Professional Documents

Culture Documents

Part 3 - Template 1 - Planning Job

Part 3 - Template 1 - Planning Job

Uploaded by

Tamer EmamCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Belt Conveyor Design-DunlopDocument161 pagesBelt Conveyor Design-Dunlopadi_ganteng12100% (36)

- H20 U20 BrochureDocument4 pagesH20 U20 BrochureTamer EmamNo ratings yet

- Belt Failure AnalysisDocument4 pagesBelt Failure AnalysisTamer EmamNo ratings yet

- BB-TSS-TFS-BR Series CAM Clutch - Catalogue PDFDocument8 pagesBB-TSS-TFS-BR Series CAM Clutch - Catalogue PDFTamer EmamNo ratings yet

- Sidewall Splicing MechanicalDocument11 pagesSidewall Splicing MechanicalTamer EmamNo ratings yet

- Company Brochure GB 8 - 2014 LRDocument6 pagesCompany Brochure GB 8 - 2014 LRTamer EmamNo ratings yet

- Optalign Plus - Alignment StepsDocument2 pagesOptalign Plus - Alignment StepsTamer EmamNo ratings yet

- Diagnosing Misalignment: Vibration AnalysisDocument5 pagesDiagnosing Misalignment: Vibration AnalysisTamer Emam100% (1)

- Base Plate GroutingDocument2 pagesBase Plate GroutingTamer EmamNo ratings yet

- Horizontal Driver Movement Positive (+) Left Negative (-) RightDocument2 pagesHorizontal Driver Movement Positive (+) Left Negative (-) RightTamer EmamNo ratings yet

- 1 6Document22 pages1 6Tamer EmamNo ratings yet

- Optalign Plus HandbookDocument65 pagesOptalign Plus HandbookTamer Emam67% (3)

Part 3 - Template 1 - Planning Job

Part 3 - Template 1 - Planning Job

Uploaded by

Tamer EmamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part 3 - Template 1 - Planning Job

Part 3 - Template 1 - Planning Job

Uploaded by

Tamer EmamCopyright:

Available Formats

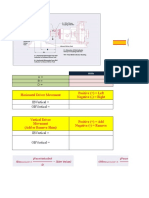

Work Management: Planning and Scheduling 103

Typical Job Template forPlanning a

Maintenance Work (Example)

Work Order Requirement: Replace Electric Motor (10 HP)

Job Time Standard: 2 hours - duration 4 Man-hours (2

craft person x 2 hour)

Multi-craft technician or Electrician

Craft Type:

Parts Required: Part# 11111 Motor, Electric; Location: 22-11-XX

Optional Parts:

(These parts are not required but could be needed if they are worn out)

Part# 2222 Coupling, Flex; Location: 11-00-YY

Part# 3311 Bolts, Coupling (9-16 x 3); Location: Free Bin, Shop

Special Tools: None

Procedure:

Step 1: Lock out / tag out (see attached procedure for details).

Step 2: Disconnect motor, mark/label wires.

Step 3: Unbolt coupling, inspect coupling and remove motor bolts.

Step 4: Remove motor using jib crane available.

Step 5: Install new motor (check motor is rotating freely).

Step 6: Bolt motor and check for soft foot. – record and correct any soft

foot findings.

Step 7: Install coupling, bolt motor (torque bolts to xx ft. lbs) and align them

using dial gauge or laser within acceptable range +/- 0.xxx (organiza-

tion standard).

Step 8: Remove lock out / tag out.

Step 9: Connect the motor and check for right rotation.

Step 10: Test run.

Step 11: Clean up and return asset to service.

Step 12: Close out the work order in CMMS detailing what was done.

Figure 4.7 A Planned Job Template

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Belt Conveyor Design-DunlopDocument161 pagesBelt Conveyor Design-Dunlopadi_ganteng12100% (36)

- H20 U20 BrochureDocument4 pagesH20 U20 BrochureTamer EmamNo ratings yet

- Belt Failure AnalysisDocument4 pagesBelt Failure AnalysisTamer EmamNo ratings yet

- BB-TSS-TFS-BR Series CAM Clutch - Catalogue PDFDocument8 pagesBB-TSS-TFS-BR Series CAM Clutch - Catalogue PDFTamer EmamNo ratings yet

- Sidewall Splicing MechanicalDocument11 pagesSidewall Splicing MechanicalTamer EmamNo ratings yet

- Company Brochure GB 8 - 2014 LRDocument6 pagesCompany Brochure GB 8 - 2014 LRTamer EmamNo ratings yet

- Optalign Plus - Alignment StepsDocument2 pagesOptalign Plus - Alignment StepsTamer EmamNo ratings yet

- Diagnosing Misalignment: Vibration AnalysisDocument5 pagesDiagnosing Misalignment: Vibration AnalysisTamer Emam100% (1)

- Base Plate GroutingDocument2 pagesBase Plate GroutingTamer EmamNo ratings yet

- Horizontal Driver Movement Positive (+) Left Negative (-) RightDocument2 pagesHorizontal Driver Movement Positive (+) Left Negative (-) RightTamer EmamNo ratings yet

- 1 6Document22 pages1 6Tamer EmamNo ratings yet

- Optalign Plus HandbookDocument65 pagesOptalign Plus HandbookTamer Emam67% (3)