Professional Documents

Culture Documents

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

Uploaded by

Lembang ApangCopyright:

Available Formats

You might also like

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- Technical Authority FrameworkDocument22 pagesTechnical Authority Frameworkronelbarafaeldiego0% (1)

- Cargo Operations Manual CTDocument260 pagesCargo Operations Manual CTCrywul Suitswitt Fazh100% (4)

- Exon Mobile Drilling Guide PDFDocument318 pagesExon Mobile Drilling Guide PDFPwint Phoo100% (3)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationDocument24 pagesPetroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationScribd100% (1)

- 525MW Main Turbine Lube Oil SystemDocument20 pages525MW Main Turbine Lube Oil SystemRaja VigneshNo ratings yet

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- IMP206 PipelinesDocument11 pagesIMP206 PipelinesMurali KumaraguruNo ratings yet

- Concept of Operations For Directional Drilling On AmphionDocument11 pagesConcept of Operations For Directional Drilling On AmphionTaymoor MalekNo ratings yet

- 20.SOP For Boiler Initial Water FilllingDocument9 pages20.SOP For Boiler Initial Water FilllingRaja VigneshNo ratings yet

- MD 04 MT Rssta PD 509Document13 pagesMD 04 MT Rssta PD 509Nguyễn Đặng LâmNo ratings yet

- Draft Method Statement For Tank Erection DTD 02.12.2019Document7 pagesDraft Method Statement For Tank Erection DTD 02.12.2019manish pathrabeNo ratings yet

- OE CORP ENG TN 0001 Rev C1 Pre Commissioning Overview PipelinesDocument20 pagesOE CORP ENG TN 0001 Rev C1 Pre Commissioning Overview PipelinesĐiệnBiênNhâmNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- C 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BDocument65 pagesC 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BFAR_A_DAY100% (3)

- EOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationDocument11 pagesEOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationRanjit MandalNo ratings yet

- 12 CW System DescriptionDocument24 pages12 CW System DescriptionnodalpcrktpsNo ratings yet

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- Method Statement For Tank ErectionDocument8 pagesMethod Statement For Tank Erectionmanish pathrabeNo ratings yet

- WHS Kambuna Mothballing - Rev1Document25 pagesWHS Kambuna Mothballing - Rev1Desy Haslyanti100% (1)

- MQ SP I 7012 2 PDFDocument42 pagesMQ SP I 7012 2 PDFJaseelKanhirathinkalNo ratings yet

- MSDocument11 pagesMSM&N ProjectsNo ratings yet

- 23-Line Up & Isolation of PA FanDocument2 pages23-Line Up & Isolation of PA FanSUBHASISH MUKHERJEE100% (1)

- Coagulation/ Flocculation Tank and Clarified Pond For WWT OperationDocument7 pagesCoagulation/ Flocculation Tank and Clarified Pond For WWT OperationKokian MckozenNo ratings yet

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- 8001-WI-05-49 Personnel TransferDocument9 pages8001-WI-05-49 Personnel TransferAgung Tri SugihartoNo ratings yet

- Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVDocument13 pagesPre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- 110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Document14 pages110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Muhammad Umer RanaNo ratings yet

- Optilobe 22Document34 pagesOptilobe 22GMS INDUSTRIALNo ratings yet

- Exxon Mobil Globa Practice gp300103 Lifting From Floating VesselsDocument14 pagesExxon Mobil Globa Practice gp300103 Lifting From Floating VesselscfkianNo ratings yet

- PR 1754Document42 pagesPR 1754Anjani PrabhakarNo ratings yet

- Electronics MTBF, MTBCF and Preventative MaintenanceDocument10 pagesElectronics MTBF, MTBCF and Preventative MaintenanceHoa LuuNo ratings yet

- NDNE1-PTW-GL-002 Rev. 00 Permit To Work Guidelines in CSP DEWA IVDocument9 pagesNDNE1-PTW-GL-002 Rev. 00 Permit To Work Guidelines in CSP DEWA IVSanaulla Abdul SubhanNo ratings yet

- Specification - Water Spray Fixed SystemsDocument23 pagesSpecification - Water Spray Fixed SystemsJaseelKanhirathinkalNo ratings yet

- 0009ND - Self-Elevating Platforms Guidelines For Elevated OperationDocument16 pages0009ND - Self-Elevating Platforms Guidelines For Elevated OperationTomkel VoonNo ratings yet

- Sop For Ro and Edi SystemDocument5 pagesSop For Ro and Edi SystemPramod PatilNo ratings yet

- Specification - Site Preparation, Excavation, and Backfill SpecificationDocument24 pagesSpecification - Site Preparation, Excavation, and Backfill SpecificationAzhar AliNo ratings yet

- Hla Cha 03 GDB DC 00 005 2 PDFDocument10 pagesHla Cha 03 GDB DC 00 005 2 PDFOsman AcostaNo ratings yet

- Checklist GuidelinesDocument11 pagesChecklist GuidelinesCMDT-59 GeraldoNo ratings yet

- SP-2113 - Specification For Commissioning and Start-Up (Key Principals)Document23 pagesSP-2113 - Specification For Commissioning and Start-Up (Key Principals)Teguhprabowo Cena100% (1)

- K1704 ManualDocument179 pagesK1704 ManualcraponzelNo ratings yet

- 7.1.E.5 Ground Bed Installation Support OkDocument4 pages7.1.E.5 Ground Bed Installation Support Okarif rhNo ratings yet

- SEPA15014 MFSTD CV 00 SPC 004 - Specification For Grouting - Rev 0Document14 pagesSEPA15014 MFSTD CV 00 SPC 004 - Specification For Grouting - Rev 0Shanu kumarNo ratings yet

- Flange Management Procedure IFUDocument32 pagesFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- Indiabulls Power Limited: SOP/OPNS/08 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/08 Operations DepartmentAmit SoniNo ratings yet

- Method Statement For PMC Activities System 01-83-02, Fire Water Train 1Document11 pagesMethod Statement For PMC Activities System 01-83-02, Fire Water Train 1Hussein Adnan FneishNo ratings yet

- Flow Control Dampening: Commandbatch V1.03 & Later 11/27/12Document8 pagesFlow Control Dampening: Commandbatch V1.03 & Later 11/27/12Aly AbdelhamedNo ratings yet

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- MQ SP M 4017 PDFDocument28 pagesMQ SP M 4017 PDFjaseelNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

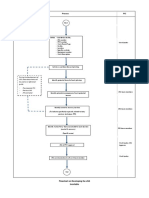

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

Uploaded by

Lembang ApangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

MCOT 018 Sea Loading Pump Station - SLPS - Operations PDF

Uploaded by

Lembang ApangCopyright:

Available Formats

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Any deviation from this procedure must follow the MANAGEMENT OF CHANGE PROCEDURE

or STANDING INSTRUCTIONS process before any deviation or change may be made.

OPERATING PROCEDURE

Contents

Foreword

Distribution List

Amendment Summary

Preface

Glossary

Reference Documents

Section 1 Introduction

Section 2 Procedure

Appendix A Checklist

Diagram

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 1 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

FOREWORD

Authority for original issue

Document Author

Issue of this document has been formally authored by:

Name: Mentor Solutions & Resources Sdn Bhd

Position: Technician/ Consultant/ Contractor

Date:

Issue Review

Issue of this document has been formally reviewed by:

Name:

Signature

Position: Production Supervisor/ Field Engineer

Date:

Issue Approval

Issue of this document has been formally approved by:

Name:

Signature:

Position: Head of Production

Date:

Document Custodian

The following person has been assigned as the document custodian:

Name:

Signature:

Position Onshore Installation Manager

Date

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 2 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Distribution List

Copy No. Title Location

01 Central Control Room MCOT

AMENDMENT SUMMARY

This sheet must be completed in detail at each revision once this document has been

approved.

Details must include revision number, description and indication of which pages and

paragraphs have been revised, date of revision approval, approvers title and signature.

Rev Description Date Approver Title Name

Rev 0 Original Document

Notes: (1) Document Holders to update Amendment Record as and when

amendments/new revisions are received.

(2) For description of amendment the Document Holder should indicate

correction, modification, update or deletion issue.

(3) Document Holder to enter their company reference number, sign and date the

record of entry.

(4) Where part amendments are issued, the relevant page(s) will be identified

with a lower case letter in the revision status line in the header.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 3 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

GLOSSARY

CCR Central Control Room

DCS Distributed Control System

DTS Daily Tank Status

EOV Electric Operated Valve

FCV Flow Control Valve

NPSH Net Positive Suction Head

PCMS Process Control and Monitoring System

SLPS Sea Loading Pump Station

RCU Remote Control Unit

REFERENCE

DOC. NO TITLE

MCOT Rejuvenation Project Phase 2 Piping & Instrumentation Diagram (P&ID)

Process Drawing (Rev. No. 6)

MY SKO O 07016 Rev.1 April 2010 MCOT Operating Procedures Manual

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 4 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Section 1

INTRODUCTION

Content Page

1.1 OBJECTIVE / PURPOSE ............................................................................................. 6

1.2 SCOPEBBB ............................................................................................................... 6

1.3 OP CATEGORY ............................................................................................................ 6

1.4 PREREQUISITES ......................................................................................................... 6

1.5 LIMITATIONS ............................................................................................................... 6

1.6 ROLES / RESPONSIBILITY ......................................................................................... 6

1.7 HSE REQUIREMENTS ................................................................................................. 7

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 5 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

1 INTRODUCTION

1.1 OBJECTIVE/PURPOSE

1.1.1 This operating procedure outlines activities required to operate SLPS booster pumps, gas

engine driven and electrical driven crude oil pumps for loading operation and inter tank

transfer.

1.2 SCOPE

1.2.1 The procedure applies to MCOT booster and crude oil loading pumps.

1.2.2 The main activities involved are operations of;

• SLPS booster pumps P-1410, P-1420, P-1430 (electric motor, vertical pump)

• Crude oil main loading pump P-1/10/11/1200 (gas engine driven)

1.3 OP CATEGORY

Categories Normal/ Start Up / Shutdown / Checklist Required: Yes/ No

Emergency / Special / Temporary /

and attributes

Abnormal / Decommissioning

1.4 PREREQUISITES

1.4.1 Choice of operating gas engine driven crude loading pumps or combination of pumps must be

planned upfront.

1.4.2 Certified ICE Engine Driver.

1.4.3 Maintain communication with CCR during inter tank operation or loading operations.

1.5 LIMITATIONS

1.6 Shortage of gas supply, instrument air and electrical power.

1.7 ROLES/RESPONSIBILITY

1.7.1 Refer to Section 2: Procedure “Action party”.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 6 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

1.8 HSE REQUIREMENTS

Hazards and The table below lists job hazards and the precautions that should be taken

precautions for safety, environmental, quality, ergonomics, Good Manufacturing

Practices, etcB before beginning this procedure.

Hazard Precaution

Pressure Ensure proper lineup to avoid high

backpressure conditions

Flammable No hot work during pump running

High Pitch Noise Wear hearing protection

Chemical/Toxic/Thermal burns Avoid crude oil contact with skin.

Loss of Containment Ensure all flanges and connections are

properly maintained

PPE The following Personnel Protection Equipment (PPE) must be used to do

required this activity in addition to mandatory PPEs. List any special PPEs required,

PPE Use

Ear muffs/plug Hearing protection during pump running

Tools and The tools and equipment listed below are needed to do this job. List any

Equipment special tools required in addition to hand tools.

Tools and/or Equipment Use

N/A

ESD / N/A

Interlocks

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 7 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Unit: P-1410/20/30 SLPS BOOSTER Safe

Never Exceed

PUMPS Operating SOL Excursions

Limit(barg)

Area: Sea Loading Pump Station Limit(barg)

Consequence of

Equipment Inst.Tag # H L HH LL Corrective Actions

Deviation

P-1410/20/30 PIAH-1412/22/32 7.3 Alarm will be activated Stop P-1410/20/30 manually, rectify the cause of

the high pressure problem and check P-

1410/20/30/40 integrity before starting them again.

P-1410/20/30 PIAL-1412/22/32 1.2 Alarm will be activated Stop P-1410/20/30 manually, rectify the cause of

the low pressure problem and check P-

1410/20/30/40 integrity before starting them again.

P-1410/20/30 PZALL-1414/24/34 1.05 Pump trips Rectify the cause of the low low pressure problem

(discharge line) There is a potential and check P-1410/20/30/40 integrity before starting

damage to the pumps them again.

P-1410/20/30 PZALL-1415/25/35 0.65 Pump trips Rectify the cause of the low low pressure problem

(suction line) There is a potential and check P-1410/20/30/40 integrity before starting

damage to the pumps them again.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 8 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Unit: P-1410/20/30 SLPS BOOSTER Safe

Never Exceed

PUMPS Operating SOL Excursions

Limit (barg)

Area: Sea Loading Pump Station Limit (barg)

Consequence of

Equipment Inst.Tag # H L HH LL Corrective Actions

Deviation

P-1200 PIAH1203 2.5 There is a potential Stop P-1200 manually, rectify the cause of the high

damage to the pump pressure problem and check P-1200 integrity before

starting it again.

P-1 PIAL410 -.05 There is a potential Stop P-1 manually, rectify the cause of the low pressure

damage to the pump problem and check P-1 integrity before starting it again

P-10 PIAL401 -.05 There is a potential Stop P-10 manually, rectify the cause of the low

damage to the pump pressure problem and check P-10 integrity before

starting it again

P-11 PIAL411 -.05 There is a potential Stop P-11 manually, rectify the cause of the low

damage to the pump pressure problem and check P-11 integrity before

starting it again

P-1200 PIAL1204 -.05 There is a potential Stop P-1200 manually, rectify the cause of the low

(Suction) damage to the pump pressure problem and check P-1200 integrity before

starting it again

P-1200 PIAL1205 -.05 There is a potential Stop P-1200 manually, rectify the cause of the low

(Discharge) damage to the pump pressure problem and check P-1200 integrity before

starting it again

P-1440 PIA 1441 -.05 4.22 -0.72 There is a potential Stop P-1440 manually, rectify the cause of the low

damage to the pump pressure problem and check P-1440 integrity before

starting it again

P-1450 PIA 1450 -.05 4.22 -0.72 There is a potential Stop P-1450 manually, rectify the cause of the low

damage to the pump pressure problem and check P-1450 integrity before

starting it again

* Not available in P&ID. The low and high pressures settings are available in CCR1 DCS screen (old set-up). These data will be migrated to CCR2 after MCOT rejuvenation

project which is on-going at this moment of writing this OP.

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 9 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Section 2

PROCEDURE

Content Page

2.1 SLPS Booster Pumps P1410/1420/1430 ................................................................... 11

2.2 Crude Oil Main Loading Pump P-1/10/11/1200.......................................................... 12

2.3 Crude Oil Main Loading Pump P-1440/1450 .............................................................. 13

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 10 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2 PROCEDURE

2.1 PREPARATION BEFORE PUMPS START-UP

No. Action Action Party

2.1.1 Check fuel gas system, lubricating system, cooling water system, ICE Driver /

electrical power supply, utility air system (for starting air starter) and Area operator

instrument air system are operational according to pre-startup checklist.

2.2 SLPS BOOSTER PUMPS P1410/1420/1430 START-UP

No. Action Action Party

2.2.1 Line up identified tanks, open tanks side valves and suction EOVs. Panel man 1

/ Area

operator

2.2.2 For crude loading operations, calculate loading time and loading flow rate. Panel man 1

Update MCOT Daily Tank Status (DTS).

2.2.3 Based on required flow rate; line up booster pumps in combination of two Panel man 1 /

pumps or three pumps in parallel at least thirty minutes before loading ICE Driver/

operation. Refer to Appendix A, item 2.1, Figure 1: SLPS Booster pumps Area

Operator

CAUTION:

• FOR LOADING OPERATION, LINE UP CRUDE OIL METERING

PRIOR TO STARTING OF PUMPS.

2.2.4 Carry out the valves checklist as per Appendix A, item 1.1, Table 1. Area operator

2.2.5 Open up respective main loading pump inlet and outlet EOVs either Panel man 1 /

remotely or locally. Area operator

2.2.6 Check pumps electrical power and instrument air system are as per ICE Driver/

requirement. Area operator

2.2.7 Start one booster pump from RCU (CCR). Panel man 1/

ICE Driver/

Area operator

2.2.8 In the event of insufficient pressure or flow, start the second booster pump Panel man 1/

(CCR). ICE Driver/

Area operator

2.2.9 Monitor pump suction, discharge pressure and temperature as per normal Panel man 1/

operating parameters. ICE Driver/

Area operator

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 11 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

No. Action Action Party

2.2.10 Check recycles valves (FCV-1410/1420/1430) operations physically and Panel man 1/

in DCS screen. Valves should be in open position until the main loading Area operator

pumps are started.

2.3 CRUDE OIL MAIN LOADING PUMP P-1/10/11/1200 START-UP

No. Action Action Party

2.3.1 Options to run electric motors, gas driven engines crude loading pumps or Shift

combination of pumps must be planned upfront with shift supervisor Supervisor

2.3.2 Based on required flow rate, line up main loading pumps in combination of ICE Driver/

two pumps or three pumps in parallel at least ten (10) minutes before Area operator

loading operation as per stated in the note below; / Panel man 1

• Refer Appendix A, item 2.2, Figure 2: SLPS pump P-1

• Refer Appendix A, item 2.3, Figure 3: SLPS pump P-10

• Refer Appendix A, item 2.4, Figure 4: SLPS pump P-11

• Refer Appendix A, item 2.5, Figure 5: SLPS pump P-1200

2.3.3 Ensure that the clutch lever at “DISENGAGE” position. ICE Driver/

Area operator

2.3.4 Turn selector switch to “OK TO RUN” position at LCP. ICE Driver/

Area operator

2.3.5 Turn selector switch to “LOCAL” position at LCP. ICE Driver/

Area operator

2.3.6 Reset all alarms on LCP until all engine status indicators on panel will turn ICE Driver/

green. Area operator

NOTE:

Low pressure sensors will be locked for 3 minutes and “LOW PRESSURE

LOCKED OUT” indicator will turn green.

2.3.7 Press “ENGINE START” button to start engine at LCP. “ENGINE Area operator

RUNNING” indicator will be illuminated.

2.3.8 Let the engine run idle for 10 minutes. Area

operator/ ICE

Driver

2.3.9 Adjust engine speed accordingly and engage the pump clutch lever. Area

operator/ ICE

Driver

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 12 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

No. Action Action Party

2.3.10 Monitor pump and engine performances and flow rates. Adjust the engine Panel man 1 /

speed accordingly to meet flow rate requirements. Area

operator/ ICE

Driver

2.3.11 Start up the next loading pumps if required and carry out checking and Area

monitoring of operation parameters. operator/ ICE

Driver

CAUTION:

IF ABNORMAL NOISES OR VIBRATION ENCOUNTERED, CARRY OUT

INVESTIGATION AND INFORM CCR.

2.4 SHUTDOWN OF MAIN LOADING PUMP P-110/11/1200

No. Action Action Party

2.4.1 Put gear box oil pressure selector switch to override ICE Driver/

Area operator

2.4.2 Disengage the clutch ICE Driver/

Area operator

2.4.3 Let the engine run idling for 5 minutes ICE Driver/

Area operator

2.4.4 Switch the selector to “STOP” position to stop the engine ICE Driver/

Area operator

2.4.5 Close gas supply manual valve to shut off the engine ICE Driver/

Area operator

2.4.6 Close instrument air supply manual valve ICE Driver/

Area operator

2.4.7 Close cooling water inlet and outlet manual valve ICE Driver/

Area operator

2.4.8 Stop cooling tower fans & pump ICE Driver/

Area operator

2.4.9 Close all opened EOV and valves involved in pre-start up ICE Driver/

Area operator

2.5 SHUTDOWN OF BOOSTER PUMP P-1410/20/30

No. Action Action Party

2.5.1 Inform CCR Panel Operator that P-1410/ 20/ 30 is to be shutdown ICE Driver/

Area operator

2.5.2 Shutdown pump by switching the “Stop” position to SS 1410 or SS 1420 Panel man 1/

or SS 1430 to shutdown P-1410, P-1420 and P-1430, respectively. ICE Driver/

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 13 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

No. Action Action Party

Area operator

2.5.3 Turn RCU selector switch to “OFF” position and lock. ICE Driver/

Area operator

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 14 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.6 MOTOR DRIVEN CRUDE OIL MAIN LOADING PUMP P-1440/1450 (AWAITING

TO BE COMMISSIONED)

No. Action Action Party

2.6.1 Base on required flow rate, line up electric motor driven main loading Area operator

pumps in parallel thirty minutes before loading operation.

• Refer Appendix A, item 2.6, Figure 6: SLPS pump P-1440

• Refer Appendix A, item 2.7, Figure 7: SLPS pump P-1450

NOTE:

• Design flow rate: 1363 Kl/hr

• Discharge pressure: 13 bar

• Electric motor : 700 kW

2.6.2 Check booster pumps pressures and flow rates. Open up main loading Panel man 1 /

pumps suction and discharge EOVs either remotely or locally. Area operator

2.6.3 Check pumps electrical power and instrument air system and lubricating Area operator

system according to the pre-startup checklist.

2.6.4 Start electric motor driven pumps one at a time and monitor pump suction Area operator

and discharge pressure and temperature

CAUTION:

• SUCTION VALVES MUST BE FULLY OPEN DURING OPERATION

• PUMP CAN RUN ON CLOSED VALVE BUT ON SHORT PERIOD

NOTE:

• Gas engine driven pumps and electric motor driven pumps have

different discharge heads and preferable to be run in its own cluster.

• If gas engine driven and electric motor driven pumps are required to

run in parallel, adjust gas engine pump speed to met discharge

pressure of electric motor pump to prevent stalling.

2.6.5 Shut off pump from local panel when loading completed. Close suction Panel man 1 /

and discharge EOVs accordingly. Area operator

2.6.6 Close back all pumps/ side suctions valves and EOVs. Panel man 1 /

Area operator

END OF PROCEDURE

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 15 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

Appendix

APPENDIX A

Content Page

1 CHECKLIST ............................................................................................................ 17

1.1 TABLE 1: SLPS BOOSTER PUMPS CHECKLIST ................................................... 17

2 DIAGRAMS ............................................................................................................ 18

2.1 FIGURE 1: SLPS BOOSTER PUMPS P-1410/20/30 ............................................... 18

2.2 FIGURE 2: SLPS PUMP P-1 ..................................................................................... 19

2.3 FIGURE 3: SLPS PUMP P-10 ................................................................................... 20

2.4 FIGURE 4: SLPS PUMP P-11 ................................................................................... 21

2.5 FIGURE 5: SLPS PUMP P-1200 ............................................................................... 22

2.6 FIGURE 6: SLPS PUMP P-1440 ............................................................................... 23

2.7 FIGURE 7: SLPS PUMP P-1450 ............................................................................... 24

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 16 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

1 CHECKLIST

1.1 TABLE 1: SLPS BOOSTER PUMPS CHECKLIST

Valve No. Description Open Close

EOV 0101 Crude Inlet to P-1 Close

EOV 0102 Crude Inlet to P-1 Close

EOV 1101 Crude Inlet to P-11 Close

EOV 1102 Crude Inlet to P-11 Close

EOV 1001 Crude Inlet to P-10 Close

EOV 1002 Crude Inlet to P-10 Close

EOV 1201 Crude Inlet to P-1200 Close

EOV 1202 Crude Inlet to P-1200 Close

EOV 1441 Crude Inlet to P-1440 Close

EOV 1442 Crude Inlet to P-1440 Close

EOV 1451 Crude Inlet to P-1450 Close

EOV 1452 Crude Inlet to P-1450 Close

EOV 0103 Discharge from P-1 Close

EOV 1103 Discharge from P-11 Close

EOV 1003 Discharge from P-10 Close

EOV 1203 Discharge from P-1200 Close

EOV 1443 Discharge from P-1440 Close

EOV 1453 Discharge from P-1450 Close

EOV 0006 Inlet to Metering Skid Close

20" VG Outlet from Metering Skid Open

16" VG5 Manual valve on S11 (P&ID No. P 0072 1 /6) Close

16" VG5 Manual valve on S11 (P&ID No. P 0072 1 /6) Close

EOV 0014 Crude to S.B.M 5 Close

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 17 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2 DIAGRAMS

2.1 FIGURE 1: SLPS BOOSTER PUMPS P-1410/20/30

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 18 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.2 FIGURE 2: SLPS PUMP P-1

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 19 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.3 FIGURE 3: SLPS PUMP P-10

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 20 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.4 FIGURE 4: SLPS PUMP P-11

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 21 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.5 FIGURE 5: SLPS PUMP P-1200

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 22 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.6 FIGURE 6: SLPS PUMP P-1440

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 23 of 24

Operating Procedure MY SKO O 05 MCOT 018

Sea Loading Pump Station (SLPS) Operations Rev. 0 Sept 2011

2.7 FIGURE 7: SLPS PUMP P-1450

"UNCONTROLLED WHEN PRINTED"

30/07/2012 9:44 AM PETRONAS CARIGALI SDN BHD Page 24 of 24

You might also like

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- Technical Authority FrameworkDocument22 pagesTechnical Authority Frameworkronelbarafaeldiego0% (1)

- Cargo Operations Manual CTDocument260 pagesCargo Operations Manual CTCrywul Suitswitt Fazh100% (4)

- Exon Mobile Drilling Guide PDFDocument318 pagesExon Mobile Drilling Guide PDFPwint Phoo100% (3)

- MCOT 049tanks FiscalisationDocument18 pagesMCOT 049tanks FiscalisationLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationDocument24 pagesPetroleum Development Oman L.L.C.: Document Title: Drain Systems SpecificationScribd100% (1)

- 525MW Main Turbine Lube Oil SystemDocument20 pages525MW Main Turbine Lube Oil SystemRaja VigneshNo ratings yet

- Seal Oil SystemDocument22 pagesSeal Oil SystemRaja VigneshNo ratings yet

- IMP206 PipelinesDocument11 pagesIMP206 PipelinesMurali KumaraguruNo ratings yet

- Concept of Operations For Directional Drilling On AmphionDocument11 pagesConcept of Operations For Directional Drilling On AmphionTaymoor MalekNo ratings yet

- 20.SOP For Boiler Initial Water FilllingDocument9 pages20.SOP For Boiler Initial Water FilllingRaja VigneshNo ratings yet

- MD 04 MT Rssta PD 509Document13 pagesMD 04 MT Rssta PD 509Nguyễn Đặng LâmNo ratings yet

- Draft Method Statement For Tank Erection DTD 02.12.2019Document7 pagesDraft Method Statement For Tank Erection DTD 02.12.2019manish pathrabeNo ratings yet

- OE CORP ENG TN 0001 Rev C1 Pre Commissioning Overview PipelinesDocument20 pagesOE CORP ENG TN 0001 Rev C1 Pre Commissioning Overview PipelinesĐiệnBiênNhâmNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- C 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BDocument65 pagesC 84514 BK KK0 PRO GN 00 0014 Subsea Pre Commissioning Procedure - Rev.0BFAR_A_DAY100% (3)

- EOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationDocument11 pagesEOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationRanjit MandalNo ratings yet

- 12 CW System DescriptionDocument24 pages12 CW System DescriptionnodalpcrktpsNo ratings yet

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- Method Statement For Tank ErectionDocument8 pagesMethod Statement For Tank Erectionmanish pathrabeNo ratings yet

- WHS Kambuna Mothballing - Rev1Document25 pagesWHS Kambuna Mothballing - Rev1Desy Haslyanti100% (1)

- MQ SP I 7012 2 PDFDocument42 pagesMQ SP I 7012 2 PDFJaseelKanhirathinkalNo ratings yet

- MSDocument11 pagesMSM&N ProjectsNo ratings yet

- 23-Line Up & Isolation of PA FanDocument2 pages23-Line Up & Isolation of PA FanSUBHASISH MUKHERJEE100% (1)

- Coagulation/ Flocculation Tank and Clarified Pond For WWT OperationDocument7 pagesCoagulation/ Flocculation Tank and Clarified Pond For WWT OperationKokian MckozenNo ratings yet

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNo ratings yet

- SOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. NumberDocument4 pagesSOP Valve Cleaning: Project Name: Pipeline Operation and Maintenance Doc. Numberarif rhNo ratings yet

- 8001-WI-05-49 Personnel TransferDocument9 pages8001-WI-05-49 Personnel TransferAgung Tri SugihartoNo ratings yet

- Pre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVDocument13 pagesPre-Commissioning and Commissioning Manual: Mellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- 110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Document14 pages110 - Startup-Shutdown & Handover of Nitric Acid Pump (02-1111 & 02-1151)Muhammad Umer RanaNo ratings yet

- Optilobe 22Document34 pagesOptilobe 22GMS INDUSTRIALNo ratings yet

- Exxon Mobil Globa Practice gp300103 Lifting From Floating VesselsDocument14 pagesExxon Mobil Globa Practice gp300103 Lifting From Floating VesselscfkianNo ratings yet

- PR 1754Document42 pagesPR 1754Anjani PrabhakarNo ratings yet

- Electronics MTBF, MTBCF and Preventative MaintenanceDocument10 pagesElectronics MTBF, MTBCF and Preventative MaintenanceHoa LuuNo ratings yet

- NDNE1-PTW-GL-002 Rev. 00 Permit To Work Guidelines in CSP DEWA IVDocument9 pagesNDNE1-PTW-GL-002 Rev. 00 Permit To Work Guidelines in CSP DEWA IVSanaulla Abdul SubhanNo ratings yet

- Specification - Water Spray Fixed SystemsDocument23 pagesSpecification - Water Spray Fixed SystemsJaseelKanhirathinkalNo ratings yet

- 0009ND - Self-Elevating Platforms Guidelines For Elevated OperationDocument16 pages0009ND - Self-Elevating Platforms Guidelines For Elevated OperationTomkel VoonNo ratings yet

- Sop For Ro and Edi SystemDocument5 pagesSop For Ro and Edi SystemPramod PatilNo ratings yet

- Specification - Site Preparation, Excavation, and Backfill SpecificationDocument24 pagesSpecification - Site Preparation, Excavation, and Backfill SpecificationAzhar AliNo ratings yet

- Hla Cha 03 GDB DC 00 005 2 PDFDocument10 pagesHla Cha 03 GDB DC 00 005 2 PDFOsman AcostaNo ratings yet

- Checklist GuidelinesDocument11 pagesChecklist GuidelinesCMDT-59 GeraldoNo ratings yet

- SP-2113 - Specification For Commissioning and Start-Up (Key Principals)Document23 pagesSP-2113 - Specification For Commissioning and Start-Up (Key Principals)Teguhprabowo Cena100% (1)

- K1704 ManualDocument179 pagesK1704 ManualcraponzelNo ratings yet

- 7.1.E.5 Ground Bed Installation Support OkDocument4 pages7.1.E.5 Ground Bed Installation Support Okarif rhNo ratings yet

- SEPA15014 MFSTD CV 00 SPC 004 - Specification For Grouting - Rev 0Document14 pagesSEPA15014 MFSTD CV 00 SPC 004 - Specification For Grouting - Rev 0Shanu kumarNo ratings yet

- Flange Management Procedure IFUDocument32 pagesFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- Indiabulls Power Limited: SOP/OPNS/08 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/08 Operations DepartmentAmit SoniNo ratings yet

- Method Statement For PMC Activities System 01-83-02, Fire Water Train 1Document11 pagesMethod Statement For PMC Activities System 01-83-02, Fire Water Train 1Hussein Adnan FneishNo ratings yet

- Flow Control Dampening: Commandbatch V1.03 & Later 11/27/12Document8 pagesFlow Control Dampening: Commandbatch V1.03 & Later 11/27/12Aly AbdelhamedNo ratings yet

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- MQ SP M 4017 PDFDocument28 pagesMQ SP M 4017 PDFjaseelNo ratings yet

- Distributed Process Control ReportFrom EverandDistributed Process Control ReportNo ratings yet

- MCOT 013 Pig Receiving From 4B 18in Crude LineDocument18 pagesMCOT 013 Pig Receiving From 4B 18in Crude LineLembang ApangNo ratings yet

- MCOT 011 Offshore Incoming Trunkline OperationsDocument16 pagesMCOT 011 Offshore Incoming Trunkline OperationsLembang ApangNo ratings yet

- MCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFDocument15 pagesMCOT 016 Wet Tanks Operation - Water and Emulsion Draining PDFLembang ApangNo ratings yet

- MCOT 010 Crude Receiving - Tank Switching OperationsDocument16 pagesMCOT 010 Crude Receiving - Tank Switching OperationsLembang ApangNo ratings yet

- MCOT 020 Tanker Loading Operations PDFDocument20 pagesMCOT 020 Tanker Loading Operations PDFLembang ApangNo ratings yet

- MCOT 019 Bundwall Water Draining PDFDocument15 pagesMCOT 019 Bundwall Water Draining PDFLembang ApangNo ratings yet

- MCOT 017 Inter Tanks Transfer OperationsDocument14 pagesMCOT 017 Inter Tanks Transfer OperationsLembang ApangNo ratings yet

- MCOT 008 WL Crude Receiving 18 InchDocument23 pagesMCOT 008 WL Crude Receiving 18 InchLembang ApangNo ratings yet

- Attachment II - Revised JHA Process FlowDocument1 pageAttachment II - Revised JHA Process FlowLembang ApangNo ratings yet