Professional Documents

Culture Documents

Data Sheet PDF

Data Sheet PDF

Uploaded by

CONDOR C8Copyright:

Available Formats

You might also like

- VITO 762 Installation GuideDocument36 pagesVITO 762 Installation GuideThái Ngọc0% (1)

- ASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument4 pagesASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsvajidqcNo ratings yet

- Astm A 780 - A 780M-09Document4 pagesAstm A 780 - A 780M-09Ramsi AnkziNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- Duplex Coatings Paint Products Guide v1.01Document12 pagesDuplex Coatings Paint Products Guide v1.01Chat Luong HSGNo ratings yet

- Working Procedure For Coating Repair C4Document7 pagesWorking Procedure For Coating Repair C4tuyen nguyenNo ratings yet

- ECS 19-1-1-1M: Coating Data SheetDocument2 pagesECS 19-1-1-1M: Coating Data SheetFlorin Daniel AnghelNo ratings yet

- TDS 33222 Marathon 1000 GF Euk GBDocument5 pagesTDS 33222 Marathon 1000 GF Euk GBNasarNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- SSPC-Paint 22-00Document5 pagesSSPC-Paint 22-00Maria Clara100% (1)

- Basis of Design - Pipeline InstallationDocument11 pagesBasis of Design - Pipeline InstallationAndreas Schlager100% (1)

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- TDS Jotafloor EP SL UniDocument6 pagesTDS Jotafloor EP SL UniGemilang KubNo ratings yet

- BES-L003 - Spec For FBE CoatingDocument12 pagesBES-L003 - Spec For FBE CoatingRamNo ratings yet

- Section 942-BR Area Coating GIIDocument31 pagesSection 942-BR Area Coating GIIchristian gordonNo ratings yet

- Painting System No. 12.01: SSPC: The Society For Protective CoatingsDocument4 pagesPainting System No. 12.01: SSPC: The Society For Protective CoatingsJuan Carlos Contreras CherresNo ratings yet

- TDS 2063 Tankguard 412 Euk GBDocument6 pagesTDS 2063 Tankguard 412 Euk GBAhmad SyawalNo ratings yet

- Basis of Design - Protective CoatingDocument10 pagesBasis of Design - Protective CoatingAndreas Schlager100% (2)

- 222-307-012K EMD 30 Grau TRDocument2 pages222-307-012K EMD 30 Grau TRszafakNo ratings yet

- Pipes FittingsDocument7 pagesPipes FittingsTushar ArekarNo ratings yet

- TDS 34002 Marathon 1000 XHB Euk GBDocument5 pagesTDS 34002 Marathon 1000 XHB Euk GBSamuel AgusNo ratings yet

- TS-C4Gas-COATMEX001 - Rev3 (Official)Document18 pagesTS-C4Gas-COATMEX001 - Rev3 (Official)Reynol Mejía OlmosNo ratings yet

- INS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesDocument18 pagesINS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesCristhian Joel VINo ratings yet

- Marathon: Technical Data SheetDocument5 pagesMarathon: Technical Data SheetOkinawa TeakNo ratings yet

- 4weq 6804Document18 pages4weq 6804Evgeniy PalnikovNo ratings yet

- Rdso Specification No. M&C/PCN/102/2020 (Rev 1.0) : Specification For Epoxy Based Zinc Phosphate Primer (Two Pack)Document11 pagesRdso Specification No. M&C/PCN/102/2020 (Rev 1.0) : Specification For Epoxy Based Zinc Phosphate Primer (Two Pack)varun saini100% (1)

- TDS 684 Resist 86 Euk GBDocument5 pagesTDS 684 Resist 86 Euk GBNgô Trung NghĩaNo ratings yet

- Painting BTS HardwareDocument5 pagesPainting BTS HardwareFlorin StanNo ratings yet

- Durashield 110 61Document6 pagesDurashield 110 61huicholeNo ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Plant Building - Epoxy PaintDocument2 pagesPlant Building - Epoxy PaintNavaneethan NatarajanNo ratings yet

- PHR Com SPC 105191Document93 pagesPHR Com SPC 105191tohaphsianturiNo ratings yet

- SSPC-Paint 40 PDF PDFDocument5 pagesSSPC-Paint 40 PDF PDFFrancisco UrtechoNo ratings yet

- TSI 136 Adani - R1 PDFDocument6 pagesTSI 136 Adani - R1 PDFKRISHNA ENGINEERING CO. BHOPALNo ratings yet

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocument8 pages6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- 1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Document5 pages1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Akram AlhaddadNo ratings yet

- Project Specification PaintingDocument13 pagesProject Specification PaintingBudi Indra100% (1)

- ASSTM A882 - Epoxy Coated PC StrandDocument5 pagesASSTM A882 - Epoxy Coated PC StrandLai DieuNo ratings yet

- Filled Epoxy-Coated Seven-Wire Prestressing Steel Strand: Standard Specification ForDocument5 pagesFilled Epoxy-Coated Seven-Wire Prestressing Steel Strand: Standard Specification ForSama UmateNo ratings yet

- Def STD 80-161 Iss 2Document22 pagesDef STD 80-161 Iss 2Joanne WaiNo ratings yet

- TDS 16560 Jotamastic 90 Euk GBDocument7 pagesTDS 16560 Jotamastic 90 Euk GBNgô Trung NghĩaNo ratings yet

- 3M Scotchkote Liquid Coatings Application SpecificationDocument4 pages3M Scotchkote Liquid Coatings Application SpecificationleoNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Astm A780 PDFDocument4 pagesAstm A780 PDFFu Ad100% (1)

- TDS Resist 78 (JOTUN)Document5 pagesTDS Resist 78 (JOTUN)RinoHpNo ratings yet

- Painting Procedure For Field Erected Tank FINAL (13850)Document22 pagesPainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNo ratings yet

- Tank Paint SpecDocument106 pagesTank Paint SpecJack100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- TDS 52742 Jotamastic 85 Euk GBDocument5 pagesTDS 52742 Jotamastic 85 Euk GBAhmad SyawalNo ratings yet

- G16S-0205-04 - Shop Coat Galv Surf (Duplex)Document3 pagesG16S-0205-04 - Shop Coat Galv Surf (Duplex)puwarin naja100% (1)

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- 4 - Tech Hardware SectorDocument126 pages4 - Tech Hardware SectorgirishrajsNo ratings yet

- Ecs2602 Tests Bank-1Document97 pagesEcs2602 Tests Bank-1corlia100% (2)

- Te 243684Document57 pagesTe 243684infoNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument4 pagesFastener Tightening Specifications: Application Specification Metric EnglishSebastiánLeonardoGuerreroVilchesNo ratings yet

- Product Range: Trelleborg Se Aling SolutionsDocument39 pagesProduct Range: Trelleborg Se Aling SolutionssandeepNo ratings yet

- Metacentric HeightDocument5 pagesMetacentric HeightKHAIRUNISANo ratings yet

- Turbojet EnginesDocument22 pagesTurbojet EnginesAldo SamuelNo ratings yet

- DP - X510 BrochureDocument2 pagesDP - X510 BrochureRommel SegismundoNo ratings yet

- VC - SM TransportDocument2 pagesVC - SM Transportsureshkumar mNo ratings yet

- Stresses in Finite Anisotropic Plate Weakened by Rectangular HoleDocument8 pagesStresses in Finite Anisotropic Plate Weakened by Rectangular Holemihir.chauhanNo ratings yet

- AOSS321 L11 021209 Static StabilityDocument50 pagesAOSS321 L11 021209 Static StabilityKattia AFNo ratings yet

- eHYDRO SERIESDocument6 pageseHYDRO SERIESBanupriya BalasubramanianNo ratings yet

- Crabs Hell Ms DsDocument1 pageCrabs Hell Ms DsRega Wahyu AnggrainiNo ratings yet

- Case Study TPM Jet AirwaysDocument15 pagesCase Study TPM Jet AirwaysSanjay Domdiya100% (1)

- List of Coolers and HeatersDocument2 pagesList of Coolers and HeatersadityasahayNo ratings yet

- Homework 2 SolutionDocument5 pagesHomework 2 SolutiongretabunciNo ratings yet

- 4 RPI To PCF8591 - PhotocellDocument4 pages4 RPI To PCF8591 - Photocellsatyam jadhavNo ratings yet

- FPM Formula Sheet 2Document13 pagesFPM Formula Sheet 2Yolo Gamer DudeNo ratings yet

- Lung Sounds Auscultation - 1Document3 pagesLung Sounds Auscultation - 1George BarajazNo ratings yet

- Iso 11124-1 2018Document14 pagesIso 11124-1 2018anon_433139120No ratings yet

- Healthy Lifestyle Ideas For Truck Drivers: EFS-IFR Anul I UBB Cluj 2019Document12 pagesHealthy Lifestyle Ideas For Truck Drivers: EFS-IFR Anul I UBB Cluj 2019Pap RobertNo ratings yet

- TAS Product Catalog 2020 01Document210 pagesTAS Product Catalog 2020 01ct0720054858No ratings yet

- NIFLECDocument6 pagesNIFLECRonald Ariyanto WiradirnataNo ratings yet

- To Study Well Design Aspects in HPHT EnvironmentDocument40 pagesTo Study Well Design Aspects in HPHT Environmentnikhil_barshettiwat100% (1)

- EEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsDocument13 pagesEEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsKai JieNo ratings yet

- Jurnal ....Document3 pagesJurnal ....Yuniati ValentinaNo ratings yet

- Fortran CF DDocument160 pagesFortran CF DLahcen AkerkouchNo ratings yet

- MSD Numbers 0410612020 Am: ClosingDocument11 pagesMSD Numbers 0410612020 Am: ClosingSanjeev JayaratnaNo ratings yet

- Princeton 112 Plus Service ManualDocument8 pagesPrinceton 112 Plus Service ManualDavid OliveiraNo ratings yet

Data Sheet PDF

Data Sheet PDF

Uploaded by

CONDOR C8Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet PDF

Data Sheet PDF

Uploaded by

CONDOR C8Copyright:

Available Formats

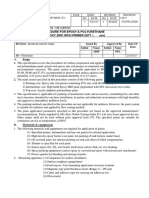

Cclient SONATRACH

Proyectt GL3Z

L location Bethioua Algérie

Apendix 1

COATING DATASHEET - COATING SYSTEM 1

Description: Zinc rich epoxy polyurethane

General application coating system 1 used for carbon steel uninsulated pipes

This coating system can be used for other applications when specified by purchaser

SYSTEM REQUIREMENTS:

Main surface preparation abrasive / sand blast per SSPC - SP 10 to a uniform anchor profile (degree 3 from ISO 8503

(LCA-CEA); <12,5µm)

Minimum Maximum

Coat no ° general Materiel Std application Colour

DFT DFT

1 Zinc Rich epoxy Manual 60 70 std

2 Epoxy Manual 125 200 std

3 Polyurethane Manual 60 75 std

Total 245 345 Note

Notes

1 This Data sheet supplements the General requirement of technical standards (General coating procedure) and the

coating manufacturer product datasheet and application instructions.

2 Unless other specified conditions, refer to the coating manufacturer data sheet for information on recommended

application temperature range, film thickness approximate coverage rate and drying time to touch handle over

coating cure of each coating product.

3 Coats number 2 and 3 may also be applied by brush or roller for limited applications and only when approved by

purchaser. Minimum required film thickness may be attained with more than one layer when applying the coating by

brush or roller

4 Unless the designated otherwise by the client, last coat colour shall be:

Service description Finish color RAL code

Piping and equipment for air (PA) Cream RAL 9001

Piping and equipment for nitrogen (NI) Burgundy / Bordeaux RAL 4004

Piping and equipment for waste water (AOC) Black blue RAL 5004

Piping and equipment for demi water (DM) Black blue RAL 5004

Piping and equipment for process water (PW) Black blue RAL 5004

Coating Material

Primary supplier coat n 1 coat n 2 coat n 3

recommended split of paint works

component application site shop

piping s s or f s or f

equipment s s s

Repairing Procedure

1 Shop repair of damaged and no-compliant coating shall be reblasted and paint reapplicated

2 Field repair of damaged and non-compliant coating and coating application on field shall be done in accordance to

technical std surface preparation and vacuum blast cleaned to the required degree of cleaness and surface profile in

accordance with SSPC SP11 Minimum

3 Field preparation of coat N1 for reparation and for coating of all filed welds shall be surface tolerant epoxy ant it

shall be applied at 100 Microns Minimum DFT

You might also like

- VITO 762 Installation GuideDocument36 pagesVITO 762 Installation GuideThái Ngọc0% (1)

- ASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument4 pagesASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsvajidqcNo ratings yet

- Astm A 780 - A 780M-09Document4 pagesAstm A 780 - A 780M-09Ramsi AnkziNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- Duplex Coatings Paint Products Guide v1.01Document12 pagesDuplex Coatings Paint Products Guide v1.01Chat Luong HSGNo ratings yet

- Working Procedure For Coating Repair C4Document7 pagesWorking Procedure For Coating Repair C4tuyen nguyenNo ratings yet

- ECS 19-1-1-1M: Coating Data SheetDocument2 pagesECS 19-1-1-1M: Coating Data SheetFlorin Daniel AnghelNo ratings yet

- TDS 33222 Marathon 1000 GF Euk GBDocument5 pagesTDS 33222 Marathon 1000 GF Euk GBNasarNo ratings yet

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDocument5 pagesG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Issue/Rev Details of Changes Date: Name Designation Signature Date LevelDocument6 pagesIssue/Rev Details of Changes Date: Name Designation Signature Date LevelAbhey DograNo ratings yet

- MDTS 262rev 02 04.11.2020Document6 pagesMDTS 262rev 02 04.11.2020Abhey DograNo ratings yet

- SSPC-Paint 22-00Document5 pagesSSPC-Paint 22-00Maria Clara100% (1)

- Basis of Design - Pipeline InstallationDocument11 pagesBasis of Design - Pipeline InstallationAndreas Schlager100% (1)

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- APS104-06 Paint System - Steel WorkDocument9 pagesAPS104-06 Paint System - Steel WorkJose MachadoNo ratings yet

- TDS Jotafloor EP SL UniDocument6 pagesTDS Jotafloor EP SL UniGemilang KubNo ratings yet

- BES-L003 - Spec For FBE CoatingDocument12 pagesBES-L003 - Spec For FBE CoatingRamNo ratings yet

- Section 942-BR Area Coating GIIDocument31 pagesSection 942-BR Area Coating GIIchristian gordonNo ratings yet

- Painting System No. 12.01: SSPC: The Society For Protective CoatingsDocument4 pagesPainting System No. 12.01: SSPC: The Society For Protective CoatingsJuan Carlos Contreras CherresNo ratings yet

- TDS 2063 Tankguard 412 Euk GBDocument6 pagesTDS 2063 Tankguard 412 Euk GBAhmad SyawalNo ratings yet

- Basis of Design - Protective CoatingDocument10 pagesBasis of Design - Protective CoatingAndreas Schlager100% (2)

- 222-307-012K EMD 30 Grau TRDocument2 pages222-307-012K EMD 30 Grau TRszafakNo ratings yet

- Pipes FittingsDocument7 pagesPipes FittingsTushar ArekarNo ratings yet

- TDS 34002 Marathon 1000 XHB Euk GBDocument5 pagesTDS 34002 Marathon 1000 XHB Euk GBSamuel AgusNo ratings yet

- TS-C4Gas-COATMEX001 - Rev3 (Official)Document18 pagesTS-C4Gas-COATMEX001 - Rev3 (Official)Reynol Mejía OlmosNo ratings yet

- INS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesDocument18 pagesINS-000-SPE-0002 Rev.1 Specification For Painting and Coating%2c Structural Steel of Marine FacilitiesCristhian Joel VINo ratings yet

- Marathon: Technical Data SheetDocument5 pagesMarathon: Technical Data SheetOkinawa TeakNo ratings yet

- 4weq 6804Document18 pages4weq 6804Evgeniy PalnikovNo ratings yet

- Rdso Specification No. M&C/PCN/102/2020 (Rev 1.0) : Specification For Epoxy Based Zinc Phosphate Primer (Two Pack)Document11 pagesRdso Specification No. M&C/PCN/102/2020 (Rev 1.0) : Specification For Epoxy Based Zinc Phosphate Primer (Two Pack)varun saini100% (1)

- TDS 684 Resist 86 Euk GBDocument5 pagesTDS 684 Resist 86 Euk GBNgô Trung NghĩaNo ratings yet

- Painting BTS HardwareDocument5 pagesPainting BTS HardwareFlorin StanNo ratings yet

- Durashield 110 61Document6 pagesDurashield 110 61huicholeNo ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Plant Building - Epoxy PaintDocument2 pagesPlant Building - Epoxy PaintNavaneethan NatarajanNo ratings yet

- PHR Com SPC 105191Document93 pagesPHR Com SPC 105191tohaphsianturiNo ratings yet

- SSPC-Paint 40 PDF PDFDocument5 pagesSSPC-Paint 40 PDF PDFFrancisco UrtechoNo ratings yet

- TSI 136 Adani - R1 PDFDocument6 pagesTSI 136 Adani - R1 PDFKRISHNA ENGINEERING CO. BHOPALNo ratings yet

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocument8 pages6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNo ratings yet

- Tankguard 412 Jotun PaintDocument6 pagesTankguard 412 Jotun PaintGurdeep Sungh AroraNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- 1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Document5 pages1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Akram AlhaddadNo ratings yet

- Project Specification PaintingDocument13 pagesProject Specification PaintingBudi Indra100% (1)

- ASSTM A882 - Epoxy Coated PC StrandDocument5 pagesASSTM A882 - Epoxy Coated PC StrandLai DieuNo ratings yet

- Filled Epoxy-Coated Seven-Wire Prestressing Steel Strand: Standard Specification ForDocument5 pagesFilled Epoxy-Coated Seven-Wire Prestressing Steel Strand: Standard Specification ForSama UmateNo ratings yet

- Def STD 80-161 Iss 2Document22 pagesDef STD 80-161 Iss 2Joanne WaiNo ratings yet

- TDS 16560 Jotamastic 90 Euk GBDocument7 pagesTDS 16560 Jotamastic 90 Euk GBNgô Trung NghĩaNo ratings yet

- 3M Scotchkote Liquid Coatings Application SpecificationDocument4 pages3M Scotchkote Liquid Coatings Application SpecificationleoNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Astm A780 PDFDocument4 pagesAstm A780 PDFFu Ad100% (1)

- TDS Resist 78 (JOTUN)Document5 pagesTDS Resist 78 (JOTUN)RinoHpNo ratings yet

- Painting Procedure For Field Erected Tank FINAL (13850)Document22 pagesPainting Procedure For Field Erected Tank FINAL (13850)Parthiban NCNo ratings yet

- Tank Paint SpecDocument106 pagesTank Paint SpecJack100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- Barrier ZEP: Technical Data Sheet Application GuideDocument7 pagesBarrier ZEP: Technical Data Sheet Application GuideNurmalinda SihombingNo ratings yet

- TDS SteelMaster 1200WF GB English ProtectiveDocument5 pagesTDS SteelMaster 1200WF GB English Protective폴로 쥰 차No ratings yet

- TDS 52742 Jotamastic 85 Euk GBDocument5 pagesTDS 52742 Jotamastic 85 Euk GBAhmad SyawalNo ratings yet

- G16S-0205-04 - Shop Coat Galv Surf (Duplex)Document3 pagesG16S-0205-04 - Shop Coat Galv Surf (Duplex)puwarin naja100% (1)

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- 4 - Tech Hardware SectorDocument126 pages4 - Tech Hardware SectorgirishrajsNo ratings yet

- Ecs2602 Tests Bank-1Document97 pagesEcs2602 Tests Bank-1corlia100% (2)

- Te 243684Document57 pagesTe 243684infoNo ratings yet

- Fastener Tightening Specifications: Application Specification Metric EnglishDocument4 pagesFastener Tightening Specifications: Application Specification Metric EnglishSebastiánLeonardoGuerreroVilchesNo ratings yet

- Product Range: Trelleborg Se Aling SolutionsDocument39 pagesProduct Range: Trelleborg Se Aling SolutionssandeepNo ratings yet

- Metacentric HeightDocument5 pagesMetacentric HeightKHAIRUNISANo ratings yet

- Turbojet EnginesDocument22 pagesTurbojet EnginesAldo SamuelNo ratings yet

- DP - X510 BrochureDocument2 pagesDP - X510 BrochureRommel SegismundoNo ratings yet

- VC - SM TransportDocument2 pagesVC - SM Transportsureshkumar mNo ratings yet

- Stresses in Finite Anisotropic Plate Weakened by Rectangular HoleDocument8 pagesStresses in Finite Anisotropic Plate Weakened by Rectangular Holemihir.chauhanNo ratings yet

- AOSS321 L11 021209 Static StabilityDocument50 pagesAOSS321 L11 021209 Static StabilityKattia AFNo ratings yet

- eHYDRO SERIESDocument6 pageseHYDRO SERIESBanupriya BalasubramanianNo ratings yet

- Crabs Hell Ms DsDocument1 pageCrabs Hell Ms DsRega Wahyu AnggrainiNo ratings yet

- Case Study TPM Jet AirwaysDocument15 pagesCase Study TPM Jet AirwaysSanjay Domdiya100% (1)

- List of Coolers and HeatersDocument2 pagesList of Coolers and HeatersadityasahayNo ratings yet

- Homework 2 SolutionDocument5 pagesHomework 2 SolutiongretabunciNo ratings yet

- 4 RPI To PCF8591 - PhotocellDocument4 pages4 RPI To PCF8591 - Photocellsatyam jadhavNo ratings yet

- FPM Formula Sheet 2Document13 pagesFPM Formula Sheet 2Yolo Gamer DudeNo ratings yet

- Lung Sounds Auscultation - 1Document3 pagesLung Sounds Auscultation - 1George BarajazNo ratings yet

- Iso 11124-1 2018Document14 pagesIso 11124-1 2018anon_433139120No ratings yet

- Healthy Lifestyle Ideas For Truck Drivers: EFS-IFR Anul I UBB Cluj 2019Document12 pagesHealthy Lifestyle Ideas For Truck Drivers: EFS-IFR Anul I UBB Cluj 2019Pap RobertNo ratings yet

- TAS Product Catalog 2020 01Document210 pagesTAS Product Catalog 2020 01ct0720054858No ratings yet

- NIFLECDocument6 pagesNIFLECRonald Ariyanto WiradirnataNo ratings yet

- To Study Well Design Aspects in HPHT EnvironmentDocument40 pagesTo Study Well Design Aspects in HPHT Environmentnikhil_barshettiwat100% (1)

- EEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsDocument13 pagesEEE40003 Digital Signal and Image Processing: LAB 3: Discrete LTI SystemsKai JieNo ratings yet

- Jurnal ....Document3 pagesJurnal ....Yuniati ValentinaNo ratings yet

- Fortran CF DDocument160 pagesFortran CF DLahcen AkerkouchNo ratings yet

- MSD Numbers 0410612020 Am: ClosingDocument11 pagesMSD Numbers 0410612020 Am: ClosingSanjeev JayaratnaNo ratings yet

- Princeton 112 Plus Service ManualDocument8 pagesPrinceton 112 Plus Service ManualDavid OliveiraNo ratings yet