Professional Documents

Culture Documents

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Uploaded by

Guilherme Silveira Dos SantosCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rivet ID and NAS523 CodeDocument4 pagesRivet ID and NAS523 Codeslam12125100% (1)

- Sheffield Edge Tool MakersDocument48 pagesSheffield Edge Tool MakersnikkicluNo ratings yet

- ASTM A325 - Portland BoltDocument3 pagesASTM A325 - Portland BoltHector BalderaNo ratings yet

- Metals: Types of Metals AlloysDocument9 pagesMetals: Types of Metals AlloysIslam ElhabsheNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizesManvendra KumarNo ratings yet

- Gerb Formulas PDFDocument4 pagesGerb Formulas PDFMuthu KumarNo ratings yet

- Alloy Metals ResearchDocument6 pagesAlloy Metals Researchalnajdawisewar2No ratings yet

- L1 Introduction To Steel DesignDocument76 pagesL1 Introduction To Steel DesignLeah GotladeraNo ratings yet

- Minerals Assignment - EafDocument18 pagesMinerals Assignment - Eafbridget mutsutsururuNo ratings yet

- Robertsons Catalogue 2014 Section 04Document51 pagesRobertsons Catalogue 2014 Section 04Nader GhrabNo ratings yet

- When Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsDocument8 pagesWhen Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsErlanggaRizkiFauziNo ratings yet

- Key Dimensions of Circles: Circumference of Outside of TyreDocument8 pagesKey Dimensions of Circles: Circumference of Outside of TyreibouNo ratings yet

- QUIZ ONE AnswersDocument2 pagesQUIZ ONE AnswersNatinael WoldeNo ratings yet

- Self Machining STANDOFFDocument12 pagesSelf Machining STANDOFFaldiNo ratings yet

- CR-050219-B-35 # Swba10m24x60b # S14211-01-19Document1 pageCR-050219-B-35 # Swba10m24x60b # S14211-01-19qc_531040655No ratings yet

- Chromate Conversion Coatings and Their Current AppDocument5 pagesChromate Conversion Coatings and Their Current AppDeni HermawanNo ratings yet

- GXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Emmanuel Hernandez100% (1)

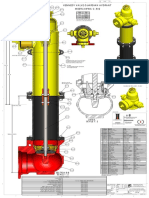

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- NEW!! Speed Tiger General Catalogue PDFDocument496 pagesNEW!! Speed Tiger General Catalogue PDFAarón MarxellyNo ratings yet

- S T A N D A R D: Metallic Element Heat-ConnectionDocument37 pagesS T A N D A R D: Metallic Element Heat-ConnectionRafa Lopez PuigdollersNo ratings yet

- Classification of SteelsDocument3 pagesClassification of SteelsHaider EjazNo ratings yet

- Gray Iron Castings For Elevated Temperatures For Non-Pressure Containing PartsDocument2 pagesGray Iron Castings For Elevated Temperatures For Non-Pressure Containing PartsfaroukNo ratings yet

- European Copper Institute European Copper Institute: Architectural ApplicationsDocument52 pagesEuropean Copper Institute European Copper Institute: Architectural ApplicationsstankoubNo ratings yet

- Unit 4-2-NonferrousDocument32 pagesUnit 4-2-NonferrousNisha JaiswalNo ratings yet

- Iron and SteelDocument6 pagesIron and SteelNur Annisa WulandariNo ratings yet

- Suction Strainer Boxes: Standard Specification ForDocument5 pagesSuction Strainer Boxes: Standard Specification ForEduardoNo ratings yet

- Kennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Document1 pageKennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Amjed HNo ratings yet

- F1852Document8 pagesF1852mrezaiNo ratings yet

- Formative Chem - The Reactivity SeriesDocument2 pagesFormative Chem - The Reactivity SeriesCaleb SodiiNo ratings yet

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Uploaded by

Guilherme Silveira Dos SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Tabela Desgastes - Tipos - Aplicacoes Pag 19

Uploaded by

Guilherme Silveira Dos SantosCopyright:

Available Formats

Classification by basic types Important features Successful appllications

Tungsten carbide deposits Maximum abrasion resistance Oil well rock drill bits and tool joints

Granules or inserts A wide range of severely abrasive

conditions

Coarse granule tube rods Worn surfaces become rough

Fine granule tube rods Best performance when gas welded

High chromium irons Excellent erosion resistance

Multiple alloy type Hot hardeness from 410-650°C (800- Abrasion by hot coke

1200°F) with W & Mo

Martensitic type Can be annealed and rehardened Erosion by 510°C (1000°F) catalysts in

refineries

Austenitic type Oxidation resistant Agricultural equipment in sandy soil

Martensitic alloy Irons Excellent abrasion resistance General abrasive conditions with light

impact

Chromium-tungsten type High compresive strength

Chromium-molybdenum type Good for light impact

Nickel-chromium type

Austenitic alloy Irons More crack-resistance than martensitic General erosion conditions with light

irons impact

Chromium-molybdenum type

Nickel-chromium type

Chromium-cobalt-tungsten-alloys Hot strength and creep resistance

High carbon (2,5%) type Brittle and abrasion-resistance Hot wear and abrasion above 650°C

(1200° F)

Medium carbon (1,4%) type

Low carbon (1,0%) type Tought and oxidation-resistance Exhaust valves of gasoline engines. Valve

trim of steam turbines

Nickel base alloys Good hot hardness and erosion-

resistance

Nickel-chromium-boron type Oil well slush pumps

Nickel-chromium-molybdenum- Corrosion resistance

tungsten type

Nickel-chromium-molybdenum Resistant to exhaust gás erosion Exaust valves of trucks, buses and aircraft

type

Nickel-chromium type Oxidation resistant

Copper base alloys Antiseizing: resistant to frictional wear Bearing surfaces

Martensitic steels General abrasive conditions with médium

impact

High carbon (0,65-1,7%) type Fair abrasion resistance

Medium carbon (0,30-0,65%) type Good resistance for medium impact Hot working dies

Low carbon (bellow 0,30%) type Tough, economical

Semiaustenitic steels Tough, crack resistant General low-cost hardfacing

Pearlitic steels Crack-resistant and low in cost Basic for surfacing or a buildup to restore

dimensions

Low alloy steels Suitable for building of worn areas

Simple carbon steel A good base for hardfacing

Austenitic steels Tough: excellent for heavy impact General metal-to-metal wear under heavy

impact

13% manganese-1% molybdenum Fair abrasion and erosion resistance Railway trackwork

type

13% manganese-3% nickel type Lower yield strenght

13% manganese-nickel-chromium High yield strength for austenitic types

type

High carbon nickel-chromium Oxidation and hot wear-resistant Frictional wear at red heat; furnace parts

stainless type

Low carbon nickel-chromium Oxidation and corrosion resistance Corrosion-resistant surfacing of large

stainless type tanks

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rivet ID and NAS523 CodeDocument4 pagesRivet ID and NAS523 Codeslam12125100% (1)

- Sheffield Edge Tool MakersDocument48 pagesSheffield Edge Tool MakersnikkicluNo ratings yet

- ASTM A325 - Portland BoltDocument3 pagesASTM A325 - Portland BoltHector BalderaNo ratings yet

- Metals: Types of Metals AlloysDocument9 pagesMetals: Types of Metals AlloysIslam ElhabsheNo ratings yet

- Tap Drill SizesDocument2 pagesTap Drill SizesManvendra KumarNo ratings yet

- Gerb Formulas PDFDocument4 pagesGerb Formulas PDFMuthu KumarNo ratings yet

- Alloy Metals ResearchDocument6 pagesAlloy Metals Researchalnajdawisewar2No ratings yet

- L1 Introduction To Steel DesignDocument76 pagesL1 Introduction To Steel DesignLeah GotladeraNo ratings yet

- Minerals Assignment - EafDocument18 pagesMinerals Assignment - Eafbridget mutsutsururuNo ratings yet

- Robertsons Catalogue 2014 Section 04Document51 pagesRobertsons Catalogue 2014 Section 04Nader GhrabNo ratings yet

- When Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsDocument8 pagesWhen Competence Counts.: Atmospheric Corrosion of Fastening and Installation SystemsErlanggaRizkiFauziNo ratings yet

- Key Dimensions of Circles: Circumference of Outside of TyreDocument8 pagesKey Dimensions of Circles: Circumference of Outside of TyreibouNo ratings yet

- QUIZ ONE AnswersDocument2 pagesQUIZ ONE AnswersNatinael WoldeNo ratings yet

- Self Machining STANDOFFDocument12 pagesSelf Machining STANDOFFaldiNo ratings yet

- CR-050219-B-35 # Swba10m24x60b # S14211-01-19Document1 pageCR-050219-B-35 # Swba10m24x60b # S14211-01-19qc_531040655No ratings yet

- Chromate Conversion Coatings and Their Current AppDocument5 pagesChromate Conversion Coatings and Their Current AppDeni HermawanNo ratings yet

- GXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Emmanuel Hernandez100% (1)

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- Spek Electoda Nikko CIN-1Document1 pageSpek Electoda Nikko CIN-1anon_962923083No ratings yet

- NEW!! Speed Tiger General Catalogue PDFDocument496 pagesNEW!! Speed Tiger General Catalogue PDFAarón MarxellyNo ratings yet

- S T A N D A R D: Metallic Element Heat-ConnectionDocument37 pagesS T A N D A R D: Metallic Element Heat-ConnectionRafa Lopez PuigdollersNo ratings yet

- Classification of SteelsDocument3 pagesClassification of SteelsHaider EjazNo ratings yet

- Gray Iron Castings For Elevated Temperatures For Non-Pressure Containing PartsDocument2 pagesGray Iron Castings For Elevated Temperatures For Non-Pressure Containing PartsfaroukNo ratings yet

- European Copper Institute European Copper Institute: Architectural ApplicationsDocument52 pagesEuropean Copper Institute European Copper Institute: Architectural ApplicationsstankoubNo ratings yet

- Unit 4-2-NonferrousDocument32 pagesUnit 4-2-NonferrousNisha JaiswalNo ratings yet

- Iron and SteelDocument6 pagesIron and SteelNur Annisa WulandariNo ratings yet

- Suction Strainer Boxes: Standard Specification ForDocument5 pagesSuction Strainer Boxes: Standard Specification ForEduardoNo ratings yet

- Kennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Document1 pageKennedy Valve Guardian Hydrant Meets Awwa C-502: Detail Scale 1: 2Amjed HNo ratings yet

- F1852Document8 pagesF1852mrezaiNo ratings yet

- Formative Chem - The Reactivity SeriesDocument2 pagesFormative Chem - The Reactivity SeriesCaleb SodiiNo ratings yet