Professional Documents

Culture Documents

En 0011 1312 90 Ed1

En 0011 1312 90 Ed1

Uploaded by

Michail PerackisCopyright:

Available Formats

You might also like

- CRCADocument10 pagesCRCAsingaravelan narayanasamyNo ratings yet

- Din 1630 PDFDocument3 pagesDin 1630 PDFv53100% (1)

- S235JRDocument1 pageS235JREmrahCayboyluNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Hyundai Welding Co., LTDDocument4 pagesHyundai Welding Co., LTDGerry Dan ChanliongcoNo ratings yet

- Domex 355 MC: High Strength Cold Forming SteelDocument2 pagesDomex 355 MC: High Strength Cold Forming SteelKhantoNo ratings yet

- TDS - ER80S-B6.GTAW Rev1Document1 pageTDS - ER80S-B6.GTAW Rev1Erick VazquezNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- MSDS Titanlene-801YYDocument1 pageMSDS Titanlene-801YYSyuhadaNo ratings yet

- Hai Point JKR Requirement Channel and Batten 2020Document23 pagesHai Point JKR Requirement Channel and Batten 2020kimchewlim82No ratings yet

- Pickled and Oiled Steel CoilsDocument36 pagesPickled and Oiled Steel CoilsX800XLNo ratings yet

- Sitesdefaultfilestata Steel Engineering 27mnb5 HR Hot Rolled Manganese Boron Wear Resistant ADocument2 pagesSitesdefaultfilestata Steel Engineering 27mnb5 HR Hot Rolled Manganese Boron Wear Resistant ASuleyman TaskazanNo ratings yet

- lnt26 EngDocument1 pagelnt26 EngVVan TanNo ratings yet

- SY-T0413-2002 - Technical Standard of Polyethylene Coating For Buried Steel Pipeline - English VersionDocument29 pagesSY-T0413-2002 - Technical Standard of Polyethylene Coating For Buried Steel Pipeline - English Versionkorakot.chavarakNo ratings yet

- Techalloy 208: Conformances Key FeaturesDocument2 pagesTechalloy 208: Conformances Key FeaturesSam RajaNo ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Spec LFM-57W TM-HP (S) 12 EDocument5 pagesSpec LFM-57W TM-HP (S) 12 EluismcmcNo ratings yet

- TM 004Document11 pagesTM 004yassir dafallaNo ratings yet

- WSM-4X4-W21 Mill CertDocument1 pageWSM-4X4-W21 Mill CertjamesNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Cold Rolled CoilDocument23 pagesCold Rolled Coilmametcool100% (1)

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- TM 002Document11 pagesTM 002yassir dafallaNo ratings yet

- DSM-0289.1 AM NiCrMo SuperalloyDocument3 pagesDSM-0289.1 AM NiCrMo SuperalloyApichitNo ratings yet

- Data Sheet 2353 COR-TEN® B-D 2022-06-30Document2 pagesData Sheet 2353 COR-TEN® B-D 2022-06-30ragget.catNo ratings yet

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabNo ratings yet

- Name of The Contractor: Sri Challa Constructions - Name of The Client: Ferring Laboratories PVT - Ltd. Name of Work:-Shape ProjectDocument3 pagesName of The Contractor: Sri Challa Constructions - Name of The Client: Ferring Laboratories PVT - Ltd. Name of Work:-Shape ProjectBilling depNo ratings yet

- Optimization of Process Parameters of CO2 LasersDocument10 pagesOptimization of Process Parameters of CO2 LasersHassan HabibNo ratings yet

- Hot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsDocument3 pagesHot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsBielXDNo ratings yet

- Irjet V6i9115Document8 pagesIrjet V6i9115JaskiratSinghNo ratings yet

- 18CrNi8 PDFDocument3 pages18CrNi8 PDFParas Sharma100% (1)

- Fio Outershield 71e-HDocument2 pagesFio Outershield 71e-HJose NevesNo ratings yet

- TM 003Document12 pagesTM 003yassir dafallaNo ratings yet

- High Strength Fine Grained Structural Steel Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel Quenched and TemperedAugusto BerdetteNo ratings yet

- Microdyn Ro XleDocument2 pagesMicrodyn Ro XlegulfengsolutionsNo ratings yet

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoNo ratings yet

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- OSNA10 Copper-Nickel Sheathing On Offshore StructuresDocument8 pagesOSNA10 Copper-Nickel Sheathing On Offshore Structuresbello imamNo ratings yet

- TM 001Document11 pagesTM 001yassir dafallaNo ratings yet

- Scad 76360 KeresztesDocument9 pagesScad 76360 KeresztesId EaNo ratings yet

- Din 2395-1Document4 pagesDin 2395-113393m210No ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- Plastic Mold & Hot-Working Tool Steel W.1.2714: Doosan IMGBDocument3 pagesPlastic Mold & Hot-Working Tool Steel W.1.2714: Doosan IMGBAlexandru GrigoreNo ratings yet

- Material Specification: 23dec2015 01sep1961Document2 pagesMaterial Specification: 23dec2015 01sep1961Chuanxiang Weinong (川香味浓)No ratings yet

- Cold Rolled Steel Sheet For Drawing and FormingDocument3 pagesCold Rolled Steel Sheet For Drawing and FormingAnonymous NRlowQUcnNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- ANG SPLOSNI KATALOG 2020 TerazzoDocument8 pagesANG SPLOSNI KATALOG 2020 TerazzoczorlubasNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Improving Reformer Pigtail Reliability - Nitrogen+Syngas2014Document7 pagesImproving Reformer Pigtail Reliability - Nitrogen+Syngas2014Jean-Noël LerouxNo ratings yet

- X6CrNiTi18-10 DataDocument9 pagesX6CrNiTi18-10 DataNajlepsze NotatkiNo ratings yet

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocument16 pagesQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezNo ratings yet

- Techalloy 718: Conformances Key FeaturesDocument2 pagesTechalloy 718: Conformances Key FeaturesvishuNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- JQ - Yj501-1-Products E71t1 Tianjing FcawDocument5 pagesJQ - Yj501-1-Products E71t1 Tianjing FcawDiego PabonNo ratings yet

- Chemcial of Ladle Analysis PDFDocument1 pageChemcial of Ladle Analysis PDFBassem KhaledNo ratings yet

En 0011 1312 90 Ed1

En 0011 1312 90 Ed1

Uploaded by

Michail PerackisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

En 0011 1312 90 Ed1

En 0011 1312 90 Ed1

Uploaded by

Michail PerackisCopyright:

Available Formats

Group

Standards

Departme nt ©

STANDARD en 0011 1312 90

Date Edition Page

2008 -01-0 9 1 1 (3)

Steel

Structural steel, non-alloyed - S235JR

Mat erial 00 11 1 312 90

1 GENERAL

This standard, based on EN 10025-2:2004, specifies the technical delivery conditions

for flat and long products and semi-finished products which are ment for further

processing, it does not apply to structural hollow sections and tubes.

The material is identical to symbol: S235JR, number: 1.0038.

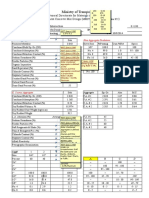

2 CHEMICAL COMPOSITION

Table 1. Chemical composition of the ladle analysis for flat and long products of steel

grades and qualities with values for the impact strength

Method

C in % max. for Si % Mn % P% S% N% Cu %

of Other %

nominal product max. max. max. max. max. max. h

deoxi-

thickness in mm d de f g max.

dationb

>16

≤16 >40c

≤40

FN 0,17 0,17 0,20 - 1,40 0,035 0,035 0,012 0,55 -

b) FN = rimming steel not permitted.

c) For sections with nominal thickness > 100 mm the C content by agreement.

d) For long products the P and S content can be 0,005 % higher.

e) For long products the S content can be increased for improved machinability by 0,015 % by agreementy if

the steel is treated to modify the sulphide morphology and the chemical composition shows min. 0,0020 %

Ca.

f) The max. value for nitrogen does not apply if the chemical composition shows a minimum total Al content of

0,020 % or alternatively min. 0,0154 % acid soluble Al or if sufficient other N binding elements are present. In

this case the N binding elements shall be mentioned in the inspection document.

g) Cu content above 0,40

% may cause hot shortness during hot forming

h) If other elements are added, they shall be mentioned on the inspection document.

3 MAXIMUM CARBON EQUIVALENT VALUE, CEV

Table 2. Maximum CEV in % for nominal product thickness in mm

Method of Maximum CEV in % for nominal product thickness in

b

deoxidation mm

≤30 >30 ≤40 >40 ≤150 >150 ≤250 >250≤ 400

- Lotus Notes data base Standard Documents - GSD

FN 0,35 0,35 0,38 0,40 -

- Internet URL http://atlascopco.com/gsd

a) If the copper-content is between 0,25 % and 0,40 % on ladle analysis, the maximum carbon equivalent

value shall be increased by 0,02 %.

b) FN = rimming steels not permitted

Edition check

Group

Standards STANDARD en 0011 1312 90

Department(

Date Edition Page

2008-01-09 1 2(3)

4 MECHANICAL PROPERTIES

Table 3. Minimum yield strength for flat and long products.

Minimum yield strength ReH

MPa

Nominal thickness

mm

>16 >40 >63 >80 >100 >150 >200 >250

≤16

≤40 ≤63 ≤80 ≤100 ≤150 ≤200 ≤250 ≤400

235 225 215 215 215 195 185 175 -

Table 4. Tensile strength for flat and long products.

Tensile strength Rm

MPa

Nominal thickness

mm

≥3 >100 >150 >250

<3

≤100 ≤150 ≤250 ≤400

360 to 510 360 to 510 350 to 500 340 to 490 -

Table 5. Minimum percentage elongation after fracture.

Minimum percentage elongation after fracture

Position %

of test L0 = 80 mm L0 = 5,65 √S0

piecesa Nominal thickness Nominal thickness

mm mm

>1 >1,5 >2 >2,5 ≥3 >40 >63 >100 >150 >250

≤1

≤1,5 ≤2 ≤2,5 <3 ≤40 ≤63 ≤100 ≤150 ≤250 ≤400

l 17 18 19 20 21 26 25 24 22 21 -

a) For plate, strip and wide flats with widths ≥ 600 mm the direction transverse (t) to the rolling direction

applies. For all other products the values apply for the direction parallel (l) to the rolling direction.

Table 6. Impact strength KV longitudional for flat and long products

Minimum energy (J)

Tempe- Nominal thickness

rature in mm

°C

>150 >250

≤150 a b

≤250 b ≤400 c

20 27 27 -

- Lotus Notes data base Standard Documents - GSD

a) For nominal thickness ≤ 12 mm, the values shall be reduced in direct proportion to the cross-sectional

- Internet URL http://atlascopco.com/gsd

area of the test piece. Impact tests shall not be required for nominal thickness < 6 mm.

b) For sections with a nominal thickness > 100 mm the values shall be agreed.

c) The values apply to flat products.

Edition check

Group

Standards STANDARD en 0011 1312 90

Department(

Date Edition Page

2008-01-09 1 3(3)

5 INSPECTION DOCUMENTATION

The products shall be delivered either with specific or non-specific inspection and testing

to indicate compliance with the order and the standard EN 10025-2:2004.

6 MARKING, LABELLING, PACKAGING

The marking, labelling and packaging shall comply with EN 10025-1:2004

7 TECHNICAL CONDITIONS OF DELIVERY

AC-STD 109001 K, General technical requirements for delivery and inspection of

metal products, is valid where applicable.

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

- Lotus Notes data base Standard Documents - GSD

- Internet URL http://atlascopco.com/gsd

Edition check

You might also like

- CRCADocument10 pagesCRCAsingaravelan narayanasamyNo ratings yet

- Din 1630 PDFDocument3 pagesDin 1630 PDFv53100% (1)

- S235JRDocument1 pageS235JREmrahCayboyluNo ratings yet

- En 0011 1312 00 Ed5Document2 pagesEn 0011 1312 00 Ed5cybula.michalNo ratings yet

- Hyundai Welding Co., LTDDocument4 pagesHyundai Welding Co., LTDGerry Dan ChanliongcoNo ratings yet

- Domex 355 MC: High Strength Cold Forming SteelDocument2 pagesDomex 355 MC: High Strength Cold Forming SteelKhantoNo ratings yet

- TDS - ER80S-B6.GTAW Rev1Document1 pageTDS - ER80S-B6.GTAW Rev1Erick VazquezNo ratings yet

- Cold-Rolled Steel CoilsDocument28 pagesCold-Rolled Steel CoilsX800XLNo ratings yet

- 16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFDocument5 pages16 Bs en 10025 2 2004 Hot Rolled Products of Structural Steel PDFmaga2000No ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- MSDS Titanlene-801YYDocument1 pageMSDS Titanlene-801YYSyuhadaNo ratings yet

- Hai Point JKR Requirement Channel and Batten 2020Document23 pagesHai Point JKR Requirement Channel and Batten 2020kimchewlim82No ratings yet

- Pickled and Oiled Steel CoilsDocument36 pagesPickled and Oiled Steel CoilsX800XLNo ratings yet

- Sitesdefaultfilestata Steel Engineering 27mnb5 HR Hot Rolled Manganese Boron Wear Resistant ADocument2 pagesSitesdefaultfilestata Steel Engineering 27mnb5 HR Hot Rolled Manganese Boron Wear Resistant ASuleyman TaskazanNo ratings yet

- lnt26 EngDocument1 pagelnt26 EngVVan TanNo ratings yet

- SY-T0413-2002 - Technical Standard of Polyethylene Coating For Buried Steel Pipeline - English VersionDocument29 pagesSY-T0413-2002 - Technical Standard of Polyethylene Coating For Buried Steel Pipeline - English Versionkorakot.chavarakNo ratings yet

- Techalloy 208: Conformances Key FeaturesDocument2 pagesTechalloy 208: Conformances Key FeaturesSam RajaNo ratings yet

- 18nicrmo14-6: Steel GradeDocument4 pages18nicrmo14-6: Steel Gradesmith willNo ratings yet

- Spec LFM-57W TM-HP (S) 12 EDocument5 pagesSpec LFM-57W TM-HP (S) 12 EluismcmcNo ratings yet

- TM 004Document11 pagesTM 004yassir dafallaNo ratings yet

- WSM-4X4-W21 Mill CertDocument1 pageWSM-4X4-W21 Mill CertjamesNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Cold Rolled CoilDocument23 pagesCold Rolled Coilmametcool100% (1)

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- TM 002Document11 pagesTM 002yassir dafallaNo ratings yet

- DSM-0289.1 AM NiCrMo SuperalloyDocument3 pagesDSM-0289.1 AM NiCrMo SuperalloyApichitNo ratings yet

- Data Sheet 2353 COR-TEN® B-D 2022-06-30Document2 pagesData Sheet 2353 COR-TEN® B-D 2022-06-30ragget.catNo ratings yet

- Web Datasheet b4.1Document3 pagesWeb Datasheet b4.1Reza Khatibi NasabNo ratings yet

- Name of The Contractor: Sri Challa Constructions - Name of The Client: Ferring Laboratories PVT - Ltd. Name of Work:-Shape ProjectDocument3 pagesName of The Contractor: Sri Challa Constructions - Name of The Client: Ferring Laboratories PVT - Ltd. Name of Work:-Shape ProjectBilling depNo ratings yet

- Optimization of Process Parameters of CO2 LasersDocument10 pagesOptimization of Process Parameters of CO2 LasersHassan HabibNo ratings yet

- Hot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsDocument3 pagesHot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsBielXDNo ratings yet

- Irjet V6i9115Document8 pagesIrjet V6i9115JaskiratSinghNo ratings yet

- 18CrNi8 PDFDocument3 pages18CrNi8 PDFParas Sharma100% (1)

- Fio Outershield 71e-HDocument2 pagesFio Outershield 71e-HJose NevesNo ratings yet

- TM 003Document12 pagesTM 003yassir dafallaNo ratings yet

- High Strength Fine Grained Structural Steel Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel Quenched and TemperedAugusto BerdetteNo ratings yet

- Microdyn Ro XleDocument2 pagesMicrodyn Ro XlegulfengsolutionsNo ratings yet

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocument6 pagesHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoNo ratings yet

- TDC Certificate PDFDocument2 pagesTDC Certificate PDFAlaxmi NarayanNo ratings yet

- OSNA10 Copper-Nickel Sheathing On Offshore StructuresDocument8 pagesOSNA10 Copper-Nickel Sheathing On Offshore Structuresbello imamNo ratings yet

- TM 001Document11 pagesTM 001yassir dafallaNo ratings yet

- Scad 76360 KeresztesDocument9 pagesScad 76360 KeresztesId EaNo ratings yet

- Din 2395-1Document4 pagesDin 2395-113393m210No ratings yet

- CZLLCW511L TN enDocument4 pagesCZLLCW511L TN endrgilleNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- Plastic Mold & Hot-Working Tool Steel W.1.2714: Doosan IMGBDocument3 pagesPlastic Mold & Hot-Working Tool Steel W.1.2714: Doosan IMGBAlexandru GrigoreNo ratings yet

- Material Specification: 23dec2015 01sep1961Document2 pagesMaterial Specification: 23dec2015 01sep1961Chuanxiang Weinong (川香味浓)No ratings yet

- Cold Rolled Steel Sheet For Drawing and FormingDocument3 pagesCold Rolled Steel Sheet For Drawing and FormingAnonymous NRlowQUcnNo ratings yet

- 4.0X1500. 23920 E250a DoDocument1 page4.0X1500. 23920 E250a Dosatyaprakashgond100% (1)

- ANG SPLOSNI KATALOG 2020 TerazzoDocument8 pagesANG SPLOSNI KATALOG 2020 TerazzoczorlubasNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Improving Reformer Pigtail Reliability - Nitrogen+Syngas2014Document7 pagesImproving Reformer Pigtail Reliability - Nitrogen+Syngas2014Jean-Noël LerouxNo ratings yet

- X6CrNiTi18-10 DataDocument9 pagesX6CrNiTi18-10 DataNajlepsze NotatkiNo ratings yet

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocument16 pagesQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezNo ratings yet

- Techalloy 718: Conformances Key FeaturesDocument2 pagesTechalloy 718: Conformances Key FeaturesvishuNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- JQ - Yj501-1-Products E71t1 Tianjing FcawDocument5 pagesJQ - Yj501-1-Products E71t1 Tianjing FcawDiego PabonNo ratings yet

- Chemcial of Ladle Analysis PDFDocument1 pageChemcial of Ladle Analysis PDFBassem KhaledNo ratings yet