Professional Documents

Culture Documents

72 NBR 902-En

72 NBR 902-En

Uploaded by

Ayman RiyadhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

72 NBR 902-En

72 NBR 902-En

Uploaded by

Ayman RiyadhCopyright:

Available Formats

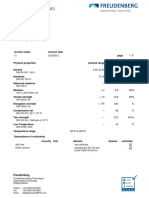

Material

72 NBR 902

blue

cross linking: sulfur

revision index revision date

8 4/13/2015 page 1/3

Physical properties required actual

Density 1.43 ±0.02 1.43 g/cm³

DIN EN ISO 1183-1

Hardness 75 ±5 75 Shore

DIN ISO 7619-1

Rebound resilence --- 26 %

DIN 53512

Modulus >4 7.2 MPa

100 %, DIN 53504, S2

Tensile strength > 10 13.8 MPa

DIN 53504, S2

Elongation at break > 300 360 %

DIN 53504, S2

Compression set < 40 30 %

DIN ISO 815, 22 h, 100 °C

Low Temperature --- -29 °C

ISO 11357-2, DSC

Certificates Country Part Remark Expires unlimited

ADI Free

RoHS 2015/863/EU and 2011/65/EU

Freudenberg

Freudenberg Sealing Technologies

Global Material Technology

Wolfgang Becker

Telefon: +49 (0)6201/80-2893

Fax: +49 (0)6201/88-2893

Email: wolfgang.becker@FST.com

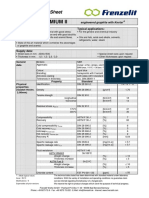

Material

72 NBR 902

blue

cross linking: sulfur

revision index revision date

8 4/13/2015 page 2/3

Tested after ASTM D 2000: M 2 BG 710 EA14 EF11 EF21 EO14 EO34 Z1

required actual

Hardness Shore 70 ±5 75

Tensile strength MPa min. 10 13.8

Elongation at break % min. 250 360

Change after aging in Air 70h/100°C

Hardness Shore A --- 4

Tensile strength % --- 10

Elongation at break % --- -11

EA14 Change after aging in Distilled water 70h/100°C

Hardness Shore A ±10 3

Volume % ±15 5

EF11 Change after aging in Fuel A 70h/23°C

Hardness Shore A ±10 -1

Tensile strength % -25 -5

Elongation at break % -25 -10

Volume % -5 to 10 2

EF21 Change after aging in Fuel B 70h/23°C

Hardness Shore A 0 to -30 -12

Tensile strength % -60 -28

Elongation at break % -60 -43

Volume % 0 to 40 28

EO14 Change after aging in IRM 901 70h/100°C

Hardness Shore A -5 to 10 5

Tensile strength % -25 9

Elongation at break % -45 -20

Volume % -10 to 5 -5

Freudenberg

Freudenberg Sealing Technologies

Global Material Technology

Wolfgang Becker

Telefon: +49 (0)6201/80-2893

Fax: +49 (0)6201/88-2893

Email: wolfgang.becker@FST.com

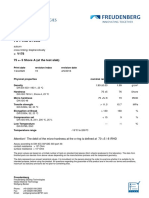

Material

72 NBR 902

blue

cross linking: sulfur

revision index revision date

8 4/13/2015 page 3/3

EO34 Change after aging in IRM 903 70h/100°C

Hardness Shore A -10 to 5 -3

Tensile strength % -45 -8

Elongation at break % -45 -18

Volume % 0 to 25 8

Z1 Low Temperature DIN 3761 Teil15 °C --- -29

Temperature-range: - 40 °C to 100 °C

Preferred area of applications: Radial Shaft Seals.

Very good resistance in motor oil based on mineral oil

Compliant with the EU-directives 2011/65/EC (RoHS) and 2002/95/EC (RoHS).

Attention!

In synthetic oils (polyalkylene-glycols / polyalphaolefins) please consider that the max. working

temperature mustn't exceed 80 °C

The given values are based on a limited number of tests on standard test pieces (2mm sheets) produced in the laboratory. The data from

finished parts can deviate from above values depending on the manufactories process and the component geometry.

The data represents our present empirical values. It is incumbent on the person placing the order to examine whether it is suitable for its

intended purpose, before using the product. All questions regarding the guarantee of this product are in line with our terms and conditions,

inasmuch as statutory provisons do not plan for something else.

Freudenberg

Freudenberg Sealing Technologies

Global Material Technology

Wolfgang Becker

Telefon: +49 (0)6201/80-2893

Fax: +49 (0)6201/88-2893

Email: wolfgang.becker@FST.com

You might also like

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- Material 72 NBR 872: Black Cross Linking: SulfurDocument3 pagesMaterial 72 NBR 872: Black Cross Linking: SulfurPhong DuongNo ratings yet

- 90 NBR 109-En - 1Document3 pages90 NBR 109-En - 1Pierre PescayNo ratings yet

- 90 NBR 109-En - 1Document3 pages90 NBR 109-En - 1ing.poliformasNo ratings yet

- Propriedades NBR 70 Shore ADocument3 pagesPropriedades NBR 70 Shore AGabriel NunesNo ratings yet

- 75 FKM 585-EnDocument3 pages75 FKM 585-EnantonioNo ratings yet

- 75 FKM 585Document3 pages75 FKM 585Victor CadilloNo ratings yet

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- 80 FKM 610-En - 1 - FREUNDENBERG - DIN 53765 - Dynamic - 25CDocument4 pages80 FKM 610-En - 1 - FREUNDENBERG - DIN 53765 - Dynamic - 25CgooogaNo ratings yet

- 75 FKM 153740-En - 1 - FREUNDENBERG - DIN 53765 - Dynamic - 25CDocument4 pages75 FKM 153740-En - 1 - FREUNDENBERG - DIN 53765 - Dynamic - 25CgooogaNo ratings yet

- Materialdatasheet 75 FKM 595 2Document3 pagesMaterialdatasheet 75 FKM 595 2Pillar ManufacturingNo ratings yet

- PU, Slicone, NBR SealDocument28 pagesPU, Slicone, NBR SealJirakom LimmongkolkulNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Megolon S540 PDFDocument2 pagesMegolon S540 PDFMuhammad Shabbir AwanNo ratings yet

- Asia Lanneret EPDM-2019Document2 pagesAsia Lanneret EPDM-2019Phung LucNo ratings yet

- Eva - RenewsysDocument1 pageEva - RenewsysShashwata ChattopadhyayNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- Abs-Hfa 70Document2 pagesAbs-Hfa 70mohamad mostafaviNo ratings yet

- TDS Co-3-X 27 03 2018 (003) - 1687274055Document2 pagesTDS Co-3-X 27 03 2018 (003) - 1687274055KSXNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- Abs 80Document2 pagesAbs 80mohamad mostafaviNo ratings yet

- Gac 250Document2 pagesGac 250mohamad mostafaviNo ratings yet

- XringDocument2 pagesXringJoão Pedro Marin De GodoiNo ratings yet

- Silicone Rubber Sheet (General Purpose, Solid)Document2 pagesSilicone Rubber Sheet (General Purpose, Solid)MohamedNo ratings yet

- Abs 10Document2 pagesAbs 10mohamad mostafaviNo ratings yet

- MFP MDS N6001 NB70Document1 pageMFP MDS N6001 NB70john garciaNo ratings yet

- Viton O Rings CommercialDocument1 pageViton O Rings CommercialErhanNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- FPM 001Document1 pageFPM 001Alberto RenauldNo ratings yet

- TP Wanhua Clarnate A1227 Vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNo ratings yet

- ECORUBBER1Document1 pageECORUBBER1Zoran BadurinaNo ratings yet

- Glass Filament Fabrics For Plastics Reinforcement: Product SpecificationDocument2 pagesGlass Filament Fabrics For Plastics Reinforcement: Product Specificationquyet ngoNo ratings yet

- Technical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VDocument1 pageTechnical Data of Adtech Fluoroplastic Polymers: Servicios E Importaciones Especializadas S.A. de C.VEdgar LucianoNo ratings yet

- Marco Material Datasheet B1105 PDFDocument2 pagesMarco Material Datasheet B1105 PDFAlaa SaadNo ratings yet

- EPDM SpecsDocument1 pageEPDM SpecsRosendo GarcíaNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Silicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)Document2 pagesSilicone Rubber Compounds, Curing Agent Dicumyl Peroxide, 40-75 Shore A, Q, Peroxide Cure (M 608 - 5 DCP)sunitaNo ratings yet

- NBR 60.10-01Document1 pageNBR 60.10-01UcokNo ratings yet

- Abs 60Document2 pagesAbs 60mohamad mostafaviNo ratings yet

- Abs 65Document2 pagesAbs 65mohamad mostafaviNo ratings yet

- FST - 70 FKM 37508 enDocument2 pagesFST - 70 FKM 37508 enXavierNo ratings yet

- PTFE-Grease K 7132Document1 pagePTFE-Grease K 7132statisticssalesNo ratings yet

- First POE - TF4 TF8Document6 pagesFirst POE - TF4 TF8Shashwata ChattopadhyayNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- Manual Tecnico de Tuberias de PVC y CPVC-GFDocument48 pagesManual Tecnico de Tuberias de PVC y CPVC-GFluis claudio c, vieiraNo ratings yet

- PVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10Document1 pagePVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10JorgeLuisRiveraNo ratings yet

- Acoustic Teardrop Seal - TRD 1944Document3 pagesAcoustic Teardrop Seal - TRD 1944billionthfakeloginNo ratings yet

- Vampamid 6 0024 V0Document1 pageVampamid 6 0024 V0Plasticos CusenNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Zurcon Z80 PDFDocument1 pageZurcon Z80 PDFLuz SmithNo ratings yet

- GENERAL Properties of PTFEDocument1 pageGENERAL Properties of PTFEIvan GhidiniNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Manual Z Long Life 75W80 TDSDocument2 pagesManual Z Long Life 75W80 TDSVusal HasanovNo ratings yet

- Marco Material Datasheet M1002Document2 pagesMarco Material Datasheet M1002Chang MikeNo ratings yet

- 01.03.03.101 Spesifikasi-BPM HDPE SmoothDocument1 page01.03.03.101 Spesifikasi-BPM HDPE SmoothRezky BaskoroNo ratings yet

- Dermatology Last Rounds Word Exams 2008 CompinedDocument29 pagesDermatology Last Rounds Word Exams 2008 CompinedAyman RiyadhNo ratings yet

- 2015 DG Charger SP 4 23Document9 pages2015 DG Charger SP 4 23Ayman RiyadhNo ratings yet

- MCQ Derma Sewilam منفصله.WhiteKnightLoveDocument6 pagesMCQ Derma Sewilam منفصله.WhiteKnightLoveAyman RiyadhNo ratings yet

- Series 2000: Pneumatic Diaphragm ActuatorDocument10 pagesSeries 2000: Pneumatic Diaphragm ActuatorAyman RiyadhNo ratings yet

- Dermatology MCQ DR - Swelam - WhiteKnightLoveDocument6 pagesDermatology MCQ DR - Swelam - WhiteKnightLoveAyman RiyadhNo ratings yet

- 350 Firmware USB Update Guide-01-16Document2 pages350 Firmware USB Update Guide-01-16Ayman RiyadhNo ratings yet

- Important Safety Recall: Front Propeller Shaft BoltsDocument2 pagesImportant Safety Recall: Front Propeller Shaft BoltsAyman RiyadhNo ratings yet

- Processes: Numerical Study On Separation Performance of Cyclone Flue Used in Grate Waste IncineratorDocument15 pagesProcesses: Numerical Study On Separation Performance of Cyclone Flue Used in Grate Waste IncineratorAyman RiyadhNo ratings yet

- Compute Sums With Summation Notation: N N N I N N N N I N IDocument2 pagesCompute Sums With Summation Notation: N N N I N N N N I N IAyman RiyadhNo ratings yet

- Investigation Towards The Efficiency of A Multi-Cyclone Dust Separator in Biomass CombustionDocument59 pagesInvestigation Towards The Efficiency of A Multi-Cyclone Dust Separator in Biomass CombustionAyman RiyadhNo ratings yet

- Knife Gate Valve: Product DescriptionDocument2 pagesKnife Gate Valve: Product DescriptionAyman RiyadhNo ratings yet

- Sewer Siphon Assessment and Air Jumper Design: WEFTEC®.06Document24 pagesSewer Siphon Assessment and Air Jumper Design: WEFTEC®.06Ayman RiyadhNo ratings yet

- Important Emissions Recall: UB4 Evaporative Emissions CanisterDocument2 pagesImportant Emissions Recall: UB4 Evaporative Emissions CanisterAyman RiyadhNo ratings yet

- Ad81df29 5c06 48Document9 pagesAd81df29 5c06 48Ayman RiyadhNo ratings yet

- Processes: Numerical Study On Separation Performance of Cyclone Flue Used in Grate Waste IncineratorDocument15 pagesProcesses: Numerical Study On Separation Performance of Cyclone Flue Used in Grate Waste IncineratorAyman RiyadhNo ratings yet

- Important Safety Recall: U60 NHTSA 18V-332 Reprogram Powertrain Control ModuleDocument2 pagesImportant Safety Recall: U60 NHTSA 18V-332 Reprogram Powertrain Control ModuleAyman RiyadhNo ratings yet

- CVJ 26054757 20190924210440Document4 pagesCVJ 26054757 20190924210440Ayman RiyadhNo ratings yet

- Engineering, Procurement, and Construction (EPC) Contracts Are The Most Common Form ofDocument1 pageEngineering, Procurement, and Construction (EPC) Contracts Are The Most Common Form ofAyman RiyadhNo ratings yet

- Chrysler 300, 300C, 300 Touring Sedans and Dodge Magnum Body Repair ManualDocument11 pagesChrysler 300, 300C, 300 Touring Sedans and Dodge Magnum Body Repair ManualAyman RiyadhNo ratings yet