Professional Documents

Culture Documents

TDS Optibent-1008 en

TDS Optibent-1008 en

Uploaded by

Alan SantosCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual Hc-V268e HC-V268E 60af8211029cbDocument49 pagesManual Hc-V268e HC-V268E 60af8211029cbRoland BokorNo ratings yet

- MKT Marunda Center ProfileDocument47 pagesMKT Marunda Center ProfileMuhammad AbidinNo ratings yet

- Meeting Minutes of 17th Departmental MeetingDocument3 pagesMeeting Minutes of 17th Departmental Meetingmyousafzai67No ratings yet

- The Paper Airplane GameDocument5 pagesThe Paper Airplane GamegoonygoogooNo ratings yet

- Thesis Statement About Business AdministrationDocument4 pagesThesis Statement About Business Administrationokxyghxff100% (2)

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Hamsters and Their OffspringDocument3 pagesHamsters and Their OffspringClaire FarronNo ratings yet

- FCE Exam 3 ListeningDocument6 pagesFCE Exam 3 ListeningSaul MendozaNo ratings yet

- Self-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalDocument7 pagesSelf-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2014 Elec HD FS CKTruck 100713 ChevroletDocument247 pages2014 Elec HD FS CKTruck 100713 ChevroletREINALDO GONZALEZNo ratings yet

- Internal Combustion Engines - R. K. RajputDocument352 pagesInternal Combustion Engines - R. K. RajputmeetbalakumarNo ratings yet

- Troy-Bilt 019191 PDFDocument34 pagesTroy-Bilt 019191 PDFSteven W. NinichuckNo ratings yet

- Investigative Report Writing and PresentationDocument25 pagesInvestigative Report Writing and PresentationShy OreoNo ratings yet

- Scrap Specifications CircularDocument57 pagesScrap Specifications Circulargiám địnhNo ratings yet

- A. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGDocument143 pagesA. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGRyan Togonon100% (1)

- Vehicle ChecklistDocument1 pageVehicle ChecklistAbdus SamadNo ratings yet

- ThesisDocument29 pagesThesisJeliah Shello Sebastian ChuaNo ratings yet

- SW-TS40T Series Sub-Miniature Toggle Switches: Straight Type - Part Numbering GuideDocument4 pagesSW-TS40T Series Sub-Miniature Toggle Switches: Straight Type - Part Numbering GuideVALTERNo ratings yet

- Job Shop Scheduling Vs Flow Shop SchedulingDocument11 pagesJob Shop Scheduling Vs Flow Shop SchedulingMatthew MhlongoNo ratings yet

- Diana Rodríguez - Habilidades Ingles Grados Once PDFDocument4 pagesDiana Rodríguez - Habilidades Ingles Grados Once PDFJuan Felipe Pacheco SanchezNo ratings yet

- Hierarchical CADNet Learning From B-Reps For Machining FeatureDocument16 pagesHierarchical CADNet Learning From B-Reps For Machining FeatureJonatas PietrNo ratings yet

- Kingair 350i Wiring - 21 Air ConditionedDocument68 pagesKingair 350i Wiring - 21 Air ConditionedLaboratorio01 AvionicsNo ratings yet

- Le Wagon FullstackDocument23 pagesLe Wagon FullstackClara VaninaNo ratings yet

- Database Connectivity in PHP: PHP Tutorials by Vineet Kumar SainiDocument3 pagesDatabase Connectivity in PHP: PHP Tutorials by Vineet Kumar SainishamagondalNo ratings yet

- Lohia (Democracy)Document11 pagesLohia (Democracy)Madhu SharmaNo ratings yet

- Microprocessor Book PDFDocument4 pagesMicroprocessor Book PDFJagan Eashwar0% (4)

- Ancamine Teta UsDocument2 pagesAncamine Teta UssimphiweNo ratings yet

- THZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionDocument4 pagesTHZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionGreeni MarcoNo ratings yet

- Komatsu Views 2014 No.31 (Ing)Document3 pagesKomatsu Views 2014 No.31 (Ing)Carlos Alfredo LauraNo ratings yet

- Coronel, Kent Kenji B. Sts Final Exam Sat 4-7pmDocument7 pagesCoronel, Kent Kenji B. Sts Final Exam Sat 4-7pmKent CoronelNo ratings yet

TDS Optibent-1008 en

TDS Optibent-1008 en

Uploaded by

Alan SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS Optibent-1008 en

TDS Optibent-1008 en

Uploaded by

Alan SantosCopyright:

Available Formats

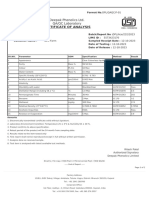

OPTIBENT-1008

Data Sheet

Issue 07/2016

OPTIBENT-1008

High-quality, powdered rheology additive based on an organically modified phyllosilicate

for aqueous, hydraulically hardening pre-mix mortars to increase the anti-sagging properties

of systems that are applied thinly.

Product Data

Composition

Modified phyllosilicate

Typical Properties

The values indicated in this data sheet describe typical properties and do not constitute specification limits.

pH value (2 %): approx. 9-11

Bulk density: 600-750 kg/m³

Moisture content: max. 14 %

Supplied as: free-flowing, beige powder

Food Contact Legal Status

For the current food contact legal status, please contact our product safety department or visit www.byk.com

for further information.

Storage and Transportation

The product is slightly hygroscopic and should be transported and stored dry in the unopened original container

at temperatures between 0 °C and 30 °C.

Applications

Construction industry

Special Features and Benefits

OPTIBENT-1008 significantly reduces the adhesiveness of mineral binder systems, particularly in polymer-modified

systems. By forming a good flow limit, the anti-sagging properties are increased and, at the same time, the

processing properties under shear stress are improved. In comparison with standard organic rheology additives,

there has less of an impact on the setting process.

Recommended Use

OPTIBENT-1008 is suitable for aqueous mineral binder systems, preferably for systems that are applied in thin

layers.

ETICS/adhesives and reinforcement mortars X

Cementitious base coats Y

X especially recommended Y recommended

OPTIBENT-1008

Data Sheet

Issue 07/2016

Recommended Levels

0.1-0.3 % additive (as supplied) based upon the total formulation, depending on the properties of the

formulation to be achieved.

The above recommended levels can be used for orientation. Optimal levels are determined through a

series of laboratory tests.

Incorporation and Processing Instructions

OPTIBENT-1008 is hydrophilic and can be added as supplied to the dry mix mortar formulation.

BYK-Chemie GmbH ACTAL®, ADD-MAX®, ADD-VANCE®, ADJUST®, ADVITROL®, ANTI-TERRA®, AQUACER®, AQUAMAT®, AQUATIX®, BENTOLITE®, BYK®, BYK®-DYNWET®,

P.O. Box 10 02 45 BYK®-SILCLEAN®, BYKANOL®, BYKETOL®, BYKJET®, BYKO2BLOCK®, BYKOPLAST®, BYKUMEN®, CARBOBYK®, CERACOL®, CERAFAK®, CERAFLOUR®,

46462 Wesel CERAMAT®, CERATIX®, CLAYTONE®, CLOISITE®, DISPERBYK®, DISPERPLAST®, FULACOLOR®, FULCAT®, GARAMITE®, GELWHITE®, HORDAMER®, LACTIMON®,

Germany LAPONITE®, MINERAL COLLOID®, MINERPOL®, NANOBYK®, OPTIBENT®, OPTIFLO®, OPTIGEL®, PAPERBYK®, PERMONT®, PRIEX®, PURE THIX®, RHEOCIN®,

Tel +49 281 670-0 RHEOTIX®, SCONA®, SILBYK®, TIXOGEL®, VISCOBYK® and Y 25® are registered trademarks of the BYK group.

Fax +49 281 65735

The information herein is based on our present knowledge and experience. The information merely describes the properties of our products but no guarantee

info@byk.com of properties in the legal sense shall be implied. We recommend testing our products as to their suitability for your envisaged purpose prior to use. No warranties

www.byk.com of any kind, either express or implied, including warranties of merchantability or fitness for a particular purpose, are made regarding any products mentioned

herein and data or information set forth, or that such products, data or information may be used without infringing intellectual property rights of third parties.

We reserve the right to make any changes according to technological progress or further developments.

This issue replaces all previous versions – Printed in Germany

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual Hc-V268e HC-V268E 60af8211029cbDocument49 pagesManual Hc-V268e HC-V268E 60af8211029cbRoland BokorNo ratings yet

- MKT Marunda Center ProfileDocument47 pagesMKT Marunda Center ProfileMuhammad AbidinNo ratings yet

- Meeting Minutes of 17th Departmental MeetingDocument3 pagesMeeting Minutes of 17th Departmental Meetingmyousafzai67No ratings yet

- The Paper Airplane GameDocument5 pagesThe Paper Airplane GamegoonygoogooNo ratings yet

- Thesis Statement About Business AdministrationDocument4 pagesThesis Statement About Business Administrationokxyghxff100% (2)

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Hamsters and Their OffspringDocument3 pagesHamsters and Their OffspringClaire FarronNo ratings yet

- FCE Exam 3 ListeningDocument6 pagesFCE Exam 3 ListeningSaul MendozaNo ratings yet

- Self-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalDocument7 pagesSelf-Efficacy Mediated Spiritual Leadership On Citizenship Behavior Towards The Environment of Employees at Harapan Keluarga HospitalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 2014 Elec HD FS CKTruck 100713 ChevroletDocument247 pages2014 Elec HD FS CKTruck 100713 ChevroletREINALDO GONZALEZNo ratings yet

- Internal Combustion Engines - R. K. RajputDocument352 pagesInternal Combustion Engines - R. K. RajputmeetbalakumarNo ratings yet

- Troy-Bilt 019191 PDFDocument34 pagesTroy-Bilt 019191 PDFSteven W. NinichuckNo ratings yet

- Investigative Report Writing and PresentationDocument25 pagesInvestigative Report Writing and PresentationShy OreoNo ratings yet

- Scrap Specifications CircularDocument57 pagesScrap Specifications Circulargiám địnhNo ratings yet

- A. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGDocument143 pagesA. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGRyan Togonon100% (1)

- Vehicle ChecklistDocument1 pageVehicle ChecklistAbdus SamadNo ratings yet

- ThesisDocument29 pagesThesisJeliah Shello Sebastian ChuaNo ratings yet

- SW-TS40T Series Sub-Miniature Toggle Switches: Straight Type - Part Numbering GuideDocument4 pagesSW-TS40T Series Sub-Miniature Toggle Switches: Straight Type - Part Numbering GuideVALTERNo ratings yet

- Job Shop Scheduling Vs Flow Shop SchedulingDocument11 pagesJob Shop Scheduling Vs Flow Shop SchedulingMatthew MhlongoNo ratings yet

- Diana Rodríguez - Habilidades Ingles Grados Once PDFDocument4 pagesDiana Rodríguez - Habilidades Ingles Grados Once PDFJuan Felipe Pacheco SanchezNo ratings yet

- Hierarchical CADNet Learning From B-Reps For Machining FeatureDocument16 pagesHierarchical CADNet Learning From B-Reps For Machining FeatureJonatas PietrNo ratings yet

- Kingair 350i Wiring - 21 Air ConditionedDocument68 pagesKingair 350i Wiring - 21 Air ConditionedLaboratorio01 AvionicsNo ratings yet

- Le Wagon FullstackDocument23 pagesLe Wagon FullstackClara VaninaNo ratings yet

- Database Connectivity in PHP: PHP Tutorials by Vineet Kumar SainiDocument3 pagesDatabase Connectivity in PHP: PHP Tutorials by Vineet Kumar SainishamagondalNo ratings yet

- Lohia (Democracy)Document11 pagesLohia (Democracy)Madhu SharmaNo ratings yet

- Microprocessor Book PDFDocument4 pagesMicroprocessor Book PDFJagan Eashwar0% (4)

- Ancamine Teta UsDocument2 pagesAncamine Teta UssimphiweNo ratings yet

- THZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionDocument4 pagesTHZ Rectangular Slitted Microstrip Patch Antenna Design For Biomedical Applications, Security Purposes & Drug DetectionGreeni MarcoNo ratings yet

- Komatsu Views 2014 No.31 (Ing)Document3 pagesKomatsu Views 2014 No.31 (Ing)Carlos Alfredo LauraNo ratings yet

- Coronel, Kent Kenji B. Sts Final Exam Sat 4-7pmDocument7 pagesCoronel, Kent Kenji B. Sts Final Exam Sat 4-7pmKent CoronelNo ratings yet