Professional Documents

Culture Documents

Guidelines For Incoming Inspection

Guidelines For Incoming Inspection

Uploaded by

Aman KatiyarCopyright:

Available Formats

You might also like

- PDF Entertainment Industry Economics A Guide For Financial Analysis Tenth Edition Harold L Vogel Ebook Full ChapterDocument37 pagesPDF Entertainment Industry Economics A Guide For Financial Analysis Tenth Edition Harold L Vogel Ebook Full Chaptertamatha.gibson116100% (3)

- Meeting Global and Local Needs - Siemens.Document7 pagesMeeting Global and Local Needs - Siemens.Cheryl Formilleza SombillaNo ratings yet

- HDT First Article Inspection Policy 01Document7 pagesHDT First Article Inspection Policy 01Srinivasan VenkatNo ratings yet

- Free Quality Management System TemplateDocument8 pagesFree Quality Management System Templateselinasimpson1401No ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- Contract Review-QMP-MK-01Document5 pagesContract Review-QMP-MK-01Rohit VishwakarmaNo ratings yet

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Corrective Action Form PDFDocument1 pageCorrective Action Form PDFchahiNo ratings yet

- CN 04 0102-BBL3 2016-06Document4 pagesCN 04 0102-BBL3 2016-06Aman KatiyarNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- QSP 06 Control of Non Conforming ProductDocument3 pagesQSP 06 Control of Non Conforming Productkmvimal36No ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- SOP QualiityDocument28 pagesSOP QualiityUttam KumarNo ratings yet

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- 04 Turtle DiagramsDocument1 page04 Turtle Diagramsabhisheksen.asindNo ratings yet

- Quality Control: and Inspection SystemDocument32 pagesQuality Control: and Inspection SystemAshley Kane P. DumayNo ratings yet

- CPP Supplier Audit ResultDocument3 pagesCPP Supplier Audit ResultKevin MejiaNo ratings yet

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- 8D Training: Quality Department Quality Training Corrective Action, 8D & Concern ReportingDocument16 pages8D Training: Quality Department Quality Training Corrective Action, 8D & Concern ReportingKarl SmithNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Iqc Chapter 01 PDFDocument8 pagesIqc Chapter 01 PDFNaveen Kumar GunisettyNo ratings yet

- Quality Management SystemDocument29 pagesQuality Management SystemArunNo ratings yet

- Control Plan TRANINGDocument18 pagesControl Plan TRANINGqualityNo ratings yet

- Process Layout ImprovementDocument5 pagesProcess Layout ImprovementhappyrockzzNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Sampling PlanDocument6 pagesSampling PlanGaurang DaveNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- Control of Non ConformingDocument5 pagesControl of Non ConformingNaveenkumar R100% (1)

- Title: Process Validation Report of Stress Relieving: 1. AbstractDocument3 pagesTitle: Process Validation Report of Stress Relieving: 1. AbstractCorrosion FactoryNo ratings yet

- QP 83001 Rev 09 Non-Conforming Material Control ProcedureDocument6 pagesQP 83001 Rev 09 Non-Conforming Material Control ProcedureImam MansyurNo ratings yet

- Global Supplier Quality Manual-Second EditionDocument43 pagesGlobal Supplier Quality Manual-Second EditionSuhas ChinchanikarNo ratings yet

- Supplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNODocument42 pagesSupplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOumtNo ratings yet

- Basic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsDocument1 pageBasic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsMichael Ang100% (1)

- Objective Monitoring Sheet: Objectiv e Target S. No Action Plan Deadline Responsibility CompletedDocument1 pageObjective Monitoring Sheet: Objectiv e Target S. No Action Plan Deadline Responsibility CompletedNiraNo ratings yet

- PPAP - 4th Edition - Course MaterialDocument18 pagesPPAP - 4th Edition - Course MaterialMy Dad My WorldNo ratings yet

- Process Capability Statistics: CPK vs. PPK: Rational SubgroupsDocument33 pagesProcess Capability Statistics: CPK vs. PPK: Rational SubgroupsAgustinus SitioNo ratings yet

- SOP For Handling of Out of Calibration (OOC) Instruments and EquipmentDocument3 pagesSOP For Handling of Out of Calibration (OOC) Instruments and EquipmentSolomonNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixjefry sitorus0% (1)

- Procedure - Outsourced ProcessesDocument1 pageProcedure - Outsourced Processesdellanadia putriNo ratings yet

- 5.6 Management Review: 5.6.1 GeneralDocument1 page5.6 Management Review: 5.6.1 GeneralTina Miller100% (1)

- 4.4.1 Product SafetyDocument5 pages4.4.1 Product SafetyVijayendran VijayNo ratings yet

- Reaction PlanDocument14 pagesReaction PlanMariaNilaZaragozaPalacioNo ratings yet

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanJoki PenangNo ratings yet

- Outsourced Processes 9001 2015Document2 pagesOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Layer Process AuditDocument8 pagesLayer Process AuditR JNo ratings yet

- Daily Morning Meeting Report at 06.10 Am: Follow Up Job RemarksDocument3 pagesDaily Morning Meeting Report at 06.10 Am: Follow Up Job RemarksmupiNo ratings yet

- Layered AuditDocument5 pagesLayered AuditlugarxNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFRehman LatifNo ratings yet

- Customer Complaint ProcedureDocument4 pagesCustomer Complaint ProcedureTom100% (1)

- Sap QM ModuleDocument2 pagesSap QM ModulemohannaiduramNo ratings yet

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Clause 9 PerformanceDocument8 pagesClause 9 Performancesharif1974No ratings yet

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya Wati100% (3)

- Quality Risk Management During COVID-19 Prevention: Created By: RBIN/QMMDocument21 pagesQuality Risk Management During COVID-19 Prevention: Created By: RBIN/QMMAman KatiyarNo ratings yet

- CN 04 0102-BBL3 2016-06 PDFDocument4 pagesCN 04 0102-BBL3 2016-06 PDFAman KatiyarNo ratings yet

- Test Dust - Test Dust Production - Particle TechnologyDocument2 pagesTest Dust - Test Dust Production - Particle TechnologyAman Katiyar100% (1)

- FEC - Filter Media Pore Test Rig PDFDocument2 pagesFEC - Filter Media Pore Test Rig PDFAman KatiyarNo ratings yet

- ASTM D200 SAE J200 (2) ASTM and SAE Rubber Code Table - enDocument2 pagesASTM D200 SAE J200 (2) ASTM and SAE Rubber Code Table - enAman Katiyar0% (1)

- Classical Consumer Lifestyle Segmentation MethodsDocument55 pagesClassical Consumer Lifestyle Segmentation MethodskristinaNo ratings yet

- SIP - Recruitment & Selection ProcessDocument25 pagesSIP - Recruitment & Selection ProcessKunal BagdeNo ratings yet

- Burberry Final DraftDocument11 pagesBurberry Final Draftmax yeangNo ratings yet

- LSS Project Report Out TemplateDocument35 pagesLSS Project Report Out TemplateVarshith JoshNo ratings yet

- PRACTICE OF TRANSLATION (Diary)Document3 pagesPRACTICE OF TRANSLATION (Diary)ElenaNo ratings yet

- DocxDocument6 pagesDocxMeshack MathembeNo ratings yet

- Partnership Liquidation NotesDocument7 pagesPartnership Liquidation NotesMary Rica DublonNo ratings yet

- Financial Markets A Beginners ModuleDocument93 pagesFinancial Markets A Beginners ModuleVishnu PearlsNo ratings yet

- Implementing A Lean Six Sigma STANDARDIZEDDocument24 pagesImplementing A Lean Six Sigma STANDARDIZEDKATY lORENA MEJIA PEDROZONo ratings yet

- HEIRS OF JOSE LIM vs. JULIET VILLA LIM G.R. No. 172690 March 3, 2010Document2 pagesHEIRS OF JOSE LIM vs. JULIET VILLA LIM G.R. No. 172690 March 3, 2010SSNo ratings yet

- NCC Cover PageDocument3 pagesNCC Cover PageDeepakNo ratings yet

- Oum - Semester January 2023 - BBMC4103 Change Management - Nahariah MD SumairiDocument14 pagesOum - Semester January 2023 - BBMC4103 Change Management - Nahariah MD SumairiNahariah Md SumairiNo ratings yet

- Athenahealth - WikipediaDocument5 pagesAthenahealth - WikipediakhanmdNo ratings yet

- TCSDocument10 pagesTCSananyaNo ratings yet

- Novo NordiskDocument14 pagesNovo NordiskHồ Trúc HuệNo ratings yet

- Topic 12 - Payables, Provisions and Contingent LiabilitiesDocument14 pagesTopic 12 - Payables, Provisions and Contingent Liabilitiesmariam simonyanNo ratings yet

- Porter's Generic Competitive Strategies and Its Influence On The Competitive AdvantageDocument10 pagesPorter's Generic Competitive Strategies and Its Influence On The Competitive AdvantageKomal sharmaNo ratings yet

- CARAVANS T k1 Kirkuk (1) 428128371Document27 pagesCARAVANS T k1 Kirkuk (1) 428128371mahmoodshowkiNo ratings yet

- Sale and Purchase Agreement Flow ChartDocument1 pageSale and Purchase Agreement Flow ChartZureen ZamriNo ratings yet

- Pallavi TS Project ReportDocument33 pagesPallavi TS Project ReportPrem KumarnNo ratings yet

- Salary Statement Ovie NewDocument6 pagesSalary Statement Ovie NewJr QomarruzzamanNo ratings yet

- Icici Bank CBRDocument49 pagesIcici Bank CBRHarshad Sutar100% (1)

- Chapter 6 ETHICAL ISSUES AND SOCIAL RESPONSIBILITY OF ENTREPRENEURS Chapter 6Document4 pagesChapter 6 ETHICAL ISSUES AND SOCIAL RESPONSIBILITY OF ENTREPRENEURS Chapter 6Kariuki CharlesNo ratings yet

- EM2301. Practical Class 6Document3 pagesEM2301. Practical Class 6luu duongNo ratings yet

- Salary Survey 2021Document340 pagesSalary Survey 2021Khalid HameedNo ratings yet

- Chapter 2 Demand (Eco)Document41 pagesChapter 2 Demand (Eco)Aneesa RoslanNo ratings yet

- Mapping The Way Forward An Analysis of Philrice's Corporate Planning StrategiesDocument8 pagesMapping The Way Forward An Analysis of Philrice's Corporate Planning StrategiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quarter III - Lesson 2 Provide Club Reception Services (CR)Document32 pagesQuarter III - Lesson 2 Provide Club Reception Services (CR)Anthony MonticilloNo ratings yet

Guidelines For Incoming Inspection

Guidelines For Incoming Inspection

Uploaded by

Aman KatiyarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines For Incoming Inspection

Guidelines For Incoming Inspection

Uploaded by

Aman KatiyarCopyright:

Available Formats

Date of Orig. 24.02.

2017

GUIDELINES FOR INSPECTION AND RECEIVING OF

Rev Date: 27.03.2017

INCOMING MATERIAL

Rev No. 1

1- PURPOSE:

This documented directive describes the guidelines for Inspection and Receiving policy of all type of raw material, packaging material, Rubber

Compounds for all products of Steelbird International. Compliance with these guidelines is essential to achieve consistency in the expected quality

of incoming materials.

2- SCOPE:

To maintain consistent quality/ Delivery/ Quantity of all type of incoming materials(Raw Material, Packaging Material, Semi finished Material).

3- DECLARATION:

3.1- All suppliers and concern person are requested kindly acknowledge this guidelines and revert with your written acceptance.

3.2- During development of New source/Supplier, kindly submit the signed copy of this form with isir or assessment form.

4- ACKNOWLEDGEMENT:

Note- All suppliers, Concern persons are requested please make sure that you have all type of specifications/Drawings/Standards

and MOQs are available at your end and also discussed with us.

4.1- Mandatory Requirements-

4.1.1- All Material should be made as per defined Specs/Drawing.

4.1.2- Inspection/Testing Report must be send along with each supply.

4.1.3- Test Sample/Tested Sample/Test Sheet(whatever required as predefined), must be send along with supply.

4.1.4- Packing slip or material detail must be send along with supply.

RESPONSIBILITY:

1- Purchase Manager

2- Store Manager

3- Quality Manager

4- Store Executive

5- QC Inspector(Incoming)

*** Name Signature Date

Prepared By:- Aman 28.02.2017

Checked By:- Pramod Yadav 28.02.2017

Approved By:- Manav Kapur

Date of Orig. 24.02.2017

GUIDELINES FOR INSPECTION AND RECEIVING OF

Rev Date: 27.03.2017

INCOMING MATERIAL

Rev No. 1

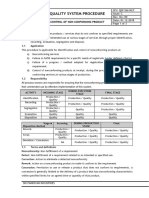

PROCEDURE:

Material Receive if

all mandatory data is

Check material

Yes receive as per No

delivery date?

Check the material receive Is Delivery

quantity

OK Yes No

and offer to Qc for Date Max 2

Against PO. Inspection. Days after

NOT OK A

Is Quantity Max

10% more than Yes

PO Qty.

Inspection

NOT OK as per OK

Specs/

No

Drawing.

B

C Forward To Store

Rejection

A Store

If Material Receive after 2 Days of PO Date.

First Chance-

* Warning to supplier about the delivery time. (Who- Store Executive, When- Same Day)

Second Chance-

* Final Warning to supplier about the delivery time. (Who- Store Manager, When- Same Day)

Third Chance-

* Payment of such consignment will be delay by 14 days from discussed in PO.

(Who- Store Executive, When- Same Day)

Fourth Chance-

* Payment of such consignment will be delay by 30 days from discussed in PO.

(Who- Purchase Manager, When- Same Day)

*** Name Signature Date

Prepared By:- Aman 28.02.2017

Checked By:- Pramod Yadav 28.02.2017

Approved By:- Manav Kapur

Date of Orig. 24.02.2017

GUIDELINES FOR INSPECTION AND RECEIVING OF

Rev Date: 27.03.2017

INCOMING MATERIAL

Rev No. 1

PROCEDURE:

If Material Receive more than 30% of PO Qty.

First Chance-

* Warning to supplier about the quantity. (Who- Store Executive, When- Same Day)

Second Chance-

* Return all excess material to supplier including the both side(Receiving and dispatch) freight charges.

(Who- Store Manager, When- Same Day)

Third Chance-

* Return All excess material with debit 5% of value of Excess Quantity and intimate also to supplier and Accounts.

(Who- Store Executive, When- Same Day)

Fourth Chance-

* Return all excess material with debit 10% of value of excess material. And intimate to supplier and Accounts as well.

(Who- Purchase Manager, When- Same Day)

If Material not as per Specification-

First Chance-

* Warning to supplier about the defects. If Material is able to rework or segregate or urgent for us, done the

segregation/rework and debit the cost of rework or segregation. If Not able to rework or segregation, return as rejection with freight

charge. Intimate to supplier and Accounts. (Who- QC Receiving Incharge, When- Same Day)

Second Chance-

* Final Warning to supplier about the defects. If Material is able to rework or segregate or urgent for us, done the segregation/rework

and debit the 2 time cost of rework or segregation. If Not able to rework or segregation, return as rejection with 10% of Invoice

Value as Penalty and freight charge. Intimate to supplier and Accounts.

(Who- Manager QC, When- Same Day)

Third Chance-

* If Material is able to rework or segregate or urgent for us, done the segregation/rework and debit the 15% of invoice value as

charge of rework or segregation. If Not able to rework or segregation, destroy the material at our end and debit 100% of Invoice

Value. Also intimate to supplier and Accounts. (Who- Manager QC, When- Same Day)

Fourth Chance-

* Same as Third Chance and start the developing of new source after developed the new source Cancel all orders and

blacklisted to such suppliers. (Who- Purchase Manager, When- Same Day)

Note- If we observed defects are repeat or material is same(as we returned to supplier) we'll destroy all material at our

end and debit 125% of invoice value to supplier. This is also applicable in each chance.

*** Name Signature Date

Prepared By:- Aman 28.02.2017

Checked By:- Pramod Yadav 28.02.2017

Approved By:- Manav Kapur

You might also like

- PDF Entertainment Industry Economics A Guide For Financial Analysis Tenth Edition Harold L Vogel Ebook Full ChapterDocument37 pagesPDF Entertainment Industry Economics A Guide For Financial Analysis Tenth Edition Harold L Vogel Ebook Full Chaptertamatha.gibson116100% (3)

- Meeting Global and Local Needs - Siemens.Document7 pagesMeeting Global and Local Needs - Siemens.Cheryl Formilleza SombillaNo ratings yet

- HDT First Article Inspection Policy 01Document7 pagesHDT First Article Inspection Policy 01Srinivasan VenkatNo ratings yet

- Free Quality Management System TemplateDocument8 pagesFree Quality Management System Templateselinasimpson1401No ratings yet

- Supplier 8D FormDocument3 pagesSupplier 8D FormBen DesireNo ratings yet

- Contract Review-QMP-MK-01Document5 pagesContract Review-QMP-MK-01Rohit VishwakarmaNo ratings yet

- Incoming Inspection-Qmp-Qc-01Document2 pagesIncoming Inspection-Qmp-Qc-01Rohit VishwakarmaNo ratings yet

- Procedure: Measurement System Analysis ExecutionDocument1 pageProcedure: Measurement System Analysis Executionaslam100% (1)

- Corrective Action Form PDFDocument1 pageCorrective Action Form PDFchahiNo ratings yet

- CN 04 0102-BBL3 2016-06Document4 pagesCN 04 0102-BBL3 2016-06Aman KatiyarNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- QSP 06 Control of Non Conforming ProductDocument3 pagesQSP 06 Control of Non Conforming Productkmvimal36No ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionDocument1 pageMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Product InspectionRohit VishwakarmaNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- QP-55-03 Customer Complaint Suggestion Comment & SurveyDocument6 pagesQP-55-03 Customer Complaint Suggestion Comment & SurveySamsudin AhmadNo ratings yet

- SOP QualiityDocument28 pagesSOP QualiityUttam KumarNo ratings yet

- Incoming VTM Material Inspection Procedure - RevisedDocument6 pagesIncoming VTM Material Inspection Procedure - RevisedMusyoka Urbanus100% (1)

- 04 Turtle DiagramsDocument1 page04 Turtle Diagramsabhisheksen.asindNo ratings yet

- Quality Control: and Inspection SystemDocument32 pagesQuality Control: and Inspection SystemAshley Kane P. DumayNo ratings yet

- CPP Supplier Audit ResultDocument3 pagesCPP Supplier Audit ResultKevin MejiaNo ratings yet

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonNo ratings yet

- 8D Training: Quality Department Quality Training Corrective Action, 8D & Concern ReportingDocument16 pages8D Training: Quality Department Quality Training Corrective Action, 8D & Concern ReportingKarl SmithNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument52 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Centurion Power Cables (P) LTD.: Control of DocumentDocument4 pagesCenturion Power Cables (P) LTD.: Control of DocumenttriveshNo ratings yet

- Iqc Chapter 01 PDFDocument8 pagesIqc Chapter 01 PDFNaveen Kumar GunisettyNo ratings yet

- Quality Management SystemDocument29 pagesQuality Management SystemArunNo ratings yet

- Control Plan TRANINGDocument18 pagesControl Plan TRANINGqualityNo ratings yet

- Process Layout ImprovementDocument5 pagesProcess Layout ImprovementhappyrockzzNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Sampling PlanDocument6 pagesSampling PlanGaurang DaveNo ratings yet

- IQA-Incoming Inspection Flow ChartDocument1 pageIQA-Incoming Inspection Flow ChartmohNo ratings yet

- Control of Non ConformingDocument5 pagesControl of Non ConformingNaveenkumar R100% (1)

- Title: Process Validation Report of Stress Relieving: 1. AbstractDocument3 pagesTitle: Process Validation Report of Stress Relieving: 1. AbstractCorrosion FactoryNo ratings yet

- QP 83001 Rev 09 Non-Conforming Material Control ProcedureDocument6 pagesQP 83001 Rev 09 Non-Conforming Material Control ProcedureImam MansyurNo ratings yet

- Global Supplier Quality Manual-Second EditionDocument43 pagesGlobal Supplier Quality Manual-Second EditionSuhas ChinchanikarNo ratings yet

- Supplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNODocument42 pagesSupplier Quality Manual: Zetor Tractors A.S. Trnkova 111 628 00 BRNOumtNo ratings yet

- Basic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsDocument1 pageBasic Flowchart of Incoming & Outgoing of Stock Indent Non-Conforming MaterialsMichael Ang100% (1)

- Objective Monitoring Sheet: Objectiv e Target S. No Action Plan Deadline Responsibility CompletedDocument1 pageObjective Monitoring Sheet: Objectiv e Target S. No Action Plan Deadline Responsibility CompletedNiraNo ratings yet

- PPAP - 4th Edition - Course MaterialDocument18 pagesPPAP - 4th Edition - Course MaterialMy Dad My WorldNo ratings yet

- Process Capability Statistics: CPK vs. PPK: Rational SubgroupsDocument33 pagesProcess Capability Statistics: CPK vs. PPK: Rational SubgroupsAgustinus SitioNo ratings yet

- SOP For Handling of Out of Calibration (OOC) Instruments and EquipmentDocument3 pagesSOP For Handling of Out of Calibration (OOC) Instruments and EquipmentSolomonNo ratings yet

- Customer Specific Requirements MatrixDocument4 pagesCustomer Specific Requirements Matrixjefry sitorus0% (1)

- Procedure - Outsourced ProcessesDocument1 pageProcedure - Outsourced Processesdellanadia putriNo ratings yet

- 5.6 Management Review: 5.6.1 GeneralDocument1 page5.6 Management Review: 5.6.1 GeneralTina Miller100% (1)

- 4.4.1 Product SafetyDocument5 pages4.4.1 Product SafetyVijayendran VijayNo ratings yet

- Reaction PlanDocument14 pagesReaction PlanMariaNilaZaragozaPalacioNo ratings yet

- How To Conduct Management ReviewDocument8 pagesHow To Conduct Management ReviewS Seetharaman100% (1)

- Ipc & Ipp Logbook or FlowDocument8 pagesIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- Steel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditDocument2 pagesSteel Konnect (India) Pvt. Ltd. Procedure Manual: Procedure For Internal Quality AuditmahendraNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanJoki PenangNo ratings yet

- Outsourced Processes 9001 2015Document2 pagesOutsourced Processes 9001 2015Navnath Tamhane0% (1)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Layer Process AuditDocument8 pagesLayer Process AuditR JNo ratings yet

- Daily Morning Meeting Report at 06.10 Am: Follow Up Job RemarksDocument3 pagesDaily Morning Meeting Report at 06.10 Am: Follow Up Job RemarksmupiNo ratings yet

- Layered AuditDocument5 pagesLayered AuditlugarxNo ratings yet

- Control Plan PQCT TableII PDFDocument1 pageControl Plan PQCT TableII PDFRehman LatifNo ratings yet

- Customer Complaint ProcedureDocument4 pagesCustomer Complaint ProcedureTom100% (1)

- Sap QM ModuleDocument2 pagesSap QM ModulemohannaiduramNo ratings yet

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessDocument1 page6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariNo ratings yet

- Clause 9 PerformanceDocument8 pagesClause 9 Performancesharif1974No ratings yet

- Procedure Recall ProductDocument3 pagesProcedure Recall ProductLinda Setya Wati100% (3)

- Quality Risk Management During COVID-19 Prevention: Created By: RBIN/QMMDocument21 pagesQuality Risk Management During COVID-19 Prevention: Created By: RBIN/QMMAman KatiyarNo ratings yet

- CN 04 0102-BBL3 2016-06 PDFDocument4 pagesCN 04 0102-BBL3 2016-06 PDFAman KatiyarNo ratings yet

- Test Dust - Test Dust Production - Particle TechnologyDocument2 pagesTest Dust - Test Dust Production - Particle TechnologyAman Katiyar100% (1)

- FEC - Filter Media Pore Test Rig PDFDocument2 pagesFEC - Filter Media Pore Test Rig PDFAman KatiyarNo ratings yet

- ASTM D200 SAE J200 (2) ASTM and SAE Rubber Code Table - enDocument2 pagesASTM D200 SAE J200 (2) ASTM and SAE Rubber Code Table - enAman Katiyar0% (1)

- Classical Consumer Lifestyle Segmentation MethodsDocument55 pagesClassical Consumer Lifestyle Segmentation MethodskristinaNo ratings yet

- SIP - Recruitment & Selection ProcessDocument25 pagesSIP - Recruitment & Selection ProcessKunal BagdeNo ratings yet

- Burberry Final DraftDocument11 pagesBurberry Final Draftmax yeangNo ratings yet

- LSS Project Report Out TemplateDocument35 pagesLSS Project Report Out TemplateVarshith JoshNo ratings yet

- PRACTICE OF TRANSLATION (Diary)Document3 pagesPRACTICE OF TRANSLATION (Diary)ElenaNo ratings yet

- DocxDocument6 pagesDocxMeshack MathembeNo ratings yet

- Partnership Liquidation NotesDocument7 pagesPartnership Liquidation NotesMary Rica DublonNo ratings yet

- Financial Markets A Beginners ModuleDocument93 pagesFinancial Markets A Beginners ModuleVishnu PearlsNo ratings yet

- Implementing A Lean Six Sigma STANDARDIZEDDocument24 pagesImplementing A Lean Six Sigma STANDARDIZEDKATY lORENA MEJIA PEDROZONo ratings yet

- HEIRS OF JOSE LIM vs. JULIET VILLA LIM G.R. No. 172690 March 3, 2010Document2 pagesHEIRS OF JOSE LIM vs. JULIET VILLA LIM G.R. No. 172690 March 3, 2010SSNo ratings yet

- NCC Cover PageDocument3 pagesNCC Cover PageDeepakNo ratings yet

- Oum - Semester January 2023 - BBMC4103 Change Management - Nahariah MD SumairiDocument14 pagesOum - Semester January 2023 - BBMC4103 Change Management - Nahariah MD SumairiNahariah Md SumairiNo ratings yet

- Athenahealth - WikipediaDocument5 pagesAthenahealth - WikipediakhanmdNo ratings yet

- TCSDocument10 pagesTCSananyaNo ratings yet

- Novo NordiskDocument14 pagesNovo NordiskHồ Trúc HuệNo ratings yet

- Topic 12 - Payables, Provisions and Contingent LiabilitiesDocument14 pagesTopic 12 - Payables, Provisions and Contingent Liabilitiesmariam simonyanNo ratings yet

- Porter's Generic Competitive Strategies and Its Influence On The Competitive AdvantageDocument10 pagesPorter's Generic Competitive Strategies and Its Influence On The Competitive AdvantageKomal sharmaNo ratings yet

- CARAVANS T k1 Kirkuk (1) 428128371Document27 pagesCARAVANS T k1 Kirkuk (1) 428128371mahmoodshowkiNo ratings yet

- Sale and Purchase Agreement Flow ChartDocument1 pageSale and Purchase Agreement Flow ChartZureen ZamriNo ratings yet

- Pallavi TS Project ReportDocument33 pagesPallavi TS Project ReportPrem KumarnNo ratings yet

- Salary Statement Ovie NewDocument6 pagesSalary Statement Ovie NewJr QomarruzzamanNo ratings yet

- Icici Bank CBRDocument49 pagesIcici Bank CBRHarshad Sutar100% (1)

- Chapter 6 ETHICAL ISSUES AND SOCIAL RESPONSIBILITY OF ENTREPRENEURS Chapter 6Document4 pagesChapter 6 ETHICAL ISSUES AND SOCIAL RESPONSIBILITY OF ENTREPRENEURS Chapter 6Kariuki CharlesNo ratings yet

- EM2301. Practical Class 6Document3 pagesEM2301. Practical Class 6luu duongNo ratings yet

- Salary Survey 2021Document340 pagesSalary Survey 2021Khalid HameedNo ratings yet

- Chapter 2 Demand (Eco)Document41 pagesChapter 2 Demand (Eco)Aneesa RoslanNo ratings yet

- Mapping The Way Forward An Analysis of Philrice's Corporate Planning StrategiesDocument8 pagesMapping The Way Forward An Analysis of Philrice's Corporate Planning StrategiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quarter III - Lesson 2 Provide Club Reception Services (CR)Document32 pagesQuarter III - Lesson 2 Provide Club Reception Services (CR)Anthony MonticilloNo ratings yet