Professional Documents

Culture Documents

MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDF

MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDF

Uploaded by

Lembang ApangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDF

MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDF

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE

or STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Glossary

Reference

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

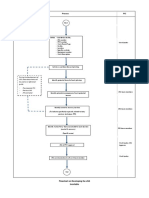

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 1 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 2 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been

approved.

Details must include revision number, description and indication of which pages and

paragraphs have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when

amendments/new revisions are received.

(2) For description of amendment the Document Holder should indicate

correction, modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified

with a lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 3 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

GLOSSARY

PCMS Process Control And Monitoring System

OWP Oily Water Pit

CCR Central Control Room

EOV Electric Operated Valve

YP Yield Product

DCS Distributed Control System

SFH Safe Filling High

SLPS Sea Loading Pumping Station

CIMAH Control of Industrial Major Accident Hazard

REFERENCE

DOC. NO TITLE

MY SKO O 07016 Rev.1 April 2010 MCOT Operating Procedures Manual

MCOT CIMAH Safety Report PCSB

MCOT CIMAH 2009 Rev 131109

SKO Rev. 0 November 2009

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 4 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE / PURPOSE ............................................................................................. 6

1.2 SCOPE .......................................................................................................................... 6

1.3 OP CATEGORY ............................................................................................................ 6

1.4 PREREQUISITES ......................................................................................................... 6

1.5 LIMITATIONS ................................................................................................................ 6

1.6 ROLES / RESPONSIBILITY. ........................................................................................ 6

1.7 HSE REQUIREMENTS ................................................................................................. 7

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 5 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE / PURPOSE

1.1.1 The operating procedure outlines the normal activities required to safely carrying out all

activities associated with Wet Tanks water and emulsion draining at MCOT.

1.2 SCOPE

1.2.1 The requirements in this procedure shall apply to;

• Wet tank preparation

• Water draining

• Emulsion draining

1.3 OP CATEGORY

Categories Normal / Start Up / Shutdown / Checklist Required: Yes / No

Emergency / Special / Temporary /

and attributes

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 MCOT Daily Tanks Status

1.4.2 Maintain radio communication with the CCR during draining operation

1.5 LIMITATIONS

1.5.1 N/A

1.6 ROLES / RESPONSIBILITY

1.6.1 Refer to Section 2: Procedure “Action party”.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 6 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

1.7 HSE REQUIREMENTS

Hazards and The table below lists job hazards and the precautions that should be taken for

precautions safety, environmental, quality, ergonomics, Good Manufacturing Practices,

etcI before beginning this procedure.

Hazard Precaution

Flammable No Hot Work within vicinity

PPE required The following Personnel Protection Equipment (PPE) must be used to do this

activity in addition to common PPEs. List any special PPEs required,

PPE Use

N/A

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

Valve wrench For valve opening

ESD / EOV valve interlocking activated

Interlocks

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 7 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Unit: Storage Tank Farm

Safe Operating Never Exceed Limit

SOL Excursions

Limit (mm) (mm)

Area: 2

Equipment Inst. Tag # H L HH LL Consequence of Deviation Corrective Actions

Control the level through diverting flow

TK-72 LT-7201 10250 600 10350 500 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-73 LT-7301 10270 600 10434 500 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-74 LT-7401 10250 600 10350 500 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-75 LT-7501 10230 600 10330 500 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-76 LT-7601 9840 980 10350 900 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-77 LT-7701 11994 800 12625 700 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-78 LT-7801 11900 800 12659 700 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-79 LT-7901 11840 1000 12601 900 Too high level will cause overflow

to other tanks

Control the level through diverting flow

TK-90 LT-9001 17320 600 17860 500 Too high level will cause overflow

to other tanks

NOTE: Only where applicable

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 8 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 PREPARATION........................................................................................................... 10

2.2 WATER DRAINING ..................................................................................................... 10

2.3 EMULSION DRAINING ............................................................................................... 11

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 9 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

2 PROCEDURE

2.1 PREPARATION

No. Action Action Party

2.1.1 Leave receiving wet tank after YP21 for 4 hours to allow for tank Panel man 1

settlement.

2.1.2 Check PCMS and ENTIS tank gauging display o n t h e t a nk l e v e l a n d Panel man 1

determine the water level and volume.

2.1.3 Check water level using ENTIS. Panel man 1

2.1.4 Check tank density profile using ENTIS to determine the emulsion level Panel man 1

and volume in tank.

2.1.5 Calculate the duration to drain the water and emulsion from the tank. Panel man 1

2.1.6 Fill up Tank Movement forms A7 and A8. Panel man 1

2.1.7 Update the MCOT Daily Tank Status. Shift

Production

Supervisor

NOTE:

• Tank will require longer settling time if there are poor crude, water

and emulsion separation from offshore fields.

2.1.8 Line-up tank water drain line to 16” header to Oily Water Pit (OWP). Area operator

Refer to Figure 1: Wet Tanks

2.1.9 Adjust OWP oil skimmers to skim position and check that the oily water Area operator

pumps and oil transfer pumps are operational.

2.2 WATER DRAINING

No. Action Action Party

2.2.1 Set level alarm on ENTIS to trigger at required level, in order to prevent over Panel man

draining and oil carry over.

NOTE:

• Water level to be drained, depends on water quality, is set between

300-1000mm below water emulsion contact.

• Under or over injection of dehydration chemicals offshore result in

poor emulsion separation which affect water quality and draining

operation.

2.2.2 Open tank side water drain line manual valves. Area operator

2.2.3 Open tank water drain line EOV from CCR. Panel man 1

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 10 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

No. Action Action Party

NOTE:

• Wet tanks water and emulsion drain lines EOVs are interlocked to

EOVs of crude oil inlet and outlet of tanks.

• Simultaneous water draining operations are possible from group of

small tanks (T67, T72, T73, T74, T75, and T76) and from group of big

tanks (T-77, T78, T79, and T90).

• Refer Table1: Receiving Tanks SFH, maximum level, capacity

CAUTION:

IN EVENT OF AREA OPERATOR REQUIRED TO MANUALLY

OPERATE THE EOV:

• PANEL MAN NEED TO ENSURE CORRECT EOV NO.

COMMUNICATED TO AREA OPERATOR

• AREA OPERATOR NEED TO VERIFY CORRECT EOV NO. PRIOR

TO OPERATING VALVE

2.2.4 Monitor tank level and water level from CCR ENTIS. Panel man 1

2.2.5 Continuous monitoring during draining at oily water pit inlet to avoid over Watcher

drain

2.2.6 Close tank water drain EOV once the emulsion is detected in the water Panel man 1

sample. Stop water draining.

CAUTION:

• DO NOT OVER DRAIN; IT WILL IMPACT THE EFFLUENT

DISCHARGE WATER QUALITY.

NOTE:

• Operations of EOV, tank side valves are recorded in the log book at

CCR.

2.3 EMULSION DRAINING

No. Action Action Party

2.3.1 Set level alarm on CCR ENTIS to trigger at required level, in order to Panel man 1

prevent over draining.

2.3.2 Line up tank emulsion drain line to the respective header, emulsion Area

transfer pumps and slop tanks. operator/

Watcher

2.3.3 Ensure tank side drain manual valves are open. Area operator

2.3.4 Open tank emulsion drain line EOV from CCR. Panel man 1

2.3.5 Commence tank emulsion draining by transferring emulsion to slop tanks Area operator

T-1680/90 via emulsion transfer pumps (P-12/13/14/6961). / Panel man 1

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 11 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

No. Action Action Party

NOTE:

• Wet tanks water and emulsion drain lines EOVs are interlocked to

EOVs of crude oil inlet and outlet of tanks.

2.3.6 Monitor tank level and emulsion level from CCR. Panel man 1

2.3.7 Visual check emulsion sample for oil content from sampling points before Area

reaching the required level. operator/

Watcher

2.3.8 Continuously monitor emulsion until traces of oil is observed. Area

operator/

Watcher

2.3.9 Stop P-12/13/14/6961 pumps. Panel man 1

NOTE:

• Close EOV emulsion drain valve from CCR in event of crude oil carry

over to slop tank.

• Do not over drain crude to slop tanks.

2.3.10 Close tank emulsion drain line EOV from CCR. Panel man 1

2.3.11 Close tank side manual drain valves. Area operator

NOTE:

• Operations of EOV, tank side valves are recorded in the panel man

log book at CCR.

• Export crude quality can be improved by over draining but it will

reduce Slop Oil treatment tank ullage.

2.3.12 Fiscalise tank upon completion of draining. Take samples from Top, Area operator

Middle, Bottom and 1 foot reference sample for lab to analyze the crude

quality.

2.3.13 Fill up Tank Movement forms A7 and A8. Panel man 1

2.3.14 Update MCOT Daily Tanks Status. Shift

Operation

Supervisor

NOTE:

• Tank is ready for inter-tank transfer or export.

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 12 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST ................................................................................................................ 14

1.1 TABLE 1: RECEIVING TANKS SFH, MAXIMUM LEVEL, CAPACITY ...................... 14

2 DIAGRAMS ................................................................................................................. 15

2.1 FIGURE 1: WET TANK DIAGRAM ............................................................................. 15

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 13 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: RECEIVING TANKS SFH, MAXIMUM LEVEL, CAPACITY

Crude Oil Low Level SFH Setting Maximum Max Operating

Tank Setting mm mm Setting, mm Capacity, kl

TK-67* 265 7560 8285 8602

TK-72 496 10251 10451 10692

TK-73 200 10276 10430 10783

TK-74 526 10250 10350 10697

TK-75 500 10230 10390 10809

TK-76 930 9840 10350 10695

TK-77 635 11994 12625 23780

TK-78 390 11900 12710 23661

TK-79* 998 11840 12600 23750

TK-90* 600 17320 17860 34517

*Wet/Dry Tank

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 14 of 15

Operating Procedure MY SKO O 05 MCOT 016

Wet Tanks Operation: Water and Emulsion Draining Rev. 0 Sept 2011

2 DIAGRAMS

2.1 FIGURE 1: WET TANK DIAGRAM

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:38 AM PETRONAS CARIGALI SDN BHD Page 15 of 15

You might also like

- 4 SOP-Tank Farm Final Sent To ZonesDocument37 pages4 SOP-Tank Farm Final Sent To ZonesVijayNo ratings yet

- Mould Change, Storage and Maintenance ProcedureDocument10 pagesMould Change, Storage and Maintenance ProcedureTechnicians SIM100% (1)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationDocument24 pagesPetroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationScribd100% (1)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- Ims 52 07 06Document14 pagesIms 52 07 06marcio de rossiNo ratings yet

- Coagulation/ Flocculation Tank and Clarified Pond For WWT OperationDocument7 pagesCoagulation/ Flocculation Tank and Clarified Pond For WWT OperationKokian MckozenNo ratings yet

- Sop For Ro and Edi SystemDocument5 pagesSop For Ro and Edi SystemPramod PatilNo ratings yet

- Hla Cha 03 GDB DC 00 005 2 PDFDocument10 pagesHla Cha 03 GDB DC 00 005 2 PDFOsman AcostaNo ratings yet

- 110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Document14 pages110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Muhammad Umer RanaNo ratings yet

- WHS Kambuna Mothballing - Rev1Document25 pagesWHS Kambuna Mothballing - Rev1Desy Haslyanti100% (1)

- Optilobe 22Document34 pagesOptilobe 22GMS INDUSTRIALNo ratings yet

- AOU B121EW09 V3 Version 1.2Document35 pagesAOU B121EW09 V3 Version 1.2divubi2004No ratings yet

- EOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationDocument11 pagesEOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationRanjit MandalNo ratings yet

- 23-Line Up & Isolation of PA FanDocument2 pages23-Line Up & Isolation of PA FanSUBHASISH MUKHERJEE100% (1)

- Containment and Blasting ProcedureDocument20 pagesContainment and Blasting ProcedureEzemeh NigeriaNo ratings yet

- IMP206 PipelinesDocument11 pagesIMP206 PipelinesMurali KumaraguruNo ratings yet

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- Bilge Water SeparatorDocument121 pagesBilge Water SeparatorКостяNo ratings yet

- Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVDocument13 pagesPre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- Air Purification Unit Ubp-170Document35 pagesAir Purification Unit Ubp-170Mohammed AlryaniNo ratings yet

- Sop-09-Washing of Motor Winding With CTCDocument3 pagesSop-09-Washing of Motor Winding With CTCOSAMANo ratings yet

- M60es54 Na549y QC Man 001Document29 pagesM60es54 Na549y QC Man 001Riski Kurniawan67% (3)

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- Flange Management Procedure IFUDocument32 pagesFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- SOP For Closed Cooling Water SystemDocument16 pagesSOP For Closed Cooling Water SystemAbeer arif100% (1)

- Siwes Presentation 2019Document12 pagesSiwes Presentation 2019AanuNo ratings yet

- M270HVN02 - 0 (BenQ GW2760HS) - Improved Viewing Angle VADocument34 pagesM270HVN02 - 0 (BenQ GW2760HS) - Improved Viewing Angle VAKoolkrayzeh KLNo ratings yet

- 20.SOP For Boiler Initial Water FilllingDocument9 pages20.SOP For Boiler Initial Water FilllingRaja VigneshNo ratings yet

- OM Manual For Splash Pad ITEMSDocument66 pagesOM Manual For Splash Pad ITEMSmukilanarul12No ratings yet

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- 12 CW System DescriptionDocument24 pages12 CW System DescriptionnodalpcrktpsNo ratings yet

- DRA-C8396-PCP-003-ILR Rev ADocument13 pagesDRA-C8396-PCP-003-ILR Rev AEbenezer OpuniNo ratings yet

- 3-AC Failure EmergencyDocument3 pages3-AC Failure EmergencySUBHASISH MUKHERJEENo ratings yet

- V320BJ6 LD1 CmimeiDocument35 pagesV320BJ6 LD1 CmimeiNurjaman ElektroNo ratings yet

- KUKA KR30 MaintenanceDocument17 pagesKUKA KR30 MaintenanceJohan Zraghoz100% (2)

- Specification - Automatic Water Mist Fire Protection SystemsDocument21 pagesSpecification - Automatic Water Mist Fire Protection SystemsJaseelKanhirathinkalNo ratings yet

- Product Specification: (V) Preliminary Specification Final SpecificationDocument28 pagesProduct Specification: (V) Preliminary Specification Final SpecificationJorge TabaresNo ratings yet

- Specification - Water Spray Fixed SystemsDocument23 pagesSpecification - Water Spray Fixed SystemsJaseelKanhirathinkalNo ratings yet

- ADCO SIL ProcedureDocument42 pagesADCO SIL ProcedureGianfrancoMangiapaneNo ratings yet

- Operating and Maintenance InstructionsDocument20 pagesOperating and Maintenance InstructionsJano Goñi100% (1)

- Commissioning Procedure APR10 GBDocument11 pagesCommissioning Procedure APR10 GBAleksanrd Mihailov100% (1)

- B156HTN03 4-AuoDocument30 pagesB156HTN03 4-AuomanojNo ratings yet

- H2so4 SpillDocument4 pagesH2so4 SpilludayNo ratings yet

- Shower Leak TestDocument12 pagesShower Leak TestSuman GhoshNo ratings yet

- Product Specification: Preliminary Specification (V) Final SpecificationDocument28 pagesProduct Specification: Preliminary Specification (V) Final SpecificationNicolas Gandolfo100% (1)

- Normal Abnormal Operation PDFDocument21 pagesNormal Abnormal Operation PDFMd AfzanNo ratings yet

- Product Specification: Preliminary Specification (V) Final SpecificationDocument31 pagesProduct Specification: Preliminary Specification (V) Final SpecificationAlfa alfaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 018 Sea Loading Pump Station - SLPS - Operations PDFDocument24 pagesMCOT 018 Sea Loading Pump Station - SLPS - Operations PDFLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet