Professional Documents

Culture Documents

VMH Anchor

VMH Anchor

Uploaded by

mohamed rafiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VMH Anchor

VMH Anchor

Uploaded by

mohamed rafiCopyright:

Available Formats

Design office: *

Person in charge: *

Construction project:

Project number:

Position: Date: 22/12/2019

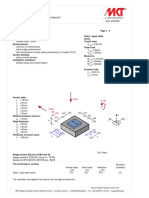

Input data: Page 1 / 4

Concrete: Static / quasi-static

cracked concrete action

strength class: C35/45 Tensile load:

long term / short term temperature ≤ 50/80 °C Nz,Sd = 0.00 kN

Reinforcement: Shear load:

normal or no reinforcement Vx,Sd = 0.00 kN

without edge reinforcement Vy,Sd = 6.79 kN

Anchor bending:

Moments:

without anchor bending

Mx,Sd = -0.51 kNm

Installation conditions:

My,Sd = 0.00 kNm

hammer-drilled hole

Mz,Sd = 0.00 kNm

dry drill hole

filled annular gap

Eccentric load

e x = 0.0 mm

e y = 0.0 mm

Anchor plate:

x = 100 mm

y = 100 mm 0.51

lx1 = 50 mm

lx2 = 50 mm

ly1 = 50 mm

ly2 = 50 mm

6.79

Edge distances: z

without influence

Thickness of anchor base:

h = 200 mm y x

h 1

ly 1 lx 2

ly 2 lx 1

y x

Injection System VMH + VM-A A4 (70) M12 hef = 70mm

Design according to EOTA Technical Report TR 029 + TR 055

Assessment ETA-17/0716: MKT VMH

The anchorage is verified. Boundary

Tension loads Shear loads Interaction conditions:

[ kN, kNm ]

bN [%] bV [%] bN,V[%]

Static / quasi-static action 76.3 35.3 87.6 OK

The calculation only applies if the notes on the last page are observed.

Anchor Design Program Version 4.43

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

Design office: *

Person in charge: *

Construction project:

Project number:

Position: Date: 22/12/2019

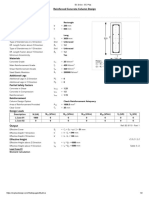

Injection System VMH + VM-A A4 (70) M12 hef = 70mm Page 2 / 4

Assessment ETA-17/0716: MKT VMH

Required proofs for tension loads

Anchor loads

Anchor 1

NSd [kN] 11.48

Proof steel failure

NhSd ≤ NRk,s / gMs = NRd,s Utilisation:

11.48 ≤ 59.00 / 1.87 = 31.55 36.4%

Proof of combined pull-out and concrete cone failure

NgSd ≤ NRk,p / gMp = NRd,p Utilisation:

11.48 ≤ 22.59 / 1.50 = 15.06 76.3%

o

N Rk,p YC (C35/45) YA,Np Ys,Np Yg,Np Yec,Np Yre,Np

21.11 kN 1.07 1.00 1.00 1.00 1.00 1.00

o

Ap,N

2

A p,N

2

d hef tRk,cr 2 tRk,ucr 2 ccr,Np ec1,Np ec2,Np

44100mm 44100mm 12.0mm 70mm 8.0N/mm 16.0N/mm 105.0mm 0.0mm 0.0mm

Proof concrete cone failure

NgSd ≤ NRk,c / gMc = NRd,c Utilisation:

11.48 ≤ 28.29 / 1.50 = 18.86 60.9%

o

N Rk,c YA,c,N Ys,N Yre,N Yec,N

28.29 kN 1.00 1.00 1.00 1.00

o

k1 Ac,N A c,N hef fck,cube ccr,N ec1,N ec2,N

2 2 2

7.2 44100mm 44100mm 70mm 45N/mm 105.0mm 0.0mm 0.0mm

Proof splitting failure

No proof of splitting failure is required because the following condition is fulfilled:

cx1,x2,y1,y2≥1,2 ccr,sp and: h≥2 hmin

ccr,sp hmin

70.0 mm 100 mm

Anchor Design Program Version 4.43

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

Design office: *

Person in charge: *

Construction project:

Project number:

Position: Date: 22/12/2019

Injection System VMH + VM-A A4 (70) M12 hef = 70mm Page 3 / 4

Assessment ETA-17/0716: MKT VMH

Required proofs for shear loads

Anchor loads

Anchor 1

VSd [kN] 6.79

Vx,Sd [kN] 0.00

Vy,Sd [kN] 6.79

Proof steel failure without lever arm

VhSd ≤ VRk,s / gMs = VRd,s Utilisation:

6.79 ≤ 30.00 / 1.56 = 19.23 35.3%

Proof concrete pryout failure

V1Sd ≤ VRk,cp / gMc = VRd,cp Utilisation:

6.79 ≤ 45.18 / 1.50 = 30.12 22.5%

o

N Rk,p YC (C35/45) YA,p,N Ys,Np Yg,Np Yre,Np Yec,Np k

21.11 kN 1.07 1.00 1.00 1.00 1.00 1.00 2.00

o

Ap,N

2

A p,N

2

d hef tRk,cr 2 tRk,ucr 2 ccr,Np ec1,V ec2,V

44100mm 44100mm 12.0mm 70mm 8.0N/mm 16.0N/mm 105.0mm 0.0mm 0.0mm

Proof concrete edge failure (most unfavourable edge)

No proof of concrete edge failure is required because one of the following conditions is fulfilled:

a) c ≥ 10hef and c ≥ 60d

b) No shear load acts in direction or parallel to the concrete edge.

hef d

70 mm 12 mm

Interaction, combined load in most unfavourable case

bNa + bVa ≤ 1,0 Utilisation:

0.761.5 + 0.351.5 = 0.88 ≤ 1,0 87.6%

Anchor Design Program Version 4.43

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

Design office: *

Person in charge: *

Construction project:

Project number:

Position: Date: 22/12/2019

Injection System VMH + VM-A A4 (70) M12 hef = 70mm Page 4 / 4

Assessment ETA-17/0716: MKT VMH

Installation parameters

Thread M = 12 mm

Diameter of drill hole d0 = 14 mm

Depth of drill hole h0(1) = 70 mm

Effective anchorage depth hef = 70 mm

Installation torque Tinst ≤ 40 Nm

Width across nut SW = 19 mm

Minimum thickness of anchor base hmin = 100 mm

Diameter of clearance hole in the fixture

· pre-installation df ≤ 14 mm

· through fastening *) df ≤ 16 mm

*) filled annular gap

Remarks

The anchors are without influence of edge distance, if: c ≥ max ( 10 hef ; 60 d )

If the diameter df of the clearance hole does not correspond with the specifications in [1], Table 6.1,

or with the design of slotted holes, follow the notes in [1], chapter 1.1.

A filled annular gap can be made with a filling washer, which shall be used instead of

the supplied wascher. In this case a reduced fixture thickness is to be observed.

A high-strength mortar with compressive strength ≥ 40N/mm² shall be used for filling.

(VMZ, VMH or VMU plus)

The design is based on the assumption that the anchor plate remains flat under the acting

forces.

The proof of the capacity of the anchor base component shall be shown according to chapter 7 in [1].

The temperature ranges are specified in [2].

Cleaning with compressed air according to installation instructions

The selected anchor can be installed deeper to reduce the fixture thickness. Therfore the borehole shall

be drilled correspondingly deeper and the minimum thickness of anchor base must be checked.

The minimum thickness of the concrete member hmin increases by this deeper drilled length.

[1] EOTA Technical Report TR 029

[2] Assessment ETA-17/0716: MKT VMH

Anchor Design Program Version 4.43

MKT Metall-Kunststoff-Technik GmbH & Co.KG | Auf dem Immel 2 | D-67685 Weilerbach | Tel.: +49 (0) 6374 / 9116-0 | support@mkt.de

You might also like

- Astm C578 PDFDocument7 pagesAstm C578 PDFraja qammar100% (2)

- APC Pallet RackingDocument10 pagesAPC Pallet Racking'Tianz Ituch Yneetz'No ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- PrePeg XC110 210g 450gDocument3 pagesPrePeg XC110 210g 450gPrakashChouhanNo ratings yet

- Schedule of Rates - RCD-Bihar-11th Edition-2016Document568 pagesSchedule of Rates - RCD-Bihar-11th Edition-2016sarsij81% (27)

- Aisi 4340Document3 pagesAisi 4340Ivan Santos100% (1)

- Petronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpDocument6 pagesPetronas/Ucc JV Malaysia Project: Painting and Coatings Epoxy-Phenolic Paint System (Inhibitive Primer) Ep-Pr/Ep/EpkhairurNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 5/8/2019ahmedebnnaderNo ratings yet

- B-Ket ReportDocument3 pagesB-Ket ReportMohammed AyeshNo ratings yet

- E-End Tocket ReportDocument4 pagesE-End Tocket ReportMohammed AyeshNo ratings yet

- C-End Bottom Bracket ReportDocument4 pagesC-End Bottom Bracket ReportMohammed AyeshNo ratings yet

- Design Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017Document3 pagesDesign Office: Person in Charge: Construction Project: Number: Position: Date: 1/26/2017jasekan.dcNo ratings yet

- A-Bottom-Bracket ReportDocument4 pagesA-Bottom-Bracket ReportMohammed AyeshNo ratings yet

- Design Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014Document4 pagesDesign Office: Invention Steel Industries Person in Charge: YJT Construction Project: Sqm-Nizwa Number: 0811 Position: Date: 7/22/2014yusuf_jtNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- Design Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Document4 pagesDesign Office: Person in Charge: Construction Project: Project Number: Position: Date: 9/20/2021Asaru DeenNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjectshoebNo ratings yet

- Veza1 2Document1 pageVeza1 2delkoskeNo ratings yet

- FCI-24-001 - C9 - 480x100 PlateDocument4 pagesFCI-24-001 - C9 - 480x100 PlateMukul DasNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DatadineshNo ratings yet

- Option-2 - Chemical Base AnchorDocument5 pagesOption-2 - Chemical Base AnchorvengadNo ratings yet

- Reinforced Concrete Column, Biaxial Bending: Structural Calculation, InputDocument40 pagesReinforced Concrete Column, Biaxial Bending: Structural Calculation, Inputask.kulkarni KulkarniNo ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- Calculation Sheet For Spit Anchors: ProjectDocument4 pagesCalculation Sheet For Spit Anchors: ProjecterezNo ratings yet

- Concrete: Input DataDocument4 pagesConcrete: Input DataARYANo ratings yet

- Welding CheckingDocument1 pageWelding Checkingxlw955597No ratings yet

- Practical Lesson 4Document11 pagesPractical Lesson 4marjory.dezNo ratings yet

- Circular Column2Document52 pagesCircular Column2BehroozNo ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- Type 2K CheckDocument7 pagesType 2K CheckAbdul basithNo ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- I. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Document30 pagesI. Material Bolt 8.8: Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023Anh KyNo ratings yet

- Base Plate CalculationDocument10 pagesBase Plate CalculationPradip NikamNo ratings yet

- MDESIGN Shaft, DIN 743 PDFDocument29 pagesMDESIGN Shaft, DIN 743 PDFSynbedNo ratings yet

- 01 FST Bs 300 Trans Top-1Document8 pages01 FST Bs 300 Trans Top-1avt premiumNo ratings yet

- Position 2 - HZA 4127Document10 pagesPosition 2 - HZA 4127mapuphamNo ratings yet

- 4.1.5.SP ConnectionDocument30 pages4.1.5.SP ConnectionAnh KyNo ratings yet

- Knoor - Bracing - Side Plate 2Document10 pagesKnoor - Bracing - Side Plate 2borceNo ratings yet

- Tests - Concrete - Apr 1, 2020Document7 pagesTests - Concrete - Apr 1, 2020Chris MedeirosNo ratings yet

- Position 1 - HTA-CE 5234Document10 pagesPosition 1 - HTA-CE 5234mapuphamNo ratings yet

- Gantry Grider FinalDocument8 pagesGantry Grider Finalasvenk309No ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument7 pages1 Input Data: WWW - Hilti.co - UkartomiNo ratings yet

- Calculation Sheet: Padeye Calculations LoadsDocument28 pagesCalculation Sheet: Padeye Calculations Loadsghoshamit4100% (5)

- 1 Input Data: Profis Anchor 2.5.2Document6 pages1 Input Data: Profis Anchor 2.5.2jasekanNo ratings yet

- Group 12 p1Document3 pagesGroup 12 p1SM WorldNo ratings yet

- Drafts - Concrete - 17 Jun 2021Document8 pagesDrafts - Concrete - 17 Jun 2021Mohammed HafizNo ratings yet

- Base Design (Blocks) - Commented On 26.09.2017Document4 pagesBase Design (Blocks) - Commented On 26.09.2017tsinghal_19No ratings yet

- 5.slab Design PDFDocument6 pages5.slab Design PDFepe civilNo ratings yet

- V F B D : Punching Shear Check (ACI 318RM-02)Document1 pageV F B D : Punching Shear Check (ACI 318RM-02)OktayNo ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document6 pages1 Input Data: Profis Anchor 2.6.0Shaikh Muhammad AteeqNo ratings yet

- Bearing Design Design NoteDocument4 pagesBearing Design Design Notearepelli madhuNo ratings yet

- Top EdgeDocument15 pagesTop EdgeZaido Al HalabiNo ratings yet

- Centre Post Base Hilti CalculationDocument10 pagesCentre Post Base Hilti CalculationKesavarajNo ratings yet

- 1 Input Data: WWW - Hilti.chDocument5 pages1 Input Data: WWW - Hilti.chkikorrasNo ratings yet

- BS8110 Beam With DeflectionDocument3 pagesBS8110 Beam With DeflectionFrederick TanNo ratings yet

- Drafts - Ecopark - Cracked Conc CaseDocument8 pagesDrafts - Ecopark - Cracked Conc CaseAniket InarkarNo ratings yet

- Design Example - Bonded AnchorsDocument6 pagesDesign Example - Bonded AnchorsmetropodikasNo ratings yet

- Reacties: ControleDocument26 pagesReacties: ControleAbdul basithNo ratings yet

- Drawing & Design GantryDocument27 pagesDrawing & Design Gantrysita ram doraNo ratings yet

- Rawlplug-HPTIIZF-20160 23122022Document7 pagesRawlplug-HPTIIZF-20160 23122022Freddie KooNo ratings yet

- Civil Structural CalculationsDocument2 pagesCivil Structural Calculations3d arch viewsNo ratings yet

- 1 Input Data: Profis Anchor 2.7.2Document6 pages1 Input Data: Profis Anchor 2.7.2ALPHYL BALASABASNo ratings yet

- Deflection Check For SlabDocument1 pageDeflection Check For Slabselvakumar sNo ratings yet

- Crystic Gelcoat 76 PA FRDocument3 pagesCrystic Gelcoat 76 PA FRmohamed rafiNo ratings yet

- Facade Issues - GRC ScreenDocument12 pagesFacade Issues - GRC Screenmohamed rafiNo ratings yet

- 150x100x4mm RHS - FinalDocument6 pages150x100x4mm RHS - Finalmohamed rafiNo ratings yet

- 200x100x6mm SHS Base Plate & Anchor ReportDocument6 pages200x100x6mm SHS Base Plate & Anchor Reportmohamed rafiNo ratings yet

- Injection System VMUplusDocument15 pagesInjection System VMUplusmohamed rafiNo ratings yet

- GRC Design and LoadsDocument4 pagesGRC Design and Loadsmohamed rafiNo ratings yet

- Conveyor Belt Tear DetectorDocument2 pagesConveyor Belt Tear DetectorKurniawan SJUNo ratings yet

- Flexible Lead-Free Piezo-/Ferroelectric Bi (Na K) Tio Ceramic Incorporated Pdms Polymer Composites For Energy Harvesting ApplicationDocument9 pagesFlexible Lead-Free Piezo-/Ferroelectric Bi (Na K) Tio Ceramic Incorporated Pdms Polymer Composites For Energy Harvesting ApplicationNeeraj PanwarNo ratings yet

- Cost API 650 Vs API 620Document3 pagesCost API 650 Vs API 620johnNo ratings yet

- KROVNE GREDE TEXST Autodesk Robot Structural Analysis Professional 2014Document6 pagesKROVNE GREDE TEXST Autodesk Robot Structural Analysis Professional 2014tovarNo ratings yet

- IV Validación de ProcesosDocument1,194 pagesIV Validación de Procesosalejandromfunes1749No ratings yet

- 2409 Steel and The Skyscraper City A Study On The Influence of Steel On The Design of Tall BuildingsDocument11 pages2409 Steel and The Skyscraper City A Study On The Influence of Steel On The Design of Tall BuildingsAndrea Perez PellegrinoNo ratings yet

- 1 Brushbond (M)Document3 pages1 Brushbond (M)marzuki0202No ratings yet

- Wall Mounted Folding Table Final PDFDocument1 pageWall Mounted Folding Table Final PDFDaniel BordeiNo ratings yet

- 2PM3N 2'x4': Features & SpecificationsDocument3 pages2PM3N 2'x4': Features & SpecificationsJesus Molina YllaNo ratings yet

- Samsung - Refrig - rs265 PDFDocument105 pagesSamsung - Refrig - rs265 PDFEdison Espinal0% (1)

- Bomba de Lodos Listado de PartesDocument59 pagesBomba de Lodos Listado de Partesjesus alfonso fragozo calderonNo ratings yet

- Compressor Station InspectionDocument8 pagesCompressor Station InspectionWelkin SkyNo ratings yet

- WOM ChokeDocument16 pagesWOM Chokegacm9875% (4)

- Class Xii PhysicsDocument4 pagesClass Xii PhysicsBiswajit BeheraNo ratings yet

- Boiler Construction Part-1Document130 pagesBoiler Construction Part-1tareas1978100% (2)

- Statutory Inspection and Maintenance Guide 04042014 0Document20 pagesStatutory Inspection and Maintenance Guide 04042014 0Sama88823No ratings yet

- Ce 388 - Fundamentals of Steel Design SPRING TERM 2013-2014: InstructorsDocument4 pagesCe 388 - Fundamentals of Steel Design SPRING TERM 2013-2014: InstructorspubaccNo ratings yet

- Wear of CeramicDocument3 pagesWear of CeramicGhaith MdljNo ratings yet

- Stainless Steel - WikipediaDocument14 pagesStainless Steel - Wikipediakirthi83No ratings yet

- 010 - Reliable Sprinkler K22.4 - HL22Document5 pages010 - Reliable Sprinkler K22.4 - HL22Andy QuynhNo ratings yet

- Esr-2948 Fas IiDocument14 pagesEsr-2948 Fas IiEduardo Antonio Duran SepulvedaNo ratings yet

- C18W10 - Drawing Issue Sheet 008Document6 pagesC18W10 - Drawing Issue Sheet 008Chung Him Joe ChanNo ratings yet

- High Performance Concrete Admixtures: The Euclid Chemical CompanyDocument10 pagesHigh Performance Concrete Admixtures: The Euclid Chemical Companyfhsn84No ratings yet

- (Sorbothane) SPGDocument32 pages(Sorbothane) SPGCristo PeregrínNo ratings yet