Professional Documents

Culture Documents

Specification For Insole

Specification For Insole

Uploaded by

abdurazak0 ratings0% found this document useful (0 votes)

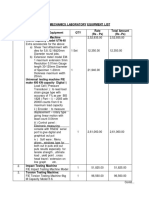

48 views2 pagesThe document outlines specifications for various components of shoes including insoles, stiffeners, threads, soles, and laces. Specifications include requirements for flexing, tensile strength, scuff resistance, laminar strength, bond ability, shape stability, shrinking, breaking load, tex value, tenacity, abrasion resistance, color fastness, hardness, density, elongation, flexing endurance, and abrasion resistance. Tests are to be conducted using equipment such as flexing machines, tensile testers, abrasion testers, and durometer according to defined minimum or maximum requirements.

Original Description:

Original Title

Specification for Insole

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines specifications for various components of shoes including insoles, stiffeners, threads, soles, and laces. Specifications include requirements for flexing, tensile strength, scuff resistance, laminar strength, bond ability, shape stability, shrinking, breaking load, tex value, tenacity, abrasion resistance, color fastness, hardness, density, elongation, flexing endurance, and abrasion resistance. Tests are to be conducted using equipment such as flexing machines, tensile testers, abrasion testers, and durometer according to defined minimum or maximum requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

48 views2 pagesSpecification For Insole

Specification For Insole

Uploaded by

abdurazakThe document outlines specifications for various components of shoes including insoles, stiffeners, threads, soles, and laces. Specifications include requirements for flexing, tensile strength, scuff resistance, laminar strength, bond ability, shape stability, shrinking, breaking load, tex value, tenacity, abrasion resistance, color fastness, hardness, density, elongation, flexing endurance, and abrasion resistance. Tests are to be conducted using equipment such as flexing machines, tensile testers, abrasion testers, and durometer according to defined minimum or maximum requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

1.

6 Specification for Insole

Test Equipment/M/Cs Requirement

Flexing Fiber board flexing 2.7 (min) for cellulose board

Machine

Tensile strength Tensile testing machine 40 (min) for light wear

Kg/cm2 (wet)

Scuff resistance SATRA rub fastness tester 0.10 (min) for light in

Vol. loss in cm3 expensive wear

Laminar strength in kg/cm2 Tensile testing machine 3.0 (min)

1.7 Specification for Stiffeners

Test Equipment/M/Cs Requirement

Bond ability Tensile testing machine 5-10 N/cm

Shape stability Dome plastimeter >9Q%

Dome collapsing load Tensile tester 40 N (min)

Shrinkage Ovens 2% max

1.8 Specifications for Threads

Test Equipment/M/Cs Requirement

Breaking load and extension at break Tensile Tester 34-40 for 40/3

25-30 for 60/3

Tex Value For 60 – 55For 40 - 83

Tenacity >42Km

Abrasion resistance Abrasion Tester 1000 – 3000 cycles

Colour fastness Visual

Fastness of colour to abrasion Bally Finish Tester Visual

Colour bleeding Visual

1.9 Specification for Soles (Pu)

Hardness (IRHD) shore A durometer 60-80

Density (g/cm3) Analytical balance 1.20-1.27

Tensile Strength (kg/cm2) Tensile tester 140 (max)

% Elongation at break Tensile Tester 300 (min)

Flexing Endurance Ross Flexing machine 3 (max)

(Ross) (mm cut

growth after 60,000

cycles)

Abrasion DIN Abrasion Tester 150 (max) for heavy

resistance duty

(mm3 loss)

1.10 Specifications for Laces

Tensile Strength in N/lace Tensile Tester >200 for normal shoes

>500 for work shoes

% Elongation at break Tensile Tester 25-30

Abrasion resistance PFI-Lace >3000 for casual wear

Abrasion tester 5000 for day to day wear

Attachment of bodkin Tensile Tester >150

Strength (N/lace)

Colour fastness Visual

You might also like

- Technical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaDocument2 pagesTechnical Data Sheet Nonwoven Polyester (Pet) : Pt. Hilon IndonesiaG Nurhidayat ANo ratings yet

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Common Testing List MKRM CompactDocument4 pagesCommon Testing List MKRM CompactM Ry ZealNo ratings yet

- 2.21.1 Neoprene Rubber Sheeting Flame Retardant TCDocument1 page2.21.1 Neoprene Rubber Sheeting Flame Retardant TCFerianto STNo ratings yet

- KT697 Bereau Veritas CPS Korea Limited Eng v1Document25 pagesKT697 Bereau Veritas CPS Korea Limited Eng v1Yassine BeroualNo ratings yet

- 718 Stangard Egf (NV)Document5 pages718 Stangard Egf (NV)Sandeep gangulyNo ratings yet

- Welding Inspection: Mechanical Testing Course Reference WIS 5Document47 pagesWelding Inspection: Mechanical Testing Course Reference WIS 5Joerge Ryan MaramotNo ratings yet

- S.No. Product / Material of Test Specific Test Performed Test Method Specification Against Which Tests Are Performed Range of Testing / Limits of DetectionDocument5 pagesS.No. Product / Material of Test Specific Test Performed Test Method Specification Against Which Tests Are Performed Range of Testing / Limits of DetectionashrafbookNo ratings yet

- Element Warren A2LA 0038 01 Mechanical PDFDocument21 pagesElement Warren A2LA 0038 01 Mechanical PDFAndre CasteloNo ratings yet

- Company Product SuciraDocument10 pagesCompany Product SuciraPejuang TPP Musola TajurNo ratings yet

- Polygomma EPDM Roofing Membrane CatalogueDocument4 pagesPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- For Solid Concrete Interlocking Paving UnitsDocument7 pagesFor Solid Concrete Interlocking Paving UnitsomerNo ratings yet

- Sikadur®-42 MP Slow - PDSDocument7 pagesSikadur®-42 MP Slow - PDSkamran abbasiNo ratings yet

- Testing Instruments For PVC IndustryDocument3 pagesTesting Instruments For PVC IndustryMuhammad AhmedNo ratings yet

- Steel: Nisco Wear Plate NM400Document2 pagesSteel: Nisco Wear Plate NM400Paolo Sebastián Bernal GómezNo ratings yet

- PETRONAS Slideway Series v2. 13 07 2016Document3 pagesPETRONAS Slideway Series v2. 13 07 2016Isay Quiroga VargasNo ratings yet

- Marine Upholstery SpecsDocument1 pageMarine Upholstery SpecsRezza KurniawanNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- School of Civil Engineering Engineering CampusDocument4 pagesSchool of Civil Engineering Engineering Campusekia_myNo ratings yet

- My FileDocument2 pagesMy FileSyed Umair RizviNo ratings yet

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- Proton PF-15Document1 pageProton PF-15HirenNo ratings yet

- Test Rate BUETDocument5 pagesTest Rate BUETEngr Swapan82% (11)

- Testing ParametersDocument13 pagesTesting ParametersSwaroopa Ravinder Goud100% (1)

- Powergrout-Ns3: High Performance Precision GroutDocument2 pagesPowergrout-Ns3: High Performance Precision GroutHemamathiNo ratings yet

- Surgical Gown EquipmentDocument5 pagesSurgical Gown EquipmentahmedNo ratings yet

- SpecificatiebladpdfDocument1 pageSpecificatiebladpdfThinh Tien NguyenNo ratings yet

- Kruss Techdata bp100 en PDFDocument4 pagesKruss Techdata bp100 en PDFTravis HNo ratings yet

- UHMWPE Catalog PDFDocument3 pagesUHMWPE Catalog PDFEmilio CastroNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- CTM PP TX 160 Technical Data SheetDocument2 pagesCTM PP TX 160 Technical Data SheetJeetendra SinghNo ratings yet

- GRI-GM30 Specification Coated Tape Polymeric BarriersDocument28 pagesGRI-GM30 Specification Coated Tape Polymeric BarriersГригорий ЛевашовNo ratings yet

- Element Warren A2LA 0038 01 MechanicalDocument21 pagesElement Warren A2LA 0038 01 MechanicalBau2NineNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- Properties Test Standard FIL B4-444 Spec Value ToleranceDocument2 pagesProperties Test Standard FIL B4-444 Spec Value ToleranceAnonymous MAQrYFQDzVNo ratings yet

- Civil Lab Equipment Details1Document17 pagesCivil Lab Equipment Details1ANKESH SHRIVASTAVANo ratings yet

- Types of Fabric TestingDocument2 pagesTypes of Fabric TestingFabric Club100% (1)

- 297Document4 pages297Durgesh TripathiNo ratings yet

- PROCUT enDocument1 pagePROCUT enNico SimarmataNo ratings yet

- Session 3 B - TestingDocument98 pagesSession 3 B - TestingYogesh SharmaNo ratings yet

- 10 Testing ScheduleDocument3 pages10 Testing ScheduleMAULIK RAVALNo ratings yet

- Certificado Calzados WorkerDocument2 pagesCertificado Calzados WorkerDANESSA CLARITA REYES ALIAGANo ratings yet

- PORON 4790-92-25041 P Extra SoftSlow ReboundSupportedDocument2 pagesPORON 4790-92-25041 P Extra SoftSlow ReboundSupportedkarpagsNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa Bhuvan100% (1)

- QAP Test Frequency CONCRETEDocument17 pagesQAP Test Frequency CONCRETEfevahe756No ratings yet

- LH 450 Ctte With OptionsDocument4 pagesLH 450 Ctte With OptionsJ.SathishNo ratings yet

- ZT Packaging Testing SolutionsDocument9 pagesZT Packaging Testing Solutionsayesha.tycoonNo ratings yet

- 1695309545tr 20Document1 page1695309545tr 20chinastatetiangbenderaNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- Test Frequency: (As Per Mort&H 5Th Revision)Document6 pagesTest Frequency: (As Per Mort&H 5Th Revision)jitendra dixitNo ratings yet

- ASTM 210cDocument1 pageASTM 210cDodi SuhendraNo ratings yet

- Abrasion Resistant Ceramic Rubber LaggingDocument1 pageAbrasion Resistant Ceramic Rubber LaggingMehmet TürkerNo ratings yet

- Neoweb Specification - October 2007 (EN) PDFDocument4 pagesNeoweb Specification - October 2007 (EN) PDFDiana Patricia Aponte LozanoNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- Silicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeDocument2 pagesSilicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeTran Tuan anhNo ratings yet

- Survey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Document4 pagesSurvey No:33/3A1B, 11th Main Road, Sidco Industrial Estate, Thirumudivakkam, Chennai - 600044Tumbin DilseNo ratings yet

- 403 Rev BDocument2 pages403 Rev BabdurazakNo ratings yet

- Static Analysis and Fatigue Life Prediction of Composite Leaf Springs of Automotive Suspension SystemDocument4 pagesStatic Analysis and Fatigue Life Prediction of Composite Leaf Springs of Automotive Suspension SystemabdurazakNo ratings yet

- Mechanical Characteristics and Analysis of Composite Leaf Spring Reinforced With AluminumDocument4 pagesMechanical Characteristics and Analysis of Composite Leaf Spring Reinforced With AluminumabdurazakNo ratings yet

- Trade of Tool MakingDocument14 pagesTrade of Tool MakingabdurazakNo ratings yet

- Entre. Group Assignment 2Document2 pagesEntre. Group Assignment 2abdurazakNo ratings yet