Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

8 viewsHydro Test Procedure

Hydro Test Procedure

Uploaded by

Eswar RaoHydro Test procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSWIP 3.1 Question PaperDocument4 pagesCSWIP 3.1 Question PaperEswar RaoNo ratings yet

- (Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Document2 pages(Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Eswar RaoNo ratings yet

- Ride Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Document4 pagesRide Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Eswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- Eticket: Inkollu Saturday, March 21, 2020Document3 pagesEticket: Inkollu Saturday, March 21, 2020Eswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- INKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Document2 pagesINKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Eswar RaoNo ratings yet

- New Doc 2020-05-08 21.03.20Document13 pagesNew Doc 2020-05-08 21.03.20Eswar RaoNo ratings yet

- New Doc 2020-07-18 12.36.25Document2 pagesNew Doc 2020-07-18 12.36.25Eswar RaoNo ratings yet

- New Doc 2020-05-11 21.27.50Document4 pagesNew Doc 2020-05-11 21.27.50Eswar RaoNo ratings yet

- INDIA Product BrochureDocument40 pagesINDIA Product BrochureEswar RaoNo ratings yet

- Aluminium ComparisionDocument2 pagesAluminium ComparisionEswar RaoNo ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet

Hydro Test Procedure

Hydro Test Procedure

Uploaded by

Eswar Rao0 ratings0% found this document useful (0 votes)

8 views8 pagesHydro Test procedure

Original Title

Hydro Test procedure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHydro Test procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views8 pagesHydro Test Procedure

Hydro Test Procedure

Uploaded by

Eswar RaoHydro Test procedure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

NDT Competency Centre] ”

Document no. - D&A-NDE-HPT-001 Rev 0|

PROCEDURE NO-DBANDE/MPT/OO1

DATE: 87,2018

PROCEDURE FOR HYDROSTATIC.

EXAMINATION

‘Prepared by

ee

A Arab,

pcan fe

uy 2018 Clasifeation: Pub Page 1 of 8

NDT Competency centre

LARSEN & TOUBRO

DDEFENCE-IC Document no, - DRAYNDE-HPT-001 Rev 0

‘TABLE OF CONTENTS

(Cove Page

“Table of Cones

0 Scope

20 Requirement

3.0 Appliatle Docanests

20

53.0 Miselacoas Regent

6.0 Calitston

710 Test method

‘80 Acceptance Standard

910 Post Cleaning

100 Report

0 Repsir Rees

12, Resord Reston

yo Test Examination Report

LARSEN & TOUBRO

DEFENCE

Document no, - DRANDE-HPT-0O1

score

‘This Procedure covers the yrostatc Testing of upstream piping spots of DRDL site The

ayo test shal be conducted ony ater the piping is completely supported on the

permanent supports

‘The test methods or techniques of thse methods canbe used fr dhelocatonofleaks or

‘the measurement of leakage rates.

[REQUIRMENT:

For the loak testing method or technique specified by the referencing Code, the referencing

‘Code Seton shall then be consulted forte fllwing

{@) personnel qualifeation/cersieation

(b) techniquo()/calloration standards

(¢) exentof examination

(a) acceptable test sensitivity or leskage rate

(c) report requirements

(O retention of records

APPLICABLE DOCUMENTS

Drawing No, 7012-01-¥-03 Ro, 77012-02-X.01 A, 77012-01X-02 RO, 77012-01-X-07 RO,

177012-91-%-09 RO, 77012-01-X-10 RO.77042-01-X-12 RO, 77012-01X-05 RD,77012-01%-

11 0, 77012-01-G.01 RE, 7012-0-6-01 Rs, 77012-01-G01 RO, 77012-01-6-03,77012

01-6-02 0,

Section Vit Div 0699

"EQUIPMENT:

Gauge Range

When dial ndeating and recoding pressure gages) ae used in leak testing they

Should preferably have the dal) graduated over arange cf approximately double the

Intended maximum pressure, but inno case shall he rangebeless than LS nor mare

‘han four mes that pressure

Gauge Location:

‘When components ae to be pressure tested the da indetng gauge) shall be

Eonnected othe component oro the component froma remete loston withthe

[puge(e) really vile tothe operator controling the promireacuum throughout

the duration of pressurizing evacuating testing and depressurizingorventingof the

‘Component For large vesas or systems where neor mor gages are specied oF

Feqlred, 2 recording ype gauges recommended, and It maybe substitute for one of|

the wo ormore ndeating ype gages

‘© When other types of gnges) are required by an applicable Mandatory Append they

‘may be used in conjunction with orm place of aia ndeatig or reconing pe gages

uly 2018 Claeifcation: Publ Page 3 of 8

tes

LARSEN & TOUBRO

DEFENCE Document no.

NDT Competency Centre

DAA-NDEHIPT-001 Rev 0

5, MISCELLANEOUS REQUIREMENTS:

Gesones:

‘The surface areas tobe tested shal be fre of ol groase pin, or athr contaminants

that might masa eae Iiquids are used to clean the component orifahydrosatc or

hyo pneumatic ests prformed before ea testing the component shall be dry

before leak testing,

Opening

‘Allopenings shal be sealed using plugs, covers, sealing wes coment or other sultable

‘mater hat canbe ready and completely removed ater completion a the est.

‘Sealing materials shall be tracer as ree.

‘Temperate:

‘The minimum metal temperature forall components during tes shall beas specified

{nthe applicable specication

‘The minimum or maximum tomperatue during the tst shall not exceed that

‘temperature compatible wth the leak testing method or technique ure,

Pressure/Vacuum (Pressure Lit)

Unless specified inthe applicable drawing speciation or bythe referencing Code

Section, components that ae to be pessureeak tested stall ot betested ata pressure

‘exceeding 25% ofthe Design Pressure,

6. CALIBRATION:

‘A. Pressure/Vacuum Gauges:

(@) Al da indicating nd recording type gauges used shalbecallbrated against a

Standard deadweight tester, a calibrated master gauge, ora mercury column and

calibrated at east once ea, when in use unless speed diferent bythe

"eferencing speifistion,

Ill gages ued shal provide results accurate to within the Manufacture’ listed

scciracy and shal le reaibrated at anytime that theres reason to beleve they arin

{@) When other shan ial indicating or recording typ gauges are required by an

applicable standard, they shal be caloated a required beh Mandatory

‘Appendix or eferencng code Section

Temperature Measuring Devices:

‘When temperature measurements required by the eerencing Standard, the device(s)

‘shallbe calibrated in accordance wid the requlrements ofthat Code Seton

iendary Ape

fads

uy 2018

Coane Pe meat]

'NDT Compatency Contre

LARSEN & TOUBRO =

DEFENCE-IC Document no, - DRANDE-HPT-001 Rev 0

‘Test medium shall be clean potable water. The quality of wate shall be analyzed after fl

‘up but rior to pressurization The chloride shall nt exceed 4Nppin. Before applying

pressure spodl/ valve shall examine tose that fastens are tht as per required argue

‘Value. Torgue tighten shall performed as per drawing

A. SoakTime

Prior to examination the test pressure shal be eli fora ininum te a pete in

dri

8, Temporttre: Asa tandard technique, he temperature of surface of the part be

ass] ap

(ev iets i

7 | esac Crag neo] TOT -

Heater 05 e ~ -

=| ect ope pine LGT | > Tass] ap

(sesintwtac) i

74 REMOTE VISUAL EXAMINATION:

In some ases,remote visual examination may have tobe substted for direct

‘examination Remote visual examination may use visual lds ich as mirror, telescopes,

‘oreseopes Aber opis, cameras, oF other suitable instrument Such syst shall have 3

resolution capability at east equivalnt a that obtainable by dct visual observation.

172 TRANSLUCENT VISUAL EXAMINATION:

‘Translucent visual examinations a supplement of rec visual examination. The method of

‘ransucont visual examination ure te ad of artical lighting which canbe conaine

Snluminator that produces directional iting The luminatr shall provide ight ofan

intensity tht wil uminate and dase te light evenly throug the area or region under

‘ramon, The ambient lighting mist be so arrange tat there are no surface ares ot

feflections from the surface der examination and shall ele than the ight applied

{hrough the area or region under examination The aril ight source shall have sulicent

Intensity to permie“canding” any translucent laminate hieknes arations

| LARSEN & TOUBRO

| DEFENCE-IC DBANDE-HPT-001 Rey 0

{ACCEPTANCE STANDARD:

‘Unless otherwise specified in the referencing standard the aceptance criteria given in

technique the area under tests aceptable when no sweat, drplt or continous bubble

formation is observed,

9, POSTTEST CLEANING:

After testing surface cleaning may be required for product serviceabily.

10. REPORT:

Report ofthe examination shall be made as per the enclosed report format (Sample Report

format Attached) Al ecordable indications shall be reported

“The test report shall contain, 84 minimum, the following information as applicable to the

method or technique:

(@) ate ortst

(Qycertied evel and name of operator

(e)tes procedure (aumber) and revision number

(@)eest method or technique

(test results

(0 component identification

(Gq) testinsrument standard leak and material dentition

(hy test conditions, est pressure

(i) gauge(s) manufacturer model range and idenieation Nunber

(jtempersture measuring device(s) and idemifcation number(s)

(sketch showing method or technique setup.

11, REPAIR / RETEST:

‘When leakage ts observed, the locaton ofthe leak() shall be marked. The component shall,

‘hen be depressurized, and theleak(s) repaired a5 required bythe referencing Standard

[Aer repairs have been mae the repaired area or areas shallbe retested in accordance

‘withthe requirements

12, RECORD RETENTION:

"The test report shal be maintained in accordance with the requrements ofthe relerencing

Standard

Babes

i

IREFORTO-

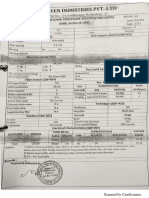

© LARSEN & TOUBRO Hyorosranic test [pate

DEFENCEAC TALEGAON REPORT

[PAGE No.

Projea. [ease

pment Narre [Equpnent Sc

inspection Agerey [ead Spe

[Procedure NOB Rav [SuppeShep Na

[nspeced iy

saree mee [Examinsten ‘Sa9e

|iSTRUMENTS USED FOR TESTING :

insumer Tira Wo wy ‘cava

[premsre Guage

[Pressure Guage

[Pressure Guape

[Recoraer Tanase

aie vee

Tester Teen

Tking Tine (at Test re Hs

Temp. at Yet Deg 5

yerotes Peston intl Veal

lord Content eM

Date of Test

JROTES Cann

Ti Gandia) Test Winenedy es TOMER OCTIPT—

rage-tor

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSWIP 3.1 Question PaperDocument4 pagesCSWIP 3.1 Question PaperEswar RaoNo ratings yet

- (Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Document2 pages(Payment Receipt) Booking Checked-Out - OYO 72156 Akshaya Inn: Booking No.: AKSI4578Eswar RaoNo ratings yet

- Ride Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Document4 pagesRide Details Bill Details: 08 Jun, 2020 Invoice Serial Id:CXCFYPD204678Eswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, B ESWAR RAODocument2 pagesRide Details Bill Details: Thanks For Travelling With Us, B ESWAR RAOEswar RaoNo ratings yet

- Eticket: Inkollu Saturday, March 21, 2020Document3 pagesEticket: Inkollu Saturday, March 21, 2020Eswar RaoNo ratings yet

- Ride Details Bill DetailsDocument2 pagesRide Details Bill DetailsEswar RaoNo ratings yet

- INKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Document2 pagesINKOLLU To Hyderabad: Vikram Srikrishna Travels Service # VSK - 07Eswar RaoNo ratings yet

- New Doc 2020-05-08 21.03.20Document13 pagesNew Doc 2020-05-08 21.03.20Eswar RaoNo ratings yet

- New Doc 2020-07-18 12.36.25Document2 pagesNew Doc 2020-07-18 12.36.25Eswar RaoNo ratings yet

- New Doc 2020-05-11 21.27.50Document4 pagesNew Doc 2020-05-11 21.27.50Eswar RaoNo ratings yet

- INDIA Product BrochureDocument40 pagesINDIA Product BrochureEswar RaoNo ratings yet

- Aluminium ComparisionDocument2 pagesAluminium ComparisionEswar RaoNo ratings yet

- Safe Work Method For Hydro TestDocument1 pageSafe Work Method For Hydro TestEswar RaoNo ratings yet