Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

7 viewsKaufman 1982

Kaufman 1982

Uploaded by

WuguTOK

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Anxious in LoveDocument17 pagesAnxious in LoveNew Harbinger Publications80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- What Is Decarbonization ?: Main Engine Decarb Preparation, Procedure & Commissioning Sumit NarayanDocument3 pagesWhat Is Decarbonization ?: Main Engine Decarb Preparation, Procedure & Commissioning Sumit NarayanManisha100% (1)

- Smoke Extraction System Sample CalculationDocument5 pagesSmoke Extraction System Sample Calculationsmcsaminda100% (3)

- Solar CoolingDocument9 pagesSolar CoolingHua Hidari YangNo ratings yet

- Security ManagementDocument35 pagesSecurity ManagementVanessa CarreteNo ratings yet

- Managemen Disritmia: Dr. Rofika Hanifa, SPPDDocument20 pagesManagemen Disritmia: Dr. Rofika Hanifa, SPPDavivlabirdNo ratings yet

- Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of PlasticsDocument6 pagesFluorescent Ultraviolet (UV) Lamp Apparatus Exposure of PlasticsFlor Areli Reyes HernándezNo ratings yet

- Food & Beverage Service Operation: Prepared By: Mr. Lance MercadoDocument22 pagesFood & Beverage Service Operation: Prepared By: Mr. Lance MercadoLyzelNo ratings yet

- Data Analysis PDFDocument10 pagesData Analysis PDFKenny Stephen CruzNo ratings yet

- Kirkpatrick Evaluation A ThoughtDocument2 pagesKirkpatrick Evaluation A ThoughtJYOTSNA ENTERPRISES100% (1)

- Topic 1: Pros and Cons of Making Friends Virtually Claim of Fact Claim of Policy Claim of ValueDocument2 pagesTopic 1: Pros and Cons of Making Friends Virtually Claim of Fact Claim of Policy Claim of ValueChristian GinebreNo ratings yet

- Dynamic Simulation of The Sour Water Stripping Process and Modified Structure For Effective PresDocument11 pagesDynamic Simulation of The Sour Water Stripping Process and Modified Structure For Effective PresjavilapiedraNo ratings yet

- Entrep 5 6 Edited 23 24Document14 pagesEntrep 5 6 Edited 23 24Godofredo HermosuraNo ratings yet

- Ariza, C. Sonifying SievesDocument8 pagesAriza, C. Sonifying SievesxdimitrisNo ratings yet

- ADTL-MSCTM - Exercises - of - Data - Input - and Exploratory Analysis Using - RDocument3 pagesADTL-MSCTM - Exercises - of - Data - Input - and Exploratory Analysis Using - RPriyankaNo ratings yet

- UntitledDocument17 pagesUntitledCarlo MoranNo ratings yet

- UNIT-3 Oscilloscopes: Cathode Ray Tube (CRT)Document16 pagesUNIT-3 Oscilloscopes: Cathode Ray Tube (CRT)sonucharyNo ratings yet

- BIRD Internet Routing DaemonDocument4 pagesBIRD Internet Routing DaemonAleksandra FeyNo ratings yet

- Networking: by Jersha JDocument29 pagesNetworking: by Jersha JT C Jermin JershaNo ratings yet

- BTD Course FileDocument23 pagesBTD Course FilePrashant S HadagaliNo ratings yet

- NI-Predictive Maintenance and Machine Health MonitoringDocument34 pagesNI-Predictive Maintenance and Machine Health Monitoringtườngt_14No ratings yet

- RFP Human Resource Management SystemDocument15 pagesRFP Human Resource Management SystemMd. Mofakker Morshed Khan ChowdhuryNo ratings yet

- Veritas NetBackup 6.5 Vault Administrator's GuideDocument268 pagesVeritas NetBackup 6.5 Vault Administrator's GuideS LS ChanNo ratings yet

- Calorimetry Practice ProblemsDocument2 pagesCalorimetry Practice ProblemsKervy Jay AgraviadorNo ratings yet

- Is 228 9 1989Document8 pagesIs 228 9 1989Andrewz PachuauNo ratings yet

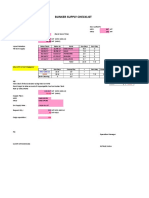

- Bunker & FW Supply ChecklistDocument3 pagesBunker & FW Supply ChecklistSampetua StmrgNo ratings yet

- Introduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)Document83 pagesIntroduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)ፍቅር እስከ መቃብር100% (2)

- 2021 DBaaS Security Architect and SolutionsDocument26 pages2021 DBaaS Security Architect and Solutionsluke luNo ratings yet

- Arnold Schwarzenegger ThesisDocument4 pagesArnold Schwarzenegger Thesislanatedrummondfortwayne100% (2)

- HTWL Service Manual: Failure ListDocument2 pagesHTWL Service Manual: Failure ListClaudio Valencia MarínNo ratings yet

Kaufman 1982

Kaufman 1982

Uploaded by

Wugu0 ratings0% found this document useful (0 votes)

7 views2 pagesTOK

Original Title

kaufman1982

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTOK

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

7 views2 pagesKaufman 1982

Kaufman 1982

Uploaded by

WuguTOK

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

analyzed by gel electrophoresis (Fig. 2).

Thermal Insulating Capabilities of Outdoor Clothing Materials

On the basis of its electrophoretic mobil-

ity, the crystalline material was judged Abstract. A single heat transfer measurement technique was used to determine the

identical to uncrystallized IFLrA. Bioas- thermal insulating capabilities offour materials used in outdoor clothing-goose

says showed that the crystals contained down, wool, polyester, and polyolefin. It was found that all provide very similar

interferon activity. Furthermore, in the degrees of insulation.

presence of PEG-4000 (100 mg/ml) virtu-

ally all of the active IFLrA added to the The increased interest in outdoor win- insulating capabilities superior to those

solution could be recovered in the crys- ter activities has produced a striking of goose down.

tals. increase in the market for insulated out- Using a modified guarded hot-plate

At high IFLrA concentrations (4 to 5 erwear. Although the down of northern technique, we measured the thermal in-

mg/ml) and low PEG-4000 concentra- geese has long been the filler material of sulation of goose down, wool, and poly-

tions (1.0 to 2.0 mg/ml), masses of large choice, the growing market and the ris- ester and polyolefin fibers. Our results

prismatic crystals appeared after about 5 ing price of goose down have stimulated show no superiority of any of the syn-

days (Fig. 3). industrial chemists to search for synthet- thetic materials over the natural fibers as

We conclude that interferon synthe- ic substitutes for natural fibers. Periodi- thermal insulators, although down has a

sized by bacteria is sufficiently homoge- cally, new materials are put on the mar- marked advantage in weight per unit loft

neous to crystallize quantitatively. Crys- ket which are claimed to have thermal (thickness).

tals large enough for an x-ray crystallo- We prepared the materials as they

graphic structure determination can be would be prepared for use in the manu-

Downloaded from www.sciencemag.org on November 19, 2015

obtained. Whether these crystals give y a 1.27x -0.12 facture ofjackets, vests, and other outer-

suitable x-ray diffraction patterns has not r2 93.7 rwcen wear garments. The filler material was

3.0

yet been demonstrated. encased in a nylon shell. The shell was

DAVID L. MILLER quilted with 13-cm squares and its edges

Roche Institute of Molecular Biology,

Nutley, New Jersey 07110

2.5

| *,X'~~~~~~~~~ were bound to form a swatch with an

area of about 1 m2. Initial loft was deter-

HSIANG-FU KUNG 0 2.0 mined by making 12 measurements at

Department of Molecular Genetics, planned points at a pressure of 0.7 g/cm2.

Hoffmann-La Roche Inc., io

1.6

The weight of the swatch was deter-

Nutley, New Jersey 07110 mined to within 0.1 g on a top-loading

SIDNEY PESTKA balance (Mettler P2010). "Density" was

* Down. al samphs

Roche Institute of Molecular Biology 1.0

o Wool fber batthng calculated from measured area, loft, and

0

*

Polyester,al samples

Polyolefin

weight.

References and Notes Each swatch was placed horizontally

0.5

1. K. C. Zoon, M. E. Smith, P. J. Bridgen, C. B. over a 50 by 50 cm constant heat source.

Anfinsen, M. W. Hunkapiller, L. E. Hood,

Science 207, 527 (1980). A heat sink in the form of a copper plate

2. W. P. Levy, J. Shively, M. Rubinstein, U. Del equal in area to the heat source was

Valle, S. Pestka, Proc. Natl. Acad. Sci. U.S.A. 0.5 1.0 1.5 2.0 2.5

77, 5102 (1980). Loft (cm) placed on top of the material. The heat

3. G. Allen and F. H. Fantes, Nature (London) Fig. 1. Thermal insulation of various clothing

287, 408 (1980). sink produced a pressure of 1.2 g/cm2;

4. W. P. Levy, M. Rubinstein, J. Shively, U. Del materials, plotted against swatch loft as mea- each material was examined at the same

Valle, C.-Y. Lai, J. Moschera, L. Brink, L. sured on the heat transfer apparatus. The force of compression. The temperature

Gerber, S. Stein, S. Pestka, Proc. Natl. Acad. shaded area delineates the 95 percent confi-

Sci. U.S.A. 78, 6186 (1981). gradient across the swatch was mea-

5. K. Zoon, in The Biology of the Interferon Sys- dence limits and the asterisks indicate swatch-

tem, E. De Maeyer, G. Galasso, H. Schelle- es that had multiple layers. sured by a thermistor and the rate of heat

kens, Eds. (Elsevier, Amsterdam, in press).

6. E. Knight, Jr., M. W. Hunkapiller, B. D. Kor-

ant, R. W. F. Hardy, L. E. Hood, Science 207,

525 (1980). Table 1. Physical properties of thermal insulating materials used in clothing.

7. H. Okamura, W. Berthold, L. Hood, M. Hunka-

piller, M. Inoue, H. Smith-Johannsen, Y. H. Loft (cm) Insulation

Tan, Biochemistry 19, 3831 (1980). Density

8. S. Stein, C. Kenny, H.-J. Friesen, J. Shively, U. Measured Measured (g/m2

Del Valle, S. Pestka, Proc. Natl. Acad. Sci. Material on flat during per centi- do do/cm

U.S.A. 77, 5716 (1980).

9. H.-J. Friesen, S. Stein, M. Evinger, P. C. Famil- surface at experiment meter)

letti, J. Moschera, J. Meienhofer, J. Shively, 0.7 g/cm2 at 1.2 g/cm2

S. Pestka, Arch. Biochem. Biophys. 206, 432

(1981). Down,* 1.2 0.6 179 0.73 1.22

10. S. Maeda, R. McCandliss, M. Gross, A. Sloma,

P. C. Familletti, J. M. Tabor, M. Evinger, W. P. Down2t 2.1 1.5 170 1.64 1.09

Levy, S. Pestka, Proc. Natl. Acad. Sci. U.S.A.

77, 7.010 (1980).

Down3A 2.8 2.0 179 2.68 1.34

Wool§ 1.9 1.3 271 1.52 1.17

11. D. V. Goeddel et al., Nature (London) 287, 411

(1980). Poly,ll 1.7 1.2 229 1.20 1.00

12. T. Staehelin, D. S. Hobbs, H.-F. Kung, C.-Y. Poly, 3.6 2.6 229 2.82 1.03

Lai, S. Pestka, J. Biol. Chem. 256, 9750 (1981). Poly2¶ 1.7 1.2 224 1.11 0.93

13. A. McPherson, Jr., in Methods of Biochemical Poly2 3.4 2.2 224 2.71 1.23

Analysis, D. Glick, Ed. (Academic Press, New

York, 1976), vol. 23, p. 149. Poly3** 1.1 0.9 368 1.02 1.13

14. K. B. Ward, B. C. Wishner, E. E. Lattman, W. Polyolefin 0.6 0.4 424 0.45 1.13

E. Love, J. Mol. Biol. 98, 161 (1975). Polyolefin 1.0 0.8 415 0.83 1.04

15. A. McPherson, Jr., J. Biol. Chem. 251, 6300 Polyolefin 1.2 1.0 310 1.14 1.14

(1 976).

16. We thank Dr. Salah Sadek for kindly permitting *Prime 80/20 goose down (80 percent down, 20 percent feathers) at 76.4 g/m2. tPrime 80/20 goose down at

us to use his Leitz Orthoplan microscope for 152.8 g/m2. *Prime 80/20 goose down at 229.2 g/m2. §Wool fiber batting. llOne hundred percent

photographing the crystals. polyester staple (Dacron II). lOne hundred percent polyester continuous filament fiber. **One

12 August 1981; revised 28 September 1981 hundred percent polyester staple (Dacron 66).

690 0036-8075/82/0205-0690$01.00/0 Copyright © 1982 AAAS SCIENCE, VOL. 215, 5 FEBRUARY 1982

transfer was measured by a heat flow were to increase the density of the heat- cost should be the major factors in se-

disk (Sensable B-1, Hy-Cal Engineer- conducting fillers, heat transfer might be lecting outerwear containing thermal in-

ing). Thermal insulation in clo units was expected to increase as well. However, sulation materials. The effects of mois-

calculated from the following equation in 38 determinations on 12 samples of ture and bellows action produced by the

(1): down, polyester, and polyolefin we have wearer's activity may outweigh thermal

found no significant effect of compres- insulative values in the wearer's percep-

dlo = (Ti 7i2) ( A ) sion on thermal insulating properties at tion of warmth.

reductions in loft to 52 percent of the W. C. KAUFMAN

where T, is the temperature of the sur- control value. D. BOTHE

face of the heat source (in degrees Cel- Burton and Edholm (3) observed that S. D. MEYER

sius), T2 is the temperature of the heat the principal function of the filling mate- Department of Human Biology,

sink's lower surface, and H is heat flow rial is "merely to immobilize the en- University of Wisconsin,

[the product of heat energy (calories) and closed air, preventing convection cur- Green Bay 54302

area (square meters) divided by time rents and making it effectively 'dead

(hours)]. air.' " Our findings, gathered by a single References and Notes

Temperatures and heat flow were ob- method comparing the thermal insulating 1. A. P. Gagge, A. C. Burton, H. C. Bazett,

served until readings were constant over qualities of fillers in the form they are Science 94, 428 (1941).

2. L. Fourt and N. R. Hollies, Clothing (Dekker,

a period of 30 minutes. The experiment used by the consumer, confirm this New York, 1970), p. 38.

was repeated two more times, each pre- statement. None of the synthetic fillers 3. A. C. Burton and 0. G. Edholm, Man in a Cold

Environment (Hafner, New York, 1969), pp. 53

ceded by dismantling and reassembling has a superior ability to provide and 55.

of the apparatus. The data were aver- "warmth" in clothing. It seems that fac- 4. We gratefully acknowledge the support of Eddie

Bauer Co. and the continuing assistance and

aged, tabulated (Table 1), and plotted tors other than thermal insulation, such suggestions of D. Jowett.

(Fig. 1). as weight, drapability, durability, and 10 August 1981

Loft of the natural and synthetic insu-

lating,materials ranged from 0.6 to 3.6

cm. During the heat transfer measure-

ments, lofts were reduced by compres- Haptoglobin: A Natural Bacteriostat

sion to 0.4 to 2.6 cm. Density ranged

from 170 to 424 g/m2 per centimeter. Abstract. The combination of bacteria and blood in a wound can have lethal

Insulation ranged from 0.93 to 1.34 clo/ consequences, probably because hemoglobin iron supports prolific bacterial growth.

cm (mean, 1.12 clo/cm), values which Rats inoculated intraperitoneally with pathogenic Escherichia coli and small

correspond closely with published val- amounts ofhemoglobin die. Simultaneous administration of haptoglobin, a naturally

ues (0.7 to 1.33 clo/cm; mean, 1.08 clo/ occurring hemoglobin-binding protein, fully protects against lethality. Therefore,

cm) (2). haptoglobin may not only accelerate the clearance offree hemoglobin, but also limit

Insulating capabilities varied little its utilization by adventitious bacteria. Haptoglobin mnay have therapeutic potential

among materials. Down provided some- in the treatment of life-threatening, hemoglobin-driven bacterial infections.

what higher value (mean, 1.22 clo/cm)

than polyester (mean, 1.08 clo/cm). The Physicians have long been aware that 4) Even if live E. coli are entrapped in

polyolefin fibers and wool filler provided the coincidence of blood and bacteria in 0.2-,um Nuclepore chambers implanted

intermediate degrees of insulation (1.13 a wound may engender life-threatening intraperitoneally, injected hemoglobin

and 1.17 clo/cm, respectively). These infection (1). Blood or free hemoglobin still exerts an adjuvant effect.

variations are unlikely to be detectable has a synergistic effect on the lethality of Thus, hemoglobin does riot appear to

by the consumer. If one considers weight intraperitoneal or subcutaneous inocula reduce the phagocytosis and killing of E.

an important factor, down (233 g/m2 per of bacteria such as Escherichia coli (2). coli. We therefore hypothesized that he-

clo) had a decided advantage over wool The effective component of hemoglobin moglobin might serve simply as a source

(339 g/m2 per clo), polyester (328 g/m2 is iron, and various soluble iron com- of nutritional iron, promoting the growth

per clo), and polyolefin (464 g/m2 per pounds exert an equivalent adjuvant ef- of inoculated E. coli. Although the total

cdo). fect (3, 4). It has been suggested that iron concentration in mammalian body

Many physical scientists have main- hemoglobin interferes with phagocytic fluids is 2 x 10-5M, almost all of the

tained that no particular fabric provides destruction of the bacteria (5). We have, iron is tightly associated with special-

superior insulation; air is the insulating however, been unable to detect such ized, iron-binding proteins, leaving a free

material, and how it is immobilized interference. Instead, we found the fol- iron concentration of 10-'8M (7). Most

makes little, if any, measurable differ- lowing (6): aerobic bacteria require - 10-6M iron

ence. The importance of this study is in 1) The phagocytosis and killing of E. for growth (7-9). Thus, as Weinberg (9)

the application of a single heat transfer coli by neutrophils in vitro is unaffected argued, the availability of iron may be

measurement technique to a variety of by the presence of hemoglobin. the major nutritional limitation to the

natural and synthetic filler materials, es- 2) The migration of neutrophils to the replication of many pathogenic bacteria

pecially the newly developed polyolefin peritoneal cavity in response to intra- in vivo.

fillers. peritoneal inoculation with E. coli is In the experiments reported here, we

Questions might be raised regarding a equally rapid and effective whether he- used a single strain of pathogenic E. coli

technique that measures heat transfer of moglobin is present or not. first isolated from an infected patient.

compressible materials subjected to a 3) The rate of clearance of heat-killed, The techniques for the routine culture

compression force of 1.2 g/cm2. Filler radioactively labeled bacteria from the and passage of this organism have been

materials exhibit different qualities of peritoneal cavity is unchanged by simul- described elsewhere (5). When we cul-

compliance. If compression of a swatch taneous injection of hemoglobin. tured the organisms in synthetic, iron-

SCIENCE, VOL. 215, 5 FEBRUARY 1982 0036-8075/82/0205-0691$01.00/0 Copyright © 1982 AAAS 691

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Anxious in LoveDocument17 pagesAnxious in LoveNew Harbinger Publications80% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- What Is Decarbonization ?: Main Engine Decarb Preparation, Procedure & Commissioning Sumit NarayanDocument3 pagesWhat Is Decarbonization ?: Main Engine Decarb Preparation, Procedure & Commissioning Sumit NarayanManisha100% (1)

- Smoke Extraction System Sample CalculationDocument5 pagesSmoke Extraction System Sample Calculationsmcsaminda100% (3)

- Solar CoolingDocument9 pagesSolar CoolingHua Hidari YangNo ratings yet

- Security ManagementDocument35 pagesSecurity ManagementVanessa CarreteNo ratings yet

- Managemen Disritmia: Dr. Rofika Hanifa, SPPDDocument20 pagesManagemen Disritmia: Dr. Rofika Hanifa, SPPDavivlabirdNo ratings yet

- Fluorescent Ultraviolet (UV) Lamp Apparatus Exposure of PlasticsDocument6 pagesFluorescent Ultraviolet (UV) Lamp Apparatus Exposure of PlasticsFlor Areli Reyes HernándezNo ratings yet

- Food & Beverage Service Operation: Prepared By: Mr. Lance MercadoDocument22 pagesFood & Beverage Service Operation: Prepared By: Mr. Lance MercadoLyzelNo ratings yet

- Data Analysis PDFDocument10 pagesData Analysis PDFKenny Stephen CruzNo ratings yet

- Kirkpatrick Evaluation A ThoughtDocument2 pagesKirkpatrick Evaluation A ThoughtJYOTSNA ENTERPRISES100% (1)

- Topic 1: Pros and Cons of Making Friends Virtually Claim of Fact Claim of Policy Claim of ValueDocument2 pagesTopic 1: Pros and Cons of Making Friends Virtually Claim of Fact Claim of Policy Claim of ValueChristian GinebreNo ratings yet

- Dynamic Simulation of The Sour Water Stripping Process and Modified Structure For Effective PresDocument11 pagesDynamic Simulation of The Sour Water Stripping Process and Modified Structure For Effective PresjavilapiedraNo ratings yet

- Entrep 5 6 Edited 23 24Document14 pagesEntrep 5 6 Edited 23 24Godofredo HermosuraNo ratings yet

- Ariza, C. Sonifying SievesDocument8 pagesAriza, C. Sonifying SievesxdimitrisNo ratings yet

- ADTL-MSCTM - Exercises - of - Data - Input - and Exploratory Analysis Using - RDocument3 pagesADTL-MSCTM - Exercises - of - Data - Input - and Exploratory Analysis Using - RPriyankaNo ratings yet

- UntitledDocument17 pagesUntitledCarlo MoranNo ratings yet

- UNIT-3 Oscilloscopes: Cathode Ray Tube (CRT)Document16 pagesUNIT-3 Oscilloscopes: Cathode Ray Tube (CRT)sonucharyNo ratings yet

- BIRD Internet Routing DaemonDocument4 pagesBIRD Internet Routing DaemonAleksandra FeyNo ratings yet

- Networking: by Jersha JDocument29 pagesNetworking: by Jersha JT C Jermin JershaNo ratings yet

- BTD Course FileDocument23 pagesBTD Course FilePrashant S HadagaliNo ratings yet

- NI-Predictive Maintenance and Machine Health MonitoringDocument34 pagesNI-Predictive Maintenance and Machine Health Monitoringtườngt_14No ratings yet

- RFP Human Resource Management SystemDocument15 pagesRFP Human Resource Management SystemMd. Mofakker Morshed Khan ChowdhuryNo ratings yet

- Veritas NetBackup 6.5 Vault Administrator's GuideDocument268 pagesVeritas NetBackup 6.5 Vault Administrator's GuideS LS ChanNo ratings yet

- Calorimetry Practice ProblemsDocument2 pagesCalorimetry Practice ProblemsKervy Jay AgraviadorNo ratings yet

- Is 228 9 1989Document8 pagesIs 228 9 1989Andrewz PachuauNo ratings yet

- Bunker & FW Supply ChecklistDocument3 pagesBunker & FW Supply ChecklistSampetua StmrgNo ratings yet

- Introduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)Document83 pagesIntroduction To Econometrics Ii (Econ-3062) : Mohammed Adem (PHD)ፍቅር እስከ መቃብር100% (2)

- 2021 DBaaS Security Architect and SolutionsDocument26 pages2021 DBaaS Security Architect and Solutionsluke luNo ratings yet

- Arnold Schwarzenegger ThesisDocument4 pagesArnold Schwarzenegger Thesislanatedrummondfortwayne100% (2)

- HTWL Service Manual: Failure ListDocument2 pagesHTWL Service Manual: Failure ListClaudio Valencia MarínNo ratings yet