Professional Documents

Culture Documents

Z13-35110 - Ring

Z13-35110 - Ring

Uploaded by

Haviss CMMCopyright:

Available Formats

You might also like

- George M. Marsden - Fundamentalism and American Culture (New Edition) (2006)Document353 pagesGeorge M. Marsden - Fundamentalism and American Culture (New Edition) (2006)Elvio Figur100% (8)

- Peter Pan A Boy From Neverland Reading Comprehension Exercises 55883Document2 pagesPeter Pan A Boy From Neverland Reading Comprehension Exercises 55883Mónica100% (1)

- Epic Features in The IliadDocument3 pagesEpic Features in The IliadHarisadhan GhoshNo ratings yet

- Shiff, Representation, Copying, and The Technique of OriginalityDocument32 pagesShiff, Representation, Copying, and The Technique of OriginalityAna FrancoNo ratings yet

- Drawing Distribution: General ToleranceDocument1 pageDrawing Distribution: General ToleranceJovelyn MillaresNo ratings yet

- SoR 2016 17 PDFDocument16 pagesSoR 2016 17 PDFMallikarjuna SarmaNo ratings yet

- KKDocument5 pagesKKksksarode78No ratings yet

- Arcomindo Sistem Teknik: Approval Consept Prepared Approved Finishing Name Qty Material Code NumberDocument1 pageArcomindo Sistem Teknik: Approval Consept Prepared Approved Finishing Name Qty Material Code NumberAmanah SiyfiversNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- SoR 2012 13Document28 pagesSoR 2012 13MuraliKrishna NaiduNo ratings yet

- SoR 2014 15Document20 pagesSoR 2014 15preauditouNo ratings yet

- SoR 2009 10Document21 pagesSoR 2009 10Mallikarjuna SarmaNo ratings yet

- Design Template - Plastic Section ModulusDocument2 pagesDesign Template - Plastic Section ModulusRoger AttwoodNo ratings yet

- Bitumen Content in Mixture by CentrifugalDocument2 pagesBitumen Content in Mixture by CentrifugalMarwa AlasheebiNo ratings yet

- Spoun MouldDocument8 pagesSpoun MouldRajanNo ratings yet

- Sharpen (8X) : 1 1 Plate T 1.5Document1 pageSharpen (8X) : 1 1 Plate T 1.5andreas endrasNo ratings yet

- Field BorelogDocument5 pagesField BoreloghavmanyfriendsNo ratings yet

- Roundness Strake - 4-TK-011 (12 Koordinat)Document1 pageRoundness Strake - 4-TK-011 (12 Koordinat)yuwantoniNo ratings yet

- Desfasuratorul Determinarilor Pentru Stabilirea Comp. Bet.Document7 pagesDesfasuratorul Determinarilor Pentru Stabilirea Comp. Bet.Alexe FloreaNo ratings yet

- Deviation Statement - SheetDocument8 pagesDeviation Statement - SheetPema GyelpoNo ratings yet

- SoR 2009 10Document25 pagesSoR 2009 10MuraliKrishna NaiduNo ratings yet

- Model GP Building EstimateDocument153 pagesModel GP Building Estimate8790922772No ratings yet

- PCC Storm Drains DeviationDocument13 pagesPCC Storm Drains DeviationSantosh ChowdaryNo ratings yet

- 752ex Compactors Brochure in enDocument4 pages752ex Compactors Brochure in enislamtabl2015No ratings yet

- Model 4Document1 pageModel 4karpagavalli NNo ratings yet

- Full 3-4 10unc 90 B7 BlackodisingDocument1 pageFull 3-4 10unc 90 B7 BlackodisingGauravNo ratings yet

- النوتة الحسابيةDocument47 pagesالنوتة الحسابيةzeinab saeedNo ratings yet

- Roundness Strake 1 Aft TK-012 - (12 Koordinat)Document1 pageRoundness Strake 1 Aft TK-012 - (12 Koordinat)yuwantoniNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- BTG Pulp & Paper Sensors AB VBW-1100 Electronics Wall Mounted A0122382Document1 pageBTG Pulp & Paper Sensors AB VBW-1100 Electronics Wall Mounted A0122382Hector HerreraNo ratings yet

- RB 2885 0101Document1 pageRB 2885 0101AWNISH PRASAD SINGHNo ratings yet

- Retaining Wall DeviationDocument35 pagesRetaining Wall DeviationSantosh ChowdaryNo ratings yet

- Revised Embedded TaxDocument22 pagesRevised Embedded TaxKarthik Prince0% (1)

- Catalogue-Tungaloy - 12 - Grades andDocument49 pagesCatalogue-Tungaloy - 12 - Grades andJose' TNo ratings yet

- DK35-P Piston Seal Datasheet - 16296 EN PDFDocument2 pagesDK35-P Piston Seal Datasheet - 16296 EN PDFSridhar TholasingamNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- Bend 1Document1 pageBend 1karpagavalli NNo ratings yet

- Engineering/Technical: V-Belt Sheave Groove DimensionsDocument3 pagesEngineering/Technical: V-Belt Sheave Groove DimensionsDavid TurnerNo ratings yet

- Plumbnes Strake 1 Aft TK-012 - (12 Koordinat)Document2 pagesPlumbnes Strake 1 Aft TK-012 - (12 Koordinat)yuwantoniNo ratings yet

- Karampodi Thanda 3Document18 pagesKarampodi Thanda 3kiranNo ratings yet

- 1910 - EN - Technical Data Sheet - 4811001211Document4 pages1910 - EN - Technical Data Sheet - 4811001211julius_xNo ratings yet

- Example Pipe ReportDocument4 pagesExample Pipe ReportYusuf BagewadiNo ratings yet

- Cswip Visual Inspection Pipe Report: & Thickness - DateDocument4 pagesCswip Visual Inspection Pipe Report: & Thickness - DateNiranjan khatuaNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsJalal Naser FaqiryarNo ratings yet

- Tanko S30 SpecificationDocument1 pageTanko S30 SpecificationJuan IglesiasNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsEndreas KebedeNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- K40 K40 Plus: Hydraulic Gear Pumps and MotorsDocument56 pagesK40 K40 Plus: Hydraulic Gear Pumps and MotorsАнатолий ДавыдовNo ratings yet

- Construction of Compound Wall Left Side To Sakhi/One Stop Center Building at Narayanpet MandalDocument3 pagesConstruction of Compound Wall Left Side To Sakhi/One Stop Center Building at Narayanpet MandalK KARTHIKNo ratings yet

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- FM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680Document1 pageFM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680GauravNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument189 pagesRCC32R Rigorous Ribbed SlabsCivil GuyNo ratings yet

- Zinc Alloys - Properties, Processing and Applications - MatmatchDocument9 pagesZinc Alloys - Properties, Processing and Applications - Matmatchshahin azNo ratings yet

- Full M20X2.5PX210L A193 B8M CL-1Document1 pageFull M20X2.5PX210L A193 B8M CL-1GauravNo ratings yet

- Soft Unalloyed Steels For Cold Forming: Steel GradesDocument8 pagesSoft Unalloyed Steels For Cold Forming: Steel GradesHemachandra ShrotriNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Coupling Alignment: Code Word/ ClientDocument3 pagesCoupling Alignment: Code Word/ ClientFernando AguilarNo ratings yet

- Games: Alliance Game DistributorsDocument35 pagesGames: Alliance Game DistributorsNeoSagaNo ratings yet

- Reflexive Pronouns 1. Read The Sentences BelowDocument3 pagesReflexive Pronouns 1. Read The Sentences BelowJennefer Gudao AranillaNo ratings yet

- 2013 Rvvav13Document289 pages2013 Rvvav13Tinn ApNo ratings yet

- Honen One-Page TestamentDocument2 pagesHonen One-Page TestamentSebastian CaloNo ratings yet

- BWV4 - Christ Lag in TodesbandenDocument52 pagesBWV4 - Christ Lag in TodesbandenLegalSheetsNo ratings yet

- Script For PitchDocument3 pagesScript For Pitchapi-301831943100% (1)

- Grade 2 EnglishDocument3 pagesGrade 2 Englishapi-232925522No ratings yet

- In The City Upper Intermediate AdvancedDocument6 pagesIn The City Upper Intermediate AdvancedcooladillaNo ratings yet

- Lirik Lagu Endah N Rhesa When You Love Someone LyricsDocument1 pageLirik Lagu Endah N Rhesa When You Love Someone LyricsVera Budiyanti IINo ratings yet

- 1903 San Juan, Puerto Rico InfoDocument3 pages1903 San Juan, Puerto Rico InfoAmir SeñerizNo ratings yet

- Arabic Graffiti TeaserDocument15 pagesArabic Graffiti TeaserChristoph Claudius PetersenNo ratings yet

- Game Dev Story CHEATDocument15 pagesGame Dev Story CHEATCarlo Reyes Jr.No ratings yet

- 455 Gita Roman Chapter 1 1Document5 pages455 Gita Roman Chapter 1 1Pri OliveiraNo ratings yet

- Play English Level 1Document68 pagesPlay English Level 1COSINA HERMANNo ratings yet

- Francesco Redi: His Life and Experiment To Test The Theory of Spontaneous GenerationDocument3 pagesFrancesco Redi: His Life and Experiment To Test The Theory of Spontaneous GenerationDrake PoetaNo ratings yet

- FW-C550 - Owner's MamualDocument30 pagesFW-C550 - Owner's MamualBillNo ratings yet

- Comparison of All The PoemsDocument13 pagesComparison of All The PoemshamzahNo ratings yet

- Axis Libri Nr. 7 (În Limba Engleză)Document78 pagesAxis Libri Nr. 7 (În Limba Engleză)Biblioteca „V.A. Urechia” GalaţiNo ratings yet

- Monteverdi Edition, Vol. 04 PDFDocument19 pagesMonteverdi Edition, Vol. 04 PDFjackim123No ratings yet

- AVE MOD V2 User GuideDocument5 pagesAVE MOD V2 User GuideCristobalzqNo ratings yet

- Pracetice I. Give The Correct Tenses of The Verbs in BracketsDocument5 pagesPracetice I. Give The Correct Tenses of The Verbs in Bracketsmomobear152No ratings yet

- Next Gen Movie: Pre-ViewingDocument4 pagesNext Gen Movie: Pre-ViewingAlexandrina OliveiraNo ratings yet

- Well Read 1 PDFDocument166 pagesWell Read 1 PDFMiraz75% (4)

- Is Your All On The Altar PDFDocument1 pageIs Your All On The Altar PDFHector Escobar Perez Jr.No ratings yet

- Esl FlashcardsDocument229 pagesEsl Flashcardsoradu1395No ratings yet

- Actividad 1 - La Industria Del Transporte Como Clave para Un Buen Crecimiento EconómicoDocument3 pagesActividad 1 - La Industria Del Transporte Como Clave para Un Buen Crecimiento EconómicoMauricio Esteban JNo ratings yet

Z13-35110 - Ring

Z13-35110 - Ring

Uploaded by

Haviss CMMOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Z13-35110 - Ring

Z13-35110 - Ring

Uploaded by

Haviss CMMCopyright:

Available Formats

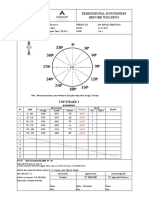

General Difference in Dimension

Cut Processing

Part No.

Nominal Difference in

Sign Change No. Revision Record Z13-35110

Size Dimension

Release

Exceeding 4 5 10 of 5

± 10 20 30

/Below Release of new drawing 0 0 0 drawing 1

16 0.2 Nakasuka Distributi

Section

16~63 0.3 on 1 2 3 4 5 6 7 8 9

63~250 0.5

250~1000 0.8 Heate Plate Mixe

10 1° Date

d d d

10~50 30°

FULL CAD

50~100 20°

General Geometric Tolerance

FQA

F Goods targeted for FQA

X Out of scope Goods

Special process

0 No

1 Surface Treatment

Surface Treatment + Hydrogen

E

Embrittlement Removal

2 Heat Treatment

3 Weld

4 Casting

5 Forging

6 Cold Heading

7 Press

8 Gum

9 Synthetic Resin

A Leather

B Spring

C Sintered Alloy

Special processing other than

X

above

Note

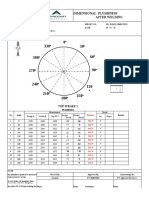

1. There should not be burr in each cutting part. (Also available in barrel finishing)

2. Total cutting corresponding to SPCC material is also possible.

3. SAS: K50-03A (Restrictions related to use of a specific material) should be fulfilled for this part.

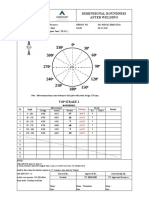

There should be no burr

− True Value

Flatness

Roundness

Cylindricity Shape

Lines Contour

Surface Contour

Parallelism

Angular Value

Inclination

Position

Coaxiality

Symmetry

Scale Deflection

Total Run-Out

Envelope Requirement

Maximum Material Condition

Special

Projected Tolerance Zone process

You might also like

- George M. Marsden - Fundamentalism and American Culture (New Edition) (2006)Document353 pagesGeorge M. Marsden - Fundamentalism and American Culture (New Edition) (2006)Elvio Figur100% (8)

- Peter Pan A Boy From Neverland Reading Comprehension Exercises 55883Document2 pagesPeter Pan A Boy From Neverland Reading Comprehension Exercises 55883Mónica100% (1)

- Epic Features in The IliadDocument3 pagesEpic Features in The IliadHarisadhan GhoshNo ratings yet

- Shiff, Representation, Copying, and The Technique of OriginalityDocument32 pagesShiff, Representation, Copying, and The Technique of OriginalityAna FrancoNo ratings yet

- Drawing Distribution: General ToleranceDocument1 pageDrawing Distribution: General ToleranceJovelyn MillaresNo ratings yet

- SoR 2016 17 PDFDocument16 pagesSoR 2016 17 PDFMallikarjuna SarmaNo ratings yet

- KKDocument5 pagesKKksksarode78No ratings yet

- Arcomindo Sistem Teknik: Approval Consept Prepared Approved Finishing Name Qty Material Code NumberDocument1 pageArcomindo Sistem Teknik: Approval Consept Prepared Approved Finishing Name Qty Material Code NumberAmanah SiyfiversNo ratings yet

- KGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingDocument1 pageKGC Full 3-4 10unc 110 MM A193 B7 Black Kgcfti34010110b7a193 - BlankingGauravNo ratings yet

- SoR 2012 13Document28 pagesSoR 2012 13MuraliKrishna NaiduNo ratings yet

- SoR 2014 15Document20 pagesSoR 2014 15preauditouNo ratings yet

- SoR 2009 10Document21 pagesSoR 2009 10Mallikarjuna SarmaNo ratings yet

- Design Template - Plastic Section ModulusDocument2 pagesDesign Template - Plastic Section ModulusRoger AttwoodNo ratings yet

- Bitumen Content in Mixture by CentrifugalDocument2 pagesBitumen Content in Mixture by CentrifugalMarwa AlasheebiNo ratings yet

- Spoun MouldDocument8 pagesSpoun MouldRajanNo ratings yet

- Sharpen (8X) : 1 1 Plate T 1.5Document1 pageSharpen (8X) : 1 1 Plate T 1.5andreas endrasNo ratings yet

- Field BorelogDocument5 pagesField BoreloghavmanyfriendsNo ratings yet

- Roundness Strake - 4-TK-011 (12 Koordinat)Document1 pageRoundness Strake - 4-TK-011 (12 Koordinat)yuwantoniNo ratings yet

- Desfasuratorul Determinarilor Pentru Stabilirea Comp. Bet.Document7 pagesDesfasuratorul Determinarilor Pentru Stabilirea Comp. Bet.Alexe FloreaNo ratings yet

- Deviation Statement - SheetDocument8 pagesDeviation Statement - SheetPema GyelpoNo ratings yet

- SoR 2009 10Document25 pagesSoR 2009 10MuraliKrishna NaiduNo ratings yet

- Model GP Building EstimateDocument153 pagesModel GP Building Estimate8790922772No ratings yet

- PCC Storm Drains DeviationDocument13 pagesPCC Storm Drains DeviationSantosh ChowdaryNo ratings yet

- 752ex Compactors Brochure in enDocument4 pages752ex Compactors Brochure in enislamtabl2015No ratings yet

- Model 4Document1 pageModel 4karpagavalli NNo ratings yet

- Full 3-4 10unc 90 B7 BlackodisingDocument1 pageFull 3-4 10unc 90 B7 BlackodisingGauravNo ratings yet

- النوتة الحسابيةDocument47 pagesالنوتة الحسابيةzeinab saeedNo ratings yet

- Roundness Strake 1 Aft TK-012 - (12 Koordinat)Document1 pageRoundness Strake 1 Aft TK-012 - (12 Koordinat)yuwantoniNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- BTG Pulp & Paper Sensors AB VBW-1100 Electronics Wall Mounted A0122382Document1 pageBTG Pulp & Paper Sensors AB VBW-1100 Electronics Wall Mounted A0122382Hector HerreraNo ratings yet

- RB 2885 0101Document1 pageRB 2885 0101AWNISH PRASAD SINGHNo ratings yet

- Retaining Wall DeviationDocument35 pagesRetaining Wall DeviationSantosh ChowdaryNo ratings yet

- Revised Embedded TaxDocument22 pagesRevised Embedded TaxKarthik Prince0% (1)

- Catalogue-Tungaloy - 12 - Grades andDocument49 pagesCatalogue-Tungaloy - 12 - Grades andJose' TNo ratings yet

- DK35-P Piston Seal Datasheet - 16296 EN PDFDocument2 pagesDK35-P Piston Seal Datasheet - 16296 EN PDFSridhar TholasingamNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- Full 3-4 10unc 115 B7 BlackodisingDocument1 pageFull 3-4 10unc 115 B7 BlackodisingGauravNo ratings yet

- Bend 1Document1 pageBend 1karpagavalli NNo ratings yet

- Engineering/Technical: V-Belt Sheave Groove DimensionsDocument3 pagesEngineering/Technical: V-Belt Sheave Groove DimensionsDavid TurnerNo ratings yet

- Plumbnes Strake 1 Aft TK-012 - (12 Koordinat)Document2 pagesPlumbnes Strake 1 Aft TK-012 - (12 Koordinat)yuwantoniNo ratings yet

- Karampodi Thanda 3Document18 pagesKarampodi Thanda 3kiranNo ratings yet

- 1910 - EN - Technical Data Sheet - 4811001211Document4 pages1910 - EN - Technical Data Sheet - 4811001211julius_xNo ratings yet

- Example Pipe ReportDocument4 pagesExample Pipe ReportYusuf BagewadiNo ratings yet

- Cswip Visual Inspection Pipe Report: & Thickness - DateDocument4 pagesCswip Visual Inspection Pipe Report: & Thickness - DateNiranjan khatuaNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsJalal Naser FaqiryarNo ratings yet

- Tanko S30 SpecificationDocument1 pageTanko S30 SpecificationJuan IglesiasNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument201 pagesRCC32R Rigorous Ribbed SlabsEndreas KebedeNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- SW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingDocument1 pageSW Full M16X2PX70 A193 B7 ZN Al SM0000000002 - BlankingGauravNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- K40 K40 Plus: Hydraulic Gear Pumps and MotorsDocument56 pagesK40 K40 Plus: Hydraulic Gear Pumps and MotorsАнатолий ДавыдовNo ratings yet

- Construction of Compound Wall Left Side To Sakhi/One Stop Center Building at Narayanpet MandalDocument3 pagesConstruction of Compound Wall Left Side To Sakhi/One Stop Center Building at Narayanpet MandalK KARTHIKNo ratings yet

- Item 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACDocument6 pagesItem 1 - Ficha Tecnica IBOP Upper Canrig 1250 ACanghelo marquezNo ratings yet

- FM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680Document1 pageFM Full M10X1.5PX40 A193 B8 CL-2 ZN 30-003-1281680GauravNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- RCC32R Rigorous Ribbed SlabsDocument189 pagesRCC32R Rigorous Ribbed SlabsCivil GuyNo ratings yet

- Zinc Alloys - Properties, Processing and Applications - MatmatchDocument9 pagesZinc Alloys - Properties, Processing and Applications - Matmatchshahin azNo ratings yet

- Full M20X2.5PX210L A193 B8M CL-1Document1 pageFull M20X2.5PX210L A193 B8M CL-1GauravNo ratings yet

- Soft Unalloyed Steels For Cold Forming: Steel GradesDocument8 pagesSoft Unalloyed Steels For Cold Forming: Steel GradesHemachandra ShrotriNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Coupling Alignment: Code Word/ ClientDocument3 pagesCoupling Alignment: Code Word/ ClientFernando AguilarNo ratings yet

- Games: Alliance Game DistributorsDocument35 pagesGames: Alliance Game DistributorsNeoSagaNo ratings yet

- Reflexive Pronouns 1. Read The Sentences BelowDocument3 pagesReflexive Pronouns 1. Read The Sentences BelowJennefer Gudao AranillaNo ratings yet

- 2013 Rvvav13Document289 pages2013 Rvvav13Tinn ApNo ratings yet

- Honen One-Page TestamentDocument2 pagesHonen One-Page TestamentSebastian CaloNo ratings yet

- BWV4 - Christ Lag in TodesbandenDocument52 pagesBWV4 - Christ Lag in TodesbandenLegalSheetsNo ratings yet

- Script For PitchDocument3 pagesScript For Pitchapi-301831943100% (1)

- Grade 2 EnglishDocument3 pagesGrade 2 Englishapi-232925522No ratings yet

- In The City Upper Intermediate AdvancedDocument6 pagesIn The City Upper Intermediate AdvancedcooladillaNo ratings yet

- Lirik Lagu Endah N Rhesa When You Love Someone LyricsDocument1 pageLirik Lagu Endah N Rhesa When You Love Someone LyricsVera Budiyanti IINo ratings yet

- 1903 San Juan, Puerto Rico InfoDocument3 pages1903 San Juan, Puerto Rico InfoAmir SeñerizNo ratings yet

- Arabic Graffiti TeaserDocument15 pagesArabic Graffiti TeaserChristoph Claudius PetersenNo ratings yet

- Game Dev Story CHEATDocument15 pagesGame Dev Story CHEATCarlo Reyes Jr.No ratings yet

- 455 Gita Roman Chapter 1 1Document5 pages455 Gita Roman Chapter 1 1Pri OliveiraNo ratings yet

- Play English Level 1Document68 pagesPlay English Level 1COSINA HERMANNo ratings yet

- Francesco Redi: His Life and Experiment To Test The Theory of Spontaneous GenerationDocument3 pagesFrancesco Redi: His Life and Experiment To Test The Theory of Spontaneous GenerationDrake PoetaNo ratings yet

- FW-C550 - Owner's MamualDocument30 pagesFW-C550 - Owner's MamualBillNo ratings yet

- Comparison of All The PoemsDocument13 pagesComparison of All The PoemshamzahNo ratings yet

- Axis Libri Nr. 7 (În Limba Engleză)Document78 pagesAxis Libri Nr. 7 (În Limba Engleză)Biblioteca „V.A. Urechia” GalaţiNo ratings yet

- Monteverdi Edition, Vol. 04 PDFDocument19 pagesMonteverdi Edition, Vol. 04 PDFjackim123No ratings yet

- AVE MOD V2 User GuideDocument5 pagesAVE MOD V2 User GuideCristobalzqNo ratings yet

- Pracetice I. Give The Correct Tenses of The Verbs in BracketsDocument5 pagesPracetice I. Give The Correct Tenses of The Verbs in Bracketsmomobear152No ratings yet

- Next Gen Movie: Pre-ViewingDocument4 pagesNext Gen Movie: Pre-ViewingAlexandrina OliveiraNo ratings yet

- Well Read 1 PDFDocument166 pagesWell Read 1 PDFMiraz75% (4)

- Is Your All On The Altar PDFDocument1 pageIs Your All On The Altar PDFHector Escobar Perez Jr.No ratings yet

- Esl FlashcardsDocument229 pagesEsl Flashcardsoradu1395No ratings yet

- Actividad 1 - La Industria Del Transporte Como Clave para Un Buen Crecimiento EconómicoDocument3 pagesActividad 1 - La Industria Del Transporte Como Clave para Un Buen Crecimiento EconómicoMauricio Esteban JNo ratings yet