Professional Documents

Culture Documents

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

Uploaded by

Shashank DubbalwarCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

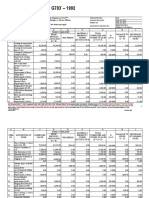

- Document G703 - 1992: Continuation SheetDocument6 pagesDocument G703 - 1992: Continuation Sheetpooja patelNo ratings yet

- Ultra High Performance Concrete (Uhpc) : Npca White PaperDocument19 pagesUltra High Performance Concrete (Uhpc) : Npca White Paperphewphewphew200No ratings yet

- Welding Cutting ListDocument9 pagesWelding Cutting ListmwineyaNo ratings yet

- Coram Brochure 2015Document25 pagesCoram Brochure 2015higgs1No ratings yet

- Rubber GuideDocument5 pagesRubber Guidekanthar972No ratings yet

- Semstone 8084 PDS 7-10Document1 pageSemstone 8084 PDS 7-10vitharvanNo ratings yet

- A220Document5 pagesA220Jarbas MoraesNo ratings yet

- Innform 2016: The Newsletter of Innoval TechnologyDocument4 pagesInnform 2016: The Newsletter of Innoval TechnologyInnoval TechnologyNo ratings yet

- 9 Specification For Mechanical Pipework Insulation PDFDocument4 pages9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiNo ratings yet

- TCC31 One-Way SlabsDocument43 pagesTCC31 One-Way SlabsMuscadin MakensonNo ratings yet

- Combination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofDocument8 pagesCombination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofWormInchNo ratings yet

- 1 CHKLSTDocument5 pages1 CHKLSTsardarmkhanNo ratings yet

- AppuisDocument10 pagesAppuisSopheaNo ratings yet

- Trilok Precast PVT - LTD (Surat)Document9 pagesTrilok Precast PVT - LTD (Surat)A Plus Wire and Fencing SolutionsNo ratings yet

- Thermal InsulationDocument60 pagesThermal InsulationSpyros IliakisNo ratings yet

- SECTION 03490 Glass Fiber Reinforced Precast Concrete Rev 1 PDFDocument24 pagesSECTION 03490 Glass Fiber Reinforced Precast Concrete Rev 1 PDFwangruiNo ratings yet

- MaterialData 15030Document2 pagesMaterialData 15030onesmileNo ratings yet

- Microstructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyDocument6 pagesMicrostructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyAnush RajNo ratings yet

- Chempart 29 (R)Document9 pagesChempart 29 (R)CanchindoNo ratings yet

- Smithers Polymer Material Properties TestingDocument2 pagesSmithers Polymer Material Properties TestingErwin ErwinNo ratings yet

- Concrete JournalDocument4 pagesConcrete JournalSrikanth BhaskaraNo ratings yet

- 07 - TDS - Concresive 1418Document4 pages07 - TDS - Concresive 1418aahtagoNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev003Document67 pagesStructural Calc Analysis of in Patient BLDG Facade Rev003عزة الإسلامNo ratings yet

- Cálculo Hidráulico Mangueras Mercado Del PueblitoDocument6 pagesCálculo Hidráulico Mangueras Mercado Del PueblitoMiguel RuizNo ratings yet

- Testing and History of Composite Repair Systems For Subsea Pipeline RepairDocument31 pagesTesting and History of Composite Repair Systems For Subsea Pipeline RepairDilipSinghNo ratings yet

- PDF of Astm A53 Standard SpecificationDocument4 pagesPDF of Astm A53 Standard Specificationmarcelo10003No ratings yet

- Butterfly Valve Ebro-ArmaturenDocument4 pagesButterfly Valve Ebro-ArmaturenRandy SihombingNo ratings yet

- Eng Bobtail Flyer-Web ResDocument2 pagesEng Bobtail Flyer-Web Ress_padu3003@yahoo.comNo ratings yet

- Self Compacting Concrete: Prepared by - Waheed Ullah Uid - 18mce1435Document25 pagesSelf Compacting Concrete: Prepared by - Waheed Ullah Uid - 18mce1435Husainahmad MadaniNo ratings yet

- TQ Plumbing - Jaim - FinalDocument14 pagesTQ Plumbing - Jaim - FinalJoanna Fe JaimNo ratings yet

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

Uploaded by

Shashank DubbalwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

T000003109 - FileName2 - Canopy and False Ceiling Tender Specifications

Uploaded by

Shashank DubbalwarCopyright:

Available Formats

ANNEXURE - I

CANOPY STRUCTURE: Design, fabrication and installation of pre-engineered / pre-

fabricated steel canopy as per the following specification:

The canopy steel structures to be designed considering roof live load of 50 kg per Sq.m in

addition to the dead weight of the steel and roof sheeting + false ceiling weight. Also

additional 300 kg point load to be considered at all canopy corner locations & weight of glow

facia @ 20kg/m may also be considered for designing. The canopy should be designed to

withstand the wind speed of 150 km / hour or as per IS: 875, whichever is higher. The design

should be safe against bending, twisting, deflection, over turning etc. as per IS: 800. The

canopy column should be rectangular box section of 400mm x 200mm x 6mm. Alternatively,

the column can be built using ISMC 200 channels welded with 6mm plates so as to give the

finished rectangular columns of 400mm x 200mm x 6mm.All steel structure should conform to

IS : 2062. Only branded steel like TISCO, SAIL, ESSAR, Lloyd to be used. The depth of the

roof canopy structure will be so designed so as to receive illuminated box facia of 800 mm size

all around. The canopy beam structure steel to comprise of built up plate I section / hot rolled

I beam / angle truss SHS / RHS tubes as per design and all secondary purlins should be cold

formed galvanized Z sections with 275 gsm galvanization total both sides & yield strength of

min. 345 mpa only. Alternatively TATA tube with 275 gsm galvanization total both sides may

be used for purlins. All the primary and secondary connection bolts shall be grade 8.8 both the

primary and secondary connection bolts shall be Electro - galvanized of precision fasteners

(Unbrako), Laxmi Precision, GKW, TVS make only. Necessary roof bracing , Wind girders

and other forms of bracing to be considered for the overall stability of the structure and the

transmission of lateral loads to the column , to and to stabilize the canopy movement as well as

strengthen the cantilever Height of the canopy will be 6 mtrs from the finished driveway level.

N.B:

(i) While designing the canopy, weight of the canopy should be min. 32 kg per Sq.m upto max

of 35 Kg per Sq. m.

(ii) In certain cyclone prone areas, swirling speed should be taken into account while designing

the canopy.

ANCHOR BOLTS: The bolt materials shall conform to IS 2062 with minimum yield strength

of 240 mpa. The lower end of the anchor bolt should be bent with a minimum radius of

curvature of 3d (dia of the bolts ) The upper exposed portion of the bolt should have min

threaded portion of 115 mm (min) with one hexagonal nut followed one hexagonal lock nut.

PAINTING: Painting the steel structure with two coats of Red oxide Zinc chromate primer or

yellow primer and column with addl. two coats of white enamel paint of approved make.

Signature of Tenderer with seal Page 1 of 4

ROOFING

ALTERNATE I

GI roofing with trapezoidal profile manufactured by cold roll forming process with 0.63 mm

thick (TCT) based galvanization of 275 gsm total both sides with a yield strength of 240 mpa

(min), conform to IS : 277 manufactured by SAIL / JINDAL / METACRAFT / M/s

INTERARCH / M/s METACOLOUR / M/s NIPPON DENRO / M/s TIGER STEEL / M/s

KIRBY BUILDERS.

ALTERNATE II

Trapezoidal roofing profile made out of 0.47mm TCT with high tensile Bare Galvalum sheet

of 550 Mpa yield strength of grade AZ-150 (55% Aluminium, 43.5% Zinc and 1.5% Silicon)

with aluzinc coating of 150 GSM from reputed make.

Fastening, Laying & Fixing method:-The sheets shall be supplied, preferably, in long

transportable lengths upto 11.5 m to avoid longitudinal laps in the roofing systems. The sheet

shall be fixed to the purlins by GI self -tapping screws of size 6.3 x 25 with EPDM bonded

washer, fixed through the troughs of the profile sheet. All the side laps should be a double

corrugation side lap and butyl in deal tape to be provided between the top & bottom sheets at

the side lap location and stitched with close end aluminium rivets. Longitudinal laps, if any,

should be minimum 200 mm with one row in seal tape and one row silicon sealant for leak

proof performance.

FLASHING: Ridge flashing shall be trapezoidal matching the roof profile and bent to the

ridge angle. All the other flashing to be manufactured out of the same material and thickness as

that of roofing, Wherever the flashing interface with trapezoidal profile roofing, filler blocks

should be provided in the gaps and sealed with silicon sealant for leak proof performance.

After the installation the roof should be cleared of all the metal wastes, screws, nails etc.

Necessary profiled filler box should be provided at the higher level of roof sheeting & also at

the valley gutter in order to ensure water tightness in the profile gaps. All external flashing in

the roof all around excluding gutter are to be of the same material and thickness as roof

sheeting.

GUTTER & DOWNPIPE: Gutter shall be manufactured out of 0.91 mm thick Plain

aluminium sheets in lengths of 2.5 - 3 m min. (Longer lengths preferred). All the gutter joints

shall be fixed by bulb tight rivets and silicon sealant shall be applied all over the joint for leak

proof performance. The gutter end caps shall be provided at either ends and duly sealed with

Signature of Tenderer with seal Page 2 of 4

silicon sealant. The opening shall be made in the gutter for down spot position with sleeves

fixed on the gutter and connecting the sown take pipe. Silicon sealant to be applied all over the

joints ensuring water tightness. The gutter slope shall be in such a way that the water collected

from the roof move on the down take pipe smoothly without stagnation of water at any point

of the gutter. Size & Shape of the gutter will be trapezoidal section of min. 400mm x 300mm

with min. 200 mm depth for effective drainage of the storm water depending upon the rainfall

to be designed by the supplier and approved by BPCL. For effective drainage of storm water,

the down pipe will be heavy duty PVC drain pipe (100-150 mm depending on design) running

inside columns. Cost of clamp, brackets and accessories etc. to be included in the cost. Please

note no structural member to be used as a gutter. Gutter to be tested with water filled for 48 hrs

to ensure it is water tight.

FACIA Provision to be made for fixing 800mm wide glow box facia to be provided along with

the canopy sides. The weight of the glow box facia on the front & the sides to be considered

while designing the canopy. The canopy supplier would liaise with the site engineer and make

arrangement for cutting of false ceiling for installing electrical fittings/fixture as directed. In

the non illuminated portions, plain channel of size 815 mm deep x 25mm flange x 2mm thick

shall be provided. The materials shall be HR sheets conforming to IS 2026 with min yield

strength of 240 mpa. The facia channel shall be supplied duly painted with a primer & fixed on

to the structure with countersunk screw.

The canopy supplier should provide the following documents:-

1. Column reactions on foundation

2. GA drawing for the proposed canopy

3. Erection Drawing - 2 Sets

4. As built drawing - 2 set

5. Structural stability certificate for canopy structure along with design calculation, connection

Design base plate etc.

6. Test certificates of structural steel, fasteners, roofing, false ceiling materials

Height of the canopy should be 6mtrs from the finished driveway level to bottom of false

ceiling.

Signature of Tenderer with seal Page 3 of 4

ANNEXURE – 2

FALSE CEILING:

Scope: The Scope of this specification covers the design, manufacture, prefabrication,

transportation, installation and commissioning of the complete false ceiling system. However,

all items required for the safe and efficient maintenance of the false ceiling.

A. Materials of Panel:

A.1: Cold rolled steel confirming to IS 513 having yield strength of 240 mpa (minimum).

A.2: Base metal thickness should not be less than 0.55 mm.

B. Design criteria:

B 1: Ceiling system to be designed to withstand wind velocity of 220 KMPH and relevant

seismic factor to the specific location where the false ceiling is to be installed or wind load as

per IS 875 Part III whichever is higher.

B 2: System to be designed as fixed system in which false ceiling panels are fixed to the false

ceiling runner (already supplied with canopy) by suitable designed GI clips or carrier. One end

of the clip or carrier is fixed to the false ceiling runners by the bolt of suitable design and other

end of the clip or carrier is designed to hold interlocking ends of the ceiling panels. Incase of

carrier the cut outs hold the panels should be suitably designed taking into consideration of the

material / pressure created by air inside the false ceiling

B 3: the flashing, capping and trims shall be manufactured from the same materials and colour

as the ceiling materials. These are fixed with aluminium rivets or stainless pins

B4: maximum deflection of sheets (panels) is limited to L/325 maximum as per IS 800

deflection criteria

C. Panel specifications

C1: Rolled formed ceiling panels of 150 F/200 F including suitable designs of tongue and

groove interlocking should be coated with Zinc in a minimum thickness of 175 GSM on both

sides. The panel should be finished with 15 to 18 micron polyester top coat 10 micron

thickness. The total coated (TCT) should not be less than 0.6 mm. Colour of the panel shall

be white matt finish.

Scope includes

1. False Ceiling Runners of suitable section to be cold rolled formed "Z" section made out of

GI coils with 275 gsm galvanized and yield strength of 345 mpa or galvanized tube section/

equivalent structural members.

2. The spacing of runner should be 1.2 m - 1.5 m based on canopy dimensions.

3. The false ceiling runners to be fixed to main structure by cleats with adjustable holes for

level adjustments to be located in the rafters.

NOTE: Supplier has to visit the site before supply of materials at site and get familiarized with

the wind velocity, seismic (earthquake) factor and accordingly design of false ceiling to be

done and submit the design calculation and drawing details to BPCL. After completion of

work, supplier has to submit warranty certificate from manufacturer of panels to BPCL.

Signature of Tenderer with seal Page 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Document G703 - 1992: Continuation SheetDocument6 pagesDocument G703 - 1992: Continuation Sheetpooja patelNo ratings yet

- Ultra High Performance Concrete (Uhpc) : Npca White PaperDocument19 pagesUltra High Performance Concrete (Uhpc) : Npca White Paperphewphewphew200No ratings yet

- Welding Cutting ListDocument9 pagesWelding Cutting ListmwineyaNo ratings yet

- Coram Brochure 2015Document25 pagesCoram Brochure 2015higgs1No ratings yet

- Rubber GuideDocument5 pagesRubber Guidekanthar972No ratings yet

- Semstone 8084 PDS 7-10Document1 pageSemstone 8084 PDS 7-10vitharvanNo ratings yet

- A220Document5 pagesA220Jarbas MoraesNo ratings yet

- Innform 2016: The Newsletter of Innoval TechnologyDocument4 pagesInnform 2016: The Newsletter of Innoval TechnologyInnoval TechnologyNo ratings yet

- 9 Specification For Mechanical Pipework Insulation PDFDocument4 pages9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiNo ratings yet

- TCC31 One-Way SlabsDocument43 pagesTCC31 One-Way SlabsMuscadin MakensonNo ratings yet

- Combination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofDocument8 pagesCombination Capacity Factors: For Conducting Flow Tests of Rupture Discs, Pressure Relief Valves AND Combinations ThereofWormInchNo ratings yet

- 1 CHKLSTDocument5 pages1 CHKLSTsardarmkhanNo ratings yet

- AppuisDocument10 pagesAppuisSopheaNo ratings yet

- Trilok Precast PVT - LTD (Surat)Document9 pagesTrilok Precast PVT - LTD (Surat)A Plus Wire and Fencing SolutionsNo ratings yet

- Thermal InsulationDocument60 pagesThermal InsulationSpyros IliakisNo ratings yet

- SECTION 03490 Glass Fiber Reinforced Precast Concrete Rev 1 PDFDocument24 pagesSECTION 03490 Glass Fiber Reinforced Precast Concrete Rev 1 PDFwangruiNo ratings yet

- MaterialData 15030Document2 pagesMaterialData 15030onesmileNo ratings yet

- Microstructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyDocument6 pagesMicrostructure and Residual Stress of Laser Rapid Formed Inconel 718 Nickel-Base SuperalloyAnush RajNo ratings yet

- Chempart 29 (R)Document9 pagesChempart 29 (R)CanchindoNo ratings yet

- Smithers Polymer Material Properties TestingDocument2 pagesSmithers Polymer Material Properties TestingErwin ErwinNo ratings yet

- Concrete JournalDocument4 pagesConcrete JournalSrikanth BhaskaraNo ratings yet

- 07 - TDS - Concresive 1418Document4 pages07 - TDS - Concresive 1418aahtagoNo ratings yet

- Structural Calc Analysis of in Patient BLDG Facade Rev003Document67 pagesStructural Calc Analysis of in Patient BLDG Facade Rev003عزة الإسلامNo ratings yet

- Cálculo Hidráulico Mangueras Mercado Del PueblitoDocument6 pagesCálculo Hidráulico Mangueras Mercado Del PueblitoMiguel RuizNo ratings yet

- Testing and History of Composite Repair Systems For Subsea Pipeline RepairDocument31 pagesTesting and History of Composite Repair Systems For Subsea Pipeline RepairDilipSinghNo ratings yet

- PDF of Astm A53 Standard SpecificationDocument4 pagesPDF of Astm A53 Standard Specificationmarcelo10003No ratings yet

- Butterfly Valve Ebro-ArmaturenDocument4 pagesButterfly Valve Ebro-ArmaturenRandy SihombingNo ratings yet

- Eng Bobtail Flyer-Web ResDocument2 pagesEng Bobtail Flyer-Web Ress_padu3003@yahoo.comNo ratings yet

- Self Compacting Concrete: Prepared by - Waheed Ullah Uid - 18mce1435Document25 pagesSelf Compacting Concrete: Prepared by - Waheed Ullah Uid - 18mce1435Husainahmad MadaniNo ratings yet

- TQ Plumbing - Jaim - FinalDocument14 pagesTQ Plumbing - Jaim - FinalJoanna Fe JaimNo ratings yet