yet

- Karoora 2012 L-3 (2013)Document9 pagesKaroora 2012 L-3 (2013)FiraolNo ratings yet

- Lesson PlanDocument2 pagesLesson PlanLUZ SELENE OLIVARES BONILLANo ratings yet

- Msds Promois W-32u 120808Document3 pagesMsds Promois W-32u 120808tia_utami23No ratings yet

- UntitledDocument292 pagesUntitledD17CQAT01-N LE THANH TUANNo ratings yet

- Disadvantages of Varience AnalysisDocument2 pagesDisadvantages of Varience AnalysisAditi KediaNo ratings yet

- Workers of The World UNITE!Document2 pagesWorkers of The World UNITE!Dominique A.M. Juntado100% (1)