Professional Documents

Culture Documents

Biofinal Design6

Biofinal Design6

Uploaded by

Princess Joy Tubera GarciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biofinal Design6

Biofinal Design6

Uploaded by

Princess Joy Tubera GarciaCopyright:

Available Formats

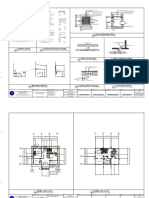

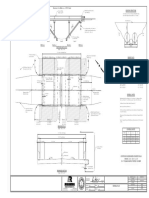

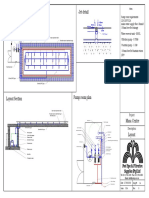

CROSS SECTION OF THE SQUARE TANK CROSS SECTION OF THE MIXING TANK CROSS SECTION OF THE INLET AND

CROSS SECTION OF THE MIXING TANK CROSS SECTION OF THE INLET AND OUTLET PIPES

RSB SPACING @12mmØ= 0.5m NOTE: NOTE: NOTE:

WALL THICKNESS= 0.1524m The floor of the mixing tank should be inclined from 8.5% - 17.5% toward *Access to the digester should be through the manhole or through the outlet *Concrete pipe (prefabricated RC pipe) should be used and it should be inclined 58% (30.11373315°) with digester wall.

Length=Width of Mixing Tank= 0.9m the inlet pipe (4.9-9.9°). chamber. If a manhole is used as the access inside the digester, it should be *The height of the floor of the chamber from the filling line shall be at least equal to the operating pressure for appliances

RC Pipe = 200mmØ constructed in the center of the dome and it should be tightly sealed. Manhole using biogas or the height should be at least 0.2 m from the filling line plus 15% freeboard (0.23m).

Mixing tank Height= 0.45m cover should be 0.65 m in diameter and 0.125 m thick. *For the floating type, the upper end of the outlet should be elevated from the floor of the sludge tank.

RC Pipe Length 0.90m *A cover made of G.I. sheet shall be provided.

Inlet = 1.42m *Lower end of inlet pipe should be positioned below the gasholder retainer for floating type.

Outlet = 1.59m *The outlet pipe shall be sealed.

0.20m 0.20m Sludge Tank

Mixing Tank

0.23m

0.90m Ø0.65m

Filling Line Filling Line

0.13m

o

30°m 30°m

8

0.15m 0.65m

0.45m

0.10m

scale 1:20 scale 1:20 scale 1:20

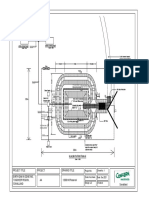

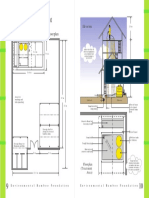

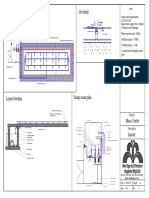

CROSS SECTION OF THE DIGESTER CROSS SECTION OF THE FLOATING TYPE BIOGASS PLANT CROSS SECTION OF THE GAS CHAMBER

NOTE: NOTE: NOTE:

*Digesters should be made of ferrocement, metal, adobe, bricks, reinforced concrete, or reinforced CHB. *Biogas plant should be located at a site with good *The gas drum should consist of 2.5 mm mild steel sheets for the sides and 2 mm sheets for the top. It

Ball valves or cock

*For reinforced digester, reinforcement shall be a minimum of 10 mm diameter RSB spaced at 0.15 m drainage. should have a welded-in brace, which break up the surface scum. The drum should be protected against

valves should be used.

(both the curved and the horizontal bars) and the curved bars shall be anchored at the top beam. All *It should be located as near as possible to the Gas Outlet

corrosion with suitable coating (oil paints, synthetic paints and bitumen paints).

reinforcement bars shall be secured and tied together with GI wire. animal pen and should be lower than elevation of *The gas drum should have a sloping roof (16.5% slope) and it should be provided with guide frame.

*The concrete walls of the digester shall be reinforced with G.I. chicken wire mesh before plastering animal pen canal. *U-tube manometer should be provided to indicate the relative amount of gas in storage within the

with class A mortar mixed with sealing compound or water-proofing compound. Plaster shall be *The utilization of biogas should be near. biogas plant.

applied in three layers (13 mm, 6 mm, and 6 mm thick). *Soil foundation should be stable and away from

*Floors, beams and foundation shall withstand the maximum load and shall be made of reinforced tree roots intrusion.

concrete. Gas Holder Voume = 10.63m3

Gas Holder Pressure head = 20cm

Width of the GH = 2.17m

0.59m

Filling Line

Height of the GH = 2.39m

Dimensions: Height of the GH roof = 0.18m

Digester Tank Voume = 8m3

1.32m

1.12m

Sludge Tank

Gas Outlet

Width of the Digester = 2.41m

9o

Mixing Tank

Height of the Digester = 2.9m

Filling line = 1.122m 0.32m

Legnth of the gas retainer = 0.319m

Filling Line

0.18m

Dist. of the Retainer below the top

Stirrer

of the digester wall = 0.59m

2mm

9m

ipe

Gas Holder

1.4

Inl

tP

1.5

Retainer

et

tle

Pip

2m

Ou

2.41m

e

DIGESTER

Gas Holder

2.41m

Design Capacity:

2.39m

No. of heads (Swine@ 73-91kg) = 20

2.41m

Standards (PAES 413:2001):

Amount of Manure for 73-91kg

= 8kg /day / head

Manhole Retention days for Swine

= 25 days

Manure to Water ratio

2.90m

Gas Outlet

= 1:1

Manhole

Mixing Tank 0.90m Filling Line

2.90m

0.90m

Gas Outlet

Sludge Tank

Stirrer

2.17m

scale 1:15

scale 1:20 scale 1:25

Prepared by: Project Title: Drawn/Designed by: R.C. Cuaresma Content: Sheet No.:

Date:

Roger C. Cuaresma Design of a 20-head Floating type Biogass Plant Checked by: Engr. I.M. Erana As shown 1/1

BSAE-5 Date:

You might also like

- Living Spaces - Mid-Century Modern Home Catalog 2021Document9 pagesLiving Spaces - Mid-Century Modern Home Catalog 2021MladenNo ratings yet

- Innbox Management GuideDocument78 pagesInnbox Management Guideedino6650% (2)

- Inspection and Test Plan (Itp) : H Hold W Witness S Surveillance R ReviewDocument6 pagesInspection and Test Plan (Itp) : H Hold W Witness S Surveillance R ReviewAli Asghar100% (1)

- Prop PracDocument3 pagesProp PracPrince Q ChanNo ratings yet

- 01 Administration - 03 Hyd 001-052 - CorrigidosDocument4 pages01 Administration - 03 Hyd 001-052 - CorrigidosAsisi Happy KurniawanNo ratings yet

- Notes & Specifications:: LegendDocument1 pageNotes & Specifications:: Legendmj sabioNo ratings yet

- Water Linelayout Sanitary Seweragelayout Septic TankDocument1 pageWater Linelayout Sanitary Seweragelayout Septic TankOwen Radaza PiranteNo ratings yet

- Electrical Vinoya ResidenceDocument4 pagesElectrical Vinoya Residence2226558No ratings yet

- 4 Mps Building Dingras PlumbingDocument6 pages4 Mps Building Dingras PlumbingAgbon TangogNo ratings yet

- UG Pipe - Hydraulic Design - Ver 1.0Document12 pagesUG Pipe - Hydraulic Design - Ver 1.0leroytuscanoNo ratings yet

- Annex 5.1 Design Water Pan OdweyneDocument3 pagesAnnex 5.1 Design Water Pan OdweyneMukhtar Case2022No ratings yet

- ABP TB - dwgTRAININGCENTERASBUILT-E1.pdf13Document1 pageABP TB - dwgTRAININGCENTERASBUILT-E1.pdf13joseph arao-araoNo ratings yet

- Swimming Pool PDFDocument1 pageSwimming Pool PDFharish amuthanNo ratings yet

- Birch-King Flow DirectionDocument4 pagesBirch-King Flow DirectionBruceNo ratings yet

- End (E) Intermediate (A) END (E1)Document1 pageEnd (E) Intermediate (A) END (E1)amirul aizadNo ratings yet

- 1 (2) - Pdfplot14.hdi 14.00.072.000 - 002953Document23 pages1 (2) - Pdfplot14.hdi 14.00.072.000 - 002953Jesson Diaz VicenteNo ratings yet

- Planning A Treatment Center: FloorplanDocument1 pagePlanning A Treatment Center: FloorplanbabakaroNo ratings yet

- Floor Plan Celing Framing Plan Roof Framing Plan: Fabricated Angular Channel StiffenerDocument1 pageFloor Plan Celing Framing Plan Roof Framing Plan: Fabricated Angular Channel StiffenerJhn Cbllr BqngNo ratings yet

- Tank SluiceDocument3 pagesTank SluiceThippeswamy PhNo ratings yet

- RB A225 Approval Rev 1 - 4 4Document1 pageRB A225 Approval Rev 1 - 4 4TariqMahmoodNo ratings yet

- Appendix B5 (Rumble Strip)Document1 pageAppendix B5 (Rumble Strip)vivekNo ratings yet

- 4"Ø PVC Pipe: Section of Water Treatment Tank PlanDocument1 page4"Ø PVC Pipe: Section of Water Treatment Tank PlanQualityNo ratings yet

- BWre21 POB CD 10 Detail Security CameraDocument1 pageBWre21 POB CD 10 Detail Security CameraRasimÖzcandanNo ratings yet

- A B C D A B C D: Ground Floor Plan 1 Second Floor Plan 2Document1 pageA B C D A B C D: Ground Floor Plan 1 Second Floor Plan 2Edward CardenasNo ratings yet

- Layout Plan Jet Detail: Pool Spa & Filtration Supplies (Pty) LTDDocument1 pageLayout Plan Jet Detail: Pool Spa & Filtration Supplies (Pty) LTDChristian Angelo BermudezNo ratings yet

- Layout Drawings PDFDocument1 pageLayout Drawings PDFChristian Angelo BermudezNo ratings yet

- Longitudinal Section: Engr. Ramon Gitamondoc Slab Bridge Details Francis Ryan R. TrayvillaDocument1 pageLongitudinal Section: Engr. Ramon Gitamondoc Slab Bridge Details Francis Ryan R. TrayvillaJohn Emerald GoloNo ratings yet

- Elevation Details: NTS ScaleDocument1 pageElevation Details: NTS ScaleJopheth RelucioNo ratings yet

- LIGHTINGDocument3 pagesLIGHTINGJamillette NovesterasNo ratings yet

- Office of The District Engineer: Project Title: Sheet No. Set No. Sheet ContentsDocument1 pageOffice of The District Engineer: Project Title: Sheet No. Set No. Sheet ContentsDarren ValienteNo ratings yet

- ST 02Document1 pageST 02yambao.geranyNo ratings yet

- Final Plan of Bruna For PrintDocument12 pagesFinal Plan of Bruna For Printmelvin bautistaNo ratings yet

- Section-Bb: Clear Key Plan With Coordinates Road SectionsDocument1 pageSection-Bb: Clear Key Plan With Coordinates Road SectionsAyman EssamNo ratings yet

- PlumbingDocument7 pagesPlumbingstephen riveraNo ratings yet

- Electrical Plan: Schedule of LoadsDocument1 pageElectrical Plan: Schedule of LoadsMichael DarmstaedterNo ratings yet

- Denah Dan Potongan PrasedDocument1 pageDenah Dan Potongan PrasedCaesar Grendi100% (1)

- Ground Floor Power & Lighting LayoutDocument1 pageGround Floor Power & Lighting LayoutJM De Guzman TuzonNo ratings yet

- Sheet 3 03252019Document1 pageSheet 3 03252019Brylle De GuzmanNo ratings yet

- C C MixedGroundTunnellingDocument11 pagesC C MixedGroundTunnellingLouis BrightonNo ratings yet

- Railway Cased CrossingDocument1 pageRailway Cased Crossingbinay kumarNo ratings yet

- General Notes: Vicinity MapDocument3 pagesGeneral Notes: Vicinity MapKenneth MolinaNo ratings yet

- Denah Tiang Pancang R. 1Document8 pagesDenah Tiang Pancang R. 1arifinNo ratings yet

- Lay Out Rig TMMJ.05 - 2021.Document1 pageLay Out Rig TMMJ.05 - 2021.Ade doccontrolNo ratings yet

- Site LayoutDocument1 pageSite LayoutBSSBNo ratings yet

- Display Center ElevationDocument1 pageDisplay Center Elevationmichael jan de celisNo ratings yet

- Floor PlanDocument1 pageFloor PlanMaria StarryNo ratings yet

- 3.1 Sample General NotesDocument6 pages3.1 Sample General NotesMaMoh MohNo ratings yet

- Plan of Intake Chamber For Submersible PumpDocument1 pagePlan of Intake Chamber For Submersible PumpRODEL YUNTINGNo ratings yet

- Concrete Pedestal Details Anchor Bolt Details City Inspectorate Team City Inspectorate TeamDocument1 pageConcrete Pedestal Details Anchor Bolt Details City Inspectorate Team City Inspectorate TeamBetinol RachelNo ratings yet

- PipeDocument18 pagesPipeSalmaan RaafiQqNo ratings yet

- DETAIL Perkerasan SUMBuDocument1 pageDETAIL Perkerasan SUMBuAdi BlokwwNo ratings yet

- Master Drain Drawing From 406 To 512 (Yet To Submit)Document1 pageMaster Drain Drawing From 406 To 512 (Yet To Submit)Anal BiswasNo ratings yet

- Shop Drawing Boq Number Pipe-ModelDocument1 pageShop Drawing Boq Number Pipe-Modelاحمد محمودNo ratings yet

- Drainage SystemDocument22 pagesDrainage SystemKHAIRINA FIKRIAH KHAIRUDDINNo ratings yet

- Ee 2Document1 pageEe 2Zyrill NavarroNo ratings yet

- Project1 - Sheet - P101 - 00Document1 pageProject1 - Sheet - P101 - 00Resty Rey Acido TacataNo ratings yet

- Open Ditch Train 3 and Utility From Brown Field To Green FieldDocument13 pagesOpen Ditch Train 3 and Utility From Brown Field To Green Fielddicky1969No ratings yet

- Visio-Pondasi Jembatan Timbang 100 Ton (16m)Document17 pagesVisio-Pondasi Jembatan Timbang 100 Ton (16m)Lalu Aditiya MardinatalNo ratings yet

- Boundary Wall DrawingDocument1 pageBoundary Wall Drawingsandip wankhadeNo ratings yet

- Gambar TeknikDocument1 pageGambar Teknikhasibuanpolin85No ratings yet

- At Support: Typical Truss DetailDocument1 pageAt Support: Typical Truss DetailRA CruzNo ratings yet

- ELECTRICALDocument5 pagesELECTRICALAggasid ArnelNo ratings yet

- Transition To Oracle Solaris 11Document3 pagesTransition To Oracle Solaris 11shahidqaviNo ratings yet

- Product Comparison Nanocad 5.0 Nanocad Plus/Pro 8.0 Autocad 2016 Autocad LT 2016Document3 pagesProduct Comparison Nanocad 5.0 Nanocad Plus/Pro 8.0 Autocad 2016 Autocad LT 2016Ihab El AghouryNo ratings yet

- System InformationDocument29 pagesSystem InformationBennel ColardoNo ratings yet

- Manual Combina Frigorifica LiebherrDocument12 pagesManual Combina Frigorifica LiebherrReviewuriNo ratings yet

- TBC PentestDocument9 pagesTBC PentestJam Tangan BrandedNo ratings yet

- Empire State BuildingDocument4 pagesEmpire State BuildinglikhithaNo ratings yet

- Revit Architecture 2012 Getting Started GuideDocument45 pagesRevit Architecture 2012 Getting Started GuideHariz MansorNo ratings yet

- 12 15 14newDocument27 pages12 15 14newMario Roberto Rodríguez RangelNo ratings yet

- Shri Ram Janam Bhoomi Ayodhya Verdict Part 11 of 14Document500 pagesShri Ram Janam Bhoomi Ayodhya Verdict Part 11 of 14satyabhashnamNo ratings yet

- GaclistDocument7 pagesGaclistNdy BeatlesNo ratings yet

- Webforge Access Systems Brochure GratingDocument10 pagesWebforge Access Systems Brochure Gratingjardean villosoNo ratings yet

- v120 Release NotesDocument15 pagesv120 Release NotesDeviprasad.Kuppuswamy7330No ratings yet

- Alfred Percival Maudslay - Alfred Percival Maudslay - Biologia Centrali-Americana Archeology Volume 3 (1902)Document184 pagesAlfred Percival Maudslay - Alfred Percival Maudslay - Biologia Centrali-Americana Archeology Volume 3 (1902)Felipe Andres asalgado hernandezNo ratings yet

- Proposal On Campus Workshop-Summer Training-Live Project On Web ProgrammingDocument3 pagesProposal On Campus Workshop-Summer Training-Live Project On Web ProgrammingRM Infotech Pvt LtdNo ratings yet

- The Cacti ManualDocument106 pagesThe Cacti Manualdannybcn_86No ratings yet

- New CommandDocument9 pagesNew CommandAnonymous SmYjg7gNo ratings yet

- Carpentry ToolsDocument19 pagesCarpentry ToolsRitsy Pantallano100% (1)

- Advantages of Aluminum Formwork SystemDocument3 pagesAdvantages of Aluminum Formwork SystemDavy GoomaxNo ratings yet

- Sap BC Administration GuideDocument324 pagesSap BC Administration GuideYugandhar .vallipiNo ratings yet

- Bluetooth Technology RajanDocument3 pagesBluetooth Technology RajanKandibanda NithinNo ratings yet

- Epson px-8Document8 pagesEpson px-8sys_64759No ratings yet

- Cutting PropagationDocument31 pagesCutting PropagationDrRuby Ranjan SharmaNo ratings yet

- RFC - 6750 - Oauth2Document18 pagesRFC - 6750 - Oauth2Jose Alonso HernandezNo ratings yet

- Latest Cisco EnsurePass ICND1 100 101 Dumps PDFDocument145 pagesLatest Cisco EnsurePass ICND1 100 101 Dumps PDFleo_dhNo ratings yet

- 75 LemaFilename: 75 Leman Street Fact Sheet - PDF N Street Fact SheetDocument7 pages75 LemaFilename: 75 Leman Street Fact Sheet - PDF N Street Fact SheetMatthewNo ratings yet