Professional Documents

Culture Documents

Ranger Pumps Brochure

Ranger Pumps Brochure

Uploaded by

diegoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ranger Pumps Brochure

Ranger Pumps Brochure

Uploaded by

diegoCopyright:

Available Formats

Manufacturer

of precision helical gear pumps

for a wide range of

industrial applications

Made in the USA

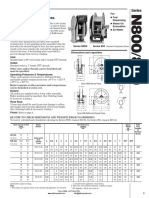

Four series of versatile helical gear pumps for

moving both low and high viscosity liquids

RANGER PUMP FEATURES

SMOOTH OPERATING HELICAL GEARS lubrication for lower bearing

• Heat treated ductile iron helical gears temperatures.

provide silent, efficient long service life. • Special outboard drive shaft bearing

• Finely keyed and machined gears are absorbs thrust loads and helps support

easily replaced by sliding on and off external radial loads.

the mainshaft. PRECISION GROUND SHAFTS

• Friction and vibration are kept at a • Induction hardened bearing and packing

11 17 22 48

minimum by careful machining of the surfaces on precision ground steel shafts

meshing helical gears. extend pump life. SERIES SERIES SERIES SERIES

EXTENDED-LIFE WEARING SERVICES • Hardened stainless steel shafts are

• High lead bronze, iron or carbon bearings available for specific installations. This series of Ranger pumps are This series of Ranger pumps are This series of Ranger pumps are This series of Ranger pumps are

are available. RUGGED CAST-IRON CASTINGS designed to output .11 gallons per designed to output .17 gallons per designed to output .22 gallons per designed to output .52 gallons per

• Pumping gears are supported by four • Maximum pumping efficiency is gained revolution at a maximum of 750 rpm revolution at a maximum of 750 rpm revolution at a maximum of 750 rpm revolution at a maximum of 900 rpm

heavy duty sleeve bearings to prolong from quality castings machined to high and generate up to 80 gallons per and generate up to 126 gallons per and generate up to 165 gallons per and generate up to 460 gallons per

2

service life.

• Special machined grooves in the

bearings allow both circulation and

tolerances.

• Positive alignment of the faceplate case

and backplate is insured by large

minute. These pumps are offered in

a 900, 2” NPT tapped port model and

a 1800 model with 2” flanges.

minute in a 900 model with 2” or 2.5”

flanges and a 900 model with 2” NPT

tapped ports.

minute. These pumps are offered in

900 and 1800 with 3” and 4” flanges.

minute. These pumps are offered in a

900 model with 3” or 4” flanges. 3

hardened steel dowel pins.

Pump Identification Guide NEW

PRODUCT

NEW

PRODUCT

NEW

PRODUCT

HB - Outboard bearing

HH - Pump with hydraulic adaptor and rigid coupling

BH - Replacement pump for HH Pump without adaptor

GO - Replacement pump for GHB unit without gear reduction

GB - Pump with gear reduction

C - Carbon graphite bearing

X - or no letter bronze bearing

T - TFE & graphite bearing

I - Iron Bearing

11 48

9 - Ports 900 H - Hi Temperature bronze bearing

DB - Double relief valve

8 - Ports 1800 RV - Relief valve

No letter - No relief valve MECHANICAL SEAL PUMP

B - Buna-N SERIES Bi-Rotational Double SERIES

V - VitonTM

180 Ported Housing

0 Relief Valve Gear Reduction

2 2 9 P H B F RV L X - S S C G

T - TeflonTM

PACKING PUMP

G - TFE & graphite packing Ranger now offers the 11 series with Ranger now offers a double relief valve for our Ranger now offers an integrated gear

11 - .11 Gallons per rev.

17 - .17 Gallons per rev. LG - Lip seal with graphite packing 1800 ports and 2” NPT flanges. This is series 11, 17 and 22 that will provide protection reduction unit for the 48 series. It

22 - .22 Gallons per rev. X - or no letter - standard packing in both shaft rotations. The double relief will

SS - Stainless

T - Pure TFE packing a good choice when your plumbing does is available in a 4.26:1, 4.88:1 and

48 - .48 Gallons per rev. steel shafts

D - DSA 8093 packing not accommodate the 900 port model. It continue to protect from overpressure even when 5.66:1 ratio. Please refer to page 7

No letter or XX -

P - Packing LD - Lip seal with DSA packing is available with the standard RV, Double the shaft rotation is changed and the pumps flow for additional information.

Steel shafts

M - Mechanical Seal is reversed. The double relief is field adjustable

RV and plain endplate. It is also available

F - Flanges Rotation & Shaft position (See Installation Manual pg. 4) with the HB, HH and GB models. and works similar to the standard RV.

No letter - Pipe port No letter - W position (See Installion Manual pg. 4)

800-264-4115 | 901-867-5555 | www.rangerpumps.com 800-264-4115 | 901-867-5555 | www.rangerpumps.com

Ranger pumps can be engineered for

Blending • Mixing • Transfer • Solvents • Molasses

Gasoline • Resins • Oil • Asphalt • Chemicals

Field Adjustable Stuffing Box

Standard Fitted Maximum

Lip Seal Design Mechanical Seal Materials of Pump Ratings

Relief Valve Construction

The relief valve will provide protection 125 PSI (862 KPA) maximum inlet and

in only one direction of rotation. A STANDARD discharge pressure

relief valve is needed for the pump PART MATERIALS OPTIONS 750 RPM maximum for 11, 17 & 22 series.

system to protect the pump (See speed vs. viscosity curve for maximum RPM).

from over- Housing & ASTM A48

Backplates Class 30 Cast Iron 900 RPM maximum for 48 series.

pressures. (See speed vs. viscosity curve for maximum RPM).

Gears Ductile Iron

350ºF (177ºC) maximum temperature for

The valves Shafts Carbon Steel 440 Stainless Steel standard packing.

can be Ranger pumps can be supplied as standard with

positioned to a single mechanical seal. They can be easily con- Bearing Carbon, Iron, TFE/ 500ºF (260ºC) Maximum temperature for

Ranger pumps can supplied as standard with Ranger pumps can be supplied with a verted from a mechanical seal to packing or lipseal. Bushings Bronze Graphite TFE/Graphite

either side of the

combination lipseal and back-up packing as R.V. Parts Carbon Steel Stainless Steel

4

stuffing box. They can be easily converted from

5

pump to provide Several types of seals are available (Buna-N, 212ºF(100ºC) maximum temperature for

protection for the discharge. packing to a lip seal or mechanical seal. Several shown above. This can be easily converted from VitonTM and TeflonTM) for various applications, for Gaskets Fiber Aluminum BUNA-N mechanical seal

types of packing are available for various applica- the lipseal combination to packing only or a example: high temperatures or corrosive condi- Hardware Zinc Plated

mechanical seal. 400ºF (204ºc) maximum temperature for

*See Installation, Operation and Maintenance manual for details.

tions: for example - high temperatures. tions. Contact Ranger for application assistance. Steel Viton mechanical seal

Key Components

Pumps come standard with fiber Various types of seals are available including

Theoretical Capacity

case gaskets (*Max 2300F/1100C). packing, lip seals or mechanical seals.

For temperature up to 4500F/2320C ,

we offer optional aluminum gaskets.

500

48 Series

450

400

350

A large outboard bearing is

Flow Rate (GPM)

furnished on all HB model

pumps that support the 300

Heat treated ductile Iron gears are drive shaft on applications

accurately machined for quiet,

efficient operation and long life.

with side loads. 250

200

22 Series

150

17 Series

100

11 Series

Carbon steel relief valve 50

springs come standard

or optional stainless steel

spring. Various springs 0

are available for a wide The steel shafts are induction hardened in the

range of operation duties. Four heavy duty sleeve bearings give bearing and packing areas and are precision

200 300 400 500 600 700 800 900

positive support to pumping gears and

ensure long, efficient service.

ground to exacting standards for maximum life. Pump Speed (RPM)

Hardened stainless steel shafts are available.

800-264-4115 | 901-867-5555 | www.rangerpumps.com 800-264-4115 | 901-867-5555 | www.rangerpumps.com

Gear Ratios Construction

for GB Units Advantages

Series Motor

Gear Pump Maximum

RPM Ratio RPM Permissible HP Positive shaft and gear support with four

4.60:1 250 5.5 internal bearings

48 11-22

1150 3.94:1 290 6.5

3.20:1 360 8.0

4.60:1 380 8.5 Dowel pins insure positive pump alignment

This series of Ranger pumps is designed the 11, 17 and 22 Series pumps. 1750 3.94:1 445 10.0

3.20:1 545 10.0 Hardened gears and shafts for long service life

to operate at reduced motor speeds. This

The charts on this page are intended as a 3450* 4.60:1 750 10.0

allows the pump to operate equally well

guide only. All application factors includ- 5.66:1 203 8.5 Integral speed reducer available as option

NEW

for both high and low viscosity liquids. 1150 4.88:1 235 10.0

ing temperature, liquid characteristics

Low pump speeds also increase pump life. 4.26:1 270 11.0

and inlet conditions must be considered 5.66:1 309 13.0 Field adjustable relief valve available

Ranger gear boxes are self contained with

to select the correct pump and reduction 1750 4.88:1 360 15.0

oil lubricated anti-friction bearings and 4.26:1 410 15.0

speed. Speeds shown for the 48 Series are Fabrication options include Base, Coupling

hardened steel gears standard for maxi- 3450* 5.66:1 609 15.0

for reference only, contact Ranger Pumps and Drives

mum service life. A common gear box has Note: Do not exceed maximum allowable HP shown. Series 11 - .11 gallons per revolution, Series 17 - .17 gallons

for more information. per revolution, Series 22 - .22 gallons per revolution, Series 48 - .52 gallons per revolution. *3450 RPM motors are

three interchangeable gear ratios that fit used in handling low viscosity lubricating liquids.

Typical Liquids/Viscosity List

30 to 100 100 to 250 250 to 800 800 to 2,500 2,500 to 8,000 8,000 to 25,000 25,000 to 75,000 75,000 to 300,000

- Alcohols - SAE #5 Oil - SAE #10 Oil - SAE #20-30 Oil - SAE #40 Oil - SAE #50 Oil - Asphalt - Tar

6 7

- Gasoline - Corn Oil - Soybean Oil - Paint Primer - Heavy Turbine Oil - Ink - Shampoo - Molasses

- Turpentine - Olive Oil - Light Crude - Spar Varnish - Enamel Paint - Heavy Crude - Gear Lube - Chocolate

SERIES RPM 250 RPM 290 RPM 360 RPM 380 RPM 445 RPM 545 RPM 750 RPM

PSI SSU 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000

11

25 GPM 25 26 27 27 29 30 31 31 37 38 39 39 40 41 42 42 47 48 49 58 59 60 80 81 82

HP .7 .7 .9 1.3 .9 .9 1.2 1.5 1.1 1.1 1.4 2.2 1.1 1.1 1.5 2.3 1.4 1.4 2.0 1.9 1.9 2.7 2.8 2.8 3.8

50 GPM 23 25 27 27 27 29 31 31 35 37 39 39 38 40 42 42 45 47 49 56 58 60 78 80 82

HP 1.1 1.1 1.3 1.7 1.3 1.3 1.5 1.9 1.7 1.7 2.0 2.8 1.7 1.7 2.1 2.9 2.1 2.1 2.6 2.7 2.7 3.5 3.9 3.9 4.9

100 GPM 23 26 27 27 30 31 35 38 39 33 38 41 42 40 45 48 51 56 59 73 78 81

HP 1.9 2.1 2.5 2.2 2.4 3.0 2.8 3.1 3.9 2.9 2.9 3.3 4.1 3.5 3.5 4.0 4.4 4.4 5.2 6.3 6.3 7.3

125 GPM 22 26 27 26 30 31 34 38 39 37 41 42 44 48 48 55 59 70 77 81

HP 2.2 2.4 2.8 2.7 2.9 3.5 3.3 3.6 4.4 3.5 3.9 4.7 4.2 4.7 5.4 5.4 6.2 7.5 7.5 8.5

17

25 GPM 38 40 41 42 45 47 48 49 57 59 60 61 60 62 63 64 71 73 74 88 90 91 123 125 126

HP .8 .8 1.1 1.8 1.0 1.0 1.3 2.2 1.2 1.2 1.8 3.0 1.3 1.3 1.9 3.3 1.7 1.7 2.5 2.3 2.3 3.6 3.5 3.5 6.0

50 GPM 33 38 41 42 40 45 48 49 52 57 60 61 55 60 63 64 66 71 74 83 88 91 118 123 126

HP 1.4 1.4 1.7 2.4 1.6 1.6 1.9 2.8 2.1 2.1 2.7 3.9 2.3 2.3 2.9 4.3 2.9 2.9 3.7 3.8 3.8 4.9 5.4 5.4 7.9

100 GPM 34 40 41 41 47 48 49 53 59 60 52 56 62 63 63 67 73 80 84 90 115 119 125

HP 2.6 2.9 3.6 3.0 3.3 4.2 3.8 3.8 4.4 5.6 4.2 4.2 4.8 6.2 5.0 5.0 5.8 6.3 6.3 7.6 9.0 9.0 11.5

125 GPM 39 41 46 48 49 51 58 60 52 54 61 63 63 65 72 80 82 89 115 117 124

HP 3.4 4.1 4.0 4.9 4.6 4.6 5.2 6.4 5.0 5.0 5.6 7.0 6.0 6.0 6.8 7.5 7.5 8.8 10.8 10.8 13.3

22

25 GPM 52 53 55 55 60 61 63 63 76 77 79 79 80 81 83 83 94 95 97 116 117 119 162 163 165

HP 1.1 1.1 1.4 1.9 1.3 1.3 1.7 2.5 2.0 2.0 2.6 3.9 2.2 2.2 3.0 4.3 2.7 2.7 3.5 3.2 3.2 4.4 5.1 5.1 7.2

50 GPM 50 52 54 55 58 60 62 63 74 76 78 79 78 80 82 83 92 94 96 114 116 118 161 162 164

HP 2.0 2.0 2.3 2.8 2.3 2.3 2.6 3.4 3.1 3.1 3.7 5.0 3.3 3.3 4.1 5.4 4.1 4.1 4.9 4.8 4.8 6.0 7.3 7.3 9.4

100 GPM 44 50 53 55 52 58 61 63 68 74 77 79 72 78 81 83 86 92 95 108 114 117 154 160 163

HP 3.5 3.5 3.8 4.3 4.2 4.2 4.5 5.3 5.4 5.4 6.0 7.3 5.7 5.7 6.5 7.8 6.6 6.8 7.6 8.2 8.2 9.4 12.0 12.0 14.1

125 GPM 49 53 55 50 57 61 63 66 73 77 79 70 77 81 83 84 91 95 106 113 117 152 159 163

HP 4.2 4.5 5.0 5.2 5.2 5.5 6.3 6.5 6.5 7.1 8.4 6.9 6.9 7.7 9.0 8.3 8.3 9.1 10.2 10.2 11.4 14.7 14.7 16.8

RPM 203 RPM 235 RPM 270 RPM 309 RPM 360 RPM 410 RPM 609 RPM

48

PSI SSU 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000 30 100 1000 10,000

25 GPM 94 97 101 103 111 114 118 120 129 132 136 138 149 152 156 158 176 179 183 185 202 205 209 211 305 308 312 314

HP 2.5 2.8 3.2 3.8 3.0 3.4 3.9 4.6 3.7 3.9 4.7 5.7 4.4 4.7 5.7 6.9 5.4 5.9 7.0 8.5 6.3 6.8 8.4 10.3 10.9 12.0 16.8 19.7

50 GPM 93 99 103 110 116 121 128 134 133 141 148 154 160 168 175 181 186 194 201 207 209 297 304 310

HP 4.7 5.3 5.1 5.6 6.3 5.9 6.7 7.7 6.8 7.1 8.1 9.3 8.0 8.5 9.6 11.1 9.5 10.0 11.6 13.5 15.4 16.5 19.3 24.2

100 GPM 88 105 123 132 143 159 170 185 196 266 288 299

HP 8.5 10.0 11.1 12.7 13.9 15.1 16.6 17.7 19.6 25.6 28.4 33.3

125 GPM 101 119 139 166 176 192 279 295

HP 11.7 14.0 16.2 19.2 20.8 22.7 32.9 37.3

800-264-4115 | 901-867-5555 | www.rangerpumps.com 800-264-4115 | 901-867-5555 | www.rangerpumps.com

90 PORTS 0

11, 17, 22 SERIES - 90o PORTS 180 PORTS 0

11, 17, 22 SERIES - 180o PORTS

OUTBOARD BEARING - HB

J

OUTBOARD BEARING - HB

D J

Plain Endplate K C C

C Plain Endplate K

I

I

1/4” SQ. Key x O 1/4” SQ. Key x

O 1.375 1.375

A A

1” Diameter

1” Diameter

Shaft

B Shaft

B H

H E L High Drive

L High Drive

Low Drive

E Low Drive

F F øM

F F øM GG

GG

J J

D Plain Endplate K C C Plain Endplate K

C I I

HYDRAULIC - HH

HYDRAULIC - HH

N N

1/4” Sq. Key x 1.375”

1” I.D. Straight

1/4” SQ. Key x Coupling

1.375 A

A Accomodates

1” Diameter 2 Bolt SAE A

Type Flange

Straight Coupling

B H

L High

B H Accommodates 2 E

Low Drive Drive

High

Drive L bolt SAE A Type

Flange

E Low Drive

F F øM

F F øM G G

GG

J J

D K

GEAR REDUCTION - GB

Plain Endplate

C C

GEAR REDUCTION - GB

Q Plain Endplate K

C I I Q

O

1/4” SQ. x 1.5”

Keyway 1/4” SQ. x 1.5”

Keyqay

R

R

A

8 B

H

1” Diameter

Shaft

E

B

O

1” Diameter

Shaft

H

9

E

E

F F øM

F F GG

øM GG

11, 17, 22 SERIES-900 A B C D E F G H I J K L M N O Q R PORTS 11, 17, 22 SERIES-1800 A B C D E F G H I J K L M N O Q R PORTS

HB & HBRV in 10.75 5.00 3.63 7.63 0.75 2.75 0.88 6.44 13.50 22.88 21.25 3.65 0.56 3.75 2” NPT TAPPED HBF & HBFRV in 9.50 5.00 4.14 8.28 0.75 2.75 0.88 6.44 13.50 22.88 21.25 3.65 0.56 3.75 2” NPT FLANGE STANDARD

mm 273 127 92 194 19 70 22 164 343 581 540 93 14 95 mm 241 127 105 210 19 70 22 164 343 581 540 93 14 95

HBF & HBFRV in 11.52 5.00 4.30 8.30 0.75 2.75 0.88 6.44 13.50 22.88 21.25 3.65 0.56 3.75 2” NPT FLANGE STANDARD

mm 51 127 109 211 19 70 22 164 343 581 540 93 14 95 2.5” NPT FLANGE OPTIONAL HHF & HHFRV in 9.50 5.00 4.14 8.28 0.75 2.75 0.88 6.44 11.84 21.00 17.50 3.65 0.56 2.72 2” NPT FLANGE STANDARD

HH & HHRV in 10.75 5.00 3.63 7.63 0.75 2.75 0.88 6.44 11.84 21.00 17.50 3.65 0.56 2.72 2” NPT TAPPED

118

mm 241 127 105 210 19 70 22 164 301 533 445 93 14 69

mm 273 127 92 194 19 70 22 164 301 533 445 93 14 69

119 HHF & HHFRV in 11.52 5.00 4.30 8.30 0.75 2.75 0.88 6.44 11.84 21.00 17.50 3.65 0.56 2.72 2” NPT FLANGE STANDARD GBF & GBFRV in 9.50 5.00 4.14 8.28 0.75 2.75 0.88 6.44 14.81 23.88 20.52 3.65 0.56 1.75 3.52 11.63 2” NPT FLANGE STANDARD

mm 293 127 109 211 19 70 22 164 301 533 445 93 14 69 2.5” NPT FLANGE OPTIONAL mm 241 127 105 210 19 70 22 164 376 607 521 93 14 44 89 295

GB & GBRV in 10.75 5.00 3.63 7.63 0.75 2.75 0.88 6.44 14.81 23.88 20.52 3.65 0.56 1.75 3.52 11.63 2” NPT TAPPED

mm 273 127 92 194 19 70 22 164 376 607 521 93 14 44 89 295

GBF & GBFRV in 11.52 5.00 4.30 8.30 0.75 2.75 0.88 6.44 14.87 23.88 20.52 3.65 0.56 1.75 3.52 11.63 2” NPT FLANGE STANDARD

mm 293 127 109 211 19 70 22 164 376 607 521 93 14 44 89 295 2.5” NPT FLANGE OPTIONAL HBF & HBFRV in 9.50 5.00 4.89 9.78 0.75 13.71 0.88 6.44 13.71 23.63 20.12 3.65 0.56 3.00 3” NPT FLANGE STANDARD

HB & HBRV in 10.75 5.00 3.63 7.75 0.75 2.75 0.88 6.44 13.71 23.63 22.00 3.65 0.56 3.00 2” NPT TAPPED mm 241 127 124 248 19 348 22 164 348 600 511 93 14 76

mm 273 127 92 197 19 70 22 164 348 600 559 93 14 76 HHF & HHFRV in 9.50 5.00 4.89 9.78 0.75 2.75 0.88 6.44 12.60 22.50 19.00 3.65 0.56 2.72 3” NPT FLANGE STANDARD

HBF & HBFRV in 11.63 5.00 4.25 8.25 0.75 2.75 0.88 6.44 13.71 23.63 20.12 3.65 0.56 3.00 2” NPT FLANGE STANDARD 178

mm 295 127 108 210 19 70 22 164 348 600 511 93 14 76 2.5” NPT FLANGE OPTIONAL mm 241 127 124 248 19 70 22 164 320 572 483 93 14 69

HH & HHRV in 10.75 5.00 3.63 7.75 0.75 2075 0.88 6.44 12.60 22.50 19.00 3.65 0.56 2.72 2” NPT TAPPED GBF & GBFRV in 9.50 5.00 4.89 9.78 0.75 2.75 0.88 6.44 15.54 25.36 22.00 3.65 0.56 1.75 3.52 11.63 3” NPT FLANGE STANDARD

mm 273 127 92 197 19 70 22 164 320 572 483 93 14 69

179 HHF & HHFRV in 11.63 5.00 4.25 8.25 0.75 2.75 0.88 6.44 12.60 22.50 19.00 3.65 0.56 2.72 2” NPT FLANGE STANDARD mm 241 127 124 248 19 70 22 164 395 644 559 93 14 44 89 295

mm 295 127 108 210 19 70 22 164 320 572 483 93 14 69 2.5” NPT FLANGE OPTIONAL

GB & GBRV in 10.75 5.00 3.63 7.75 0.75 2.75 0.88 6.44 15.54 25.36 22.00 3.65 0.56 1.75 3.52 11.63 2” NPT TAPPED

mm 273 127 92 197 19 70 22 164 395 644 559 93 14 44 89 295 HBF & HBFRV in 9.44 5.00 4.75 9.50 0.75 2.75 0.88 6.44 14.50 25.00 21.50 3.65 0.56 3.00 4” NPT FLANGE STANDARD

GBF & GBFRV in 11.52 5.00 4.30 8.30 0.75 2.75 0.88 6.44 15.54 25.36 22.00 3.65 0.56 1.75 3.52 11.63 2” NPT FLANGE STANDARD

mm 295 127 108 210 19 70 22 164 395 644 559 93 14 35 89 295 2.5” NPT FLANGE OPTIONAL mm 240 127 121 241 19 70 22 164 368 635 546 93 14 76 3” NPT FLANGE OPTIONAL

HBF & HBFRV in 12.25 5.00 6.50 11.00 0.75 2.75 0.88 6.44 14.50 25.00 21.50 3.65 0.56 3.00 3” NPT FLANGE STANDARD HHF & HHFRV in 9.44 5.00 4.75 9.50 0.75 2.75 0.88 6.44 13.40 24.00 20.50 3.65 0.56 2.72 4” NPT FLANGE STANDARD

mm 311 127 165 279 19 70 22 164 368 635 546 93 14 76 4” NPT FLANGE OPTIONAL

228

mm 240 127 121 241 19 70 22 164 340 610 521 93 14 69 3” NPT FLANGE OPTIONAL

229 HHF & HHFRV in 12.25 5.00 6.50 11.00 0.75 2.75 0.88 6.44 13.40 24.00 20.50 3.65 0.56 2.72 3” NPT FLANGE STANDARD

GBF & GBFRV in 9.44 5.00 4.75 9.50 0.75 2.75 0.88 6.44 16.38 27.00 23.50 3.65 0.56 1.75 3.52 11.63 4” NPT FLANGE STANDARD

mm 311 127 165 279 19 70 22 164 340 610 521 93 14 69 4” NPT FLANGE OPTIONAL

GBF & GBFRV in 12.25 5.00 6.50 11.63 0.75 2.75 0.88 6.44 16.38 27.00 23.50 3.65 0.56 1.75 3.52 11.63 3” NPT FLANGE STANDARD mm 240 127 121 241 19 70 22 164 416 686 597 93 14 44 89 295 3” NPT FLANGE OPTIONAL

mm 311 127 165 295 19 70 22 164 416 686 597 93 14 44 89 295 4” NPT FLANGE OPTIONAL

800-264-4115 | 901-867-5555 | www.rangerpumps.com 800-264-4115 | 901-867-5555 | www.rangerpumps.com

OUTBOARD BEARING - HB ANGLED GEARS 48 SERIES ANGLED GEAR PUMPS

U D

Plain Endplate

J

K

HYDRAULIC PUMPS HYDRAULIC PUMPS

All of the Ranger 11, 17, 22 and 48 series pumps can be

I supplied with a hydraulic motor adaptor. The adaptor and

rigid coupling to connect the pump and hydraulic motor

A O 1/4” SQ. Key

are included in the hydraulic package. Upon request,

H 1 1/4” Diameter Ranger can supply the hydraulic motor as well.

High

Drive Shaft

L

Low Drive

B H

High Drive

T

L

Low Drive

F1 F2

S øM G G

U D J

Plain Endplate K

I Accommodates

HYDRAULIC - HH

4 Bolt SAE B

N Type Flange

5/16” SQ. x 2”

Keyway

A

H

High

1.25” I.D.

Drive

L

Low Drive B Straight Coupling

T

F1 F2 E

S øM G G

Identifying Direction of Rotation Mounting

J

K

GEAR REDUCTION - GB

Plain Endplate

Q

4” NPT Flange I

Standard

O 1/4” x 2”

SQ. Key W Discharge Inlet X Inlet Discharge W Inlet Hi-Drive Pumps

A W: Clockwise Rotation X: Counterclock-

10 H

High

Drive

L

Lo Drive

E

1 1/8” Diameter Shaft

R

H

High

Drive

CW CCW

CW

wise Rotation Y: Clockwise Rotation

Z: Counterclockwise Rotation

11

T

F1 F2 900 900 Discharge 1800

S D øM

G G

Lo-Drive Pumps

489 ANGLED GEAR A B D E F1 F2 H I J K L M N O Q R S T U PORTS Discharge

LW Inlet Discharge LX Inlet LW Discharge

LW: Clockwise Rotation LX: Counterclock-

HBF & HBFRV in 11.54 3.15 5.53 0.63 6.09 1.90 6.40 17.55 28.00 27.25 3.75 0.75 4.08 6.89 2.65 3.25

mm 293 80 140 16 155 48 163 446 711 692 95 19 104 175 67 83 wise Rotation LY: Clockwise Rotation

489 HHF & HHFRV in 11.54 3.15 5.53 0.63 6.09 1.90 6.40 16.35 27.00 26.00 3.75 0.75 3.75 6.89 2.65 3.25 4” NPT FLANGE STANDARD

CW LZ: Counterclockwise Rotation

mm 293 80 140 16 155 48 163 415 686 660 95 19 95 175 67 83 3” NPT FLANGE OPTIONAL CCW

CW

GBF & GBFRV in 11.54 3.15 5.53 0.63 6.09 1.90 6.40 22.27 34.00 33.00 3.75 0.75 2.87 4.188 12.04 6.89 2.65 Inlet

900 900 1800

mm 293 80 140 16 155 48 163 566 864 838 95 19 73 106 306 175 67 Pump Rotation

Pumping rotation is determined when facing

Y Inlet

Z Discharge Z Discharge

Mounted Pump Systems the drive shaft. These diagrams will serve as

a helpful basis for you to determine the

CW CCW CCW

Ranger pumps can be mounted direction of rotation wanted according to

on a base with an electric Discharge 900 Inlet 900 Inlet

1800 your piping system. Example:

motor, coupling and guard

with an integral gear box CW

Discharge

or stand alone gear box. LY LZ Inlet

LZ Inlet

There are many different WARNING: Read installation, operation

options that can deliver a and maintenance Manual before install-

CW CCW

wide range of gallons CCW ing, performing maintenance or operating

per minute. Inlet 900 Discharge 900 Discharge 1800 a Ranger pump.

800-264-4115 | 901-867-5555 | www.rangerpumps.com 800-264-4115 | 901-867-5555 | www.rangerpumps.com

COMPANY

Company History

HISTORY

Ranger pumps are built in the USA from parts made in Shipping

the USA. We are proud of our history of providing our Memphis, Tennessee is a major distribution center hub in

customers with the highest quality helical gear pumps for the United States. We are able to ship quickly with short

over 20 years. lead times to virtually anywhere in the world.

Ranger Pumps is a privately held corporation that was Investing in Our Product

founded in 1989 in Memphis, Tennessee. The company We are constantly adding new equipment and processes.

has become a national supplier serving customers in all 50 We have recently added a state-of-the-art coordinate

states and numerous countries around the world. measuring machine that allows us to make more accurate

parts, thus insuring a very high quality end product.

Customer Service

We consider customer service to be a high priority. We are Made in the USA

proud of the fact that when you call our offices you will We are extremely proud of the fact that all Ranger castings

talk to a knowledgeable representative who understands are poured and machined in the USA. All Ranger gears,

all aspects of our business, not a voice mail message. shafts, bushings and packings are made in the USA. All

major Ranger components are made in the USA.

Quality Assurance

All of our products are built to exacting standards and are Pumps Are Our Business

tested to be sure We specialize in the manufacture of precision helical gear

they work before pumps. Our vision is focused very closely on these specific

they go out the products, outstanding customer service, with on-time

door. delivery and excellent technical support.

Competitively Priced Products

Ranger pumps performance meets or exceeds the

competition in every way. We are careful to be sure that

our quality exceeds our competitors while providing

an outstanding value on every pump we

manufacture.

Ranger, Inc.

12624 Cypress Creek Drive • Eads, TN 38028 • 800-264-4115 • 901-867-5555

Fax 901-867-5351 • Email: info@RangerPumps.com • www.rangerpumps.com

You might also like

- Test Bank PDFDocument14 pagesTest Bank PDFGwenn Salazar100% (2)

- DRYPIX Smart Reference GuideDocument80 pagesDRYPIX Smart Reference GuideHugo79% (33)

- Ficha Tecnica Con Curva Myers Bomba Tipo CampanaDocument4 pagesFicha Tecnica Con Curva Myers Bomba Tipo CampanaRonald FranciaNo ratings yet

- Fairbanks End SuctionDocument16 pagesFairbanks End SuctionKitikhun VichanarksornsitNo ratings yet

- Catalogo FRANTZ GralDocument52 pagesCatalogo FRANTZ GralGiovanni Escobedo Villanueva100% (1)

- Brochure - Vertical In-Line Pumps 1590 SeriesDocument8 pagesBrochure - Vertical In-Line Pumps 1590 SeriesFrancisNo ratings yet

- Alfa Laval 3s Pumps Emd00458enDocument6 pagesAlfa Laval 3s Pumps Emd00458enMuhd Khir RazaniNo ratings yet

- Nitraheavydutydcylinder 4Document6 pagesNitraheavydutydcylinder 4AzifahNo ratings yet

- Deep Well Turbine PumpsDocument20 pagesDeep Well Turbine Pumpshasnain shah100% (1)

- Firefighter Twin ProDocument2 pagesFirefighter Twin Propr1m4f1tr4No ratings yet

- 60hz Fan Curves & DrawingsDocument531 pages60hz Fan Curves & DrawingsGonzalo GuzmanNo ratings yet

- Sta Rite J and JB Series High Head Centrifugal Pumps Sell Sheet 1Document4 pagesSta Rite J and JB Series High Head Centrifugal Pumps Sell Sheet 1Alejandro VerdugoNo ratings yet

- Renold SugarDocument8 pagesRenold SugarVolodymуr VorobetsNo ratings yet

- Folder SNP seriesDocument7 pagesFolder SNP seriesleoomarNo ratings yet

- Sentinel 250 Fire Hydrant: Product FeaturesDocument2 pagesSentinel 250 Fire Hydrant: Product FeaturesBalaji NaikNo ratings yet

- Nov Mission Drilling SolutionsDocument24 pagesNov Mission Drilling SolutionsahnafNo ratings yet

- PTC Excavator Mounted Vibrodrivers WEB 09-2015 PDFDocument20 pagesPTC Excavator Mounted Vibrodrivers WEB 09-2015 PDFDaniel FuhrNo ratings yet

- Crompton Greaves Agro Centrifugal Submersible Pumps Catalogues PDFDocument40 pagesCrompton Greaves Agro Centrifugal Submersible Pumps Catalogues PDFbijubijayNo ratings yet

- HVT Auxilliary Vane Axial Fan InfoDocument1 pageHVT Auxilliary Vane Axial Fan InfoGabo Luna MorenoNo ratings yet

- NSL LetterformatDocument4 pagesNSL LetterformatMohamed MohamedNo ratings yet

- Valveco Product RangeDocument7 pagesValveco Product RangeBobbie RuckNo ratings yet

- Bombas Centífugas KSBDocument12 pagesBombas Centífugas KSBkarmencitaconk4035No ratings yet

- Bomba Emilio Mendizabal - Rovatti Pompe ItalyDocument16 pagesBomba Emilio Mendizabal - Rovatti Pompe Italyprobetaspro132No ratings yet

- Johnston Pump Jts Vertical Turbine PumpDocument6 pagesJohnston Pump Jts Vertical Turbine PumpJhonathan CanzarioNo ratings yet

- API 610 Major Changes From 5th Through 10th Editions 4Document1 pageAPI 610 Major Changes From 5th Through 10th Editions 4ahmedNo ratings yet

- Watts Radiant Radiant Heating ManifoldsDocument28 pagesWatts Radiant Radiant Heating Manifoldse-ComfortUSANo ratings yet

- BB 1 - 1 Estapa - Pump WorksDocument2 pagesBB 1 - 1 Estapa - Pump WorksMarco Pompa ReyesNo ratings yet

- Solids Handling WEMCO Self PrimerDocument4 pagesSolids Handling WEMCO Self Primermiguel_vera6592No ratings yet

- Brochure Turbina Vertical AMPDocument1 pageBrochure Turbina Vertical AMPAmedt García HernándezNo ratings yet

- VS6Document4 pagesVS6Arash Sotoudeh100% (1)

- SPLT & SPLT.M Series (50 HZ) : Split Case Double Suction Centrifugal PumpDocument41 pagesSPLT & SPLT.M Series (50 HZ) : Split Case Double Suction Centrifugal Pumplee marvin BilongNo ratings yet

- G2C Brochure Sept 2022 ScreenDocument5 pagesG2C Brochure Sept 2022 ScreenMarco Rocha100% (1)

- Puma Catalbg I Hit: SeriesDocument8 pagesPuma Catalbg I Hit: SeriesSALES 1 YUVAIKANo ratings yet

- FLSmidth vMAX Pump BrochureDocument4 pagesFLSmidth vMAX Pump BrochureSendi El MehdiNo ratings yet

- NLB Tabla de Pistones Cilindro BDocument2 pagesNLB Tabla de Pistones Cilindro Blalo lopezNo ratings yet

- 9.4.6 Goulds 320L Spec Sheet7313Document7 pages9.4.6 Goulds 320L Spec Sheet7313LeonelleNo ratings yet

- M 1064 SERIES Brochure - TifDocument4 pagesM 1064 SERIES Brochure - TifNilsNo ratings yet

- Spec Jack Enerpac RRDocument4 pagesSpec Jack Enerpac RRdennis rio perdanaNo ratings yet

- Crane IndustrialDocument12 pagesCrane IndustrialAhmed HakamNo ratings yet

- Dynabolt Sleeve Anchor Product Data 2088518Document3 pagesDynabolt Sleeve Anchor Product Data 2088518Chuck AnsphilNo ratings yet

- WARMAN - Q-Series Axial Flow Pumps-EN-2015 - PREVIEWDocument8 pagesWARMAN - Q-Series Axial Flow Pumps-EN-2015 - PREVIEWmicheldenijs84No ratings yet

- GP - AF - Low 1Document8 pagesGP - AF - Low 1maguilar20No ratings yet

- Pompa REED A30HP PDFDocument2 pagesPompa REED A30HP PDFMarginean VictorNo ratings yet

- Compactrotosonic V (CRS-V) : Meet The DifferenceDocument4 pagesCompactrotosonic V (CRS-V) : Meet The DifferenceAnonymous nZcViIP0hNo ratings yet

- Bombas de Turbina VerticalDocument113 pagesBombas de Turbina VerticalJaime Arturo Ruiz MoraNo ratings yet

- Sec 410-4625Document12 pagesSec 410-4625Automa Viet NamNo ratings yet

- Catalogo Aurora PneumaticDocument84 pagesCatalogo Aurora PneumaticSam MarmorNo ratings yet

- SH 60 TD enDocument98 pagesSH 60 TD enCésar David Pedroza DíazNo ratings yet

- Cast Steel Globe Valve Api 600Document12 pagesCast Steel Globe Valve Api 600Andy SetyawanNo ratings yet

- Spring Rewind Reels: To Handle 3/4" or 1" I.D. HoseDocument1 pageSpring Rewind Reels: To Handle 3/4" or 1" I.D. Hosegustavoac834217No ratings yet

- Agi 2019 York - en Masse - Conveyor Brochure Fin WebDocument16 pagesAgi 2019 York - en Masse - Conveyor Brochure Fin WebnareshpaneruNo ratings yet

- Dynabolt Performance DataDocument3 pagesDynabolt Performance DataJudy-an RanuloNo ratings yet

- HPS2200 Pump & GearboxDocument2 pagesHPS2200 Pump & GearboxFrederik CañabiNo ratings yet

- Warren Pumps Jaguar 2200 Series 沥青泵选型Document4 pagesWarren Pumps Jaguar 2200 Series 沥青泵选型Ana PaolaNo ratings yet

- Super Centurion HydrantDocument2 pagesSuper Centurion HydrantForum PompieriiNo ratings yet

- 1 1061GBDocument8 pages1 1061GBPatricio RojasNo ratings yet

- Weir Skimmer 120m / HR - 180m / HR Self - Adjusting Weir: FeaturesDocument1 pageWeir Skimmer 120m / HR - 180m / HR Self - Adjusting Weir: Featuresapi-3703371No ratings yet

- VLT VMT Pump Brochure enDocument4 pagesVLT VMT Pump Brochure enLuis YañezNo ratings yet

- Ps 20 1 eDocument8 pagesPs 20 1 efaisal100% (1)

- 320 Series Vertical Sump PumpsDocument8 pages320 Series Vertical Sump PumpsEsteban TobarNo ratings yet

- 4 Floating SublineDocument4 pages4 Floating SublineSavoNo ratings yet

- Nurse Burnout ThesisDocument5 pagesNurse Burnout Thesisafkokocqw100% (2)

- Catalog 6.4.1 Master R0Document164 pagesCatalog 6.4.1 Master R0psaayoNo ratings yet

- Enterobius Vermicularis: Ciulla Chapter 8 - ParasitologyDocument13 pagesEnterobius Vermicularis: Ciulla Chapter 8 - ParasitologySalve Rachelle BillenaNo ratings yet

- RFB ManualDocument22 pagesRFB Manualstormtrooper1015No ratings yet

- CBSE Class 7 Science Important Questions On Chapter 2-Nutrition in AnimalsDocument4 pagesCBSE Class 7 Science Important Questions On Chapter 2-Nutrition in Animalsdrushti luteNo ratings yet

- Matter and ChangeDocument23 pagesMatter and ChangeDionisio BrinosaNo ratings yet

- EIA Envt Impact Assessment Report On Myitsone Dam BurmeseDocument13 pagesEIA Envt Impact Assessment Report On Myitsone Dam BurmesePugh JuttaNo ratings yet

- Lipid Transport and StorageDocument34 pagesLipid Transport and StorageGuru Kiran C KNo ratings yet

- NaskahDocument78 pagesNaskahOlvie DenintaNo ratings yet

- Food AdulterationDocument20 pagesFood AdulterationMahanth ThoraviNo ratings yet

- Obstetrics & GynecologyDocument10 pagesObstetrics & GynecologyRaul DoctoNo ratings yet

- SMEA2402 - Manufacturing Processes LabDocument15 pagesSMEA2402 - Manufacturing Processes LabPurusothamanManiNo ratings yet

- Valedictorian SpeechDocument1 pageValedictorian SpeechaloieNo ratings yet

- Municipal Trial Court: Page 1 of 2Document2 pagesMunicipal Trial Court: Page 1 of 2unjustvexationNo ratings yet

- RobotsDocument12 pagesRobotsArim ArimNo ratings yet

- Test 1 Paper 4: Listening: Part 1 (Questions 1-8)Document24 pagesTest 1 Paper 4: Listening: Part 1 (Questions 1-8)Trần Anh KiệtNo ratings yet

- DB2 SQL ExamplesDocument283 pagesDB2 SQL ExamplessumantasorenNo ratings yet

- Humanizacion en PediatriaDocument10 pagesHumanizacion en PediatriaAndrea Sanchez LaraNo ratings yet

- Jet Compressors Pulp PaperDocument10 pagesJet Compressors Pulp PaperIsmail SalihNo ratings yet

- Gollis University Assignment One Name: Hamse Mohamed Jama ID:15117 QuestionsDocument2 pagesGollis University Assignment One Name: Hamse Mohamed Jama ID:15117 Questionsmohamed jamaNo ratings yet

- Estimation of The Vitamin D Content of Foods For The Assessment of Dietary IntakeDocument1 pageEstimation of The Vitamin D Content of Foods For The Assessment of Dietary IntakeNancy Kosasih 2No ratings yet

- Carti Scrise de Pema ChodronDocument38 pagesCarti Scrise de Pema ChodronSpiridon Andrei CristianNo ratings yet

- Manufacturing & Fitting The Jaipur Above-the-Knee Prosthesis and Jaipur FootDocument122 pagesManufacturing & Fitting The Jaipur Above-the-Knee Prosthesis and Jaipur FootoxideheraNo ratings yet

- BGC FormDocument3 pagesBGC FormMudassir HussainNo ratings yet

- Chemical ReactionsDocument41 pagesChemical ReactionsJeffreyNo ratings yet

- Feasibility Study On Pure Water Business in NigeriaDocument8 pagesFeasibility Study On Pure Water Business in NigeriaAnonymous jlLBRMAr3O50% (2)

- Myron Spector - Biomaterials-Based Tissue Engineering and Regenerative Medicine Solutions To Musculoskeletal ProblemsDocument10 pagesMyron Spector - Biomaterials-Based Tissue Engineering and Regenerative Medicine Solutions To Musculoskeletal ProblemsHutsDMNo ratings yet

- J of Cosmetic Dermatology - 2021 - Segurado - An Expert Consensus Report On The Clinical Use of The Vycross HyaluronicDocument10 pagesJ of Cosmetic Dermatology - 2021 - Segurado - An Expert Consensus Report On The Clinical Use of The Vycross HyaluronicHong Nhung NguyenNo ratings yet