Professional Documents

Culture Documents

Homework 3-Due Feb 13 2020

Homework 3-Due Feb 13 2020

Uploaded by

sai ayyankiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homework 3-Due Feb 13 2020

Homework 3-Due Feb 13 2020

Uploaded by

sai ayyankiCopyright:

Available Formats

Homework 3

1. What is the magnitude of the maximum stress that exists at the tip of an internal crack having a radius

of curvature of 1.9 × 10–4 mm (7.5 × 10–6 in.) and a crack length of 3.8 × 10–2 mm (1.5 × 10–3 in .) when

a tensile stress of 140 MPa (20,000 psi) is applied?

2. A large plate is fabricated from a steel alloy that has a plane strain fracture toughness of 82.4 MPa

m (75.0 ksi in. ). If, during service use, the plate is exposed to a tensile stress of 345 MPa (50,000

psi), determine the minimum length of a surface crack that will lead to fracture. Assume a value of

1.0 for Y.

3. Compute the critical crack tip radius for a glass specimen that experiences tensile fracture at an

applied stress of 70 MPa (10,000 psi). Assume a critical surface crack length of 10 –2 mm and a

theoretical fracture strength of E/10, where E is the modulus of elasticity, which is 69 GPa for this

material.

4. Given the following data, plot the stress-strain curves for the two unknown materials on the same set

of stress-strain axes.

Density 4.43g/cm3 3.98g/cm3

E 114 GPa 380 GPa

0.34 0.22

Yield stress (at 0.2% 830 MPa Not

strain) applicable

Ultimate tensile 900 MPa 550 MPa

strength

Failure stress 840 MPa 550 MPa

% elongation 14 Negligible

What likely types are Materials A and B?

5. A specimen of a ceramic material having an elastic modulus of 250 GPa is pulled in tension with a

stress of 750 MPa. Will the specimen fail if its “most severe flaw” is an internal crack that has a length

of 0.20 mm and a tip radius of curvature of 0.001 mm? Why or why not?

6. Some aircraft component is fabricated from an aluminum alloy that has a plane strain fracture

toughness of 40 MPa m (36.4 ksi in. ). It has been determined that fracture results at a stress of

300 MPa (43,500 psi) when the maximum (or critical) internal crack length is 4.0 mm (0.16 in.). For

this same component and alloy, will fracture occur at a stress level of 260 MPa (38,000 psi) when the

maximum internal

crack length is 6.0 mm (0.24 in.)? Why or why not?

7. A structural component in the form of a wide plate is to be fabricated from a steel alloy that has a

plane strain fracture toughness of 98.9 MPa m (90 ksi in. ) and a yield strength of 860 MPa (125,000

psi). The flaw size resolution limit of the flaw detection apparatus is 3.0 mm (0.12 in.). If the design

stress is one-half of the yield strength and the value of Y is 1.0, determine whether or not a critical

flaw for this plate is subject to detection.

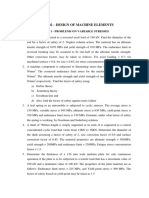

You might also like

- Chap 8 SolnsDocument71 pagesChap 8 SolnsCarolina Paz100% (1)

- Design Calculation of Working Platform-1Document26 pagesDesign Calculation of Working Platform-1Khandaker Khairul Alam100% (1)

- 3a - 8.1 A 8.11FRATURA E FADIGA PDFDocument70 pages3a - 8.1 A 8.11FRATURA E FADIGA PDFmatheus oliveira100% (6)

- Problems Solutions On Fracture MechanicsDocument50 pagesProblems Solutions On Fracture MechanicsRajesh N Priya Gopinathan100% (5)

- Principles of Fracture MechanicsDocument49 pagesPrinciples of Fracture MechanicsgodzillafoodNo ratings yet

- Review Fracture Mech Mes Test 3Document8 pagesReview Fracture Mech Mes Test 3Natalie RussellNo ratings yet

- AEB650 Materials For Engineering Chapter 8 SolutionsDocument6 pagesAEB650 Materials For Engineering Chapter 8 SolutionsNina Fadzil50% (2)

- Suggested Problems (L12-15 Failure)Document2 pagesSuggested Problems (L12-15 Failure)Isaac MitchellNo ratings yet

- EMM7241-Advanced Machine Design Examination June 2016Document8 pagesEMM7241-Advanced Machine Design Examination June 2016Charles OndiekiNo ratings yet

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- MTN 513 - Tutorial 4Document1 pageMTN 513 - Tutorial 4Rakshit KeswaniNo ratings yet

- AMD Tutorial ME CADCAM 2022-23Document6 pagesAMD Tutorial ME CADCAM 2022-23rip111176No ratings yet

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Practice Questions - Mechanical PropertiesDocument1 pagePractice Questions - Mechanical Propertiesalexchitongwe48No ratings yet

- Engineering Failure Analysis-MEE3003: AssignmentDocument1 pageEngineering Failure Analysis-MEE3003: AssignmentAdarsh NageshNo ratings yet

- Assignment 1Document2 pagesAssignment 1Supratim Bhattacharjee100% (1)

- Assignment 3Document3 pagesAssignment 3Hasan AliNo ratings yet

- CH6 AssignmetDocument11 pagesCH6 AssignmetHasan AhmedNo ratings yet

- Assignment 2Document2 pagesAssignment 2spal1715No ratings yet

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyNo ratings yet

- SM Mid3 Model QuestionsDocument3 pagesSM Mid3 Model QuestionsSaitama BackupNo ratings yet

- Stress Concentration ExamplesDocument5 pagesStress Concentration ExamplesUday NarasimhaNo ratings yet

- Material Yr1 - Tutorial 6Document16 pagesMaterial Yr1 - Tutorial 6Ahmed TahaNo ratings yet

- Th. of FailureDocument3 pagesTh. of Failureraja50% (2)

- DomeDocument3 pagesDomevikaskumar1986No ratings yet

- M.D-I Final Tutorial and AssignmentDocument16 pagesM.D-I Final Tutorial and AssignmentnageshNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- DMEDocument4 pagesDMEManivannanNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- Design of Machine Element ProblemsDocument2 pagesDesign of Machine Element Problemsmaxpayne5550% (1)

- Taller 3 - Propiedades MecánicasDocument2 pagesTaller 3 - Propiedades MecánicasJuan Pablo Rinc�n Ru�zNo ratings yet

- Important Questions For Weak StudentsDocument1 pageImportant Questions For Weak StudentsDhanabal Palanisamy PNo ratings yet

- Latihan SoalDocument3 pagesLatihan SoalDaus100% (1)

- Btech Me 3 Sem Mechanics of Solids Rme303 2022Document2 pagesBtech Me 3 Sem Mechanics of Solids Rme303 2022Gulshan AryaNo ratings yet

- Creep Sheet3Document2 pagesCreep Sheet3Unc StappyNo ratings yet

- Unit - 1 - Variable StressesDocument1 pageUnit - 1 - Variable Stressesgangadharan tharumarNo ratings yet

- Department of Mechanical Engineering MD - II: Tutorial Sheet For Fatigue Consideration in Design (Session 2020-21)Document2 pagesDepartment of Mechanical Engineering MD - II: Tutorial Sheet For Fatigue Consideration in Design (Session 2020-21)djadja nakamayaNo ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Unit - 1Document8 pagesUnit - 1Dhileepan KumarasamyNo ratings yet

- DE5302 Strength of Materials 1 S2 2019 - Exam - FINALDocument24 pagesDE5302 Strength of Materials 1 S2 2019 - Exam - FINALGopal KrishanNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- Suez University Faculty of Petroleum &mining Engineering Mechanical Design Sheet # 5Document3 pagesSuez University Faculty of Petroleum &mining Engineering Mechanical Design Sheet # 5Flying KiteNo ratings yet

- Integrated Mechanical Design Question: Fundamentals and Design of ShaftsDocument2 pagesIntegrated Mechanical Design Question: Fundamentals and Design of Shafts9944805552No ratings yet

- Mech PropertiesDocument5 pagesMech Propertiesaksgupta24No ratings yet

- ME2303-Design of Machine ElementsDocument17 pagesME2303-Design of Machine ElementsSith AnanthanNo ratings yet

- DME Question BankDocument4 pagesDME Question BankILAYAPERUMAL KNo ratings yet

- Sheet#8Document7 pagesSheet#8oreaby05No ratings yet

- Assignment ProblemsDocument3 pagesAssignment ProblemsKaushik SreenivasNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- DMM - I Question Bank For StudentsDocument11 pagesDMM - I Question Bank For StudentsDushyanthkumar DasariNo ratings yet

- Assignment 2 Fluctuating LoadDocument3 pagesAssignment 2 Fluctuating Loadabhishek chaurasiyaNo ratings yet

- ME 303 Study Set PDFDocument44 pagesME 303 Study Set PDFFajar RumantoNo ratings yet

- Problems 4012 PDFDocument8 pagesProblems 4012 PDFjonthemesNo ratings yet

- QP Pe Series 2Document2 pagesQP Pe Series 2AADARS M SNo ratings yet

- Design of Machine ElementDocument11 pagesDesign of Machine ElementVenkat RajaNo ratings yet

- E8 E8M 09 Traccion Metales NuevaDocument5 pagesE8 E8M 09 Traccion Metales NuevaTerminatorNo ratings yet

- Nanyang Technological University: Manufacturing Lab ReportDocument5 pagesNanyang Technological University: Manufacturing Lab ReportPrayogo TioNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Fluid Mechanics SanfoundaryDocument277 pagesFluid Mechanics Sanfoundaryengineersalam786No ratings yet

- Material PropertiesDocument20 pagesMaterial Propertiesnikhilpathak16674100% (1)

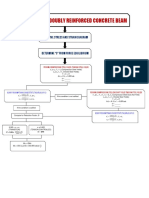

- Analysis of Doubly Reinforced Concrete Beam: Draw The Stress and Strain DiagramDocument1 pageAnalysis of Doubly Reinforced Concrete Beam: Draw The Stress and Strain DiagramPrincess Joy Villareal EncinasNo ratings yet

- How To Write ReportDocument33 pagesHow To Write ReportHomam MohammadNo ratings yet

- Refrigeration Pipe Sizing Methods and TechniquesDocument64 pagesRefrigeration Pipe Sizing Methods and TechniquesZaid SamhaNo ratings yet

- Carmen - Dup Notes - NSW 700 - First 3 Days of Class UpdatedDocument48 pagesCarmen - Dup Notes - NSW 700 - First 3 Days of Class UpdatedNduP78No ratings yet

- 8.2 - Aerodynamics PDFDocument43 pages8.2 - Aerodynamics PDFjeremy_scerri100% (1)

- Hardy Cross Method.Document7 pagesHardy Cross Method.Arsani RomaniNo ratings yet

- Post BucklingDocument14 pagesPost BucklingthaoNo ratings yet

- Phy433 Assignment 2Document18 pagesPhy433 Assignment 2Michael McBertNo ratings yet

- Design Guide BC05 - 2019Document89 pagesDesign Guide BC05 - 2019rameshkaaNo ratings yet

- CHM131 - Chapter 7 - Chemical EquilibriumDocument30 pagesCHM131 - Chapter 7 - Chemical EquilibriumNotes NotesNo ratings yet

- Refrigerant Piping Rev2Document31 pagesRefrigerant Piping Rev2123john123No ratings yet

- Practical Approaches To Sand Management, Andrew Acock, 2004Document18 pagesPractical Approaches To Sand Management, Andrew Acock, 2004Anonymous Xy309m9Sm9No ratings yet

- Master's Thesis, Justin Reinhart - Final - Final Format Approved LW 7-30-2021Document119 pagesMaster's Thesis, Justin Reinhart - Final - Final Format Approved LW 7-30-2021nem124No ratings yet

- Condenser TechnologyDocument282 pagesCondenser TechnologyLeonardo Diaz67% (3)

- Analysis of Vapour Compression Refrigeration Cycle: Dr.A.Valan ArasuDocument10 pagesAnalysis of Vapour Compression Refrigeration Cycle: Dr.A.Valan ArasuSyed Shahryar HussainNo ratings yet

- GDJP Course Plan NewDocument4 pagesGDJP Course Plan NewbalajimeieNo ratings yet

- Chemistry - Unit 2 Review: EnergyDocument2 pagesChemistry - Unit 2 Review: EnergyAbigail MarinoNo ratings yet

- External Casing Packers ECPDocument1 pageExternal Casing Packers ECPKevin MuellerNo ratings yet

- Specific-Speed LNG-Industry November 2015Document5 pagesSpecific-Speed LNG-Industry November 2015Agung NugrahaNo ratings yet

- Theory of Structural Stability (CET-308)Document52 pagesTheory of Structural Stability (CET-308)Gautam PoddarNo ratings yet

- Undersluice Bay Design Report PDFDocument57 pagesUndersluice Bay Design Report PDFSubodh PoudelNo ratings yet

- Reservoir ManagementDocument39 pagesReservoir ManagementGorillas NgobamNo ratings yet

- PsikometrikDocument1 pagePsikometrikTEP B19-056NIA SILVIANI BRAHMANANo ratings yet

- 7 Marking Scheme: Worksheet: P V NRT P 1.22 × 10 PV NRT y PVDocument3 pages7 Marking Scheme: Worksheet: P V NRT P 1.22 × 10 PV NRT y PVН. НаранцацралтNo ratings yet

- (AMCP 706-283) - Engineering Design Handbook - Ballistic Missile Series - Aerodynamics - U.S. Army Materiel CommandDocument98 pages(AMCP 706-283) - Engineering Design Handbook - Ballistic Missile Series - Aerodynamics - U.S. Army Materiel CommandSoufiane HazelNo ratings yet

- Direct Design MethodDocument90 pagesDirect Design Methodborja familyNo ratings yet