Professional Documents

Culture Documents

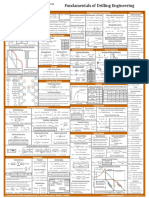

Studyon Drilling Fluidsproprieties

Studyon Drilling Fluidsproprieties

Uploaded by

Aniekan SabastineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Studyon Drilling Fluidsproprieties

Studyon Drilling Fluidsproprieties

Uploaded by

Aniekan SabastineCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/267327034

.2 [Drilling fluid properties] Experiment conducted on [03 December 2012]

Module title: EUB_4_005 Design and Practise 2 Occurrence Number: [9]

Course: [BEng (Hons) Petroleum Engine...

Technical Report · December 2012

CITATIONS READS

0 6,151

1 author:

Arcanjo Wacunzo

London South Bank University

5 PUBLICATIONS 0 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Deepwater Horizon project View project

All content following this page was uploaded by Arcanjo Wacunzo on 24 October 2014.

The user has requested enhancement of the downloaded file.

1.2 [Drilling fluid properties]

Experiment conducted on [03 December 2012]

Module title: EUB_4_005 Design and Practise 2

Occurrence Number: [9]

Course: [BEng (Hons) Petroleum Engineering]

Prepared for: Dr Ahmed Al-Sadday

Prepared by: [Arcanjo Malo Wacunzo]

Student Number: [3021399]

[December/2012]

London South Bank University

Department of Urban Engineering

Faculty of Engineering, Science and the Built Environment

103 Borough Road, London, SE1 0AA

www.lsbu.ac.uk

December 14, 2012 [DRILLING FLUID PROPERTIES]

CONTENTS

Contents .................................................................................................................. 2

List of Appendices ......................................................... Error! Bookmark not defined.

Summary ................................................................................................................. 3

CHAPTER 1 INTRODUCTION ................................................................ 4

AIMS ..................................................... ERROR! BOOKMARK NOT DEFINED.

BACKGROUND ................................................................................................ 5

CHAPTER 2 APPARATUS AND EXPERIMENTAL PROCEDURE ................. 6

INSTRUMENTS ............................................................................................. 7

EXPERIMENTAL PROCEDURE ..................................................................... 8-11

CHAPTER 3 CALCULATIONS AND RESULTS....................................12-13

CHAPTER 4 ANALYSIS AND DISCUSSION .....................................14-15

CHAPTER 5 CONCLUSION AND RECOMENDATIONS .......................16-17

NOMENCLATURE ……………………………………………………………………………18

References ........................................................................................................... 19

LIST OF TABLES

TABLE 1.1 RESULTS OBTAINED ............................................................... 8,9,10

LIST OF FIGURES

FIGURE 1 Shearometer for Gel ....................................................................... 5

FIGURE 2 SPEED REHOMETER …………………………………………………………………………………….5

FIGURE 3 SPEED SELECTION ………………………………………………………………………………………5

FIGURE 4 MARSH FUNNEL ……………………………………………………………………………………………6

FIGURE 5 BAROID MUD BALANCE …………………………………………………………………………………6

Figure 6 Ph DISPENSORS ……………………………………………………………………………………………………………6

London South bank University Page 2

December 14, 2012 [DRILLING FLUID PROPERTIES]

SUMMARY

The experiment was undertaken with the purpose of measure the properties of the fluids.

In addition to those objectives was included the aim of understand the different

behaviour of the mud.

In general, to proceed with the experiment in order to achieve the goals mentioned, a

range of instruments were selected such Baroid mud density, mash funnel and liter cup,

Viscometer, shearometer variable spead Rheometer and the PH dispensers with the ph

meters. All these materials were used in order to understand the reasons why the mud

varies and to know with precision the different properties that the fluids have.

On the whole, at this experiment were used two substances which are the bentonaite and

barite and study the effect of them on the density and consequently their application on

the formation.

In general, after the experiment was seen how properties such as viscosity, density,

shear, yield point and pH are very important to understand the behaviour of the fluids in

the formation and how to be able to control them in order to obtain the economics

results that are aimed.

The key to making the rotary drilling system work is the ability to circulate a fluid

continuously down through the drill pipe, out through the bit nozzles and back to the

surface.

Completely drilling fluids, especially drilling mud, can have a wide range of chemical and

physical properties. These properties are specifically designed for drilling conditions and

the special problems that must be handled in drilling a well.

London South bank University Page 3

December 14, 2012 [DRILLING FLUID PROPERTIES]

CHAPTER 1 -- INTRODUCTION

The main objective for the experiment was to be familiar with the instruments used to

measure the properties of the fluids and the most important to understand the properties

of these fluids. At this experiment were measured some of the most important properties

such as density, viscosity and pH.

A drilling fluid is any fluid which is dispersed through a well in order to remove

cuttings from a wellbore.

Drilling Fluids

A drilling fluid is any fluid which is circulated through a well in order to remove

cuttings from a wellbore. This section will discuss fluids which have water or oil as

their continuous phase. Air, mist and foam, which can be used as drilling fluids, will not

be discussed at this time.

A drilling fluid must fulfil many functions in order for a well to be drilled successfully,

safely, and economically. The most significant purposes are:

Remove drilled cuttings from under the bit

Carry those cuttings out of the hole

Suspend cuttings in the fluid when circulation is stopped

Release cuttings when processed by surface equipment

Allow cuttings to settle out at the surface

Provide enough hydrostatic pressure to balance formation pore pressures

Prevent the bore hole from collapsing or caving in

Protect producing formations from damage which could impair production

Clean, cool, and lubricate the drill bit

Control formation pressure

In addition to it, the drilling fluids conduct hydraulic energy to tools and bit, they stop

reservoir fluids entering the borehole, minimize drilling damage to the reservoir, seal

permeable formations, control corrosion, suspend the cuttings to prevent them from

falling back down the hole when pumping stops.

London South bank University Page 4

December 14, 2012 [DRILLING FLUID PROPERTIES]

1.2 - Detailed functions of the drilling fluids.

1. Cooling and lubrication - By way of the bit drills into the rock

formation, the friction produced by the rotating bit against the rock

generate heat. The heat is dissipated by the circulating drilling fluid.

The fluid also lubricates the bit.

2. Cuttings removal - A significant purpose of the drilling fluid is to

carry rock cuttings removed by the bit to the surface. The drilling flows

through treating equipment where the cuttings are removed and the clean

fluid is again pumped down through the drill pipe string.

3. Suspend cuttings - There are times once circulation has to be stopped.

The drilling fluid must have those gelling characteristics that will prevent

drill cuttings from settling down at the bit. This may cause the drill pipe

to be stuck.

Pressure control. The drilling mud can be the first line of defense

against a blowout or loss of well control caused by formation pressures.

The hydrostatic head produced by the mud in psi is = 0.052 x G x H

Where G = density of mud in ppg

H = depth of the hole in feet.

This hydrostatic head will counter the formation pressure in order to avoid a

blowout while drilling.

London South bank University Page 5

December 14, 2012 [DRILLING FLUID PROPERTIES]

CHAPTER 2 –2.1 APPARATUS AND EXPERIMENTAL PROCEDURE

In this experiment were used a range of instruments with an extreme importance

Concerning to the fluids within the industry. These instruments are mentioned as:

.

Figure 1: Shearometer for Gel or shear- strength measurement

Figure 2: Variable Speed Rheometer.

Figure 3: Rheometer top part, Speed selection.

London South bank University Page 6

December 14, 2012 [DRILLING FLUID PROPERTIES]

This equipment was used to measure the viscosity it’s a very popular method of measuring the viscosity

used by most engineering and it’s used with a watch to control the flow with the time.

Figure 4: Marsh Funnel and One-litre cup for measuring Marsh viscosity. The Marsh

Funnel is a simple device for indicating viscosity on a routine basis. When used with a

measuring cup the funnel gives an empirical value for the consistency of a fluid. The

number obtained depends partly on the effective viscosity at the rate of shear prevailing in

the orifice, and partly on the rate of gelation.

London South bank University Page 7

December 14, 2012 [DRILLING FLUID PROPERTIES]

Figure 5: Baroid Mud balance.

Figure 6: pH Dispensers and pH meter.

London South bank University Page 8

December 14, 2012 [DRILLING FLUID PROPERTIES]

2.2 – EXPERIMENTAL PROCEDURE.

The techniques undertaken in this experiment were done according to the different

properties of drilling mud that were studied in this experiment. The various

experimental procedures are discussed below for each property considered in this

experiment:

To measure the density was used the equipment shown on the figure 5 after it

was calibrated.

First, the instrument was levelled;

Then the fill was cleaned and the dry cup was tested with mud then was

putted and rotated until was seated, was ensured that the mud was

expelled through the hole in the cap in order to free the trapped gas,

The mud was swiped outside the cup and the beam was placed to support

the balance that because the beam is horizontal when the bubble is on the

centre line,

After that the read was taken at the side of the rider towards the knife

edge,

To measure the Viscosity (Mud rheology) was used the equipment in figure 4

the Marsh funnel.

Firstly, the funnel and the vessel were prepared and cleaned while the

mud was been prepared,

Then, the orifice was covered with the fingers and forward the pour mud

sample was filled into the upright funnel until the level on the bottom

screen was reached,

When the mud was inside the funnel totally, very quick the fingers were

removed to measure the time for the mud to fill the vessel which was

receiving the mud,

Then the results were recorded,

London South bank University Page 9

December 14, 2012 [DRILLING FLUID PROPERTIES]

Viscosity measurement using direct-indicating viscometer :

Direct-indicating viscometers are rotational-type instruments powered by

means of an electronic motor. This method was used to determine the

plastic viscosity (PV), the Yield point (YP) and the Gel Strength.

These parameters were measured using the speed rheometer in the

following way:

The plastic Viscosity:

First, the mud sample was placed at the container and the rotor

sleeve and immersed until the line scribed,

The sleeve rotating at 600 rpm and after few seconds the reading

was taken at the steady value. That was the reading for 600 rpm,

Then to take the reading for 300 rpm was waited until the value

became steady and the reading was taken,

Those readings were based on the low and high speed from 600

rpm, 300 rpm, 200 rpm, 100 rpm, 6 rpm and 3rpm.

The yield point:

To calculate the yield point, the plastic viscosity was subtracted

from the dial readings of the plastic viscosity Hence, Yield point

is expressed as: (Dial reading for 300 – Plastic Viscosity)

Apparent Viscosity:

This was obtained by calculating using the division of the

600rpm value by 2.

London South bank University Page 10

December 14, 2012 [DRILLING FLUID PROPERTIES]

Gel-strength:

1) This was measured by using the direct-indicating viscometer and also using a

shearometer, the mud sample was placed in position as in the procedure for

plastic viscosity;

2) Then, stirred at high speed for 10 seconds and then allowed to stand undisturbed

for 10 seconds. Then the hand wheel was slowly and steadily turned to produce

a positive dial reading.

3) The maximum reading was then taken as the initial gel strength at 3rpm; finally,

the mud was retired at high speed for 10 seconds and allowed to stand

undisturbed for 10 minutes.

Observation: The dial readings of 200 rpm, 100 rpm, 6 rpm and 3 rpm that were taken

were not used when evaluating the mud rheology. They were not just taken for granted

per say but it was because according to the API, even with just two points, the

rheological behaviour of the mud can be predicted but to get a bigger picture of how the

mud will behave (respond to shear at different shear rate), since most drilling fluids are

non-Newtonian (ratio of shear stress to shear rate is not constant) it is therefore pertinent

to include them. The different dial speeds in this case represents the rate of shear.

Hydrogen Ion Concentration (pH) measurement:

For this measurement, a pH paper was used, the paper was dipped into the mud to be

tested and then the colour changes was observed and then matched with its

corresponding value.

London South bank University Page 11

December 14, 2012 [DRILLING FLUID PROPERTIES]

CHAPTER 3 -- CALCULATIONS AND RESULTS

Table 1: Results of the mud parameters obtained at the experiment.

Mud parameters Mud Compositions

Mud Parameters Bentonite(150g) + Water(2L) Bentonite(150g) +

Water(2L) + Barite

(150g)

Mud Weight(ppg) 8.7 = 1.040g/cm3 9.2 = 1.1g/cm3

Marsh 37 37

Viscosity(seconds)

Plastic Viscosity 6 7

(cp)

Apparent Viscosity 11 13.5

Yield Point 10 13

2

(lb/100ft )

Gel Strength 10s =8 10sec=17

2

(lb/100ft ) 10min=18 10min=32

Gel Strength, 10sec=4.7 10sec=8.2

Shearometer 10min=5.7 10min=5.3

2

(lb/100ft )

pH 8.5 8.5

London South bank University Page 12

December 14, 2012 [DRILLING FLUID PROPERTIES]

Table 2: Experimental results showing density all the dial readings taken using variable

speed rheometer.

Dial speed ( rpm ) Dial Reading ( cp )

ɸ600 27

ɸ 300 20

ɸ 200 17

ɸ 100 14

ɸ6 12

ɸ3 9

Calculus

Yield Point :

Yp = ɸ300 –Pv = 16 -6 =10 1b/100ft2

Plastic Viscosity :

PV = Reading for ɸ 600 – reading for ɸ 300

Pv = 27 cp – 20 cp = 7 cp

Apparent Viscosity :

Av =

Av = = 11

London South bank University Page 13

December 14, 2012 [DRILLING FLUID PROPERTIES]

CHAPTER 4 -- ANALYSIS AND DISCUSSION

After the experiment taken place the results were analysed and was seen the range of

questions answered related to the fluid properties which was the aim of the experiment.

Many drilling problems are due to conditions or situations that occur after drilling

begins and for which the drilling fluid was not designed. Some of these problems can be

solved by adding materials to the drilling fluid to adjust its properties.

The reason to measure mud density and why it varies?

It is very important to measure the mud weight and vary it accordingly to ensure

adequate hydrostatic head or pressure to prevent the influx of formation, but not too

high to cause loss of circulation or affect the drilling rate and damage the formation.

Throughout drilling operations, the pressure at the bottom of the column of drilling mud

must balance or be considerably higher than the pressure exerted by the fluids in the

porous formation to stop fluids entering the wellbore and causing a kick or in the

extreme case a blowout.

Pt = h ρ g (1) to maintain pressure control, Pt = h ρ g ≥ Pr.

Pr is the formation pore and from the above, it shows that the density of the mud must

be measured so as to help maintain pressure control.

The procedure of varying the weight of the drilling mud is recognized as mud

balancing. This could be both by increasing it or diminishing it. One way of doing this

is by adding a heavy solid known as weighting agent to the mud. The commonest

weighting agent is barite which was used. Because of its high density (35.82 ppg),

barite can increase the density of drilling mud to as much as about 25 ppg (2500

kg/m3). This explains why the parameters of the mud changed as seen in table 1 when

barite was added to the mud from 8.7 to 9.2.

London South bank University Page 14

December 14, 2012 [DRILLING FLUID PROPERTIES]

Reasons why the mud viscosity was measured and how to maintain it.

The viscosity of the mud had to be measured because this rheological parameter helps to

determine how drilling fluids will flow under a variety of different conditions.

Furthermore, Viscosity can be in the form of plastic or apparent viscosity. The former

is a measure of the internal resistance to fluid flow resulting from interaction of solids in

a drilling mud, while the latter is the viscosity of the drilling mud measured at a given

shear rate at a fixed temperature.

The Yield point is influenced by the concentration of solids, their electrical charge, and

other factors. If not at the proper value, it can also reduce drilling efficiency by cutting

penetration rate, increasing circulating pressure, and posing the danger of lost

circulation.

To maintain the viscosity can be used a process that consists in addition of water,

phosphates or lignite. This act by thinning the drilling mud thereby keeping the mud

viscosity at a level required for the drilling operation. In a situation where water is used,

the quantity of water to barite should not exceed 1gallon of water per 100bl of barite.

How to Increase or decrease the yield point?

The yield point of a mud can be reduced by adding deflocculant to a clay-based mud

and increased by adding freshly dispersed clay or a flocculant.

Importance of the pH value and how to increase it for alkaline?

The pH is a very important parameter and it can be acid or alkaline depending on our

objectives. It helps to prevent the corrosion of the downhole materials.

The reason for this is that the tools and tubular used in drilling process, casing and

completing a well can be subjected to corrosion by the action of the drilling mud left in

the annulus after cementation.

What makes the pH decrease below 7 the formation of H2S it forms acid and damages

the equipment, however, to keep the value alkaline between 9 and 10 it is recommended

to used hydroxyl and other hydroxide substances because under high temperature they

are very active and they react against the clay.

London South bank University Page 15

December 14, 2012 [DRILLING FLUID PROPERTIES]

CHAPTER 5 - CONCLUSION

To conclude, the experiment occurred at the predicted conditions. It is important to refer

some of the most important aspects such as:

The parameters of the mud altered due to a weighting agent which was the barite. These

weighting agents are high specific gravity materials or substances that are used to

change the parameters and or rheology of drilling muds for example density.

The difference between the yield point and the gel strength measurements is that gel

strength is time dependent. This is usually done in 10 seconds and 10 minutes range.

The following are some of the reasons why gel strength of drilling mud should be

measured and maintained in the favourable range.

Overall, these parameters are extremely relevant in dealing with fluids the constant

maintenance and control of them can decrease the range of problems and prevent

accidents like blowouts and formation damages.

London South bank University Page 16

December 14, 2012 [DRILLING FLUID PROPERTIES]

5.2 - Recommendation

This aspect which is usually ignored by some operators is very important, whenever

using the instrument to measure the density of more than one fluid it is recommended to

calibrate it and wash per each time it is used because these will influence the results.

This process should be done also for the viscosity and the other parameters.

In addition, when measuring Gel strength, the mud must be agitated for few minutes in

order to prevent precipitation.

London South bank University Page 17

December 14, 2012 [DRILLING FLUID PROPERTIES]

NOMENCLATURE

p plastic viscosity, cp

aF = apparent viscosity, cp

Yb = Bingham yield point, lb/100 ft2

= Torque readings from instrument dial at 600 and 300 rpm.

Hp = hydrostatic pressure.

Dv = vertical depth.

Fl = flowline depth.

MD = fluid density.

g = gravitational constant

Ph = potential Hydrogen

London South bank University Page 18

December 14, 2012 [DRILLING FLUID PROPERTIES]

REFERENCES

1) HTTP://WWW.MID-

CONTINENTS.COM/CATEGORY/EQUIPMENT-

SPARES/FANN-INSTRUMENTS [accessed on 06.12.12]

2) HTTP://WWW.SERENEENERGY.ORG/DRILLING-FLUID-

PROPERTIES.PHP [accessed on 09.12.12]

3) Azzar, J. J and Lummus, J. L. (1975) The Effect of Drilling Fluid pH

on Drill Pipe Corrosion Fatigue Performance: Paper presented at

the SPE fall meeting (No. 5516-MS). [Online]

4) HTTP://HUBCAP.CLEMSON.EDU/~BLPPRT/ACID5.HTML

[accessed on 10.12.12]

5) HTTP://WWW.URI.EDU/CE/WQ/WW/PUBLICATIONS/P

H&ALKALINITY.PDF [accessed on 12.12.12]

London South bank University Page 19

View publication stats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Build Up Rate Format - PavingDocument4 pagesBuild Up Rate Format - PavingFaiz Ahmad83% (6)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- General Notes: Roof Slab PlanDocument1 pageGeneral Notes: Roof Slab PlansolebNo ratings yet

- Aes Primary Emulsifier SDS 04-2015Document7 pagesAes Primary Emulsifier SDS 04-2015Aniekan SabastineNo ratings yet

- Piggery CareDocument8 pagesPiggery CareAniekan SabastineNo ratings yet

- Well Completion For Severe Corrosive OilDocument35 pagesWell Completion For Severe Corrosive OilAniekan SabastineNo ratings yet

- Hazardous Waste CharacteristicsDocument2 pagesHazardous Waste CharacteristicsAniekan SabastineNo ratings yet

- MIT-Multifinger Caliper Interpretation and ApplicationsDocument43 pagesMIT-Multifinger Caliper Interpretation and ApplicationsAniekan SabastineNo ratings yet

- Solids Dilution ChartDocument6 pagesSolids Dilution ChartAniekan SabastineNo ratings yet

- Drilling and ProductionDocument2 pagesDrilling and ProductionAniekan SabastineNo ratings yet

- Products Specific GravitiesDocument4 pagesProducts Specific GravitiesAniekan SabastineNo ratings yet

- Gas LiftDocument34 pagesGas LiftAniekan Sabastine100% (2)

- Casing DesignDocument26 pagesCasing DesignAniekan SabastineNo ratings yet

- Schedule Gantri Crane 160TDocument1 pageSchedule Gantri Crane 160TdaniNo ratings yet

- Marine Structure Designs: Lecture #15 (Rubble Mount Structures)Document24 pagesMarine Structure Designs: Lecture #15 (Rubble Mount Structures)prash_mceNo ratings yet

- European Wide Flange Beams in Accordance With enDocument4 pagesEuropean Wide Flange Beams in Accordance With enj_herndz100% (1)

- Water Distribution: PipelinesDocument4 pagesWater Distribution: PipelinesYash DhabaliaNo ratings yet

- 15 Recommended Books For GATE Civil Engineering 2018Document5 pages15 Recommended Books For GATE Civil Engineering 2018Amit SharmaNo ratings yet

- Criteria of Judgement of BearingDocument1 pageCriteria of Judgement of BearingzaheerNo ratings yet

- Classification of Engineering ServicesDocument9 pagesClassification of Engineering ServicesJulius ValerioNo ratings yet

- Tute 07 Traffic Loading & Pavement DesignDocument2 pagesTute 07 Traffic Loading & Pavement Designyu yanNo ratings yet

- Manual FOR Highway Bridge Maintenance Inspection: Lndian S Esial 18Document37 pagesManual FOR Highway Bridge Maintenance Inspection: Lndian S Esial 18sameer mistryNo ratings yet

- Revised National Plumbing Code of The Philippines (Principles)Document2 pagesRevised National Plumbing Code of The Philippines (Principles)Vanessa DamasoNo ratings yet

- Concrete LCDA - Technical Data Panbeton OriginDocument8 pagesConcrete LCDA - Technical Data Panbeton OriginGeneral RobertNo ratings yet

- DPPR 210519 Utility+etpDocument1 pageDPPR 210519 Utility+etpRavi ShankarNo ratings yet

- Top Beam Details1Document13 pagesTop Beam Details1AATVIK SHRIVASTAVANo ratings yet

- GC Plus PVC 2024 - 20240122Document43 pagesGC Plus PVC 2024 - 20240122Andrian NugrohoNo ratings yet

- CS 25 RockfillDocument3 pagesCS 25 Rockfillraduga_fb100% (1)

- Iapmo Ues Er493Document13 pagesIapmo Ues Er493jeffuangNo ratings yet

- How To Fix Fibre Cement Slates - Cembrit - ESI Building DesignDocument7 pagesHow To Fix Fibre Cement Slates - Cembrit - ESI Building DesignHood RockNo ratings yet

- Presentasi Waste Water Treatment PlantDocument8 pagesPresentasi Waste Water Treatment Plantika yuliyani murtiharjonoNo ratings yet

- 2020.01.13 Guide Line File - BHTC-2 PDFDocument196 pages2020.01.13 Guide Line File - BHTC-2 PDFAdnan IslamNo ratings yet

- PEX Installation Handbook 2006Document17 pagesPEX Installation Handbook 2006obNo ratings yet

- Material InventoryDocument1 pageMaterial InventorylegallyhungryblueNo ratings yet

- Precast Segmental Box Girder Bridges PDFDocument15 pagesPrecast Segmental Box Girder Bridges PDFJoni BarjonoNo ratings yet

- 1D Consolidation - Terzhagi Theory (SEP 2011)Document38 pages1D Consolidation - Terzhagi Theory (SEP 2011)bsitlerNo ratings yet

- Final Term - Fall Introduction To Structural Dynamics & Earthquake EngineeringDocument3 pagesFinal Term - Fall Introduction To Structural Dynamics & Earthquake EngineeringAtif KhanNo ratings yet

- Objective of A Pushover AnalysisDocument3 pagesObjective of A Pushover Analysishemantkle2uNo ratings yet

- 2D Structural Analysis GRASP PDFDocument68 pages2D Structural Analysis GRASP PDFKeirl John AsinguaNo ratings yet

- (FEM) Geotechnical Analysis by The Finite Element Method - Ok!!!Document43 pages(FEM) Geotechnical Analysis by The Finite Element Method - Ok!!!gzapas100% (1)