Professional Documents

Culture Documents

WPS 05

WPS 05

Uploaded by

Naqqash SajidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS 05

WPS 05

Uploaded by

Naqqash SajidCopyright:

Available Formats

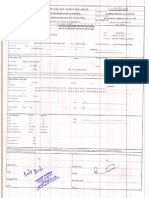

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

Company Name Siddique ice

WPS No. 5 Rev 0 Date 01/01/2020

PQR No. 1 Date

Welding Process GTAW/SMAW Type: MANUAL

This procedure applying for fabrication welding/repair welding of P 1

Scope

material with PWHT

JOINTS (QW-402)

Joint Design Refer Sketch

Root Space (A) 2mm

Root land (B) 2mm

Bevel Angle 60°±5˚

Backing Yes

Backing Material Weld area

Retainer Nil

BASE METALS (QW-403)

P.NO 1 Group No. 2 to P. No. 1(all P.NO 1 material) Group No 22

Material Specification SA516 Grade GR 70

Chemical Analysis As per specification

Mechanical Properties As per specification

Base Metal 5-200mm Fillet All size

Thickness Range

Pipe Diameter Greater than 73mm Fillet All dia

Weld pass thickness ≥ 13 mm Yes

FILLER METALS (QW-404)

Specification No. (SFA) 5.18

AWS No. (Classification) ER70s-2

F-No. 6

A-No. 1

Size of Electrode / Filler Metal 2.4/2.5

Filler Metal Product Form Solid bare Wire

Weld Metal Thickness Range 5-200mm Groove/Fillet All Size

Electrode Flux (Classification) NA Consumables Brand Name

Consumable Insert NA Manufacturer

Specification No. (SFA) 5.1

AWS No. (Classification) E7018

F-No. 4

A-No. 1

Size of Electrode / Filler Metal 3.2/4

Filler Metal Product Form N/A

Weld Metal Thickness Range 5-200mm Fillet/Groove All Size

Electrode Flux (Classification) NA Consumables Brand Name

Consumable Insert NA Manufacturer

POSITIONS (QW-405) PREHEAT (QW-406)

Position 1G Preheat Temperature, min. 150˚C

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

VERTICAL

Welding Progression Interpass Temperature, max. 300°C

UPHILL

Position(s) of Groove All Preheat Maintenance NIL

Position(s) of Fillet All

POST WELD HEAT TREATMENT (QW-407)

Type of PWHT

Holding Temperature 620-640°C

Time Range, min 1 1/2hr min

Time Range, max 2 hrs

Rate of Heating Max. 100°C

Loading / Unloading Temperature,

300°C Rate of Cooling Max. 100°C

Max

Tungsten type 2% Thoriated Size (mm) = 2.4 or equilvalent

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

GAS (QW-408)

Gas Mixture composition (%) FlowRate(litres/minute)

±Shielding Gas Argon Single (No change in composition 5 ̴ 15

±Backing Gas N/A N/A N/A

±Trailing Gas N/A N/A N/A

ØSheilding Trailing Gas N/A N/A N/A

ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal Current Travel Speed

Volt

Weld Pass Process Diameter (range)

Classification Type Polarity Amps (Range) (Range)

(mm) (mm/min)

Root run GTAW/TIG

Filling

Capping

Pulsing Current NA

Heat input (max) NA

Tungsten Electrode Size & Type

Mode of metal transfer

Electrode wire feed speed range

TECHNIQUE (QW-410)

String or Weave Bead Both (Weave not more than 3 times of the electrode)

Oriffice, Nozzle and Gas cup size NA

Initial and interpass cleaning method Wire brushing & Chipping

Method of back gouging Grinding

Oscillation NA

Multiple or single pass (per side) Multiple Pass

Multiple or single layer Multiple

Multiple or single electrode single

Electrode Spacing NA

Welding Process GMAW

Peening NA

Use of thermal process NA

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

Note:

The filler metal shall be stored, issued and controlled as per manufacturer's recommendation / Precision Profiles India procedures.

Prepared by Reviewed by Approved by

Name: Name: Name:

Signature: Signature: Signature:

You might also like

- HVAC Duct & Fittings Area Calculation Formulas ??Document12 pagesHVAC Duct & Fittings Area Calculation Formulas ??Naqqash Sajid100% (3)

- Carrier Service ManualDocument40 pagesCarrier Service ManualMetalloy67% (9)

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- Condenser DesignDocument1 pageCondenser DesignNaqqash SajidNo ratings yet

- Scope: AOCS Official Method Ba 3-38Document3 pagesScope: AOCS Official Method Ba 3-38Ammar Marzuki100% (1)

- Strain-Life Fatigue AnalysisDocument17 pagesStrain-Life Fatigue AnalysisDeepak ChachraNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- WPS API1104 A516 GR 70Document1 pageWPS API1104 A516 GR 70Erick HoganNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Univeral WPS For Pipe To Plate Fillet Welding (6800009)Document1 pageUniveral WPS For Pipe To Plate Fillet Welding (6800009)Ibrahim shaikNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- Electrode Brand Name and Class MirfaDocument13 pagesElectrode Brand Name and Class MirfaAnonymous rYZyQQot55No ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Insulation Inspection ReportDocument1 pageInsulation Inspection ReportKarthikNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- Welder Card - 6G and 3GDocument1 pageWelder Card - 6G and 3GRavi singhNo ratings yet

- WPS PQR-08Document8 pagesWPS PQR-08Ranjan KumarNo ratings yet

- QAP Seamless PipeDocument2 pagesQAP Seamless Pipeashokkahirwar100% (1)

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- 57 PQRDocument13 pages57 PQRAbdul Tri Hamdani Hamdani100% (1)

- NoticeDocument1 pageNoticeAnirban Sen SharmaNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- OCS Prel WPS 007Document2 pagesOCS Prel WPS 007vinothNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- WPS & PQRDocument24 pagesWPS & PQRtulasirao.nammiNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme Ix &Document1 pageWeld Procedure Specification (WPS) : According To Asme Ix &Mina Roger SamyNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- OC-1-1-FCAW-1 Rev 0 PDFDocument4 pagesOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument7 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýNo ratings yet

- Dha Store Floor PlanDocument2 pagesDha Store Floor PlanNaqqash SajidNo ratings yet

- Eco-Smart HEPA ERV: Best Indoor Air For YouDocument1 pageEco-Smart HEPA ERV: Best Indoor Air For YouNaqqash SajidNo ratings yet

- Senva CO CoverageDocument1 pageSenva CO CoverageNaqqash SajidNo ratings yet

- Election Results Circular NOV 07, 2023Document4 pagesElection Results Circular NOV 07, 2023Naqqash SajidNo ratings yet

- Commodity ClassificationsDocument24 pagesCommodity ClassificationsNaqqash SajidNo ratings yet

- Project SummaryDocument10 pagesProject SummaryNaqqash SajidNo ratings yet

- Pacheco Home Residence Drawings-EssentialsDocument4 pagesPacheco Home Residence Drawings-EssentialsNaqqash SajidNo ratings yet

- Slant Fin Engineering DataDocument2 pagesSlant Fin Engineering DataNaqqash SajidNo ratings yet

- Enhancement of Heat Transfer Coefficient Through Helical CoilDocument5 pagesEnhancement of Heat Transfer Coefficient Through Helical CoilNaqqash SajidNo ratings yet

- International Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuDocument17 pagesInternational Journal of Heat and Mass Transfer: B.K. Hardik, P.K. Baburajan, S.V. PrabhuNaqqash SajidNo ratings yet

- ,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersDocument2 pages,,,,,,,,,,,,, Heat Transfer Coefficient Input ParametersNaqqash SajidNo ratings yet

- Energy Audit ReportDocument22 pagesEnergy Audit ReportNaqqash SajidNo ratings yet

- Helical Coil Length - UpdDocument2 pagesHelical Coil Length - UpdNaqqash SajidNo ratings yet

- Huayi Compressor CMLT90LD N R404A 115 60Document2 pagesHuayi Compressor CMLT90LD N R404A 115 60Naqqash SajidNo ratings yet

- AD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayDocument24 pagesAD10B AD10B: E4 Intake at West Areaway E4 Intake at West AreawayNaqqash SajidNo ratings yet

- General Demolition Notes: Mercy Hall RenovationDocument17 pagesGeneral Demolition Notes: Mercy Hall RenovationNaqqash SajidNo ratings yet

- Design DataDocument283 pagesDesign DataNaqqash SajidNo ratings yet

- Project 2: The Capital Asset Pricing Model and Portfolio TheoryDocument11 pagesProject 2: The Capital Asset Pricing Model and Portfolio TheoryNaqqash SajidNo ratings yet

- Report FinalDocument99 pagesReport FinalNaqqash SajidNo ratings yet

- Ground Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Document1 pageGround Floor: N E W S Zone 3 4.1x54.7 Internal Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8Naqqash SajidNo ratings yet

- Comparsion of Existing System and New SystemDocument4 pagesComparsion of Existing System and New SystemNaqqash SajidNo ratings yet

- Load CalculationDocument13 pagesLoad CalculationNaqqash SajidNo ratings yet

- Evaporator DesignDocument1 pageEvaporator DesignNaqqash SajidNo ratings yet

- Load Calculation NewDocument13 pagesLoad Calculation NewNaqqash SajidNo ratings yet

- 3604 4157 - 00 - SW Fanuc ManDocument24 pages3604 4157 - 00 - SW Fanuc ManGuillermo RamirezNo ratings yet

- Flowserve Oil and Gas Upstream and Pipeline PDFDocument20 pagesFlowserve Oil and Gas Upstream and Pipeline PDFmesplamaxNo ratings yet

- NG NP Sikatop Seal 107Document3 pagesNG NP Sikatop Seal 107NourhoudaNo ratings yet

- Chemistry Markscheme (All in One)Document728 pagesChemistry Markscheme (All in One)AliMushtaq50% (2)

- gForceUltraIOM 09-2020Document64 pagesgForceUltraIOM 09-2020Renzo RosasNo ratings yet

- New Microsoft Office Excel WorksheetDocument11 pagesNew Microsoft Office Excel WorksheetUmar NazarNo ratings yet

- Lab Report 4Document17 pagesLab Report 4Lee Yann LynnNo ratings yet

- MK003 - Why Use ICE Solair Over OthersDocument2 pagesMK003 - Why Use ICE Solair Over OthersFatmir KelmendiNo ratings yet

- Mineral FibrelDocument19 pagesMineral FibrelnitishkohliNo ratings yet

- Sustainable Textiles From Renewable Carbon To Fib-Wageningen University and Research 563384Document1 pageSustainable Textiles From Renewable Carbon To Fib-Wageningen University and Research 563384Yassin Alaoui BelhassanNo ratings yet

- 5-Corrective Maintenance FahuDocument2 pages5-Corrective Maintenance FahuUmair LiaqatNo ratings yet

- The Use of Coal As Fuel For Cement Rotary KilnDocument23 pagesThe Use of Coal As Fuel For Cement Rotary KilnDheo Ebhee LouVeNo ratings yet

- Elementis Selector Chart AdditiveDocument14 pagesElementis Selector Chart AdditiveEugene Pai100% (1)

- A1114 PDFDocument4 pagesA1114 PDFAjaykumarNo ratings yet

- Wire Edm HandbookDocument5 pagesWire Edm HandbookWega Wahyu0% (1)

- Prince CPVC Pipes and Fittings PricelistDocument1 pagePrince CPVC Pipes and Fittings PricelistAlok KapoorNo ratings yet

- ESAB Transportation Catalogue 201181132250 20118916190 PDFDocument68 pagesESAB Transportation Catalogue 201181132250 20118916190 PDFcengizarda1979No ratings yet

- M105 93to9Document21 pagesM105 93to9Ravi RanjanNo ratings yet

- Product Datasheet: Closed Toroid A Type, For Vigipact and Vigilhom, Ga300, Inner Diameter 300 MM, Rated Current 630 ADocument3 pagesProduct Datasheet: Closed Toroid A Type, For Vigipact and Vigilhom, Ga300, Inner Diameter 300 MM, Rated Current 630 ATosikur RahmanNo ratings yet

- Fin HMTDocument12 pagesFin HMTbalakalees100% (1)

- VagogyuruDocument856 pagesVagogyurupsnmyNo ratings yet

- Eye Bolt Rating and SpecificationsDocument7 pagesEye Bolt Rating and SpecificationsIlham Adi SusiloNo ratings yet

- PE Pipes and WeightsDocument2 pagesPE Pipes and WeightsSandesh PoudelNo ratings yet

- TAD7, TAD5 Service Protocol 47704013Document4 pagesTAD7, TAD5 Service Protocol 47704013mkNo ratings yet

- Mixers MixerGrindersDocument21 pagesMixers MixerGrindersKumar PranavNo ratings yet

- 04274108foto BigDocument6 pages04274108foto BigvalstavNo ratings yet

- TBT Rebar Impalement Hazards EnglishDocument1 pageTBT Rebar Impalement Hazards Englishpete chizNo ratings yet