Professional Documents

Culture Documents

Utp 34 N

Utp 34 N

Uploaded by

brayanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Utp 34 N

Utp 34 N

Uploaded by

brayanCopyright:

Available Formats

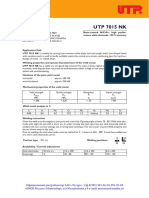

UTP 34 N

Basic-coated complex aluminiumbronze stick electrode

Classifications

DIN 8555 EN 14700 AWS A5.13

E 31-UM-200-CN E Cu2 E CuMnNiAl (mod.)

Characteristics and field of use

UTP 34 N is suitable for joinings and surfacings on copper-aluminium alloys, especially with high

Mn-content as well as for claddings on cast iron materials and steel. Main application fields are in

the shipbuilding (propeller, pumps, armatures) and in the chemical industry. The good friction

coefficient permits claddings on shafts, bearings, stamps, drawing tools and all kind of gliding

surface.

UTP 34 N has excellent welding properties, spatter-free welding, good slag removal. The weld

deposit has high mechanical values, a good corrosion resistance in oxidizing media, best gliding

properties and a very good machinability. Crack resistant and pore-free.

Typical analysis in %

Mn Ni Cu Al Fe

13.0 2.5 balance 7.0 2.5

Mechanical properties of the weld metal

Yield strength Rp0,2 Tensile strength Rm Elongation A Hardness

MPa MPa % HB

400 650 15 220

Welding instruction

Clean welding area thoroughly. Preheating of thick-walled parts to 150 – 250°C. Hold electrode as

vertically as possible and weld with slight weaving. Weld with dry stick electrodes only!

Redrying: 2 – 3 h at 150°C.

Welding positions

Current type DC (+)

Approvals

DB

Recommended welding parameters

Electrodes Ø x L [mm] 2.5 x 350 3.2 x 350 4.0 x 350

Amperage [A] 50 – 70 70 – 90 90 – 110

All information provided is based upon careful investigation and intensive research. 05/2018 Rev. 2 TA/dp

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Utp 63Document1 pageUtp 63brayanNo ratings yet

- Utp A 3444Document1 pageUtp A 3444Sun SunNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Utp A 3444 - 2Document1 pageUtp A 3444 - 2Sun SunNo ratings yet

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- مكونات نقط اللحام شامل بنط اللحامDocument2 pagesمكونات نقط اللحام شامل بنط اللحامdaha333No ratings yet

- Utp Af A7Document1 pageUtp Af A7VIRPOPNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- Thermanit P24Document1 pageThermanit P24Branko FerenčakNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Bohler Fox S 308L-16Document1 pageBohler Fox S 308L-16HAKANNo ratings yet

- UTP Raiilways BrochureDocument8 pagesUTP Raiilways Brochurekamals55No ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- L1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Document1 pageL1 - 7855 - en - B - Boehler Fox KW 10 - Se - en - v2Dimitris NikouNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Carbocast 1 - eDocument1 pageCarbocast 1 - eali torabiNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- Utp Ledurit 65Document1 pageUtp Ledurit 65brayanNo ratings yet

- Thermanit P23Document1 pageThermanit P23Branko FerenčakNo ratings yet

- Böhler Fox CN 29/9-A: DescriptionDocument1 pageBöhler Fox CN 29/9-A: DescriptionKadir Koray BozyelNo ratings yet

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- Toolcord (E 6 Um 65 GS, e Fe4)Document1 pageToolcord (E 6 Um 65 GS, e Fe4)brunizzaNo ratings yet

- LH 104Document1 pageLH 104Sandeep gangulyNo ratings yet

- UTP 3545 NB PDFDocument1 pageUTP 3545 NB PDFhqnscNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- Page - 6Document1 pagePage - 6Bharat KumaneNo ratings yet

- Utp Ledurit 61Document1 pageUtp Ledurit 61brayanNo ratings yet

- L1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENDocument1 pageL1 34410 en Avesta 309 AC DC 2SE6A22E 3383012 ENkamals55No ratings yet

- LH 106Document1 pageLH 106Sandeep gangulyNo ratings yet

- A389 CuNiDocument1 pageA389 CuNiPrathamesh OmtechNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- UTP A 8051 Ti: ClassificationsDocument1 pageUTP A 8051 Ti: ClassificationsGustavo OrozcoNo ratings yet

- D and H NewDocument37 pagesD and H NewBharat AhirNo ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- L1 34385 en U UTP-AF-ROBOTIC-352 Fde enDocument1 pageL1 34385 en U UTP-AF-ROBOTIC-352 Fde enl.raickNo ratings yet

- 1 - UTP 614 KBDocument1 page1 - UTP 614 KBKrishna VachaNo ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- Submerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelDocument17 pagesSubmerged Arc Welding Consumables For Mild Steel and 490N/mm Class High Tensile Strength SteelManish MNo ratings yet

- UTP Cladding en 2017Document12 pagesUTP Cladding en 2017Gourav SharmaNo ratings yet

- Utp A 80 M: ClassificationsDocument1 pageUtp A 80 M: ClassificationsInaamNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- Teromatec Eo 8355: Description Procedure of UseDocument1 pageTeromatec Eo 8355: Description Procedure of UseAravind rajNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- Utp 86 FNDocument1 pageUtp 86 FNc131508No ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boehler EAS 4 M-IG - Tig RodDocument1 pageBoehler EAS 4 M-IG - Tig RodbrayanNo ratings yet

- UTP CementDocument56 pagesUTP CementbrayanNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- 11062016000000utp 86 FNDocument1 page11062016000000utp 86 FNbrayanNo ratings yet

- Bohler Fox N Ev48-1Document1 pageBohler Fox N Ev48-1brayanNo ratings yet

- BÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedDocument1 pageBÖHLER Ti 52 NG T-FD (Diamondspark 31 NG) : Flux Cored Wire, Seamless, Self-Shielded, UnalloyedbrayanNo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- Boehler NiCu1 Ti T-FD - CWDocument1 pageBoehler NiCu1 Ti T-FD - CWbrayanNo ratings yet

- Официальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@Document1 pageОфициальный дистрибьютор ЗАО «Ресурс» т/ф 8 (383) 363-26-24, 291-93-02 630020 Россия г.Новосибирс ул.Объединения д.9 e-mail: resurszao@brayanNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Utp Ledurit 65Document1 pageUtp Ledurit 65brayanNo ratings yet

- Union Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantDocument1 pageUnion Er90S-B3: TIG Rod, Low-Alloyed, Creep ResistantbrayanNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- 03072016000000A 200 W-Brazing RodsDocument1 page03072016000000A 200 W-Brazing RodsbrayanNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- Utp Ledurit 61Document1 pageUtp Ledurit 61brayanNo ratings yet

- Nursing Care of Prisoners: Staff Views and Experiences: OriginalresearchDocument9 pagesNursing Care of Prisoners: Staff Views and Experiences: OriginalresearchbrayanNo ratings yet

- Identifying Health Promotion Needs Among Prison Staff in Three English Prisons: Results From A Qualitative StudyDocument8 pagesIdentifying Health Promotion Needs Among Prison Staff in Three English Prisons: Results From A Qualitative StudybrayanNo ratings yet

- Applied ErgonomicsDocument12 pagesApplied ErgonomicsbrayanNo ratings yet

- PlanoDocument1 pagePlanobrayanNo ratings yet

- Utp 63Document1 pageUtp 63brayanNo ratings yet

- Solidworks Flow Simulation Project Report: (Company Logo Here)Document14 pagesSolidworks Flow Simulation Project Report: (Company Logo Here)brayanNo ratings yet

- L1 34454 en B Boehler Aws E6013 Se en v1Document1 pageL1 34454 en B Boehler Aws E6013 Se en v1brayanNo ratings yet