Professional Documents

Culture Documents

ESP Installation Procedure PDF

ESP Installation Procedure PDF

Uploaded by

heri setyawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESP Installation Procedure PDF

ESP Installation Procedure PDF

Uploaded by

heri setyawanCopyright:

Available Formats

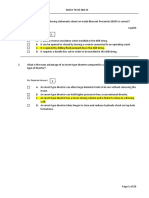

TITLE SCHLUMBERGER ELECTRICAL SUBMERSIBLE PUMP & MULTISENSOR XT

TYPE 1 INSTALLATION PROCEDURE – PERENCO GABON – OPY-

OPY -05 – RIG

HI5

1.0 OBJECTIVE

This procedure details the installation of Electrical Submersible Pump (ESP) with a

Multisensor XT type 1 on well OPY-05 using HI5 rig for PERENCO GABON.

2.0 ACTIONS

Note: Prior to start the installation, the pump discharge head can be made & torqued

up to the first tubing to run in hole on the rig floor. Multisensor XT have to be

pressure tested as per ScSchlumberger

hlumberger procedures.

3.1 Upon Schlumberger Artificial Lift crew arrival offshore, all ESP & MDT equipments will

be checked accordingly with Schlumberger Artificial Lift pre-job procedures in place.

All ESP & MDT equipments will be taken out of shipping boxes and laid down on top of

production tubings.

All ESP equipments (motor, protector, pump etc) will be fitted with their specified

lifting clamps ready to be picked up.

During the offshore job preparation, adaptor will be fitted to the motor, XT fitted to the

adaptor and centralizer made up to the Multisensor. Both motor and XT will then be

electrically tested.

Spooler positioning will have to be agreed on between Company man & Schlumberger

crew.

Small hand tool box will be brought to the rig floor – it contains all necessary hand

tools used for ESP installation.

Surface ESP cable will have to be tested.

Integgrated Surface Panel (ISP), Multisensor choke console (MCC) will have to be

installed.

3.2 Tie up winch to motor lifting clamp. Wrap sling around the bottom of the motor

approximately 10ft from the bottom and attach second winch (or use crane) to it.

3.3 Start lifting up of about five (5) feet the bottom of the motor and stop. Lift up of about

three (3) feet the head of the motor and stop. Repeat this step until the motor can be

lifted up in vertical position without the XT touching the floor at any time.

Once the motor is in vertical position unwrap the sling at its bottom and remove it.

Bring the motor, still in vertical position above the hole.

3.4 Start filling the motor with oil as per Schlumberger procedure.

Written By: Gildas. Paraiso

th

Reviewed & Approved By: Ben Fornasier Page 1 13 April 2005

3.3 Once the motor is serviced, lower it down in the well and rest its lifting clamp on the

stove pipe. Release the bloc. Ensure the pothole screws are tight.

3.4 Pick up the protector in the same way as the motor and bring it at about one (1) feet

above the motor.

3.5 Remove the protector’s lower shipping cap and make it up to the motor accordingly to

Schlumberger procedure.

3.7 Pick up the ESP assembly with the bloc until the lifting clamp at the motor head is lifted

one (1) foot and stop. Remove motor head’s lifting clamp.

3.8 Lower down ESP assembly in the well until the protector head’s lifting clamp rests on

the stove pipe. Release the bloc.

3.9 Pick up the Vortex Gas Separator (VGSA) in the same way as the protector and bring it

at about one (1) foot above the protector.

3.10 Remove the VGSA’s lower shipping cap and make it up to the protector accordingly to

Schlumberger procedure.

3.11 Pick up the ESP assembly with the bloc until the lifting clamp at the protector’s head is

lifted one (1) foot and stop. Remove protector’s head lifting clamp.

3.12 Lower down the ESP assembly until the VGSA’s head lifting clamp rests on the stove

pipe. Release the bloc.

3.13 Pick up the Advanced Gas Handler (AGH) in the sames way as the VGSA and bring it at

about one (1) foot above the VGSA.

3.14 Remove the AGH lower shipping cap, proceed with shimming and make it up to the

VGSA accordingly to Schlumberger procedure.

3.15 Pick up the ESP assembly with the bloc until the lifting clamp at the VGSA head is lifted

one (1) foot and stop. Remove VGSA’s head lifting clamp.

3.16 Pick up the ESP assembly out of the hole until the centralizer (at the bottom of the ESP

string – below Multisensor) is reached. Note that at this stage the total ESP length is

16.86 meters (55.31 feet).

3.17 Lower down the ESP assembly and stop when the Multisensor discharge port reaches

human height.

3.18 Connect the discharge pressure control line to the Multisensor and pressure test to

5,000 Psi for 10 minutes.

Written By: Gildas. Paraiso

th

Reviewed & Approved By: Ben Fornasier Page 2 13 April 2005

3.19 Lower down ESP assembly until motor pothead is reached. Tie-in Motor Lead

Extension (MLE) to motor according to Schlumberger Procedure.

3.20 Electrically function test the Multisensor through the MLE & cable and test MLE &

cable (continuity & megger tests).

3.21 Service protector by filling with oil.

3.22 Once protector servicing is completed, install the first MLE protectolizer at pothead.

3.23 Lower down the ESP assembly and stop at the connection VGSA – AGH. Install the

second MLE protectolizer.

3.24 Lower down the ESP assembly until the AGH head’s lifting clamp rests on the stove

pipe. Release the bloc.

3.25 Pick up the lower pump in the same way as the AGH and bring it at about one (1) foot

above the AGH.

3.26 Remove the lower pump shipping cap, proceed with shimming and make it up to the

AGH accordingly to Schlumberger procedure.

3.27

3.28 Pick up the ESP assembly with the bloc until the lifting clamp at the AGH’s head is

lifted one (1) foot and stop. Remove AGH’s head lifting clamp.

3.29 Install the third MLE protectolizer.

3.30 Continue to lower down the ESP assembly until the lower pump lifting clamp rests on

the stove pipe. Release the bloc.

3.31 Pick up the middle pump in the same way as the lower pump and bring it at about one

(1) foot above the lower pump.

3.32 Remove the middle pump lower shipping cap, proceed with shimming and make it up

to the lower pump accordingly to Schlumberger procedure.

3.33 Pick up the ESP assembly with the bloc until the lifting clamp at the lower’s head pump

is lifted one (1) foot and stop. Remove the lower pump’s head lifting clamp.

3.34 Install the fourth MLE protectolizer.

3.35 Lower down ESP assembly until the middle pump’s head lifting clamp rests on the

stove pipe. Release the bloc.

3.36 Pick up the upper pump in the same way as the middle pump and bring it at about one

(1) foot above the middle pump.

Written By: Gildas. Paraiso

th

Reviewed & Approved By: Ben Fornasier Page 3 13 April 2005

3.37 Remove the upper pump lower shipping cap, proceed with shimming and make it up to

the middle pump accordingly to Schlumberer procedure.

3.38 Pick up the ESP assembly with the bloc until the lifting clamp at the middle’s head

pump is lifted one (1) foot and stop. Remove the middle’s head lifting clamp.

3.39 Install the fifth MLE protectolizer.

3.40 Lower down the ESP assembly until the upper pump head’s lifting clamp rests on the

stove pipe. Release the bloc.

3.41 Make up the discharge pressure sub to the upper pump accordingly to Schlumberger

procedure.

3.42

3.43 Pick up the pup joint with pump discharge head and make up pump discharge head to

discharge pressure sub accordingly to Schlumberger procedure.

3.44

3.45 Make the discharge pressure transfer line connection to the discharge pressure sub.

3.46

3.47 Lower down the ESP assembly and set the 4 ½” pup joint in slips.

Note:: Care must be taken when setting production tubing in slips as the ESP power

Note

cable can be caught in and get damaged.

3.48 Make up first production tubing, install cross coupling protector on tubing collar as per

Schlumberger procedure.

3.49 Carry out electrical tst on Multisensor and ESP power cable every ten (10) joints and

record data.

Note:: Ensure that the ESP cable is well along side the tubing to avoid damaging it while

Note

running in hole.

3.50 Once at the hanger stage, make up hanger to the production tubing.

3.51 Install the hanger penetrator through the hanger.

3.52 Connect hanger lower pigtail to the bottom side of the hanger penetrator.

3.53 Cut ESP power to the appropriate length and electrically test the Multisensor and ESP

power cable.

3.54 Proceed with splicing hanger lower pigtail to the ESP power cable.

Written By: Gildas. Paraiso

th

Reviewed & Approved By: Ben Fornasier Page 4 13 April 2005

3.55 Once the splice is completed, electrically test the Multisensor and ESP power cable

through the upper side of the hanger penetrator.

3.56 Replace shipping cap on hanger penetrattor to avoid moisture from entering and

protect thread.

3.57 Proceed with landing string operations.

Note:: Ensure that the ESP cable is well along side the tubing to avoid damaging it while

Note

landing off the completion.

Pressure test tubing and set packer.

3.58 Pressure test annulus and bleed off as per Schlumberger procedure in order to

avoid ESP power

powe r cable explosive de-

de -compression.

3.59 Electrically test Multisensor and ESP power cable according to Schlumberger

procedure

3.60 Make up Xmas tree.

3.61 Electrically test the Multisensor and ESP power cable through the hanger penetrator

once the Xmas tree is in place.

3.62 Connect surface connector to hanger penetartor.

3.63 Electrically test Multisensor through the surface power cable.

3.64 Connect ESP power cable to the secondary of the transformer.

3.65 Electrically test power cable between the variable speed drive and the transformer.

3.66 Proceed with ESP start up & commissioning as per Schlumberger procedure.

Written By: Gildas. Paraiso

th

Reviewed & Approved By: Ben Fornasier Page 5 13 April 2005

You might also like

- Pope Mac Series AmpilifiersDocument9 pagesPope Mac Series AmpilifiersFikri HidayatNo ratings yet

- Coiled Tubing - Emergency ProceduresDocument50 pagesCoiled Tubing - Emergency ProceduresSarasevina Anggraeni100% (2)

- ES-238 Compression Pump Shimming Field Instruction PDFDocument10 pagesES-238 Compression Pump Shimming Field Instruction PDFKeivin AriasNo ratings yet

- Subsea Exercise No.5Document16 pagesSubsea Exercise No.5rverretNo ratings yet

- SCSSVDocument8 pagesSCSSVSaqxank100% (4)

- Bop Test 1Document1 pageBop Test 1asiraza100% (2)

- Note Calc PWRI InjectivityDocument9 pagesNote Calc PWRI InjectivityDoddy VallentynoNo ratings yet

- Liner Lap TestingDocument1 pageLiner Lap TestingEmad JamshidiNo ratings yet

- Well CompletionDocument29 pagesWell CompletionAkol MajookNo ratings yet

- Well Head EquipmentsDocument10 pagesWell Head EquipmentsParth Trivedi100% (1)

- Artificial Lift Design, Optimization and Cost EstimationDocument71 pagesArtificial Lift Design, Optimization and Cost EstimationRiadh Jendoubi0% (1)

- AC-0019 Practical Assessment Grading Sheet - Subsea BOP OperationsDocument6 pagesAC-0019 Practical Assessment Grading Sheet - Subsea BOP Operationsairlinemembership100% (1)

- ESP 9 Step Design PDFDocument31 pagesESP 9 Step Design PDFDwiki Ramadhani100% (2)

- SOP Rig Up Snubbing 225-340Document5 pagesSOP Rig Up Snubbing 225-340Deddy Bram100% (1)

- BOP Test Procedure PDFDocument2 pagesBOP Test Procedure PDFAhmed100% (2)

- Value Stream Mapping ProcessDocument40 pagesValue Stream Mapping ProcessAtifKhan100% (10)

- RR 446 GDocument8 pagesRR 446 Gmitul78No ratings yet

- Hand Hell Ge FanucDocument64 pagesHand Hell Ge FanucLuis Humberto Ruiz BetanzosNo ratings yet

- ESP 9-Step DesignDocument31 pagesESP 9-Step Designeng.osama100% (2)

- Perforation GeometryDocument10 pagesPerforation GeometryJawaid HussainNo ratings yet

- Workover Kill Fluid Density CalculationDocument3 pagesWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Dogleg, Deviation ESP Recommendation (Generic)Document2 pagesDogleg, Deviation ESP Recommendation (Generic)luis100% (1)

- Pressure Testing of Well Control EquipmentDocument7 pagesPressure Testing of Well Control EquipmentAmit Kumar SinghNo ratings yet

- Well Completion and Stimulation - Chapter 3 Well Performance Analysis-NewDocument56 pagesWell Completion and Stimulation - Chapter 3 Well Performance Analysis-NewsouthliNo ratings yet

- Workover OperationsDocument13 pagesWorkover OperationsnarendrajaredaNo ratings yet

- Formation Integrity TestDocument1 pageFormation Integrity Testfad003100% (1)

- Chapter 01 IntroductionDocument12 pagesChapter 01 Introductiondewidar1234100% (1)

- Total Dynamic Head - TDHDocument37 pagesTotal Dynamic Head - TDHs pNo ratings yet

- Tubing Performance VLPDocument4 pagesTubing Performance VLPDhiaa LaMiNo ratings yet

- DrillSIM Portable SetupDocument14 pagesDrillSIM Portable SetupMehdi SoltaniNo ratings yet

- Optimising ESP Runlife - A Practical Checklist - 7th European ESP Round Table, Aberdeen 2002 PDFDocument8 pagesOptimising ESP Runlife - A Practical Checklist - 7th European ESP Round Table, Aberdeen 2002 PDFazareiforoushNo ratings yet

- P&Pof Intervention Pressure ControlDocument69 pagesP&Pof Intervention Pressure ControlRajat Khanna100% (4)

- 803 Subsea L4 EquiptDocument25 pages803 Subsea L4 EquiptKen ANo ratings yet

- Top Squeeze or Top FillDocument5 pagesTop Squeeze or Top Filldrilling moneytreeNo ratings yet

- Well Completion TechniquesDocument91 pagesWell Completion Techniquesmts1234100% (7)

- Rig DesginDocument25 pagesRig DesginImam Pranadipa100% (1)

- Well Barrier Gas Lifted ProducerDocument2 pagesWell Barrier Gas Lifted Producerdragan2507No ratings yet

- Spe 120632 MS PDocument0 pagesSpe 120632 MS PMagaña AuryNo ratings yet

- Formation Integrity Test (FIT) and Leak Off Test (LOT)Document1 pageFormation Integrity Test (FIT) and Leak Off Test (LOT)mmohsinaliawan0% (1)

- Wellheads 01Document12 pagesWellheads 01arianaseriNo ratings yet

- Casing DesignDocument43 pagesCasing DesignBen Umobi Jnr50% (2)

- Well Testing StudyDocument29 pagesWell Testing StudyDavid LutmangNo ratings yet

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenNo ratings yet

- IWCF by Eng. Abd El-Salam 11-2020Document166 pagesIWCF by Eng. Abd El-Salam 11-2020Mohamed Othman0% (1)

- Combined Surface & Subsea, Equipment - Exercise 1Document16 pagesCombined Surface & Subsea, Equipment - Exercise 1tonyNo ratings yet

- SnubbingDocument52 pagesSnubbinggoodeel setyana100% (3)

- Esp System Start-Up, Commissioning and Operation - LastDocument42 pagesEsp System Start-Up, Commissioning and Operation - LastAnonymous 4hOjnj5100% (1)

- Zenith Gauge PDFDocument2 pagesZenith Gauge PDFCarlos EscobarNo ratings yet

- Introduction To Drilling V2Document66 pagesIntroduction To Drilling V2mikibala100% (2)

- Leak Off TestDocument16 pagesLeak Off Testahmed1adnan-10No ratings yet

- Design Overview: Basic Design and Maintenance InstructionsDocument8 pagesDesign Overview: Basic Design and Maintenance InstructionsOctopusNo ratings yet

- ESP Failure Analysis of Forties Experience ApacheDocument14 pagesESP Failure Analysis of Forties Experience ApacheMohamed AshrafNo ratings yet

- DPT1-01-Rig Sizing and Selection (New)Document65 pagesDPT1-01-Rig Sizing and Selection (New)Brahim Letaief100% (1)

- Vogel EquationDocument10 pagesVogel EquationEvan RandikaNo ratings yet

- Well ControlDocument70 pagesWell ControlAbd EnnacerNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Sand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!From EverandSand Control and Gravel Packing Techniques: It Never Rains in the Oil Field!Rating: 5 out of 5 stars5/5 (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Esp Running ProceduresDocument12 pagesEsp Running ProceduresAhmedMohsenNo ratings yet

- Horizontal Split Case Fire Pumps Installation and Operating ManualDocument12 pagesHorizontal Split Case Fire Pumps Installation and Operating ManualPuntanata SiagianNo ratings yet

- Binance - Ftmusd, 30Document53 pagesBinance - Ftmusd, 30Eduardo Paulini VillanuevaNo ratings yet

- Pipeline DesignDocument60 pagesPipeline DesignEduardo Paulini Villanueva0% (1)

- Cover Letter LipesaDocument1 pageCover Letter LipesaEduardo Paulini VillanuevaNo ratings yet

- 02 - Testing & Drilling IntroDocument39 pages02 - Testing & Drilling IntroEduardo Paulini VillanuevaNo ratings yet

- DataDocument3 pagesDataEduardo Paulini VillanuevaNo ratings yet

- Measurements of Dissolved Substances in Water Injection LinesDocument6 pagesMeasurements of Dissolved Substances in Water Injection LinesEduardo Paulini VillanuevaNo ratings yet

- 01 - SlbwellactivitiesDocument17 pages01 - SlbwellactivitiesEduardo Paulini VillanuevaNo ratings yet

- BLLDGSF SDF SDF SDF S DF S DF SDF SD Fs DF SD FS DF SD FDocument1 pageBLLDGSF SDF SDF SDF S DF S DF SDF SD Fs DF SD FS DF SD FEduardo Paulini VillanuevaNo ratings yet

- Baker - Hughes - BHI Bits Uni Aberdeen SlidesDocument9 pagesBaker - Hughes - BHI Bits Uni Aberdeen SlidesEduardo Paulini VillanuevaNo ratings yet

- Schlumberger WELL ActivitiesDocument17 pagesSchlumberger WELL ActivitiesEduardo Paulini VillanuevaNo ratings yet

- Flare SystemsDocument93 pagesFlare SystemsEduardo Paulini Villanueva100% (1)

- Source Writter Pages 97-116: Oil and Gas Exploration and Production: Reserves, Costs, Contracts Denis BabusiauxDocument7 pagesSource Writter Pages 97-116: Oil and Gas Exploration and Production: Reserves, Costs, Contracts Denis BabusiauxEduardo Paulini VillanuevaNo ratings yet

- Blackmer LPG Handbook 500Document38 pagesBlackmer LPG Handbook 500Eduardo Paulini VillanuevaNo ratings yet

- Stainless Steel 1.4501Document3 pagesStainless Steel 1.4501Eduardo Paulini VillanuevaNo ratings yet

- SolutionsDocument66 pagesSolutionsEduardo Paulini VillanuevaNo ratings yet

- Munnangi Sea Foods Private LimitedDocument77 pagesMunnangi Sea Foods Private LimitedDevaraj SubrmanayamNo ratings yet

- Pipe Stress Analysis Information For FRPDocument10 pagesPipe Stress Analysis Information For FRPchemy5No ratings yet

- Six Sigma Black Belt Roadmap-Lynda PDFDocument4 pagesSix Sigma Black Belt Roadmap-Lynda PDFChino Estoque FragataNo ratings yet

- Fixture ReleasenotesDocument1,439 pagesFixture ReleasenotesChris FarncombeNo ratings yet

- Draft Smart Cities Proposal Hubballi Dharwad1 PDFDocument39 pagesDraft Smart Cities Proposal Hubballi Dharwad1 PDFshekhar100% (1)

- SSP NVH Noise Vibration and HarshnessDocument70 pagesSSP NVH Noise Vibration and HarshnessAntónio FernandesNo ratings yet

- Airflow FormulasDocument16 pagesAirflow FormulasJames ChanNo ratings yet

- Introduction To Software Testing Why Do We Test Software?: Paul Ammann & Jeff OffuttDocument14 pagesIntroduction To Software Testing Why Do We Test Software?: Paul Ammann & Jeff OffuttFexy Chikezie IfeNo ratings yet

- Syscall Product ManualDocument39 pagesSyscall Product ManualEvelin IcNo ratings yet

- Conclusion For SrsDocument5 pagesConclusion For SrsLalit KumarNo ratings yet

- Making Sense of Wi-Fi:: An Operator'S Guide To Aircraft Internet OptionsDocument8 pagesMaking Sense of Wi-Fi:: An Operator'S Guide To Aircraft Internet OptionsQadirNo ratings yet

- TFC On Double LineDocument9 pagesTFC On Double LineSoumen BhattaNo ratings yet

- ECMVDocument2 pagesECMVardic wiraNo ratings yet

- Dip LabDocument55 pagesDip Labmohan vanapalliNo ratings yet

- Learning From Failures: Case StudiesDocument71 pagesLearning From Failures: Case Studiesyedida v r aviswanadhNo ratings yet

- Indraprastha Power Generation Co. LTD.: Company NameDocument19 pagesIndraprastha Power Generation Co. LTD.: Company NameNikhil GuptaNo ratings yet

- Design of Crop Cutter Machine Ijariie5257Document6 pagesDesign of Crop Cutter Machine Ijariie5257Vijay PulavarthiNo ratings yet

- Process Flow Chart of Quality Assurance DepartmentDocument4 pagesProcess Flow Chart of Quality Assurance DepartmentRanjeetKamatNo ratings yet

- Job Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Document1 pageJob Safety Analysis SEG 6.1 - Hotwork (Grinding, Cutting, and Welding) Rev.0Jayvee Baradas ValdezNo ratings yet

- Leadership Development Program Brochure Center For Creative LeadershipDocument8 pagesLeadership Development Program Brochure Center For Creative LeadershipZe RoNo ratings yet

- WMCC2020 Draft Program25NOVDocument2 pagesWMCC2020 Draft Program25NOVDino RatnaweeraNo ratings yet

- Jindal PaperDocument2 pagesJindal PaperSibasish SarkhelNo ratings yet

- Deviation in Pharma: What Is A DeviationDocument2 pagesDeviation in Pharma: What Is A DeviationAshok KumarNo ratings yet

- STS Chapter 1 6Document7 pagesSTS Chapter 1 6adlersolace61No ratings yet

- PM and QSDocument9 pagesPM and QSAlekhyaReddy100% (1)

- IDOCDocument35 pagesIDOCsrinivasNo ratings yet