Professional Documents

Culture Documents

Shear Lag Factors For Connections To Tension Members

Shear Lag Factors For Connections To Tension Members

Uploaded by

Aljon Maglalang JimenezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shear Lag Factors For Connections To Tension Members

Shear Lag Factors For Connections To Tension Members

Uploaded by

Aljon Maglalang JimenezCopyright:

Available Formats

16.1 –28 BUILT-UP MEMBERS [Sect. D4.

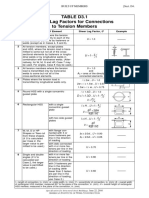

TABLE D3.1

Shear Lag Factors for Connections

to Tension Members

Case Description of Element Shear Lag Factor, U Example

1 All tension members where the tension

load is transmitted directly to each of the U = 1.0

cross-sectional elements by fasteners or

welds (except as in Cases 4, 5 and 6).

2 All tension members, except plates

and HSS, where the tension load is trans-

mitted to some but not all of the cross-

sectional elements by fasteners or longitu- U = 1− x l

dinal welds or by longitudinal welds in

combination with transverse welds. (Alter-

natively, for W, M, S and HP, Case 7 may

be used. For angles, Case 8 may be used.)

3 All tension members where the tension U = 1.0

load is transmitted only by transverse and

welds to some but not all of the An = area of the directly

cross-sectional elements. connected elements

4 Plates where the tension load is / ≥ 2w…U = 1.0

transmitted by longitudinal welds only.

2w > / ≥ 1.5w…U = 0.87

1.5w > / ≥ w…U = 0.75

5 Round HSS with a single concentric / ≥ 1.3D…U = 1.0

gusset plate

D ≤ l < 1.3D …U = 1− x l

x =D π

6 Rectangular HSS with a single l ≥ H …U = 1− x l

concentric gusset

plate 2

x = B + 2BH

4(B + H )

with two side gusset l ≥ H …U = 1− x l

plates

2

x= B

4(B + H )

7 W, M, S or HP with flange con-

Shapes or Tees cut nected with 3 or bf ≥ 2/3d…U = 0.90

from these shapes. more fasteners per

(If U is calculated line in the direction bf < 2/3d…U = 0.85

per Case 2, the of loading

larger value is per- with web connected

mitted to be used.) with 4 or more fas- U = 0.70

teners per line in the

direction of loading

8 Single and double with 4 or more fas-

angles (If U is teners per line in the U = 0.80

calculated per direction of loading

Case 2, the larger with 3 fasteners per

value is permitted line in the direction

to be used.) of loading (With

fewer than 3 fasten- U = 0.60

ers per line in the

direction of loading,

use Case 2.)

l = length of connection, in. (mm); w = plate width, in. (mm); x– = eccentricity of connection, in. (mm); B = overall width

of rectangular HSS member, measured 90° to the plane of the connection, in. (mm); H = overall height of rectangular

HSS member, measured in the plane of the connection, in. (mm)

Specification for Structural Steel Buildings, June 22, 2010

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

You might also like

- Table 204-1 Minimum Densities For Design Loads From Materials (KN/M) Material Density Material DensityDocument3 pagesTable 204-1 Minimum Densities For Design Loads From Materials (KN/M) Material Density Material DensityJhondy TibubosNo ratings yet

- Table D3.1 Shear Lag Factors For Connections To Tension MembersDocument7 pagesTable D3.1 Shear Lag Factors For Connections To Tension MembersalexNo ratings yet

- Reinforced and Prestressed Concrete DesignDocument24 pagesReinforced and Prestressed Concrete DesignJoshua John JulioNo ratings yet

- 1B. - Tension Members Ce134p - Escruz - LRFDDocument43 pages1B. - Tension Members Ce134p - Escruz - LRFDJed CernechezNo ratings yet

- Solutions Act. 2-Structural TheoryDocument3 pagesSolutions Act. 2-Structural TheoryChuckie EntocNo ratings yet

- Time-Scaled Network and Manpower LevelingDocument11 pagesTime-Scaled Network and Manpower LevelingRuel ElidoNo ratings yet

- Chapter 1: Appropriate Selection of Interior and Exterior Constuction MaterialsDocument5 pagesChapter 1: Appropriate Selection of Interior and Exterior Constuction MaterialsKris To PherNo ratings yet

- Module 1 Asst PDFDocument10 pagesModule 1 Asst PDFJay ReyesNo ratings yet

- Chapter 4 PDFDocument5 pagesChapter 4 PDFtrishia arcillaNo ratings yet

- Two Way SlabDocument19 pagesTwo Way SlabAllysa Joy MoralesNo ratings yet

- Doubly Reinforced Beams: F F F F C D CDocument17 pagesDoubly Reinforced Beams: F F F F C D CEly ReyesNo ratings yet

- Compression Members CE137-1 - ESCRUZDocument25 pagesCompression Members CE137-1 - ESCRUZNash GNo ratings yet

- Shear StrengthDocument17 pagesShear StrengthVon San Jose100% (1)

- MidTerm HydraulicsDocument8 pagesMidTerm HydraulicsFernan FalogmeNo ratings yet

- Timber Design Chapter 1Document10 pagesTimber Design Chapter 1Mac MacNo ratings yet

- Design and Analysis For ShearDocument20 pagesDesign and Analysis For Shearhonesto reynaNo ratings yet

- List of Symbols. ap Ca Cp Ct Cv Fp Ft hn I Na Nv R Rp S T V W Z Ωo ΔsDocument20 pagesList of Symbols. ap Ca Cp Ct Cv Fp Ft hn I Na Nv R Rp S T V W Z Ωo ΔsAnton_Young_1962No ratings yet

- Cap 8 Bending Strength of Compact and Noncompact ShapesDocument13 pagesCap 8 Bending Strength of Compact and Noncompact Shapescarlomonsalve1No ratings yet

- NSCP Code: Specificatio N ScoreDocument17 pagesNSCP Code: Specificatio N ScoreMarco SatomeraNo ratings yet

- Module 2 TranspoDocument95 pagesModule 2 TranspomarcusluismacusiNo ratings yet

- Prepared By: John Lloyd B. Agapito - 201610485Document13 pagesPrepared By: John Lloyd B. Agapito - 201610485John Lloyd AgapitoNo ratings yet

- IM BSCE 4 - Steel Design Part 1Document86 pagesIM BSCE 4 - Steel Design Part 1acurvz2005No ratings yet

- CE ProblemDocument5 pagesCE ProblemJho FNo ratings yet

- M05 - SEC 5 Solution (131331) For FB PostingDocument11 pagesM05 - SEC 5 Solution (131331) For FB PostingRimar LiguanNo ratings yet

- RCD Chapter 3Document58 pagesRCD Chapter 3jereck loquisoNo ratings yet

- RCDDocument17 pagesRCDKim GabaynoNo ratings yet

- Lesson 3 Analysis & Design of Singly Reinforced Beams PDFDocument18 pagesLesson 3 Analysis & Design of Singly Reinforced Beams PDFrose ann claveriaNo ratings yet

- Cepe2s - 4B - Assignment 1-M Ken Marco C. SalipsipDocument2 pagesCepe2s - 4B - Assignment 1-M Ken Marco C. SalipsipKen Marco SalipsipNo ratings yet

- Cengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Document9 pagesCengr 520 - Steel Design & Cengr3220 - Timber & Steel Design - 03192021 - 1Benjamin EngelNo ratings yet

- Hydraulics 2: Polytechnic University of The PhilippinesDocument83 pagesHydraulics 2: Polytechnic University of The Philippinesacurvz2005No ratings yet

- Soil - Chapter 1 Summary and ReviewerDocument2 pagesSoil - Chapter 1 Summary and ReviewerRene RaynesNo ratings yet

- Consultation Research Investigation and ReportsDocument3 pagesConsultation Research Investigation and ReportsCha PaineNo ratings yet

- Required Steel Area: Situation I: SolutionDocument5 pagesRequired Steel Area: Situation I: Solutionmike reyesNo ratings yet

- Design of Square Footing (With or Without Moment)Document13 pagesDesign of Square Footing (With or Without Moment)Ella Clent moralesNo ratings yet

- Module 5 Structural Steel Design 1Document19 pagesModule 5 Structural Steel Design 1Rich Lenard L. MagbooNo ratings yet

- CE 314 AssignmentDocument6 pagesCE 314 AssignmentMathew YukaNo ratings yet

- Lecture 3.a Analysis and Design of One-Way SlabDocument50 pagesLecture 3.a Analysis and Design of One-Way SlabMary Dominique OnateNo ratings yet

- Constructing The RoadbedDocument15 pagesConstructing The RoadbedMoira Santos100% (1)

- Chapter II Strain 2.7Document4 pagesChapter II Strain 2.7Joshua John JulioNo ratings yet

- Kraft Paper Sandwiched Between Steel Fiber Reinforced Concrete For CeilingDocument26 pagesKraft Paper Sandwiched Between Steel Fiber Reinforced Concrete For CeilingDan Alfred BaleñaNo ratings yet

- Ce 135 Problem Set 1Document3 pagesCe 135 Problem Set 1johannes100% (1)

- Module1 IntroductionDocument13 pagesModule1 Introductionmarlo ignacioNo ratings yet

- Reinforced Concrete Midterm Exam AnskeyDocument4 pagesReinforced Concrete Midterm Exam AnskeyAngelito AngelesNo ratings yet

- 3rd Plate SampleDocument39 pages3rd Plate SampleJhunel Ivan Goyena100% (1)

- Pile Foundation HandoutsDocument21 pagesPile Foundation HandoutsChristian BausoNo ratings yet

- Table 2-1. Allowable Stress On Fasteners, Mpa: G V E, IDocument4 pagesTable 2-1. Allowable Stress On Fasteners, Mpa: G V E, ILouie Jay CabunocNo ratings yet

- Plate No.5 - Autor, Joy - STEELDocument10 pagesPlate No.5 - Autor, Joy - STEELJoy lauria100% (1)

- Steel Design Problem SetxzDocument35 pagesSteel Design Problem SetxzMiah N. PascualNo ratings yet

- Aci 211 - 1 - 91Document35 pagesAci 211 - 1 - 91teresapulga6No ratings yet

- Timber Activity Prob 1 N 2Document8 pagesTimber Activity Prob 1 N 2Wico MalaladNo ratings yet

- Geotechnical Engineering 1 Problem #1Document4 pagesGeotechnical Engineering 1 Problem #1Muhammad BasitNo ratings yet

- Tabla D3 Coeficiente UDocument1 pageTabla D3 Coeficiente UCarlos SalgadoNo ratings yet

- Tabla D3 - 1Document1 pageTabla D3 - 1cristianNo ratings yet

- Factor UDocument1 pageFactor UseaedoNo ratings yet

- Tension MemberDocument75 pagesTension Memberalan saeed AbdulrahmanNo ratings yet

- Mechanics of SolidsDocument10 pagesMechanics of SolidsAnshuman SinghNo ratings yet

- Tensio Member Part-1Document14 pagesTensio Member Part-1syed muneeb haiderNo ratings yet

- Shear Lag FactorDocument12 pagesShear Lag FactorLarissa RiveraNo ratings yet

- Bending of Plates A StudyDocument2 pagesBending of Plates A Studyadit.shet23No ratings yet

- Green's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)From EverandGreen's Function Estimates for Lattice Schrödinger Operators and Applications. (AM-158)No ratings yet

- CE 552 Lecture 1Document31 pagesCE 552 Lecture 1Aljon Maglalang JimenezNo ratings yet

- Limiting Width Ratio of Compression Elements Under FlexureDocument1 pageLimiting Width Ratio of Compression Elements Under FlexureAljon Maglalang JimenezNo ratings yet

- Shear Lag Factors For Connections To Tension MembersDocument1 pageShear Lag Factors For Connections To Tension MembersAljon Maglalang JimenezNo ratings yet

- W SectionDocument47 pagesW SectionAljon Maglalang JimenezNo ratings yet