Professional Documents

Culture Documents

Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling Calculations PDF

Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling Calculations PDF

Uploaded by

AanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling Calculations PDF

Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling Calculations PDF

Uploaded by

AanuCopyright:

Available Formats

About This Blog Contact Us Privacy Policy

! MENU

SPONSORED SEARCHES

oil and gas training courses

piping design

petroleum oil

pipe engineering

casing pipe

Casing Seat Selection –

How To Select Casing

Setting Depth

By DrillingFormulas.Com | June 2, 2014 - 5:24 am |

Casing Design

! Post Views:5,009

AdBuka

From the previous article, you’ve learnt about overall of

casing design process and in this article we are going to

discuss about how to select casing setting depth. The

selection of casing string and setting depth is based on

formation pore pressure and fracture gradient of the well.

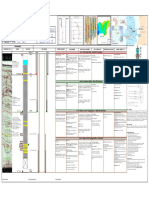

For the casing setting depth determination, pore pressure

and fracture gradient are normally described in PPG

(Figure 1).

Figure 1 – Pore Pressure and Fracture Pressure Plot

The solid lines in the chart are not accounted for safety

factor; therefore, for the first step of casing seat design,

safety margin must be applied. For this example, we will

add 0.3 ppg for safety for both pore pressure and fracture

gradient (Figure 2). You need to add the safety factor into

formation pressure and subtract it from the fracture

gradient. What’s more, the safety factor value may

depends on where you work and how much confident in

your data.

Figure 2 – Pore Pressure and Fracture Pressure Plot with

Safety Margin

The dashed lines are design range which will be used for

the design. There are two ways to determine casing setting

depths which are bottom-up and top-down method.

Bottom Up Casing Design

This design will start from the bottom of the well up to

surface and the setting depths are designed within the

safety factor limits (dotted lines). Starting at the bottom

(formation pressure dashed line – Point A), draw a vertical

line upward to fracture pressure dashed line – Point B

(Figure 3). Casing should be set from 4,500’ TVD to 12,000’

TVD because you can reach TD (12,000’ TVD) with highest

equivalent mud weight and you will not break the formation

at shallow depth (4,500 TVD). We will apply this same

concept to another string.

Figure 3 – Bottom Up Design Step#1

The next casing string is determined by drawing a

horizontal line from Point B to intersect the pore pressure

dashed line at Point C. Then draw a vertical line from Point

C to the fracture gradient dashed line at Point D (Figure 4).

The Casing must be set from 1,800’ TVD to 4,500’ TVD.

Figure 4 – Bottom Up Design Step#2

With the same idea, the next casing string is determined by

drawing a horizontal line from Point D to Point E and a

vertical line from Point E to Point F (Figure 5). The Casing

must be set from surface to 1,800’ TVD.

Figure 5 – Bottom Up Design Step#3

Based on the bottom up design concept, we will need to

have 3 strings of casing set at 1800’ TVD, 4500’ TVD and

12,000 TVD (Figure 6).

Figure 6 – Bottom Up Design Final

From the example, you can see how the bottom up casing

design process is done. If you have the different pore

pressure/fracture gradient, you can repeat the process for

other casing strings until you reach surface casing.

Top Down Casing Design

This design will start from the surface of the well down to

the bottom and the setting depths are designed within the

safety factor limits (dotted lines). We start by drawing the

vertical line from the facture gradient dashed line (point A)

down to pore pressure dashed line (point B). See Figure 7.

The first casing should be set from surface to 3,000’ TVD.

Figure 7 – Top Down Design Step#1

Next, draw the horizontal line from Point B to Point C

located in the fracture dashed line curve. Then draw the

vertical line from Point C to intersect the formation

pressure dashed line curve at Point D. This is the section

casing string which should be set from 3,000’ TVD to

6,000’ TVD (Figure 8).

Figure 8 – Top Down Design Step#2

Applying the same concept to the next string, draw the

horizontal line from Point D to intersect the fracture

gradient with safety factor chart at Point E and draw the

vertical line from Point E to the target depth at Point F. The

last casing string should be set from 6,000’ TVD to 12,000’

TVD (Figure 9).

Figure 9 – Top Down Design Step#3

Based on the tow down design concept, we will need to

have 3 strings of casing set at 3,000’ TVD, 6,000’ TVD and

12,000 TVD (Figure 10).

Figure 10 – Top Down Design Final

From the example, you can see how the top down casing

design process is done. You can repeat the same process

to determine the setting depth based on your fracture and

pressure plot.

Ref Book -> Applied Drilling Engineering Book special

offer

Sponsored Links

Ad

Yam Processing Plant - Free Catalog &

Free Quotation

bizoe-machine.com

Ad

Factory Price Oil Presser

Honest-industrial

Ad

Multi Purpose Water & Chemical Pumps.

Fire Fighting or water transferring

pumps.

KM Hydraulic Solutions

Ad

Make profit with opay

OPay

Share the joy

551

551

Shares

Tagged casing design, Casing Seat Selection. Bookmark the

permalink.

About DrillingFormulas.Com

Working in the oil field and loving to

share knowledge.

View all posts by

DrillingFormulas.Com →

« Basic Knowledge of Kelly Petrobras P-36 Sinking –

and Top Drive VDO Training The Biggest Oil Rig Sinking

In the Oilfield Industry »

6 Responses to Casing Seat Selection

– How To Select Casing Setting Depth

Curd JUNE 3, 2014 AT 4:37 PM

any pros/cons for bottom up & top down?

Reply

Victor RUS JUNE 3, 2014 AT 5:37 PM

Gents, I completely agree with top down and

bottom up method except that you should

use Bottom UP when you have reservoirs, if

you don’t have reservoirs you should use top

down method and then choose the CSG

depth depending on lithology. This is

simplest thing in CSG design, then we need

to choose casing P110, L80, K55, etc. It

would be great if you show us biaxial

collapse, triaxial burst calculations etc and

kick tolerance as well.

Reply

DrillingFormulas.Com

JULY 14, 2014 AT 8:08 AM

Hi Victor,

We will have more article regarding casing

design which will focus on biaxial, burst,

collapse, etc.

Reply

Soran JUNE 4, 2014 AT 12:37 AM

well done, this is really excellent and well

explained casing setting depth selection

procedure. However, would it be possible to

demonstrate or provide us a real casing

design calculation scenario for surface and

intimidate section. please advise.

Reply

DrillingFormulas.Com

JULY 14, 2014 AT 8:07 AM

You may need to read this article.

http://www.drillingformulas.com/casing-

size-selection-how-to-select-casing-size-

to-match-the-drilling-and-completion-

goal/

Reply

AWAD AUGUST 15, 2018 AT 9:21 PM

well done.thanks a lot

Reply

Leave a reply

Default Comments (6) Facebook Comments

Your email address will not be published. Required fields

are marked *

Comment

Name

*

Email

*

Website

Post Comment

This site uses Akismet to reduce spam. Learn how your

comment data is processed.

Categories

Select Category

Get Drilling Formulas Sheet For Free

Subscribe to Get Free Calculation Sheet

email address

Click Here

Search on Drillingformulas.com

Search

Custom Search

Well Control One Page

Drillingformulas.com on Facebook

Drillingformulas.…

340K likes

Like Page

Be the first of your friends to like this

OilfieldPix.com

Oilfield Acronyms

Recent Comments

Ahmad Alshammari on Possible Wellbore Problems

during Well Kill Operation

Ahmad Alshammari on Possible Wellbore Problems

during Well Kill Operation

DrillingFormulas.Com on Kill Weight Mud

DrillingFormulas.Com on Kill Weight Mud

Dellabani Mouloud on Driller’s Method Quiz No. 1

"

You might also like

- Service Manual: Includes H SeriesDocument214 pagesService Manual: Includes H Seriesjulianmata100% (1)

- SPE-105068-MS-How Good Is The Torque-Drag ModelDocument9 pagesSPE-105068-MS-How Good Is The Torque-Drag ModelHassaanAhmedNo ratings yet

- Subsea Bop SpaceoutDocument1 pageSubsea Bop SpaceoutWell ControlNo ratings yet

- Oil - Solid Controls PDFDocument282 pagesOil - Solid Controls PDFsezaitanyolu100% (1)

- Mud Plug InstallationDocument4 pagesMud Plug InstallationVahid TaghdiriNo ratings yet

- Fire Safety Inspection ChecklistDocument8 pagesFire Safety Inspection ChecklistNikka LopezNo ratings yet

- Well PlanningDocument13 pagesWell Planningkeen dela cruzNo ratings yet

- Well Service IWCF Test and AnswersDocument33 pagesWell Service IWCF Test and Answersseyyid ali lylNo ratings yet

- 01 - Drill 16'' Hole Section & POOHDocument3 pages01 - Drill 16'' Hole Section & POOHDrilling Engineering ChannelNo ratings yet

- Casing DesignDocument10 pagesCasing DesignAry Rachman0% (1)

- Lesson 8b Introduction To UBDDocument57 pagesLesson 8b Introduction To UBDbon1ngNo ratings yet

- 2-Important OperationsDocument17 pages2-Important OperationsLazharNo ratings yet

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Omar Drilling Supervisor CV.Document5 pagesOmar Drilling Supervisor CV.cgmqf89286No ratings yet

- Lecture2-Well CompletionDocument43 pagesLecture2-Well CompletionRamy MaamounNo ratings yet

- Drilling Technology and Costs - Chapter - 6Document51 pagesDrilling Technology and Costs - Chapter - 6zdq02100% (1)

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- JDS - Drilling Fluid - 2021 - HandoutsDocument57 pagesJDS - Drilling Fluid - 2021 - Handoutsrainaldy sebastianNo ratings yet

- Well InterventionDocument83 pagesWell InterventionJosue FishNo ratings yet

- Water: As A Drilling Fluid in Production Zone of Geothermal WellsDocument4 pagesWater: As A Drilling Fluid in Production Zone of Geothermal WellsSuci Nur HidayahNo ratings yet

- Kicks IndicatorsDocument17 pagesKicks IndicatorsGhavban DavidNo ratings yet

- Drilling 1 AutoRecoveredDocument52 pagesDrilling 1 AutoRecoveredKhaled AdelNo ratings yet

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 pagesA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadNo ratings yet

- ADC Well Control Formula SheetDocument3 pagesADC Well Control Formula SheetshahpourscribdNo ratings yet

- Quiz AITDocument4 pagesQuiz AITazizsarshoghNo ratings yet

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignGFariz100% (1)

- Cement Plug CalculationDocument7 pagesCement Plug CalculationEmad JamshidiNo ratings yet

- FOCUSSTUCKPIPEDocument21 pagesFOCUSSTUCKPIPEVikas kumar singhNo ratings yet

- IWCF Operations Limited: 05 July 2016Document13 pagesIWCF Operations Limited: 05 July 2016airlinemembership100% (1)

- Oil and Gas CementingDocument15 pagesOil and Gas Cementingnissefar007No ratings yet

- 1 CompletionDesignDocument38 pages1 CompletionDesignMikko Delos ReyesNo ratings yet

- Remedial CementingDocument4 pagesRemedial CementingColor RougeNo ratings yet

- Stuck Pipe Prevention 1637664167Document14 pagesStuck Pipe Prevention 1637664167jerikhoNo ratings yet

- Brine Fluids PlanningDocument4 pagesBrine Fluids PlanningKolawole AdisaNo ratings yet

- 1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif SamiDocument17 pages1) Anusha A/P Nagaih 2) Melinda Mallini A/P Loudersamy 3) Sangeetha A/P Balaram 4) Vinohthinii A/P R Tamilselvan 5) Youssif Samitashh raoNo ratings yet

- Deep Illustration For Loss of Circulation While DrillingDocument17 pagesDeep Illustration For Loss of Circulation While DrillingfuatNo ratings yet

- Well Planning and DesignDocument7 pagesWell Planning and DesignCyril PintoNo ratings yet

- OKW 61 (De Comp.) TimelineDocument6 pagesOKW 61 (De Comp.) TimelineVibhu GuptaNo ratings yet

- Stuck Pipe Prevention: Dr. Qamar J. SharifDocument5 pagesStuck Pipe Prevention: Dr. Qamar J. SharifMohamded100% (2)

- Well Blueprint: Lost CirculationDocument8 pagesWell Blueprint: Lost CirculationapsekarNo ratings yet

- OMNI Roller ReamerDocument2 pagesOMNI Roller ReamerCaptain NematollahiNo ratings yet

- Casing Setting Depth SelectionDocument33 pagesCasing Setting Depth Selectionمصطفى مجدي100% (1)

- Q1: List The Features of The Ideal Drilling Bit.: 1. High Drilling Rate 2. Long LifeDocument3 pagesQ1: List The Features of The Ideal Drilling Bit.: 1. High Drilling Rate 2. Long Lifeنور الهدى احمد بشير A 50No ratings yet

- DAY 6 - Loss Circulation & Stuck Pipe Sharing SessionDocument27 pagesDAY 6 - Loss Circulation & Stuck Pipe Sharing SessionReza Syahputra MulyanaNo ratings yet

- Stuck PipeDocument1 pageStuck Pipesaeed65No ratings yet

- Drilling and Completion Egy Petroleum Engineer PDFDocument208 pagesDrilling and Completion Egy Petroleum Engineer PDFRahma Mejri100% (2)

- 03 - Differential StickingDocument0 pages03 - Differential StickingSam AbdulNo ratings yet

- Casing Running Masterclass Southern Cone Session 2 (1) BPDocument79 pagesCasing Running Masterclass Southern Cone Session 2 (1) BPHector Daniel Sosa0% (1)

- ISCWSA Error Model Rev4Document57 pagesISCWSA Error Model Rev4ciucalata88No ratings yet

- Alaska Drilling and Wells Recommended Practice: Lost CirculationDocument4 pagesAlaska Drilling and Wells Recommended Practice: Lost CirculationAdel Ahmed AlkhaligyNo ratings yet

- 7B - HydraulicsDocument33 pages7B - Hydraulicsagus alexandri100% (2)

- Stuck Pipe TOTALDocument41 pagesStuck Pipe TOTALmosli_No ratings yet

- Extended Reach Drilling1 PDFDocument18 pagesExtended Reach Drilling1 PDFMayra Betancourt Dominguez100% (1)

- Well: B-166 18-5/8" Casing Cementing DesignDocument8 pagesWell: B-166 18-5/8" Casing Cementing DesignIbnu HasanNo ratings yet

- Stuck Pipe PreventionDocument64 pagesStuck Pipe PreventionmmbatainehNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- An Introduction to Petroleum Technology, Economics, and PoliticsFrom EverandAn Introduction to Petroleum Technology, Economics, and PoliticsNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Computational Neuroscience of Neuronal Networks: Samuel A. Neymotin, Annmary Mathew, Cliff C. Kerr, and William W. LyttonDocument32 pagesComputational Neuroscience of Neuronal Networks: Samuel A. Neymotin, Annmary Mathew, Cliff C. Kerr, and William W. LyttonAanuNo ratings yet

- Biological Modeling: George ReekeDocument22 pagesBiological Modeling: George ReekeAanuNo ratings yet

- Yekini Siwes Presentation 2019Document12 pagesYekini Siwes Presentation 2019AanuNo ratings yet

- PRODUCTION OF 7000KG LEMONGRASS CEOsDocument105 pagesPRODUCTION OF 7000KG LEMONGRASS CEOsAanuNo ratings yet

- Siwes Presentation 2019Document12 pagesSiwes Presentation 2019AanuNo ratings yet

- PRODUCTION OF 7000KG LEMONGRASS CEOsDocument105 pagesPRODUCTION OF 7000KG LEMONGRASS CEOsAanuNo ratings yet

- Preliminary Design of The Green Diesel Production Process by Hydrotreatment of Vegetable OilsDocument15 pagesPreliminary Design of The Green Diesel Production Process by Hydrotreatment of Vegetable OilsNina KonitatNo ratings yet

- Gemtp Final List of ParticipantsDocument4 pagesGemtp Final List of ParticipantsMD ABUL KHAYERNo ratings yet

- Par Flex PipeDocument24 pagesPar Flex PipeRana Abdul RehmanNo ratings yet

- Study On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDocument7 pagesStudy On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDyshelly Nurkartika PascapurnamaNo ratings yet

- QUOTATION of Tyre Pyrolysis PlantDocument5 pagesQUOTATION of Tyre Pyrolysis PlantRavishankar BansalNo ratings yet

- Rubber Industries (Handouts)Document18 pagesRubber Industries (Handouts)daabgchi100% (1)

- Turkish Rules On Sulphur Content in Marine FuelsDocument2 pagesTurkish Rules On Sulphur Content in Marine Fuelsvmike63No ratings yet

- Fabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDocument8 pagesFabrication of Turbocharger For Two Wheeler: Ahir Nischal A, Sofia Ali A, Darshan S Shah, Sneh R PrajapatiDeepak sutarNo ratings yet

- Lawn-Vac-Model No. 247.77010Document25 pagesLawn-Vac-Model No. 247.77010jp20058379No ratings yet

- ReliancepxDocument42 pagesReliancepxAkshata DalviNo ratings yet

- Summer Internship ON: Basics of Well Logging, Well Log Operations & Interpretation-Ongc Mehsana AssetDocument38 pagesSummer Internship ON: Basics of Well Logging, Well Log Operations & Interpretation-Ongc Mehsana AssetYaashpal Malik50% (2)

- M.V MSC LUGANO Fire in E/R Investigation Report by ATSBDocument60 pagesM.V MSC LUGANO Fire in E/R Investigation Report by ATSBJasper AngNo ratings yet

- FS260 C 360 C ManualDocument124 pagesFS260 C 360 C ManualneusNo ratings yet

- Hydrocarbon Processing Refining Processes 2000 PDFDocument95 pagesHydrocarbon Processing Refining Processes 2000 PDFmarinuta20004403No ratings yet

- Overview Gas ProcessesDocument140 pagesOverview Gas ProcessesR.S.Sankarasubramanian100% (1)

- ETQ Diesel GeneratorDocument34 pagesETQ Diesel GeneratorDerek StampsNo ratings yet

- 06 - Fuel and Lubrication SystemDocument21 pages06 - Fuel and Lubrication SystemAmirul Shahmin B. ZubirNo ratings yet

- Tank Battery Design PDFDocument4 pagesTank Battery Design PDFdigeca100% (1)

- Geochemistry in Petroleum Exploration - AugDocument44 pagesGeochemistry in Petroleum Exploration - AugShivamTiwariNo ratings yet

- Health, Safety and Environment (Hse) CGE653 Assignment: Fire and Explosion PO5, CO2, C4Document4 pagesHealth, Safety and Environment (Hse) CGE653 Assignment: Fire and Explosion PO5, CO2, C4LouisNo ratings yet

- Substantial To Hashish Oil CreationDocument2 pagesSubstantial To Hashish Oil Creationfruit9boatNo ratings yet

- Shri Ram Centennial School: Topic - Plastic 2 Fuel - Pyrolysis ProcessDocument44 pagesShri Ram Centennial School: Topic - Plastic 2 Fuel - Pyrolysis ProcessReshma Baid RamchandaniNo ratings yet

- Technical Data MQ-6: Gas SensorDocument2 pagesTechnical Data MQ-6: Gas SensorIhwanNo ratings yet

- WPC 20 2866Document8 pagesWPC 20 2866annasitNo ratings yet

- Diagnosis and Testing - I (Auto Engines)Document2 pagesDiagnosis and Testing - I (Auto Engines)raumil1237590100% (1)

- Table of Contents of Final Year Design ProjectDocument13 pagesTable of Contents of Final Year Design ProjectAnonymous 9aTxrqvU7cNo ratings yet

- Parts of Boiler and Their FunctionDocument4 pagesParts of Boiler and Their FunctionsadNo ratings yet