Professional Documents

Culture Documents

Ijsred V2i5p54

Ijsred V2i5p54

Uploaded by

IJSREDCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wattle & DaubDocument9 pagesWattle & DaubRemya R. KumarNo ratings yet

- Ponzi Scheme - EditedDocument4 pagesPonzi Scheme - EditedGifted MaggieNo ratings yet

- ABMM2Document3 pagesABMM2QAISER IJAZNo ratings yet

- A To Z: Social Media MarketingDocument89 pagesA To Z: Social Media MarketingJordan Kasteler100% (1)

- I-765 Online Filing Instructions - FINALDocument13 pagesI-765 Online Filing Instructions - FINALTrân LêNo ratings yet

- Contract Act LawDocument8 pagesContract Act Lawmukmin09No ratings yet

- OJT ReportDocument52 pagesOJT ReportMARK MATUMBA0% (1)

- 134 Motion Pro Hac TantilloDocument6 pages134 Motion Pro Hac Tantillolarry-612445No ratings yet

- Magpie Lab Student Guide Updated 2014 FinalDocument13 pagesMagpie Lab Student Guide Updated 2014 FinalAmanueNo ratings yet

- AnalogI PDFDocument48 pagesAnalogI PDFJerc ZajNo ratings yet

- Lenovo G460 G560 User GuideDocument130 pagesLenovo G460 G560 User GuidejoreyvilNo ratings yet

- Smart Home: An-Najah National University Faculty of EngineeringDocument27 pagesSmart Home: An-Najah National University Faculty of Engineeringمعتز بسام محمود مرداوي معتز بسام محمود مرداويNo ratings yet

- Question BankDocument9 pagesQuestion Bankshama JNo ratings yet

- 21st Century Nanoscience Vol 5Document489 pages21st Century Nanoscience Vol 5pedro100% (1)

- Introduction To GNU Radio and Software RadioDocument4 pagesIntroduction To GNU Radio and Software RadioDinesh VermaNo ratings yet

- Midterm Exam DM 213 Fiscal ManagementDocument8 pagesMidterm Exam DM 213 Fiscal Managementbplo aguilarNo ratings yet

- EIC5000 Electronic Indicator Control Installation and Operation InstructionsDocument8 pagesEIC5000 Electronic Indicator Control Installation and Operation InstructionsАртемNo ratings yet

- Governance Modes in Supply Chains and Financial Performance at Buyer, Supplier and Dyadic Levels: The Positive Impact of Power BalanceDocument30 pagesGovernance Modes in Supply Chains and Financial Performance at Buyer, Supplier and Dyadic Levels: The Positive Impact of Power BalancegiovanniNo ratings yet

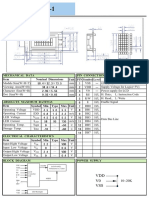

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 pageV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNo ratings yet

- Q4 Module 8.2Document14 pagesQ4 Module 8.2Derick0% (1)

- Learning Agreement Student Mobility For StudiesDocument6 pagesLearning Agreement Student Mobility For StudiesEmin FerhatovicNo ratings yet

- Understanding Price Action Practical Analysis of The 5 Minute Time Frame Full ChapterDocument41 pagesUnderstanding Price Action Practical Analysis of The 5 Minute Time Frame Full Chapterjoseph.chavez825100% (29)

- Kamadhenu ReportDocument6 pagesKamadhenu ReportRajaram IyengarNo ratings yet

- GodotDocument977 pagesGodotClaudio Alberto ManquirreNo ratings yet

- Impact of Compensation and Reward SystemDocument88 pagesImpact of Compensation and Reward SystemDhanshri KavatkarNo ratings yet

- Aviary Report Released by City of WatertownDocument26 pagesAviary Report Released by City of WatertownNewzjunkyNo ratings yet

- Using The SQL Transformation in An Informatica Developer MappingDocument10 pagesUsing The SQL Transformation in An Informatica Developer MappingShannonNo ratings yet

- Succeeding A LegendDocument4 pagesSucceeding A LegendFrancie DaltonNo ratings yet

- Mangaliag Vs Catubig-PastoralDocument2 pagesMangaliag Vs Catubig-PastoralPauline LicaycayNo ratings yet

- ASSINGMENT Pavement EngineeringDocument12 pagesASSINGMENT Pavement Engineeringmrafiruler90No ratings yet

Ijsred V2i5p54

Ijsred V2i5p54

Uploaded by

IJSREDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijsred V2i5p54

Ijsred V2i5p54

Uploaded by

IJSREDCopyright:

Available Formats

International Journal of Scientific Research and Engineering Development-– Volume 2 Issue 5, Sep – Oct 2019

Available at www.ijsred.com

RESEARCH ARTICLE OPEN ACCESS

Electronic Waste impacting Health and Environment, It’s

Management -Global & Indian Perspective

Dr. Anju RatheeAhlawat, Assistant Professor,

Department of Applied Sciences, Maharaja Surajmal Institute of Technology, C-4, JanakPuri, New Delhi

Email:anu.ahlawat@gmail.com

----------------------------------------************************----------------------------------

Abstract:

Use of electronics equipment and their disposal is increasing exponentially with time. The disposal of

equipment is in proportion to obsolescence which in turn is linked with adoption of new technology. It

has attributed around 10 % growth in e-Waste in India. Recycling of e-Waste through environment

friendly means is utmost need of the day. Still in India, instead of using standardised technology based

methods in recycling, it is carried out by using primitive means which are extremely hazardous and

spoiling the environment. Development of an ecosystem comprising adequate legislation, restrictions on

hazardous substance (RoHS) , cost-effective technology based recycling solution, awareness to all

stakeholders & general public on electronic waste is to be ensured and full proof management practices

warrantying environment protection and eco-friendly manufacturing and recycling are to be adopted.

Keywords —e-Waste, WEEE, RoHS, Recycling, Extraction

----------------------------------------************************----------------------------------

majorly imported as well as locally generated in

I. INTRODUCTION

developing countries, is largely ending up in

Discarded electronics and electrical equipment landfill contaminating soil and groundwater,

appliances are considered widely Electronic Waste putting food supply systems and water sources at

(E-Waste). It is generally utilised for refurbishment, risk or it is being informally recycled through

recycling for material recovery for reuse. It primitive methods exposing labours to hazardous

potentially contains toxic , hazardous, carcinogenic and carcinogenic substances leading to adverse

substances such as mercury, lead and cadmium etc human health effects .

and essentially is to be handled & disposed with

The substances found in e-waste which are toxic

scientific & eco-friendly manner. and hazardous to human & environment include :

Annually , approx. 50 million tonnes of electronic Lead and Cadmium in Cathode Ray Tubes (CRT),

and electrical waste is generated globally which is Computers Batteries , Plating Metal Enclosures/

more than six kilograms per person per year. If it Metal Parts in sub-assemblies, Printed Circuit

keeps on increasing with current pace, it will be Boards (PCBs), ; mercury in Switches, Flat Screen,

doubled by 2050. Only 20 % e-Waste is recycled CFL etc ; Poly Chlorinated Biphenyls in

through formal sector recyclers. Rest 80 % , Capacitors, Transformers , retardant on Printed

ISSN : 2581-7175 ©IJSRED:All Rights are Reserved Page 645

International Journal of Scientific Research and Engineering Development-– Volume 2 Issue 5, Sep – Oct 2019

Available at www.ijsred.com

Circuit Boards, plastic casings, cables ; Poly Vinyl screens, 3.9 MT small IT equipment, 0.7 MT lamps

[1]

Chloride (PVC) in cable sheathing ; PBD/PBDE in .

plastic parts of electronics ; and various other Though forecasting the volumes of e-waste

substances [6] generation is difficult, yet considering the current

E-Waste contains around 7% of world’s gold. As pace and in the absence of some effective

compared to gold ore, e-Waste have 100 times more controlling & managing mechanism, it is expected

gold. Poor management of e-waste is ensuing in a that by 2021 the annual total volume may surpass

significant loss of rare, scarce and valuable raw 52 million tonnes.

materials viz gold, platinum, cobalt, apart from Some other indicators - EE devices connected to the

polluting the planet and effecting health adversely. internet at between 25-50 billion by 2020 i.e. three

In India, ill effects of improper e-waste processing times the world population; By 2040, carbon

- leaching of hazardous contents from landfills to emissions from production and use of electronics

soil, contamination of rivers & underground water including devices like PCs, laptops, monitors,

sources, emission of gases to air, impacted human smartphones and tablets reaching 14% of total

through inhalation of gases emitted during emissions; By 2060, the world’s consumption of

recycling and through contact with hazardous raw materials is set to double - give insight that by

substances used in recovery processes – is 2050, the volume of e-waste, in the worst-case

substantially visible. With the support of scenario, could top 120 million tonnes annually.

legislation which has been updated time to time, India generates around two million tonnes of e-

Ministry of Environment and Forests, Government waste per annum and is at fifth rank among e-waste

of India along with agencies like Central Pollution producing countries, after the US, China, Japan and

Control Board, State Pollution Control Board and Germany. However, there is no government data on

others are handling, managing, controlling the e- e-waste generation in the country (ii).

Waste related affairs including Restriction of However important indicators -rapid growth of

Hazardous Substance (RoHS) directives in India. Mobile subscriber in India from 310 million in

Despite it, no formal data from Government is 2001 to 1.1 billion in 2016 which is nearly 4 times

readily available. However, by efforts of some Non that of United States and ranking second only to

Government Organisations ( NGOs) , the China in the world, which has 1.3 billion

assimilated data is eye opener and informs that still subscribers ; 57 million computers in use and

e-Waste collection, segregation, recycling is plethora of other gadgets and consumer electronics-

majorly dealt by informal sector and labour health predict growth in domestic e-Waste generation in

& environment issues are grossly ignored. India. 10 year ago, around 70 % of e-Waste

processed or disposed of in India was originated

II. SIZE OF ELECTRONICS WASTE

from abroad. Afterward efforts to control the

inflow have been effective , but surge in domestic

E-waste today often consists of products from the

consumption have overshoot it, leading to an over

past. In year 2016, 44.7 Million Tonnes (MT) of e-

all growth in e-Waste generation.

Waste was generated globally by adding in 16.8

Computer equipment and mobile telephones as the

MT small equipment, 9.1 MT large equipment, 7.6

principal e-waste generators in India contributing

MT temperature exchange equipment, 6.6 MT

around 70 per cent of the total e-waste generated in

ISSN : 2581-7175 ©IJSRED: All Rights are Reserved Page 646

International Journal of Scientific Research and Engineering Development-– Volume 2 Issue 5, Sep – Oct 2019

Available at www.ijsred.com

India, while telecommunication equipment Li, Sc, Hf,

Na, K,

Mg, Ta, Cr,

attribution is about 12 per cent. Mumbai is first Sr, Ba, Mo, W,

Rb, Cs,

among cities generating around 1,20,000 tonnes of La, Si,

Y, Ti, Be, Cu, Ag, Re,

Ce, Pr,

e-waste per annum, followed by Delhi and Ca Zr, Nb, Ni, Zn, Ga, Pd Pt, Au

Nd, Sm,

Mn, Bi In, Tl, Hg

Bengaluru with generation of 98,000 and 92,000 Fe, Co, Ge, As,

Eu, Gd,

tonnes of e-waste per annum [4]. About 70 per cent Cd, Al, Sb, Se,

Tb, Ho,

Er, Yb

of heavy metals in landfills is sourced from E- Sn, Pb Te

waste. Recycling Rates of elements from e-Waste:

III. ELEMENTS AND ECONOMIC VALUE: Low < Recycling Rate > High

There are so many elements which are scarcely >10- > 25-

<1% 1-10% >50 %

available in nature but available in e-Waste with 25% 50%

good recycling rates. Extraction of these scarce Li, Be, Sr, Ba, Sc, Ti, Nb, Cr,

elements from e-Waste is more economical than Y, La, Zr, Hf, Ta, Mn, Re, Fe,

Ga, In, Tl, Ge, As, Hg, W, Co, Ni, Pd,

their extraction from ore. Also extraction from ore Mg, Mo

Bi, Se, Te, Ce, Pr, Sb Cd Pt, Cu, Ag,

mines is also causing enormous pollution. Nd, Sm, Eu, Gd, Au, Zn, Al,

Availability in nature, pollution caused by mining Tb, Ho, Er, Yb Sn, Pb

and recycling rates of some important elements

[1]

are which are available in e-Waste is depicted in

Tables 1: By seeing the elements in above table and analysing

TABLE1 :

pollution in their mining, scarcity in nature vis a vis

CLASSIFICATION OF ELEMENTS PRESENT IN E-WASTE BASED UPON

recycling rates gives an enormous clue that scarce

PARAMETERS-THEIR AVAILABILITY IN NATURE, POLLUTION CAUSED DURING elements like Gold (Au) having high recycling rate

MINING , AND RECYCLING RATES :

and polluting environment heavily during their

Availability in Nature:

mining must be recycled as it adds enormous value

Low < Scarcity in Nature > High to e-Waste Economy Chain and in environment

Rising protection.

Limited Serious

Threats

Available in Availability, Threat in

from Elements such as Iron, Aluminium, Copper

Nature Future Risk of Next 100

increased amounts around 40-50 % of weight of e-Waste

Supply years

use

whereas valuable elements are found in lesser

Li, Mg, Sr, Sc, amounts but are still of high importance.

Na, K, Rb, Cs, Be, Y, Zr, Nb, Cr,

Ca, Ba, LA, Ti, Mo, W, Mn, Ag, Zn, TABLE 2: METAL COMPOSITION OF SOME COMMON ELECTRONIC APPLIANCES

Ta, Te, Fe, Al, Si, Co, Ni, Pd, Ga, In, [3]

Pt

Ce, Pr, Sm, Eu, Cu, Au, Cd, Ge, As, e-Waste Weight (%) Weight (ppm)

Gd, Tb, Ho, Er, Hg, Ti, Sn, Te Items Fe Cu Al Pb Ni Ag Au Pd

Yb Pb, Sb, Bi, Se, TV 28 10 10 1 0.3 280 20 10

Nd Board

PC 7 20 5 1.5 1 1000 250 110

Pollution Caused by Mining of elements: Board

Mobile 5 13 1 0.3 0.1 1380 350 210

Low < Pollution Caused by Mining > High Phone

Portable 23 21 1 0.14 0.03 150 10 44

Audio

System

ISSN : 2581-7175 ©IJSRED: All Rights are Reserved Page 647

International Journal of Scientific Research and Engineering Development-– Volume 2 Issue 5, Sep – Oct 2019

Available at www.ijsred.com

DVD 62 5 2 0.1 0.05 115 15 4 open burning and Mercury

Player inhalation

Calculat 4 3 5 0.1 0.5 260 50 5

or

Chips and Chemical Acid contact with Hydrocarbons,

Printed 5.3 26. 1.9 NR 0.14 3300 80 NR other Gold- stripping eyes, skin may result heavy metals,

Circuit 8 plated items using nitric in permanent injury; brominated

Board and Inhalation of acids substances etc.

E-waste 36 4.1 4.9 0.29 1.0 NR NR NR hydrochloric fumes, chlorine and discharged

Mixture acid along sulfur dioxide gases directly into

riverbanks can cause respiratory river ;Acidifies

difficulty ,pulmonary the river

Some precious metals like gold are contained in E- allergy, respiratory destroying fish

Waste as large as around 7% of world’s gold and failure and death and flora

100 times more available in as compared to gold

ore. 24 kg Gold is present in 148.4 tons (1 million

units) of Mobile phones and to extract the same Plastics Shredding and Probable Emission of

from the low- hydrocarbon, brominated

weight of Gold from gold ore, 23763.4 tons of gold computer temperature brominated dioxin dioxins and

ore is to be processed. and melting and PAH exposure heavy metals

peripherals to workers and and

people living in the hydrocarbons

nearby area

IV. HEALTH & ENVIRONMENTAL IMPACT: Steel, Furnace Exposure to dioxins Emission of

EEEs are manufactured with various components , Copper & recovers steel and heavy metals dioxins and

metal or copper heavy metals

some containing high value substances. Recycling smelting from waste

of these substances may be toxic and have an Open burning Brominated and Hydrocarbon

adverse impact on human health and the Wires to recover Chlorinated Dioxin and ashes

copper and PAH exposure including PAHs

environment ,if not handled properly. It may affect to workers and discharged into

seriously human involved in recycling process people living in air, water and

nearby area soil

and/or living in proximity to places where e-waste

is recycled or burnt [5]. A computer contains highly V. REGULATION AND ECOSYSTEM DEVELOPMENT

toxic chemicals like Lead, Cadmium, Mercury, With the new E-Waste Management Rules 2016,

Beryllium, BFR, Poly Vinyl Chloride and Phosphor responsibility of recycling now lies with equipment

compounds. manufacturers too to take up the task of recycling

TABLE 3 : HAZARDOUS OF PROCESSING OF WASTE COMPUTER ON HUMAN LIFE the products they produce. Though anticipated

AND ENVIRONMENT

outcome is not feasible until & unless , society at

Potential Potential

e-Waste

Process Occupational Environmental

large is sensitised about its necessity to manage e-

Component

Hazards Hazards Waste.

Cathode Breaking to Silicosis, Cuts from Lead, Barium Taking measures by Government to turn the

Ray Tubes extract copper glass, Inhalation or and other heavy

and dumping contact with toxic metals leaching

informal sector into a well-managed system will not

phosphor containing into ground be adequate. In most proposed sustainable e-waste

cadmium or other water and

metals release of toxic

models , informal e-waste value chains are offered

phosphor in air. no alternate livelihood options and ultimately they

Printer De-soldering Tin and Lead Air emission of will lose their livelihoods. Safe, low-cost or

Circuit to removing inhalation, Possible the same

Boards computer Brominated Dioxin, substances

intermediate e-waste recycling technology,

chips and Beryllium, Cadmium enabling appropriate finance mechanism, are the

ISSN : 2581-7175 ©IJSRED: All Rights are Reserved Page 648

International Journal of Scientific Research and Engineering Development-– Volume 2 Issue 5, Sep – Oct 2019

Available at www.ijsred.com

need of the day , so that some alternative livelihood VII. REFERENCES

options are emerged for existing e-waste markets by

re-shaping value chain for the better instead only [1] AreportNew Circular Vision for Electronics -Time for a Global Reboot, a

in support of the United Nations e-Waste Coalition, Jan 2019 ,

imposing regulations. published as part of the PACE.

It requires better cooperation and trust between [2] Clean and inclusive Recycling e-Waste in China and India by Kate

Lines Garside, with Satish Sinha and Irina Fedorenko , March 2016 -

national and local governments, manufacturers and published by International Institute for Environment & Development,

retailers, and small informal businesses. An UK

ecosystem- where informal sector functions [3] Status of E-Waste In India- A Review, IsraelCherukuri, Nazia Sultana

And SankaraPitchaiahPodila , IOSR Journal of Environmental Science,

alongside and with the formal, new innovative Toxicology and Food Technology e-ISSN: 2319-2402, p- ISSN: 2319-

2399.Volume 12, Issue 11 Ver. I (November. 2018), PP 08-16

&equitable models of functioning, with key [4] Health hazards caused by unorganised e-waste disposal by V.

economic and non-economic incentives for Ranganathan – web article at link

https://yourstory.com/2018/06/unorganised-e-waste-disposal-dangers

informal and formal, large and small-scale

[5] E-waste: From Toxic to Green India, web article at United Nations-

stakeholders , with greater understanding of the Climate Change

diversity, inequalities and vulnerabilities that exist [6] Electronic Waste and India by Dr. S. Chatterjee, an article on website

within the informal e-waste sector - is to be of Ministry of Electronics & Information Technology, Government of

India

developed in India for settling a balance among all

stakeholder to manage e-Waste better.

Improved scientific understanding of the different

environmental and health risks along the chain, and

the technologies that could mitigate risks, will also

serve to inform better targeted interventions.

VI. CONCLUSIONS

In India, significant size of manpower in informal

sector is involved recycling of e-Waste to extract

elements by using primitive means resulting in

health and environment hazards. Despite

regulations, the concerns of livelihood, & lack of

awareness are important constraints for managing

e-Waste in appropriate ways. A suitable model is to

be evolved including all stakeholders. One

approach could be to create an ecosystem having all

stakeholders in one value chain - unorganized

sector to concentrate on collection, dismantling,

segregation etc; whereas the metal extraction,

recycling and disposal could be done by the

organized sector ; setting responsibilities with

manufacturers to recycle their obsolete produce;

and awareness of masses - so that e-Waste can be

managed in a better way.

ISSN : 2581-7175 ©IJSRED: All Rights are Reserved Page 649

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wattle & DaubDocument9 pagesWattle & DaubRemya R. KumarNo ratings yet

- Ponzi Scheme - EditedDocument4 pagesPonzi Scheme - EditedGifted MaggieNo ratings yet

- ABMM2Document3 pagesABMM2QAISER IJAZNo ratings yet

- A To Z: Social Media MarketingDocument89 pagesA To Z: Social Media MarketingJordan Kasteler100% (1)

- I-765 Online Filing Instructions - FINALDocument13 pagesI-765 Online Filing Instructions - FINALTrân LêNo ratings yet

- Contract Act LawDocument8 pagesContract Act Lawmukmin09No ratings yet

- OJT ReportDocument52 pagesOJT ReportMARK MATUMBA0% (1)

- 134 Motion Pro Hac TantilloDocument6 pages134 Motion Pro Hac Tantillolarry-612445No ratings yet

- Magpie Lab Student Guide Updated 2014 FinalDocument13 pagesMagpie Lab Student Guide Updated 2014 FinalAmanueNo ratings yet

- AnalogI PDFDocument48 pagesAnalogI PDFJerc ZajNo ratings yet

- Lenovo G460 G560 User GuideDocument130 pagesLenovo G460 G560 User GuidejoreyvilNo ratings yet

- Smart Home: An-Najah National University Faculty of EngineeringDocument27 pagesSmart Home: An-Najah National University Faculty of Engineeringمعتز بسام محمود مرداوي معتز بسام محمود مرداويNo ratings yet

- Question BankDocument9 pagesQuestion Bankshama JNo ratings yet

- 21st Century Nanoscience Vol 5Document489 pages21st Century Nanoscience Vol 5pedro100% (1)

- Introduction To GNU Radio and Software RadioDocument4 pagesIntroduction To GNU Radio and Software RadioDinesh VermaNo ratings yet

- Midterm Exam DM 213 Fiscal ManagementDocument8 pagesMidterm Exam DM 213 Fiscal Managementbplo aguilarNo ratings yet

- EIC5000 Electronic Indicator Control Installation and Operation InstructionsDocument8 pagesEIC5000 Electronic Indicator Control Installation and Operation InstructionsАртемNo ratings yet

- Governance Modes in Supply Chains and Financial Performance at Buyer, Supplier and Dyadic Levels: The Positive Impact of Power BalanceDocument30 pagesGovernance Modes in Supply Chains and Financial Performance at Buyer, Supplier and Dyadic Levels: The Positive Impact of Power BalancegiovanniNo ratings yet

- V0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemDocument1 pageV0 VSS VDD: Unit PIN Symbol Level Nominal Dimensions Pin Connections Function Mechanical Data ItemBasir Ahmad NooriNo ratings yet

- Q4 Module 8.2Document14 pagesQ4 Module 8.2Derick0% (1)

- Learning Agreement Student Mobility For StudiesDocument6 pagesLearning Agreement Student Mobility For StudiesEmin FerhatovicNo ratings yet

- Understanding Price Action Practical Analysis of The 5 Minute Time Frame Full ChapterDocument41 pagesUnderstanding Price Action Practical Analysis of The 5 Minute Time Frame Full Chapterjoseph.chavez825100% (29)

- Kamadhenu ReportDocument6 pagesKamadhenu ReportRajaram IyengarNo ratings yet

- GodotDocument977 pagesGodotClaudio Alberto ManquirreNo ratings yet

- Impact of Compensation and Reward SystemDocument88 pagesImpact of Compensation and Reward SystemDhanshri KavatkarNo ratings yet

- Aviary Report Released by City of WatertownDocument26 pagesAviary Report Released by City of WatertownNewzjunkyNo ratings yet

- Using The SQL Transformation in An Informatica Developer MappingDocument10 pagesUsing The SQL Transformation in An Informatica Developer MappingShannonNo ratings yet

- Succeeding A LegendDocument4 pagesSucceeding A LegendFrancie DaltonNo ratings yet

- Mangaliag Vs Catubig-PastoralDocument2 pagesMangaliag Vs Catubig-PastoralPauline LicaycayNo ratings yet

- ASSINGMENT Pavement EngineeringDocument12 pagesASSINGMENT Pavement Engineeringmrafiruler90No ratings yet