Professional Documents

Culture Documents

TDR Measurement App Note - REV2 - 07232019

TDR Measurement App Note - REV2 - 07232019

Uploaded by

Jayakrishna JKCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Marguerite Yourcenar - Oriental TalesDocument160 pagesMarguerite Yourcenar - Oriental TalesErnesto Che100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Sample PMP Earned Value Questions ScenarioDocument13 pagesSample PMP Earned Value Questions ScenarioAsfurix Mesfin100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Professionalism and Transformative Education: in This Module 1. The 21 Century TeacherDocument38 pagesProfessionalism and Transformative Education: in This Module 1. The 21 Century TeacherNormina Cagunan100% (5)

- An International Baccalaureate Education For AllDocument7 pagesAn International Baccalaureate Education For AllLorraine SabbaghNo ratings yet

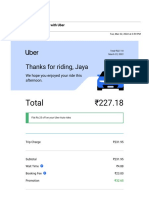

- Gmail - Your Tuesday Afternoon Trip With UberDocument3 pagesGmail - Your Tuesday Afternoon Trip With UberJayakrishna JKNo ratings yet

- EVAL - 38060 - PMAC1 / EV104 User Guide: UG - 201703 - PL17 - 03Document71 pagesEVAL - 38060 - PMAC1 / EV104 User Guide: UG - 201703 - PL17 - 03Jayakrishna JKNo ratings yet

- XDS560 Emulator Technical Reference: SPRU589A April 2002 Revised October 2007Document42 pagesXDS560 Emulator Technical Reference: SPRU589A April 2002 Revised October 2007Jayakrishna JKNo ratings yet

- Brochura Connectors For SMT Production PDFDocument48 pagesBrochura Connectors For SMT Production PDFJayakrishna JKNo ratings yet

- Sprabv 0Document127 pagesSprabv 0Jayakrishna JKNo ratings yet

- GR Lte Nov 2016 PDFDocument88 pagesGR Lte Nov 2016 PDFJayakrishna JKNo ratings yet

- Calculating Lost Labor Productivity-Is There A Better WayDocument17 pagesCalculating Lost Labor Productivity-Is There A Better Waypatrickcarvalho6df100% (1)

- Prepositions and The Haunted HouseDocument6 pagesPrepositions and The Haunted HouseHanna MykhalskaNo ratings yet

- PDF Pozdravi Na SrpskomDocument42 pagesPDF Pozdravi Na SrpskomTanana97No ratings yet

- Worksheet Verb To Be and Pronouns1Document3 pagesWorksheet Verb To Be and Pronouns1Evelin RinconNo ratings yet

- m1010 Final sp12Document8 pagesm1010 Final sp12DEANGELO AVILESNo ratings yet

- Treasury and War Justicia (Supreme Council of Grace andDocument4 pagesTreasury and War Justicia (Supreme Council of Grace andCaila PanerioNo ratings yet

- What Is Breast CancerDocument20 pagesWhat Is Breast CancerKesyaNo ratings yet

- Navicat MacDocument1,041 pagesNavicat MacCarlos Jese Lomeli ValderrabanoNo ratings yet

- Adjectives and Adverbs Ex. 1. Use The Required Form of The AdjectiveDocument3 pagesAdjectives and Adverbs Ex. 1. Use The Required Form of The AdjectiveThảo VyVyNo ratings yet

- Unidad Didáctica "The Parts of The Body"Document14 pagesUnidad Didáctica "The Parts of The Body"Laura Deltell Polo100% (1)

- 5badiou - The Critique of Critique Critical Theory As A New Access To TheRealDocument3 pages5badiou - The Critique of Critique Critical Theory As A New Access To TheRealLuis GonzálezNo ratings yet

- Put in 'Mustn't' or 'Don't / Doesn't Have To':: 1) We Have A Lot of Work Tomorrow. You Be LateDocument8 pagesPut in 'Mustn't' or 'Don't / Doesn't Have To':: 1) We Have A Lot of Work Tomorrow. You Be LateEmir XHNo ratings yet

- 7331 AU680 Datasheet 8Document2 pages7331 AU680 Datasheet 8imrecoNo ratings yet

- TDAU1 1617 scheme-KS3 Ancient-MarinerDocument14 pagesTDAU1 1617 scheme-KS3 Ancient-MarinerIssam LabeckNo ratings yet

- Syllabus Class NURSERYDocument5 pagesSyllabus Class NURSERYGanesh Datt SharmaNo ratings yet

- Ultra High Field Magnetic Resonance ImagingDocument487 pagesUltra High Field Magnetic Resonance ImagingEduardoAndresChacamaVernal100% (1)

- Week 11Document5 pagesWeek 11api-582257412No ratings yet

- Buber Resume2019 2Document2 pagesBuber Resume2019 2Matthew BuberNo ratings yet

- Petition For Declaration of Nullity of MarriageDocument13 pagesPetition For Declaration of Nullity of MarriageIrene QuimsonNo ratings yet

- Dr. Ram Manohar Lohiya National Law University, Lucknow: Project Topic-"1947 and WTO"Document4 pagesDr. Ram Manohar Lohiya National Law University, Lucknow: Project Topic-"1947 and WTO"Abhishek K. SinghNo ratings yet

- AL Bio 2C-1 - Gene MutationDocument18 pagesAL Bio 2C-1 - Gene MutationJyoti BarnwalNo ratings yet

- RD100 Party Pack AmericanDocument20 pagesRD100 Party Pack AmericanHari Bathula100% (1)

- Presentation Title: Debugging Simulation ModelsDocument74 pagesPresentation Title: Debugging Simulation ModelsflyingdreamsNo ratings yet

- Ehadig Final Research ProposalDocument17 pagesEhadig Final Research Proposalአማን በአማንNo ratings yet

- Rwanda's Application For Membership of The Commonwealth: Report and Recommendations of The Commonwealth Human Rights Initiative - Yash GhaiDocument81 pagesRwanda's Application For Membership of The Commonwealth: Report and Recommendations of The Commonwealth Human Rights Initiative - Yash GhaiIntelligentsiya HqNo ratings yet

- Hofstede's Framework For Assessing CulturesDocument12 pagesHofstede's Framework For Assessing CulturesSidharth KatyayanNo ratings yet

TDR Measurement App Note - REV2 - 07232019

TDR Measurement App Note - REV2 - 07232019

Uploaded by

Jayakrishna JKOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDR Measurement App Note - REV2 - 07232019

TDR Measurement App Note - REV2 - 07232019

Uploaded by

Jayakrishna JKCopyright:

Available Formats

Application Note

TDR Measurements

Measuring PCB, Cable and Interconnect Impedance,

Dielectric Constants, Velocity Factor, and Lengths

Controlled impedance printed circuit boards (PCBs) often include a measurement “coupon”,

which typically includes sample traces, 6 inches long and constructed as part of the printed

circuit board panel. They are measured to assure the PCB stack-up and the accuracy of the

PCB transmission lines. These coupons, as well as the actual PCB signal traces, interconnects

and cables are typically measured using a Time Domain Reflectometer (TDR). A TDR is

generally a large, expensive instrument that includes a high-speed edge pulse and a

sampling oscilloscope.

Most modern circuit designs depend on accurate logic signals at the logic receiver. This

assurance is based on the careful design of printed circuit board (PCB) transmission lines,

interconnects, and cables. For that matter, it is advisable to verify the instrument cables

and interconnects at regular intervals. Cable crimps frequently degrade, particularly in low-

cost cables, and can significantly impact the quality of the measurement.

PerfectPulse®, from Picotest, is a low-cost, pocket-sized pulse generator (J2151A). The

signal generator, combined with an included resistive port splitter, and a real time

oscilloscope can be used as a precise TDR/TDT measurement systems. It can measure PCB

test coupon impedance, cables and bad crimps, trace length, dielectric constant (Dk), and

velocity factor (Vf). This application note shows how to measure PCB, cable, and

interconnect impedance, dielectric constant, velocity factor and cable length with J2151A.

Theory of the TDR measurement

Signals travel in air at the speed of light, approximately 3 ∙ 108 𝑚/𝑠𝑒𝑐 1. The signal velocity

is slowed when travelling over a dielectric material. The amount it is slowed down is the

velocity factor (Vf) of the signal transmission, sometimes referred to as the velocity of

propagation.

1

The actual speed of light is 2.99792458 ∙ 108 𝑚/𝑠𝑒𝑐, so 3 ∙ 108 𝑚/𝑠𝑒𝑐 is a reasonable approximation

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 1 of 7

Application Note

TDR Measurements

Coaxial cable specifications often include the velocity factor, which is typically between 60%

and 90% (1). A cable with a velocity factor of 70% means that the signal travels at 0.7 times

the speed of light or 2.1 ∙ 108 𝑚/𝑠𝑒𝑐.

The velocity factor is directly related to the permittivity of the transmission line. The ratio

of the permittivity of a cable, or printed circuit board to the permittivity of free space is the

dielectric constant of the transmission line or PCB. Dielectric constant is sometimes

expressed as εr and sometimes as Dk. Typical dielectric constant values range from a low of

about 2 to as high as about 24.

The relationship between the velocity factor and the dielectric constant is:

1

𝑉𝑓 (𝑖𝑛 𝑝𝑒𝑟𝑐𝑒𝑛𝑡𝑎𝑔𝑒) = ∙ 100 (1)

√Dk

Since we know that the signal propagates through the cable or PCB at a speed of light

reduced by the velocity factor it is possible to relate time and distance.

𝐷𝑖𝑠𝑡𝑎𝑛𝑐𝑒

𝑇𝑖𝑚𝑒 = 𝑉 8

(2)

𝑓 3∙10 𝑚/𝑠𝑒𝑐

Solving the signal propagation in units of inches and picoseconds

𝑝𝑠 11.81 𝑖𝑛𝑐ℎ

𝑆𝑖𝑔𝑛𝑎𝑙 𝑉𝑒𝑙𝑜𝑐𝑖𝑡𝑦 = 84.75 ∙ √𝐷𝑘 𝑖𝑛𝑐ℎ 𝑜𝑟 (3)

√𝐷𝑘 𝑛𝑠

And therefore, a round trip through the trace or cable is

11.81∙𝑡𝑛𝑠

𝐿𝑒𝑛𝑔𝑡ℎ = 𝑖𝑛𝑐ℎ𝑒𝑠 (4)

2∙√𝐷𝑘

And solving for Dk from a known length

34.875∙(𝑡

𝑛𝑠 )2

𝐷𝑘 = (𝐿𝑒𝑛𝑔𝑡ℎ 𝑖𝑛 𝑖𝑛𝑐ℎ𝑒𝑠)2 (5)

In a single ended TDR measurement, the high-speed edge travels from the beginning of the

transmission line to the end of the transmission line and then reflects to the instrument

where it is measured. The signal makes a round trip through the transmission line and the

instrument uses the incident and returned signals to measure the propagation time and the

reflection coefficient, Γ, which is used to compute the transmission line impedance.

𝑍 −𝑍

Γ = 𝑍𝑇𝐿+𝑍𝑜 (6)

𝑇𝐿 𝑜

where ZTL is the transmission line impedance and Zo is the reference impedance, typically

50Ω.

Solving for impedance,

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 2 of 7

Application Note

TDR Measurements

1+Γ

𝑍𝑇𝐿 = 𝑍𝑜 1−Γ (7)

Putting this all together, the TDR source generates a fast-edge signal, which is split into two

equal magnitude signals. One signal is used by the oscilloscope to monitor the reflection

signal and the other signal is delivered to the transmission line. The reflected voltage is

used to calculate the impedance while the round-trip signal time is used to calculate either

the dielectric constant of the transmission line or the length of the transmission line,

depending on which of the values is unknown. The dielectric constant can be determined

from the signal propagation time and the length can be determined from the signal

propagation time and the velocity factor, Vf.

Measurement setup

Figure 1 shows a picture of the TDR measurement setup. One TDR splitter port is connected

to the oscilloscope. Since many lower bandwidth scopes use BNC connectors an RF adapter

might be required. High quality adapters, preferably calibration quality adapters are

recommended. The second TDR port is connected to the measurement sample using a high-

quality cable, high bandwidth 1-port probe, or connectors as applicable. Figure 2 shows the

Picotest demo board used in the measurements in this application note.

The general procedure to make the TDR connections are,

1. Connect the J2151A to the port splitter and connect the port splitter to the

oscilloscope as shown in Figure 1. Connect a coaxial cable or probe to the TDR port

of the splitter.

2. Set the oscilloscope trigger slope to the falling edge and set the trigger close to the

left side of the screen.

3. Use a measurement function or place cursors to measure the width of the negative

pulse. The functions or methods used for each measurement are discussed in the

following sections.

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 3 of 7

Application Note

TDR Measurements

Figure 1: Measurement setup for the TDR measurements in this application note. The setup uses the

PerfectPulse® USB connected TDR with a splitter (included) that has one output connected to the DUT and

the other connected to the oscilloscope.

Figure 2: Picotest TDR demo board.

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 4 of 7

Application Note

TDR Measurements

Measuring PCB, cable and interconnect impedance

The measured oscilloscope voltage can be converted into impedance by the following

equation,

2∙𝑅𝐺𝐸𝑁 ∙𝑉𝑆𝐶𝑂𝑃𝐸

𝑅𝐷𝑈𝑇 = (8)

𝑉𝐺𝐸𝑁 −2∙𝑉𝑆𝐶𝑂𝑃𝐸

Where RDUT is the impedance of the device under test (DUT), RGEN is the generator output

impedance (50 ), and VSCOPE is the voltage received in the oscilloscope (-500 mV). This can

be further reduced as,

12.5

𝑅𝐷𝑈𝑇 (𝑖𝑛 ) = − 50 (9)

𝑉𝑆𝐶𝑂𝑃𝐸 +0.25

The equation can usually be applied within the oscilloscope, using a math function, to obtain

the impedance. The scope values can also be exported to use with a program like Mathcad,

Matlab, or Octave to plot the DUT impedance functions using this equation.

Figure 3: Measurement of trace 4 from the top in the Picotest TDR demo board shown in Figure 3 shows the

step change in impedance from 47 to 52 Ohms. Impedance is plotted using (9).

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 5 of 7

Application Note

TDR Measurements

Measuring dielectric constant and velocity factor

No calibration is required for the measurement of dielectric constant. This is a time

measurement and based on a known value of length, the dielectric constant, Dk, can be

determined from (5). Velocity factor (Vf) can be determined from (1) for a known value of

length. The measurement setup in shown in Figure 1.

Figure 4: Measurement of 3rd trace from the top in the Picotest TDR demo board shown in Figure 3. Signal

travelled 3” forward and 3” backward in 944 ps. So, based on (5), Dk = 3.45, Based on (1), Vf = 53.84 %.

Measuring trace or cable length

It is assumed that the cable velocity factor is known prior to the measurement and most

cable manufacturers publish this parameter. If not, a small known piece of the cable can be

cut to measure the velocity factor as shown in the previous section. After measuring the

round trip time using TDR-oscilloscope combination, we can measure the length using (4)

with the known value of Vf. An example is shown in Figure 5.

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 6 of 7

Application Note

TDR Measurements

Figure 5: Measurement of RTK028 cable that has a velocity factor of 70 %. The round trip took 4.47 ns and so

the length is calculated based on (4) as 0.47 m. (The actual length of the cable was 0.5 m).

Tips for Measurement

• Use high quality cables and probes. If RF adapters are required, use calibration

quality adapters.

• Measure the flattest portion of the impedance signal. This is typically between 50%

and 75% of the trace/cable length.

• Using gated cursors to obtain the mean value in this range.

• Reducing the bandwidth degrades resolution but provides a lower noise result. A

standard IPC coupon can generally be measured using a 1GHz-2GHz oscilloscope.

Conclusion

The Picotest J2151A is a good choice for low cost TDR/TDT using an existing oscilloscope. It

can be used to measure PCB test coupons impedance, to test cables and bad crimps, trace

length, Dk, and velocity factor. This application note shows how to use J2151A to measure

PCB, cable and interconnect impedance, dielectric constants (Dk), velocity factor (Vf) and

length. For additional information and products please visit

https://www.picotest.com/measurements/MeasuringPCB.html.

REV 2_7/23/2019 Copyright © 2018 Picotest, All Rights Reserved Page 7 of 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Marguerite Yourcenar - Oriental TalesDocument160 pagesMarguerite Yourcenar - Oriental TalesErnesto Che100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Sample PMP Earned Value Questions ScenarioDocument13 pagesSample PMP Earned Value Questions ScenarioAsfurix Mesfin100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Professionalism and Transformative Education: in This Module 1. The 21 Century TeacherDocument38 pagesProfessionalism and Transformative Education: in This Module 1. The 21 Century TeacherNormina Cagunan100% (5)

- An International Baccalaureate Education For AllDocument7 pagesAn International Baccalaureate Education For AllLorraine SabbaghNo ratings yet

- Gmail - Your Tuesday Afternoon Trip With UberDocument3 pagesGmail - Your Tuesday Afternoon Trip With UberJayakrishna JKNo ratings yet

- EVAL - 38060 - PMAC1 / EV104 User Guide: UG - 201703 - PL17 - 03Document71 pagesEVAL - 38060 - PMAC1 / EV104 User Guide: UG - 201703 - PL17 - 03Jayakrishna JKNo ratings yet

- XDS560 Emulator Technical Reference: SPRU589A April 2002 Revised October 2007Document42 pagesXDS560 Emulator Technical Reference: SPRU589A April 2002 Revised October 2007Jayakrishna JKNo ratings yet

- Brochura Connectors For SMT Production PDFDocument48 pagesBrochura Connectors For SMT Production PDFJayakrishna JKNo ratings yet

- Sprabv 0Document127 pagesSprabv 0Jayakrishna JKNo ratings yet

- GR Lte Nov 2016 PDFDocument88 pagesGR Lte Nov 2016 PDFJayakrishna JKNo ratings yet

- Calculating Lost Labor Productivity-Is There A Better WayDocument17 pagesCalculating Lost Labor Productivity-Is There A Better Waypatrickcarvalho6df100% (1)

- Prepositions and The Haunted HouseDocument6 pagesPrepositions and The Haunted HouseHanna MykhalskaNo ratings yet

- PDF Pozdravi Na SrpskomDocument42 pagesPDF Pozdravi Na SrpskomTanana97No ratings yet

- Worksheet Verb To Be and Pronouns1Document3 pagesWorksheet Verb To Be and Pronouns1Evelin RinconNo ratings yet

- m1010 Final sp12Document8 pagesm1010 Final sp12DEANGELO AVILESNo ratings yet

- Treasury and War Justicia (Supreme Council of Grace andDocument4 pagesTreasury and War Justicia (Supreme Council of Grace andCaila PanerioNo ratings yet

- What Is Breast CancerDocument20 pagesWhat Is Breast CancerKesyaNo ratings yet

- Navicat MacDocument1,041 pagesNavicat MacCarlos Jese Lomeli ValderrabanoNo ratings yet

- Adjectives and Adverbs Ex. 1. Use The Required Form of The AdjectiveDocument3 pagesAdjectives and Adverbs Ex. 1. Use The Required Form of The AdjectiveThảo VyVyNo ratings yet

- Unidad Didáctica "The Parts of The Body"Document14 pagesUnidad Didáctica "The Parts of The Body"Laura Deltell Polo100% (1)

- 5badiou - The Critique of Critique Critical Theory As A New Access To TheRealDocument3 pages5badiou - The Critique of Critique Critical Theory As A New Access To TheRealLuis GonzálezNo ratings yet

- Put in 'Mustn't' or 'Don't / Doesn't Have To':: 1) We Have A Lot of Work Tomorrow. You Be LateDocument8 pagesPut in 'Mustn't' or 'Don't / Doesn't Have To':: 1) We Have A Lot of Work Tomorrow. You Be LateEmir XHNo ratings yet

- 7331 AU680 Datasheet 8Document2 pages7331 AU680 Datasheet 8imrecoNo ratings yet

- TDAU1 1617 scheme-KS3 Ancient-MarinerDocument14 pagesTDAU1 1617 scheme-KS3 Ancient-MarinerIssam LabeckNo ratings yet

- Syllabus Class NURSERYDocument5 pagesSyllabus Class NURSERYGanesh Datt SharmaNo ratings yet

- Ultra High Field Magnetic Resonance ImagingDocument487 pagesUltra High Field Magnetic Resonance ImagingEduardoAndresChacamaVernal100% (1)

- Week 11Document5 pagesWeek 11api-582257412No ratings yet

- Buber Resume2019 2Document2 pagesBuber Resume2019 2Matthew BuberNo ratings yet

- Petition For Declaration of Nullity of MarriageDocument13 pagesPetition For Declaration of Nullity of MarriageIrene QuimsonNo ratings yet

- Dr. Ram Manohar Lohiya National Law University, Lucknow: Project Topic-"1947 and WTO"Document4 pagesDr. Ram Manohar Lohiya National Law University, Lucknow: Project Topic-"1947 and WTO"Abhishek K. SinghNo ratings yet

- AL Bio 2C-1 - Gene MutationDocument18 pagesAL Bio 2C-1 - Gene MutationJyoti BarnwalNo ratings yet

- RD100 Party Pack AmericanDocument20 pagesRD100 Party Pack AmericanHari Bathula100% (1)

- Presentation Title: Debugging Simulation ModelsDocument74 pagesPresentation Title: Debugging Simulation ModelsflyingdreamsNo ratings yet

- Ehadig Final Research ProposalDocument17 pagesEhadig Final Research Proposalአማን በአማንNo ratings yet

- Rwanda's Application For Membership of The Commonwealth: Report and Recommendations of The Commonwealth Human Rights Initiative - Yash GhaiDocument81 pagesRwanda's Application For Membership of The Commonwealth: Report and Recommendations of The Commonwealth Human Rights Initiative - Yash GhaiIntelligentsiya HqNo ratings yet

- Hofstede's Framework For Assessing CulturesDocument12 pagesHofstede's Framework For Assessing CulturesSidharth KatyayanNo ratings yet