Professional Documents

Culture Documents

Ecc For Aparri

Ecc For Aparri

Uploaded by

Mary Mae Mina0 ratings0% found this document useful (0 votes)

8 views11 pagesOriginal Title

ecc for aparri

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

8 views11 pagesEcc For Aparri

Ecc For Aparri

Uploaded by

Mary Mae MinaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 11

PHI} (FEN EN, (NEER '..s SERV). iS

150 Philand Drive Ext., Tandang Sqve. Quezon City

Telefax: (02) 992-4963 » (02) 084-063 « (02) 738-2019

‘e-mail : phiigen_engineers@yahoo com

22 May 2017

BUENO BUILDERS AND MANAGEMENT

Unit 3G Edificio Enriqueta Bldg. 422 N.S.

Amoranto St., Cor, D Tuazon St.,

Quezon City

Attention : MR. LOMAR TIANGSON

General Manager

PROPOSAl. FOR THE

SEWAGE TREATMENT PLANT

(SBR-PROCESS)

A. © SCOPE OF WORK

1. Process and equipment design of the Sewage Treatment Plant for

CITYMALL APARRI, with a capacity indicated in tr: design basis. The

designed treatment facility is cecable of consistently resi sing the BOD, COD.

TSS, pH, Oil and Grease, and coliform surpassing to tle DENR prescribed

effluent requirements.

2. Supply and installation of all electromechanical equipment STP specified

Under equipment summary :

Supply and installation of necessary mechanical, piuribing and electrical

‘works. Point of termination within the STP area only.

Preparation and submission of three (3) sets of operation and maintenance

Training of personnel for STP operation and maintenance: of the system.

‘Submission of Sign & Sealed three (3) sets of as-built pian drawings.

Testing, start-up and commissioning of the wasteweter treatment plant

equipment and its appurtenances.

Preparation of Engineers Repor.. and assistance in processing of sewage

treatment plant (STP) Discharge Permit to DENR.

@ 19H A ©

B. DESIGN BASIS

‘The process and equipment design of the proposed sewags treatment plant was

based on the following design criteria and parameters.

Design Flow Rate

Parameter [Unit | "Volume Capacity

Design Flow Rate midday 40 1

Design Criteria

[ Parameter Unit Value

[Biochemical Oxygen Demand ‘Mg/L 500

‘Chemical Oxygen Demand Mg/t 1000

Total Suspended Solids Mg/L 500

(OivGrease Mg/t 50

Color PCU. 850

Total Coliforms MPN/100mi 30,000

pH 60-90

PERFORMANCE GUARANTEE

Guarantees that the performance of the STP to surpass DENRI/LLDA set

standards as prescribed in the Table below.

Parameter Unit Guaranteed DENR Set |

Effluent Standards

Quality “Class C

Inland Water” |

Biochemical Oxygen Demand | mg/l 20 550 |

Chemical Oxygen Demand mg/L =70, 100

Total Suspended Solids mg/L £10 =70

Oil/Grease mg/L. =3 s5

Color PCU = 80. = 150

(Total Coliforms MPN/00mi | £5,000, = 10,000

[pH 65-85 6.0-9.0

‘SEWAGE TREATMENT PLANT

The proposed sewage treatment plant consists of a bar screen, equalization

tank, SBR Tank, Chlorine Application. The sludge will be further treated to

Sludge Drying Bed.

MANUAL BAR SCREEN

A bar screen is installed to remove large solids that may clog the process

equipment downstream.

EQUALIZATION TANK (EQT)

The equalization tank is used to stabilize the variations in flow and influent

characteristics. This is too achieved by providing sufficient retention time in the

tank, and installing a mixing system to ensure uniform effluent quantity at a

predetermined flow volume. The tank is also installed with submersible pumps

with level switches to regulate the flow going in to the SBR Tank.

a eee se se Se SE SS SE SBS SE SE SE ESE SB SE

SEQUENCING BATCH REACTOR (SBR)

‘The Sequencing Batch Reactor (SBR) process is the most advanced activated

sludge process used today. It is a system that operates by batch and allows

microorganisms, to biodegrade the fluctuating and high organic matter and

converts them to stable gases such as carbon dioxide, nitrogen and water under

the aerobic, anoxic and anaerobic conditions. It had combined carbon oxidation

and nitrfcation/de-nitrfication process in the reactor ensuring the total treatment

of biological waste. The various operating mode of the SBR are Fill, React,

Settle, Decant and Idle. Because of the non-off operation of equipment is

inherent in SBR, it therefore allows organic pollutants to undergo a complete

cycle, from aerobic oxidation to anaerobic degradation. The SBR shall be

installed to provide the biological removal of carbonaceous substances.

The various modes of operation in SBR are described as follows:

Operation Modes Description ]

FILL The purpose of the fil operation is to add |

substrate (raw wastewater or primary effluent)

to the reactor. The fill process normally last |

approximately 25% of the full cycle time.

[REACT The purpose of react is to complete the

| reactions that were initiated during fil. Typically,

the react period takes up to 35% of the total

cycle time.

[SETTLE The purpose of settle is to allow solide

| separation to occur, providing a clatified

supernatant to be discharged as effluent. In an

SBR, this process is normally much more

efficient than in a continuous-flow system

because in the settie mode the reactor contents

‘are completely quiescent.

DECANT The purpose of decant is to remove clarified

treated water at the top layer of the reactor. The

time dedicated to decant can range from 5% to

30% of the total cycle time (15 minutes to 2

| hours) with 45 minutes being @ typical draw

riod. |

(DLE «The purpose of idle in a mulf-tank system is to |

provide time for one reactor to complete its fil

cycle before switching to another unit. Because |

idle is not a necessary phase, it is sometimes |

omitted,

CHLORINATION SYSTM

Decanted Sewage from the CBC tank will be treated with hypochlorite solution to

remove any remaining color and kill-off pathogenic bacteria and coliform prior

discharge to the nearby storm drainage or creek.

SLUDGE DRYING BED (SDB)

Waste excess sludge that settled on the bottom of the CBC Tank is pumped into

‘Sludge Drying Bed (SDB) to dry up. Sludge may be disposed off as ordinary

garbage or used as soil conditioner directly on the nearby landscaping,

ae eee ee eSB Se Ee eS eS Ue US CUS CUS

PLC CONTROL SYSTEM

The operation of the equipment as well as process control will be carried out by a

programmable logic controller (PLC) placed in NEMA enclosure control panel.

This PLC will detect and signal any equipment operation and failure, and will

automatically take action, so that the system may resume operation using the

remaining basins/equipment as programmed in the PLC. The unit control of each

equipment is also provided with manual override.

LIST OF SUPPLIED ELECTROMECHANICAL EQUIPMENT

Qty | Unit Equipment [Brand | Origin}

1 | unit | Pvc Manual Bar Screen [eae moral Local

Atlanta |

SBR Rotary Air Blower, |

| 10Bcu.m/min @ 40Kpa, 1.5kW, | Te nj

2 Units | 2HP, 60Hz, 230-400V, 3 phase Equivaient Japan

complete with standard} ©

Accessories,

Transfer Pump, _ Submersible

| 4. |Non Clog, 6m TDH, 0.4kw,

| 2. | Units | o SH, edFiz, 230-400V, 3 phase | Ebara Japan

complete with all accessories

Decanter Pump, Submersible

Non Clog, 6m TDH, 0.75kw,

: AHP, 60H2, 230-400V, 3 phase | Ebara Japan

| complete with all accessories

] WAS Airlif, Air Operated | Emerald

1_| Unit | complete with all accessories Atlanta | boca!

| Chlorination System, 0-30gpd, ‘Seko

1 | Set |0.18kw, 60Hz, 220V, Single Italy |

| phase : |

‘Air Diffuser, non-dlog, Fine ; |

4 Pes Bubble, 12" dia. Disc Type Kam-Air Singapore

+ | set [Filtration System of Treated] Fiber Glass | Locally

[ water prior discharge _Tank Fabricated

Motor Control Panel with PLC,

[1 | S# | Cote standart seceesones "| Panasonic | Japan

EQUIPMENT GUARANTEE

The contractor guaranteé all the process equipment for a period of one (1) year

from the date of acceptance of the sewage treatment plant, but in all cases not to

exceed eighteen (18) months after the shipment date of equipment, whichever

comes first.

This warranty is subject to the following conditions:

a. All design parameters and flow rate of the influent are strictly observed at

all times within the specified limit as the data provided in our design;

b. The equipment shall be properly maintained in accordance with the

operation and maintenance manual and has never been subjected to

‘external damages, overload conditions that may cause its early failure

and void the guarantee.

CONSTRUCTION SCHEDULE

The STP Electro-mechanical scope of work shall be completed in Thirty (30)

calendar days upon Receipt of Mobilization notice.

H. BID PROPOSAL

For the consideration of the scope of work stipulated, the proposal cost is in the

‘amount of Pesos:

Amount in Words :

One Million Three Hundred Fifty Eight Thousand Pesos Only

(Php 1,358,000.00)

1 TERMS OF PAYMENT

30% Down Payment upon receipt of approved NTP.

60% By progress billing

10% Upon installation and successful start up.

Note: Successful Start-Up should be determined by passing the Effluent

Analysis from the third party laboratory.

J. VALIDITY

The prices and terms indicated in this proposal in its entirety are valid up to

Ninety (90) days.

K. SCOPE OF WORK NOT INCLUDED

Construction of Structural Tank

Fresh Water Supply for Chlorination System.

STP Air Ventilation System.

Supply of Main Feeder and Circuit Breaker, 75amps, 3phase, 230volts.

Emergency generator.

Utilities during construction such as power and water.

-paogp

We trust that our offer is acceptable to you. Should you need further assistance, please

do not hesitate to contact us anytime.

Very truly yours,

MARJORIE M. CORDER(

Business Devt. Manager

Noted By,

A

CHARLES 4 CORDERO JR. :

General Manager

v

BHometnmpuowttnnttnnetntreiwetweHieweewen ww

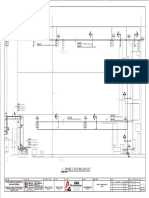

STPSECTIONA

aR

YIN

RK

CCITYMALL APPAR

SECTION A

AK

x

XY

My

SJ

<

Ss

AS LAKE

ye RRR

DESIGNS BOLD OF

‘SEWAGE TREATMENT PLANT (STP)

PHILGEN ENGINEERING SERVICES

SNouDas dis eva TALI (ais) anid ANavuuvat 30¥NES

40.gN@ ¥ NBIS3O_

pete

@ NoloasO

Dav NouYZrNOs is

B

ma wl

WL 3909S 1

Yau ANaMINOS i

3

ant ig 5

a

ah

|

4 00% 4 ory 09%

NOLES dis aveay THWALIO

ah

(aus) anv id uvanuvat 39vNaS|

30.a1Na ¥NOISIG

9 NOWoaSO |

ES

Yr

R

RA

A

wn

eR

wx,

YN,

Ss

SS

Ss

K

RR

OX

SS

NY BS

NL NOUYZr¥NOS

yaw ARAN g

fava TWA Gis) nvignanuvaus aownas| __ sista. Caress

s0.g1n@ ¥NOIS30 ‘owas OnIAaNTONS NATE

= ee =

a NowoasO)

7 '

7 bmivt Nouvern03

lo 1

7 id Ny '

am i A

I)

"OoT Soe "ped Of,

e ce t

Soy oo'e

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aemax: Schedule of DoorsDocument1 pageAemax: Schedule of DoorsMary Mae MinaNo ratings yet

- 3 HvacDocument32 pages3 HvacMary Mae MinaNo ratings yet

- Phase 2 Routing LayoutDocument1 pagePhase 2 Routing LayoutMary Mae MinaNo ratings yet

- 4 2007 August ORBP Newsletter 240102 7 PDFDocument4 pages4 2007 August ORBP Newsletter 240102 7 PDFMary Mae MinaNo ratings yet