Professional Documents

Culture Documents

Mengganti Bearing Mast Forklift

Mengganti Bearing Mast Forklift

Uploaded by

kushOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mengganti Bearing Mast Forklift

Mengganti Bearing Mast Forklift

Uploaded by

kushCopyright:

Available Formats

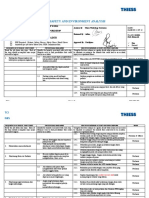

JOB SAFETY AND ENVIRONMENT ANALYSIS

PROJECT: LOCATION OF WORK:

Analysis By: DATE:

SATUI MINE MAINSHOP 14/09/2012

Agus Ariadi

PAGE NO: OF

Reviewed By:

JOB DESCRIPTION: Suripto JSA NO. ……….

…….

MENGGANTI BEARING MAST FORKLIFT Approved By:

Denda Suhenda

New

Revised

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of Identify the hazards associated with Using the first two columns as a guide, decide what actions are necessary

the steps should accomplish some major each step. Examine each to find to eliminate or minimise the hazards that could lead to an accident, injury

task and be logical. possibilities that could lead to an or occupational illness.

accident.

1. Parkir unit 1.1 Area terbatas 1.1.1 Gunakan spotter Operator/mekanik

1.1.2 Aktifkan parking brake Mekanik

1.1.3 Pasang ganjal Mekanik

2. isolasi unit 2.1 Unit di start orang lain 2.1.1 Matikan switch utama battery Mekanik

2.1.2 Matikan switch start Mekanik

2.1.3 Pasang service tag,danger tag/padlock Mekanik

2.1.4 Ikuti procedure JSEA,manual,SOP Mekanik

2007-02 Page 1 of 2 TCI-H&S-FO-031

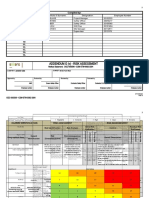

PROJECT: SATUI MINE JOB DESCRIPTION: MENGGANTI BEARING MAST FORKLIFT

PAGE 02 OF 02

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE WHO

Break the job down into steps. Each of Identify the hazards associated with Using the first two columns as a guide, decide what actions are necessary

the steps should accomplish some major each step. Examine each to find to eliminate or minimise the hazards that could lead to an accident, injury

task and be logical. possibilities that could lead to an or occupational illness.

accident.

3. Melepas frame mast 3.1 Area sempit 3.1.1 Perhatikan posisi badan dan gunakan APD yang sesuai Mekanik

3.2 Peralatan rusak 3.1.2 Gunakan tool yang sesuai mekanik

3.3 Area kerja licin 3.3.1 Gunakan penampungan grease Mekanik

3.3.2 Gunakan majun/absorbent untuk mengurangi grease Mekanik

3.3.3 Gunakan alat bantu angkat seperti over head crane Elektrik

Untuk melepas mast frame

3.3.4 Lepaskan pin cylinder tilt dan mounting frame mast

4. Mengganti bearing mast 4.1 Benda berat 4.1.1 Tempatkan frame mast pada tanah atau lantai

4.2 Tempat part sempit 4.2.1 Gunakan panduan part book Mekanik

4.2.2 Gunakan tool yang sesuai Mekanik

5.Memasang frame mast 5.1 Area sempit 5.1.1 Perhatikan posisi badan dan gunakan APD yang sesuai Mekanik

5.1.2 Gunakan tool yang sesuai

5.1.3 Gunakan alat bantu angkat seperti over head crane

Untuk memasang frame mast

5.1.4 Pasang bolt mounting dan pin cylinder tilt

6. House keeping 6.1 Area licin 6.1.1 Gunakan majun/absorbent untuk membersihkan grease Mekanik

2007-02 Page 2 of 2 TCI-H&S-FO-031

2007-02 Page 3 of 2 TCI-H&S-FO-031

You might also like

- Kioti Daedong FX751 Tractor Service Manual LX68WMDocument37 pagesKioti Daedong FX751 Tractor Service Manual LX68WMLisakolyNo ratings yet

- 3 - Air CompressorDocument2 pages3 - Air CompressorRafee Pie92% (12)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- Generator: P16C / BBR84, Bandar Bukit Raja, Klang, Selangor. 4. GeneratorDocument2 pagesGenerator: P16C / BBR84, Bandar Bukit Raja, Klang, Selangor. 4. GeneratorRafee Pie100% (3)

- Manual Book Microscope CX22 LEDDocument28 pagesManual Book Microscope CX22 LEDtomatNo ratings yet

- Spm-Jsea-001-Xii-2019 Pengangkatan Mash (Menggunakan Crane) Dari Low Boy Di Area Site Melak - GbuDocument3 pagesSpm-Jsea-001-Xii-2019 Pengangkatan Mash (Menggunakan Crane) Dari Low Boy Di Area Site Melak - GbuSPM GBU MelakNo ratings yet

- Job Safety and Environment Analysis: Remove Engine GraderDocument13 pagesJob Safety and Environment Analysis: Remove Engine GraderAhmad RozaliNo ratings yet

- JSA Operational of Generator Set TSKDocument3 pagesJSA Operational of Generator Set TSKrosli muhamadNo ratings yet

- PBSSFTJSA005-Work at HighDocument4 pagesPBSSFTJSA005-Work at HighHSE Pakubumi SemestaNo ratings yet

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie0% (1)

- PDF 6jsa of Batching Plant Installation - CompressDocument4 pagesPDF 6jsa of Batching Plant Installation - CompressRiandoNo ratings yet

- JSA (Job Safety Analysis) : PTW #: Job Supervisor: Site / Location: Date: Issued by Client: Job / Task DescriptionDocument3 pagesJSA (Job Safety Analysis) : PTW #: Job Supervisor: Site / Location: Date: Issued by Client: Job / Task DescriptionMeysam DoskiNo ratings yet

- RA-02 Formwork Sep 2020Document7 pagesRA-02 Formwork Sep 2020Martin Ewuradze-BassawNo ratings yet

- Hiradc - Hot WorkDocument4 pagesHiradc - Hot WorkAlieya MustafaNo ratings yet

- JSA - Job# 4518 Tank Erection - Docx Updated 15th Nov-2018Document20 pagesJSA - Job# 4518 Tank Erection - Docx Updated 15th Nov-2018ALWIN T RAJNo ratings yet

- Adjust Front Suspension Pos 2 DA 433Document4 pagesAdjust Front Suspension Pos 2 DA 433kurniarung oceandaNo ratings yet

- 26 - Welding WorksDocument1 page26 - Welding WorksRafee Pie100% (1)

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument3 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- Sistema de Integrado de Gestión La Joya Mining S.A.CDocument7 pagesSistema de Integrado de Gestión La Joya Mining S.A.CÁngel Motta MedinaNo ratings yet

- Job Safety Environment Analysis: Las Cair Busur GasDocument8 pagesJob Safety Environment Analysis: Las Cair Busur GasjenggotNo ratings yet

- Job Safety and Environment Analysis: Project: Location of WorkDocument1 pageJob Safety and Environment Analysis: Project: Location of WorkTofan Fauzi SulistionoNo ratings yet

- 01 SMART Erecting Scaffolding RADocument4 pages01 SMART Erecting Scaffolding RAmaumelarofhiNo ratings yet

- Jsea For Assemble and Disassemble of Hydra EngineDocument14 pagesJsea For Assemble and Disassemble of Hydra EngineMD AbdullahNo ratings yet

- Mini Hi-Fi System: Service ManualDocument65 pagesMini Hi-Fi System: Service ManualFelipeNo ratings yet

- Risk Assessment SheetDocument4 pagesRisk Assessment Sheetfuturecolor7No ratings yet

- Appendix E1 - HSE Minimum Design RequirementsDocument42 pagesAppendix E1 - HSE Minimum Design RequirementsRaymond SmithNo ratings yet

- JSA Piping FabricationDocument8 pagesJSA Piping FabricationArib RahmanNo ratings yet

- HIRARC-MFG-36 Cleaning Raw Mill 2 Inlet Chute BlockageDocument2 pagesHIRARC-MFG-36 Cleaning Raw Mill 2 Inlet Chute Blockagekhairul japriNo ratings yet

- 1 JSA Pemasangan DuctingDocument4 pages1 JSA Pemasangan Ductingfitri widya100% (1)

- Jsa For Dismentaling Lift - BalcoDocument44 pagesJsa For Dismentaling Lift - BalcoShivam MishraNo ratings yet

- PDF Gi 0002721 2016 Arc Flash CompressDocument23 pagesPDF Gi 0002721 2016 Arc Flash CompressMark DingalNo ratings yet

- Cover 5W1H SheetDocument1 pageCover 5W1H Sheetpurchase.electricals2No ratings yet

- 02 - JSA CAR-002 Electrical, Mechanical (Revised)Document8 pages02 - JSA CAR-002 Electrical, Mechanical (Revised)rigig007No ratings yet

- Kioti Daedong DK752C, DK902C Tractors Service ManualDocument19 pagesKioti Daedong DK752C, DK902C Tractors Service ManualLisakolyNo ratings yet

- JSA HOLCIM Gudang ClinkerDocument6 pagesJSA HOLCIM Gudang ClinkerAji MargoyesNo ratings yet

- 73 53HP SMDocument95 pages73 53HP SMpellboyzpowersportsNo ratings yet

- Job Safety & Environmental Analysis (Jsea) : Schlumberger CTSDocument4 pagesJob Safety & Environmental Analysis (Jsea) : Schlumberger CTShans vatriolisNo ratings yet

- BMW Workshop Installation Instructions - Brake Lever Machined - 06.2016Document5 pagesBMW Workshop Installation Instructions - Brake Lever Machined - 06.2016aviaqualNo ratings yet

- Jsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000Document12 pagesJsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000thennarasuNo ratings yet

- Stock Level Change RequestDocument2 pagesStock Level Change RequestPatrick HillmanNo ratings yet

- RA-PROD-013-GALLAF - Hotwork Marking, Cutting, Fit Up On The Rotator MachineDocument8 pagesRA-PROD-013-GALLAF - Hotwork Marking, Cutting, Fit Up On The Rotator MachineidrisNo ratings yet

- Ra - MC 9 Kiln RepairDocument4 pagesRa - MC 9 Kiln RepairalbinkhanNo ratings yet

- Lube Oil Console Functional Test ProcedureDocument10 pagesLube Oil Console Functional Test Proceduremohamedsaib438No ratings yet

- Item 311 UBI Angel RegionDocument11 pagesItem 311 UBI Angel RegionFil Conol iiiNo ratings yet

- Int FMECA For MFBE-04 Powder Escape IncidentDocument11 pagesInt FMECA For MFBE-04 Powder Escape Incidentq6xx8tdfw9No ratings yet

- 3954-009-JSA-NDT Rev 0Document3 pages3954-009-JSA-NDT Rev 0Viron BaxhiaNo ratings yet

- Super Power Mini Hi-Fi System: Service ManualDocument89 pagesSuper Power Mini Hi-Fi System: Service Manualalfredo moreraNo ratings yet

- Rekayasa Industri: Daftar IsiDocument13 pagesRekayasa Industri: Daftar IsiArieNo ratings yet

- Sop-4 Jsa & TraDocument15 pagesSop-4 Jsa & TraArieNo ratings yet

- Jsa EXCAVATIONDocument4 pagesJsa EXCAVATIONHSE Pakubumi SemestaNo ratings yet

- Jsa Hot WorkDocument4 pagesJsa Hot WorkAW ChannelNo ratings yet

- Commissioning: SAIS Information For BuffersDocument16 pagesCommissioning: SAIS Information For BuffersAli DiabNo ratings yet

- 8900 Laser Imager: Kodak DryviewDocument7 pages8900 Laser Imager: Kodak DryviewMario RamosNo ratings yet

- 10 JSA - Cable Drums InstallationsDocument6 pages10 JSA - Cable Drums Installationssyed khaja misbhuddinNo ratings yet

- Publication Part No. 63 n432Document382 pagesPublication Part No. 63 n432jhon aguileraNo ratings yet

- 3954-011a-JSA-Field Joint Coating Rev 1Document3 pages3954-011a-JSA-Field Joint Coating Rev 1CaminBonNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- 28 - Sewerage WorksDocument1 page28 - Sewerage WorksRafee PieNo ratings yet