Professional Documents

Culture Documents

Badger Meter 200 Series Flow Sensor DS

Badger Meter 200 Series Flow Sensor DS

Uploaded by

Dale SapachCopyright:

Available Formats

You might also like

- Sage X3 - User Guide - HTG-Customer Search PDFDocument16 pagesSage X3 - User Guide - HTG-Customer Search PDFcaplusincNo ratings yet

- The Cadbury Code of Best Practices Had 19 RecommendationsDocument2 pagesThe Cadbury Code of Best Practices Had 19 RecommendationsAnam Shoaib82% (11)

- Badger 200 Series Installation & Operation ManualDocument16 pagesBadger 200 Series Installation & Operation ManualLeo MedinaNo ratings yet

- 3.sensor de CaudalDocument4 pages3.sensor de CaudalGONZALO ROJASNo ratings yet

- Hydro-Air Electromagnetic Flowmeter DatasheetDocument3 pagesHydro-Air Electromagnetic Flowmeter DatasheetCandrá WardayaNo ratings yet

- Lit 2468Document8 pagesLit 2468jashanpreet singhNo ratings yet

- Sanitary and Industrial RTDsDocument4 pagesSanitary and Industrial RTDsPrihartono Danan WingusNo ratings yet

- Birotor Plus Models B261, B264, B271, B274, B281, B284, B291Document2 pagesBirotor Plus Models B261, B264, B271, B274, B281, B284, B291Helver PachónNo ratings yet

- Yokogawa Model ISC40G Inductive Conductivity Sensor Data SheetDocument12 pagesYokogawa Model ISC40G Inductive Conductivity Sensor Data SheetTrEnD SeT vicky rioNo ratings yet

- Digital Pirani Vacuum GaugeDocument11 pagesDigital Pirani Vacuum GaugeSwagata BeraNo ratings yet

- TESIC P3297 Data SheetDocument4 pagesTESIC P3297 Data SheetLe Quang VuNo ratings yet

- Oti & Wti: Salient FeaturesDocument3 pagesOti & Wti: Salient FeaturesKarthik_Govind_6702No ratings yet

- Optiflux 4000: Electromagnetic Flow SensorDocument8 pagesOptiflux 4000: Electromagnetic Flow SensoryashNo ratings yet

- KROHNE Optiflux 2000R11Document8 pagesKROHNE Optiflux 2000R11janithNo ratings yet

- LaboomDocument4 pagesLaboomAndrei SpiridonNo ratings yet

- ls3200 Point Level SwitchDocument2 pagesls3200 Point Level Switchkhaldoun samiNo ratings yet

- Nixon Col Brochure 2003 PDFDocument32 pagesNixon Col Brochure 2003 PDFShiau FenNo ratings yet

- BC-AIS Flyer-0217 (1) AustraliaDocument2 pagesBC-AIS Flyer-0217 (1) AustraliaJose HuescaNo ratings yet

- Alibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputDocument2 pagesAlibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputrameshNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Mobrey 9000 Series Pressure TransmittersDocument6 pagesMobrey 9000 Series Pressure TransmittersCardoso MalacaoNo ratings yet

- Smart Sroat 1002 V12Document4 pagesSmart Sroat 1002 V12Vishnu PatidarNo ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- MC608 ManualDocument12 pagesMC608 Manualn_zeinounNo ratings yet

- PLT10-Liquid-Level-4-20mA-v3Document3 pagesPLT10-Liquid-Level-4-20mA-v3Alwin DammanNo ratings yet

- Electromagnetic Flow Meter: DescriptionDocument8 pagesElectromagnetic Flow Meter: DescriptionJohan Carranza AlvarezNo ratings yet

- DB LMP307 eDocument5 pagesDB LMP307 egilad.leizerNo ratings yet

- 12.17 Temperature Transmitter TR10, E&HDocument20 pages12.17 Temperature Transmitter TR10, E&HTichaonaNo ratings yet

- Glass Tube Flowmeters: Series 6000Document8 pagesGlass Tube Flowmeters: Series 6000zizouNo ratings yet

- Flow Measurement of Gases & Clear Liquids With Series 6001 & 6002Document8 pagesFlow Measurement of Gases & Clear Liquids With Series 6001 & 6002Jani WidodoNo ratings yet

- 200 Series: Insert Style Flow Sensors by Data Industrial Owner's ManualDocument16 pages200 Series: Insert Style Flow Sensors by Data Industrial Owner's Manualaries26marchNo ratings yet

- DS TV2802 GB 6933Document2 pagesDS TV2802 GB 6933MohammaNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- At200 + KM26Document5 pagesAt200 + KM26João Paulo PiresNo ratings yet

- Cat 662R0-SLT PDFDocument9 pagesCat 662R0-SLT PDFk v s s GuptaNo ratings yet

- Sensor de Temperatura 0-200ºC - STI - T2850-101Document2 pagesSensor de Temperatura 0-200ºC - STI - T2850-101Marcos ViniciusNo ratings yet

- Conductivity Yokogawa SC SensorDocument12 pagesConductivity Yokogawa SC SensorAbid HameedNo ratings yet

- KH15 Pressure Transmitter: Wetted Parts SUS316L AvailableDocument19 pagesKH15 Pressure Transmitter: Wetted Parts SUS316L AvailableTỉnh NgôNo ratings yet

- Pressure Trasducers ArkerDocument26 pagesPressure Trasducers ArkerVictor Hugo Benitez Paez100% (1)

- Pressure, Vacuum, Differential Pressure and Temperature SwitchesDocument16 pagesPressure, Vacuum, Differential Pressure and Temperature SwitchesJavier CarrizoNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- PT209 Pressure SensorDocument2 pagesPT209 Pressure SensorRajat KumarNo ratings yet

- MCG 310 Analog Output Resistance Temperature Detector: Features Specifi CationsDocument2 pagesMCG 310 Analog Output Resistance Temperature Detector: Features Specifi CationsAsep DarojatNo ratings yet

- General Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42Document4 pagesGeneral Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42HolicsNo ratings yet

- 420, 422 Transducers: General Industrial TransducerDocument4 pages420, 422 Transducers: General Industrial TransducerargaNo ratings yet

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LDocument4 pagesRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauNo ratings yet

- 7me65202yj122aa2 ZDocument2 pages7me65202yj122aa2 ZElvis AlvarezNo ratings yet

- Series 604D Indicating Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 604D Indicating Pressure Transmitter: Specifications - Installation and Operating Instructionsdana_oanaNo ratings yet

- Datasheet - Ultrasonic Heat Meter RC82Document5 pagesDatasheet - Ultrasonic Heat Meter RC82MostafaHeshmatNo ratings yet

- Data Sheet Turbina Medidora de GasDocument2 pagesData Sheet Turbina Medidora de GasDiego RuanoNo ratings yet

- United-Electric-100-Datasheet ACTDocument16 pagesUnited-Electric-100-Datasheet ACTEduardo RuizNo ratings yet

- Thermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFDocument20 pagesThermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFfitrichynNo ratings yet

- ELH 05059 en NaDocument2 pagesELH 05059 en NaOmar Velazquez HernandezNo ratings yet

- Gfps 2581 Datasheet Flowtramag Meter Flow Sensors enDocument8 pagesGfps 2581 Datasheet Flowtramag Meter Flow Sensors enasghar khanNo ratings yet

- Catálogo WLDocument1 pageCatálogo WLWillian CastroNo ratings yet

- Pressure Sensors For Industrial Applications Model P3297: Description FeaturesDocument4 pagesPressure Sensors For Industrial Applications Model P3297: Description Featureseaglego00No ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- SENSORDocument2 pagesSENSORDhouha Ben AbdallahNo ratings yet

- Magnetic Level Indicator BrochureDocument8 pagesMagnetic Level Indicator Brochureelia nugraha adiNo ratings yet

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Nanofiltration - WikipediaDocument7 pagesNanofiltration - WikipediaSrinivas DsNo ratings yet

- A Study of Ratio Analysis ofDocument57 pagesA Study of Ratio Analysis ofAditya KadamNo ratings yet

- GR 6 NST (English) June 2023 Possible AnswersDocument7 pagesGR 6 NST (English) June 2023 Possible Answerslanga350No ratings yet

- HRM 390 ReportDocument8 pagesHRM 390 ReportAmi SakilNo ratings yet

- Job Analysis AssignmentDocument9 pagesJob Analysis AssignmentHazem AminNo ratings yet

- Training Slides HSE-OH-ST10 Biological HazardsDocument18 pagesTraining Slides HSE-OH-ST10 Biological HazardsAbdul Malik AnsariNo ratings yet

- Basic Modules of Instruction Agriculture NC IIDocument13 pagesBasic Modules of Instruction Agriculture NC IIMEAMALLORCANo ratings yet

- Research Paper Example in Citation Guide PDFDocument6 pagesResearch Paper Example in Citation Guide PDFDm Wivinny JesonNo ratings yet

- Dhinakar Balakrishnan - Administration Updated On 29 May 2011Document8 pagesDhinakar Balakrishnan - Administration Updated On 29 May 2011Dhinakar BalakrishnanNo ratings yet

- Cash Flow StatementDocument16 pagesCash Flow Statementrajesh337masssNo ratings yet

- Homework Punch CardsDocument5 pagesHomework Punch Cardsafetynbpy100% (1)

- Module 5 Introduction To Stochastic Processes Eec605Document89 pagesModule 5 Introduction To Stochastic Processes Eec605daniel developerNo ratings yet

- Master Key To Imagination GuideDocument60 pagesMaster Key To Imagination GuideAnonymous ecgjAAD98% (45)

- Contoh Financial PlanDocument4 pagesContoh Financial PlanJonathan ChandhikaNo ratings yet

- Chapter 3 - Entity Relationship ModellingDocument34 pagesChapter 3 - Entity Relationship ModellingShrawan Trivedi100% (1)

- Seismic Sequence Stratigraphy - PresentationDocument25 pagesSeismic Sequence Stratigraphy - PresentationYatindra Dutt100% (2)

- SEASONAL CHANGES OF TISSUE ORGANS OF LONG WISKERED CATFISH (Sperata Aor) IN HAOR BASIN IN SYLHETDocument50 pagesSEASONAL CHANGES OF TISSUE ORGANS OF LONG WISKERED CATFISH (Sperata Aor) IN HAOR BASIN IN SYLHETA K M Munzurul Hasan100% (1)

- Python Interview QuestionsDocument2 pagesPython Interview Questionsriyaz husainNo ratings yet

- Nmo QuesDocument12 pagesNmo QuesmaheshnagarkarNo ratings yet

- Impact of Artificial Intellgence in Education SectorDocument9 pagesImpact of Artificial Intellgence in Education Sectorsravi271No ratings yet

- University of PeradeniyaDocument6 pagesUniversity of PeradeniyaAmila SampathNo ratings yet

- New M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Document6 pagesNew M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Himesh KumarNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- 05 Inventory ManagementDocument47 pages05 Inventory ManagementjackNo ratings yet

- BM-24 HRM Assignment Brief - 1654313266Document9 pagesBM-24 HRM Assignment Brief - 1654313266aung san0% (1)

- 10 DM Commandments EbookDocument9 pages10 DM Commandments EbookLily KimNo ratings yet

- Zumba DLPDocument8 pagesZumba DLPJohnne Erika LarosaNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

Badger Meter 200 Series Flow Sensor DS

Badger Meter 200 Series Flow Sensor DS

Uploaded by

Dale SapachCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Badger Meter 200 Series Flow Sensor DS

Badger Meter 200 Series Flow Sensor DS

Uploaded by

Dale SapachCopyright:

Available Formats

Series 200

Insertion Flow Sensor

DESCRIPTION

The Data Industrial® Series 200 flow sensors by Badger Meter

feature a six bladed impeller design with a proprietary

non-magnetic sensing mechanism. The forward swept impeller

shape provides higher, more consistent torque and is less prone

to be fouled by water borne debris. The forward curved shape

coupled with the absence of magnetic drag provides improved

operation and repeatability at lower flow rates. This is especially

true where the impeller is exposed to metallic or rust particles

found in steel or iron pipes. As the liquid flow turns the impeller, a

low impedance square wave signal is transmitted with a frequency

proportional to the flow rate. The signal can travel up to 2000 feet

between the flow sensor and the display unit without the need for

amplification. All sensors except irrigation versions are supplied

with 20 feet of Belden type 9320 two-conductor shielded cable.

MODEL 220BR (BRASS) AND

220SS (STAINLESS STEEL) SENSORS

The 220BR and 220SS sensors are used in most general flow

measuring applications in metallic or non-metallic pipes. The

sensor mounts in a 2-inch NPT pipe saddle or Threadolet®

for installation in pipe sizes from 3 inches to over 40 inches. MODEL 220PVS SENSOR

Positioning nuts on the three threaded retaining rods allow the

sensor to be accurately positioned to a standard insertion depth of The Badger Meter 220PVS flow sensor is an insertion style flow

1-1/2 inches into the pipe. When this insertion depth is maintained, sensor will all wetted parts constructed of non-metallic materials.

and there is at least 10 upstream and 5 downstream diameters of These sensors are designed for service in corrosive liquids. The

straight uninterrupted flow, an accuracy of +/-1 percent of full scale metallic trim, in non-wetted areas, is 316 stainless steel. The sensor

can be obtained from flow velocities of 0.5 to 30 feet/second (± 4.0 mounts in a 2-inch NPT thread and may be attached to the pipe

percent of reading within calibration range). with a saddle or other types of mounting hardware.

Figure 1: Dimensions for models 220BR and 220SS Figure 2: Dimensions for model 220PVS

DTB-003-04-EN (February, 2013)

Rev. 4 Technical Brief

SPECIFICATIONS

Wetted Materials for all Sensors Output Frequency

(See ordering matrix) 3.2…200 Hz

Sensor Sleeve and Hex Adapter for 220BR

Output Pulse Width

• Sleeve: Admiralty Brass, UNS C44300

Hex Adapter: Valve Bronze, UNS C83600 5 msec ± 25%

Sensor Sleeve and Hex Adapter for 220SS Electrical Cable for Standard Sensor Electronics

316 Series Stainless Steel 20 feet of two-conductor AWG 20 with AWG 22 drain wire shielded

UL type PTLC wire provided for connection to display or transmitter

Temperature Ratings unit. Rated to 105° C. May be extended to a maximum of 2000 feet

• Standard Version: with similar cable and insulation appropriate for application.

221° F (105° C) continuous service Electrical Cable for IR Sensor Electronics

• Irrigation Version: 48 inches of UL Style 116666 copper solid AWG 18 wire with direct

150° F (66° C) continuous service burial insulation. Rated to 105° C.

• PVC Version:

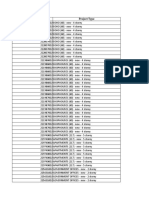

Example: 2 20 BR 00 0 5 - 1 2 1 1

140° F (60° C) continuous service STYLE

Standard Flow 20

MATERIAL

Pressure Ratings Brass BR

Stainless Steel SS

PVC Sleeve w/Stainless Steel Trim PVS

• Metallic Sensor at 100° F SIZE

Insert Style for pipe sizes 3" and up 00

220BR: 400 psi ELECTRONINCS HOUSING

220SS: 400 psi PPS

ELECTRONICS

0

CSA Approved 4

Standard Flow (STANDARD) 5

• Plastic Sensor at 100° F IR-Irrigation 6

220PVS: 100 psi O-RING

Viton ® 0

EPDM (STANDARD) 1

Recommended Design Flow Range Buna N

SHAFT

8

Zirconia Ceramic 0

• 0.5…30 ft/sec Tungsten Carbide (STANDARD)

316 Stainless Steel

2

6

IMPELLER

• Initial detection below 0.3 ft/sec Nylon (STANDARD) 1

Tefzel ® 2

Accuracy BEARING

UHMWPE (STANDARD) 1

Tefzel ® 2

• ± 1.0% of full scale over recommended Teflon ® 3

design flow range Figure 3: Series 220 sensors ordering matrix

• ± 4.0% of reading within calibration range

Repeatability

± 0.3% of full scale over recommended design flow range

Linearity

± 0.2% of full scale over recommended design flow range

Transducer Excitation

• Quiescent current 600 uA @ 8V DC to 35V DC max.

• Quiescent voltage (Vhigh)

Supply Voltage – (600 uA * Supply impedance)

• ON State (VLow) Max. 1.2V DC @ 40 mA current limit

(15W + 0.7V DC)

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities.

Due to continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specifications without notice, except to the extent an outstanding

contractual obligation exists. © 2013 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuffen | Germany | +49-7025-9208-0

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacific | Badger Meter | 80 Marine Parade Rd | 21-04 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | Rm 501, N° 11 Longyue Apartment | N° 180 Longjin Rd, Jiuting Songjiang District | Shanghai, China | 201615 | +86-21-5763 5412

You might also like

- Sage X3 - User Guide - HTG-Customer Search PDFDocument16 pagesSage X3 - User Guide - HTG-Customer Search PDFcaplusincNo ratings yet

- The Cadbury Code of Best Practices Had 19 RecommendationsDocument2 pagesThe Cadbury Code of Best Practices Had 19 RecommendationsAnam Shoaib82% (11)

- Badger 200 Series Installation & Operation ManualDocument16 pagesBadger 200 Series Installation & Operation ManualLeo MedinaNo ratings yet

- 3.sensor de CaudalDocument4 pages3.sensor de CaudalGONZALO ROJASNo ratings yet

- Hydro-Air Electromagnetic Flowmeter DatasheetDocument3 pagesHydro-Air Electromagnetic Flowmeter DatasheetCandrá WardayaNo ratings yet

- Lit 2468Document8 pagesLit 2468jashanpreet singhNo ratings yet

- Sanitary and Industrial RTDsDocument4 pagesSanitary and Industrial RTDsPrihartono Danan WingusNo ratings yet

- Birotor Plus Models B261, B264, B271, B274, B281, B284, B291Document2 pagesBirotor Plus Models B261, B264, B271, B274, B281, B284, B291Helver PachónNo ratings yet

- Yokogawa Model ISC40G Inductive Conductivity Sensor Data SheetDocument12 pagesYokogawa Model ISC40G Inductive Conductivity Sensor Data SheetTrEnD SeT vicky rioNo ratings yet

- Digital Pirani Vacuum GaugeDocument11 pagesDigital Pirani Vacuum GaugeSwagata BeraNo ratings yet

- TESIC P3297 Data SheetDocument4 pagesTESIC P3297 Data SheetLe Quang VuNo ratings yet

- Oti & Wti: Salient FeaturesDocument3 pagesOti & Wti: Salient FeaturesKarthik_Govind_6702No ratings yet

- Optiflux 4000: Electromagnetic Flow SensorDocument8 pagesOptiflux 4000: Electromagnetic Flow SensoryashNo ratings yet

- KROHNE Optiflux 2000R11Document8 pagesKROHNE Optiflux 2000R11janithNo ratings yet

- LaboomDocument4 pagesLaboomAndrei SpiridonNo ratings yet

- ls3200 Point Level SwitchDocument2 pagesls3200 Point Level Switchkhaldoun samiNo ratings yet

- Nixon Col Brochure 2003 PDFDocument32 pagesNixon Col Brochure 2003 PDFShiau FenNo ratings yet

- BC-AIS Flyer-0217 (1) AustraliaDocument2 pagesBC-AIS Flyer-0217 (1) AustraliaJose HuescaNo ratings yet

- Alibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputDocument2 pagesAlibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputrameshNo ratings yet

- TX Thermal Dispersion Switch Data SheetDocument5 pagesTX Thermal Dispersion Switch Data SheetROGELIO QUIJANONo ratings yet

- Mobrey 9000 Series Pressure TransmittersDocument6 pagesMobrey 9000 Series Pressure TransmittersCardoso MalacaoNo ratings yet

- Smart Sroat 1002 V12Document4 pagesSmart Sroat 1002 V12Vishnu PatidarNo ratings yet

- Medidor Caudal Kobold BGFDocument6 pagesMedidor Caudal Kobold BGFBase SistemasNo ratings yet

- MC608 ManualDocument12 pagesMC608 Manualn_zeinounNo ratings yet

- PLT10-Liquid-Level-4-20mA-v3Document3 pagesPLT10-Liquid-Level-4-20mA-v3Alwin DammanNo ratings yet

- Electromagnetic Flow Meter: DescriptionDocument8 pagesElectromagnetic Flow Meter: DescriptionJohan Carranza AlvarezNo ratings yet

- DB LMP307 eDocument5 pagesDB LMP307 egilad.leizerNo ratings yet

- 12.17 Temperature Transmitter TR10, E&HDocument20 pages12.17 Temperature Transmitter TR10, E&HTichaonaNo ratings yet

- Glass Tube Flowmeters: Series 6000Document8 pagesGlass Tube Flowmeters: Series 6000zizouNo ratings yet

- Flow Measurement of Gases & Clear Liquids With Series 6001 & 6002Document8 pagesFlow Measurement of Gases & Clear Liquids With Series 6001 & 6002Jani WidodoNo ratings yet

- 200 Series: Insert Style Flow Sensors by Data Industrial Owner's ManualDocument16 pages200 Series: Insert Style Flow Sensors by Data Industrial Owner's Manualaries26marchNo ratings yet

- DS TV2802 GB 6933Document2 pagesDS TV2802 GB 6933MohammaNo ratings yet

- Tecsis P3276Document4 pagesTecsis P3276benNo ratings yet

- At200 + KM26Document5 pagesAt200 + KM26João Paulo PiresNo ratings yet

- Cat 662R0-SLT PDFDocument9 pagesCat 662R0-SLT PDFk v s s GuptaNo ratings yet

- Sensor de Temperatura 0-200ºC - STI - T2850-101Document2 pagesSensor de Temperatura 0-200ºC - STI - T2850-101Marcos ViniciusNo ratings yet

- Conductivity Yokogawa SC SensorDocument12 pagesConductivity Yokogawa SC SensorAbid HameedNo ratings yet

- KH15 Pressure Transmitter: Wetted Parts SUS316L AvailableDocument19 pagesKH15 Pressure Transmitter: Wetted Parts SUS316L AvailableTỉnh NgôNo ratings yet

- Pressure Trasducers ArkerDocument26 pagesPressure Trasducers ArkerVictor Hugo Benitez Paez100% (1)

- Pressure, Vacuum, Differential Pressure and Temperature SwitchesDocument16 pagesPressure, Vacuum, Differential Pressure and Temperature SwitchesJavier CarrizoNo ratings yet

- RIM20Document10 pagesRIM20GeorgeNo ratings yet

- PT209 Pressure SensorDocument2 pagesPT209 Pressure SensorRajat KumarNo ratings yet

- MCG 310 Analog Output Resistance Temperature Detector: Features Specifi CationsDocument2 pagesMCG 310 Analog Output Resistance Temperature Detector: Features Specifi CationsAsep DarojatNo ratings yet

- General Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42Document4 pagesGeneral Specifications: 2-Electrode Conductivity Sensor For High Temperature Model SX42HolicsNo ratings yet

- 420, 422 Transducers: General Industrial TransducerDocument4 pages420, 422 Transducers: General Industrial TransducerargaNo ratings yet

- Robust Pressure Transmitters T.3: 1.4404 / AISI 316LDocument4 pagesRobust Pressure Transmitters T.3: 1.4404 / AISI 316LRodica PuscauNo ratings yet

- 7me65202yj122aa2 ZDocument2 pages7me65202yj122aa2 ZElvis AlvarezNo ratings yet

- Series 604D Indicating Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 604D Indicating Pressure Transmitter: Specifications - Installation and Operating Instructionsdana_oanaNo ratings yet

- Datasheet - Ultrasonic Heat Meter RC82Document5 pagesDatasheet - Ultrasonic Heat Meter RC82MostafaHeshmatNo ratings yet

- Data Sheet Turbina Medidora de GasDocument2 pagesData Sheet Turbina Medidora de GasDiego RuanoNo ratings yet

- United-Electric-100-Datasheet ACTDocument16 pagesUnited-Electric-100-Datasheet ACTEduardo RuizNo ratings yet

- Thermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFDocument20 pagesThermowell Omnigrad M TR10 (TT-101, TT-201, TT-301, TT-302, TT-303A, TT-303B) PDFfitrichynNo ratings yet

- ELH 05059 en NaDocument2 pagesELH 05059 en NaOmar Velazquez HernandezNo ratings yet

- Gfps 2581 Datasheet Flowtramag Meter Flow Sensors enDocument8 pagesGfps 2581 Datasheet Flowtramag Meter Flow Sensors enasghar khanNo ratings yet

- Catálogo WLDocument1 pageCatálogo WLWillian CastroNo ratings yet

- Pressure Sensors For Industrial Applications Model P3297: Description FeaturesDocument4 pagesPressure Sensors For Industrial Applications Model P3297: Description Featureseaglego00No ratings yet

- Sandvik SAF 2304: Duplex Stainless SteelDocument8 pagesSandvik SAF 2304: Duplex Stainless SteelmattiaNo ratings yet

- SENSORDocument2 pagesSENSORDhouha Ben AbdallahNo ratings yet

- Magnetic Level Indicator BrochureDocument8 pagesMagnetic Level Indicator Brochureelia nugraha adiNo ratings yet

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- Nanofiltration - WikipediaDocument7 pagesNanofiltration - WikipediaSrinivas DsNo ratings yet

- A Study of Ratio Analysis ofDocument57 pagesA Study of Ratio Analysis ofAditya KadamNo ratings yet

- GR 6 NST (English) June 2023 Possible AnswersDocument7 pagesGR 6 NST (English) June 2023 Possible Answerslanga350No ratings yet

- HRM 390 ReportDocument8 pagesHRM 390 ReportAmi SakilNo ratings yet

- Job Analysis AssignmentDocument9 pagesJob Analysis AssignmentHazem AminNo ratings yet

- Training Slides HSE-OH-ST10 Biological HazardsDocument18 pagesTraining Slides HSE-OH-ST10 Biological HazardsAbdul Malik AnsariNo ratings yet

- Basic Modules of Instruction Agriculture NC IIDocument13 pagesBasic Modules of Instruction Agriculture NC IIMEAMALLORCANo ratings yet

- Research Paper Example in Citation Guide PDFDocument6 pagesResearch Paper Example in Citation Guide PDFDm Wivinny JesonNo ratings yet

- Dhinakar Balakrishnan - Administration Updated On 29 May 2011Document8 pagesDhinakar Balakrishnan - Administration Updated On 29 May 2011Dhinakar BalakrishnanNo ratings yet

- Cash Flow StatementDocument16 pagesCash Flow Statementrajesh337masssNo ratings yet

- Homework Punch CardsDocument5 pagesHomework Punch Cardsafetynbpy100% (1)

- Module 5 Introduction To Stochastic Processes Eec605Document89 pagesModule 5 Introduction To Stochastic Processes Eec605daniel developerNo ratings yet

- Master Key To Imagination GuideDocument60 pagesMaster Key To Imagination GuideAnonymous ecgjAAD98% (45)

- Contoh Financial PlanDocument4 pagesContoh Financial PlanJonathan ChandhikaNo ratings yet

- Chapter 3 - Entity Relationship ModellingDocument34 pagesChapter 3 - Entity Relationship ModellingShrawan Trivedi100% (1)

- Seismic Sequence Stratigraphy - PresentationDocument25 pagesSeismic Sequence Stratigraphy - PresentationYatindra Dutt100% (2)

- SEASONAL CHANGES OF TISSUE ORGANS OF LONG WISKERED CATFISH (Sperata Aor) IN HAOR BASIN IN SYLHETDocument50 pagesSEASONAL CHANGES OF TISSUE ORGANS OF LONG WISKERED CATFISH (Sperata Aor) IN HAOR BASIN IN SYLHETA K M Munzurul Hasan100% (1)

- Python Interview QuestionsDocument2 pagesPython Interview Questionsriyaz husainNo ratings yet

- Nmo QuesDocument12 pagesNmo QuesmaheshnagarkarNo ratings yet

- Impact of Artificial Intellgence in Education SectorDocument9 pagesImpact of Artificial Intellgence in Education Sectorsravi271No ratings yet

- University of PeradeniyaDocument6 pagesUniversity of PeradeniyaAmila SampathNo ratings yet

- New M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Document6 pagesNew M Tech Programme in Computer Science and Engineering Artificial Intelligence Data Analytics Self Financing Mode Admissions 2023 - 0Himesh KumarNo ratings yet

- ECM Power Source CircuitDocument4 pagesECM Power Source CircuitErln LimaNo ratings yet

- 05 Inventory ManagementDocument47 pages05 Inventory ManagementjackNo ratings yet

- BM-24 HRM Assignment Brief - 1654313266Document9 pagesBM-24 HRM Assignment Brief - 1654313266aung san0% (1)

- 10 DM Commandments EbookDocument9 pages10 DM Commandments EbookLily KimNo ratings yet

- Zumba DLPDocument8 pagesZumba DLPJohnne Erika LarosaNo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet