Professional Documents

Culture Documents

ASTM E761 - 92 Reapproved 2011 PDF

ASTM E761 - 92 Reapproved 2011 PDF

Uploaded by

Trà Trần SơnCopyright:

Available Formats

You might also like

- Astm C1180-10Document3 pagesAstm C1180-10LydiaNo ratings yet

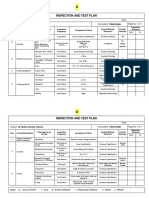

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurianNo ratings yet

- Astm e 1745Document2 pagesAstm e 1745Zahoor Ahmed Mohsan100% (1)

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2No ratings yet

- Concrete Batch Plants CommentsDocument2 pagesConcrete Batch Plants CommentsShoaib SafdarNo ratings yet

- DCPT TestDocument10 pagesDCPT TestMonirul Islam BadalNo ratings yet

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyNo ratings yet

- D806-11 Standard Test Method For Cement Content of Hardened Soil-Cement MixturesDocument4 pagesD806-11 Standard Test Method For Cement Content of Hardened Soil-Cement MixturesRony YudaNo ratings yet

- D 4718 - 87 R94Document3 pagesD 4718 - 87 R94Joseph LinajaNo ratings yet

- Concrete Protective CoatingDocument10 pagesConcrete Protective CoatingShabbar Abbas MalikNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanKhurram ShehzadNo ratings yet

- Deviation Approval FormDocument3 pagesDeviation Approval FormMv PatelNo ratings yet

- Earth WorksDocument14 pagesEarth WorksJam100% (1)

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

- Aashto t23 FormDocument5 pagesAashto t23 FormTuan Do VanNo ratings yet

- Concrete Placement (Spec)Document18 pagesConcrete Placement (Spec)Vetrivel MuruganNo ratings yet

- Astm Codes For Paving TilesDocument2 pagesAstm Codes For Paving TilesrinjumathewNo ratings yet

- Early Cracking of Concrete PavementDocument25 pagesEarly Cracking of Concrete PavementRajesh KhadkaNo ratings yet

- C94C94M-15 Standard Specification For Ready-Mixed Concrete PDFDocument14 pagesC94C94M-15 Standard Specification For Ready-Mixed Concrete PDFdiego rodriguezNo ratings yet

- 02225Document6 pages02225uddinnadeemNo ratings yet

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanNo ratings yet

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- Astm C1586Document3 pagesAstm C1586Lydia100% (1)

- Agencies Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Testing Agency EvaluationDocument9 pagesAgencies Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Testing Agency EvaluationCory BradleyNo ratings yet

- SSPC QS 1Document9 pagesSSPC QS 1FCTNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Renderoc TgxtraDocument2 pagesRenderoc TgxtratalatzahoorNo ratings yet

- ASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodDocument9 pagesASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodAdam Jones0% (1)

- 524r 16 PreviewDocument4 pages524r 16 Previewosama anterNo ratings yet

- Elcometer 266 DC Portable Holiday DetectorDocument3 pagesElcometer 266 DC Portable Holiday DetectorkhuramluckNo ratings yet

- Pull-Off Strength of Coatings Using Portable Adhesion TestersDocument16 pagesPull-Off Strength of Coatings Using Portable Adhesion TestersKok Keong TanNo ratings yet

- Cri 104 Standard For Installation of Commercial CarpetDocument48 pagesCri 104 Standard For Installation of Commercial Carpetbalan 16No ratings yet

- Pre-Grouting ChecklistDocument1 pagePre-Grouting ChecklistChukwuma OgbonnaNo ratings yet

- D 7167 Monitoring Performance of Safety Related Linings PDFDocument7 pagesD 7167 Monitoring Performance of Safety Related Linings PDFImmanuel100% (1)

- Saudi Aramco Inspection Checklist: Masonry Materials Receiving and Storage Inspection SAIC-M-1007 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Masonry Materials Receiving and Storage Inspection SAIC-M-1007 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Initial Concrete Batch Plant QC Surv (2002)Document6 pagesInitial Concrete Batch Plant QC Surv (2002)aslam.amb100% (1)

- Astm D5199-01Document4 pagesAstm D5199-01thaiduyduc123No ratings yet

- C938Document3 pagesC938jorgepitaNo ratings yet

- QCS 2014 - Section 2, Part 14 Appendix ADocument1 pageQCS 2014 - Section 2, Part 14 Appendix AJenna Mortel-DoligolNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- Asphalt ConcreteDocument132 pagesAsphalt ConcretePipim Pogi100% (1)

- Flood Testing Horizontal Waterproofing Installations: Standard Guide ForDocument5 pagesFlood Testing Horizontal Waterproofing Installations: Standard Guide ForCarlos Olivares ZegarraNo ratings yet

- ACI 301 - New Business - Whats Next - WilsonDocument33 pagesACI 301 - New Business - Whats Next - Wilsoneros100% (1)

- Chapter 9: Evalua On and Acceptance of Hardened ConcreteDocument9 pagesChapter 9: Evalua On and Acceptance of Hardened ConcreteGaneshNo ratings yet

- Astm C 32Document2 pagesAstm C 32yaseenNo ratings yet

- ASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsDocument10 pagesASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsMohammad Raihan MukhlisNo ratings yet

- Cold Weather ConcretingDocument2 pagesCold Weather ConcretingBoris DikovNo ratings yet

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Document7 pages1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNo ratings yet

- Civil Inspector For ARAMCO Interview-Question & Answers (1) CTSADocument6 pagesCivil Inspector For ARAMCO Interview-Question & Answers (1) CTSAmunirNo ratings yet

- Saic M 1031Document3 pagesSaic M 1031noor mohamedazeezNo ratings yet

- 09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteDocument7 pages09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteAbdul HannanNo ratings yet

- Standard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFDocument7 pagesStandard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFVCNo ratings yet

- C-CS-10-003 Inspection Testing Rev1Document13 pagesC-CS-10-003 Inspection Testing Rev1Johnny vargas suclupeNo ratings yet

- Water Tite 101Document2 pagesWater Tite 101Ruel Buntog100% (1)

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselNo ratings yet

- QCS 2010 Section 16 Part 5 WeldingDocument12 pagesQCS 2010 Section 16 Part 5 Weldingbryanpastor106No ratings yet

- E761 Gtqu3601Document3 pagesE761 Gtqu3601prasanth cpNo ratings yet

- Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling PanelsDocument6 pagesStrength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling PanelsMina RemonNo ratings yet

- Astm E736 E736m 19 2023Document2 pagesAstm E736 E736m 19 2023Jorgen AertsNo ratings yet

- PSA MOB PF2 PS SPU Spec PDFDocument95 pagesPSA MOB PF2 PS SPU Spec PDFTrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption Thermobreak 140518 PDFDocument2 pagesASTM C1763 Water Absorption Thermobreak 140518 PDFTrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption Thermobreak 140518 PDFDocument2 pagesASTM C1763 Water Absorption Thermobreak 140518 PDFTrà Trần SơnNo ratings yet

- ASTM E 648 Test Class IDocument7 pagesASTM E 648 Test Class ITrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption ThermobreakDocument2 pagesASTM C1763 Water Absorption ThermobreakTrà Trần SơnNo ratings yet

- ASTM E937 - 93 Reapproved 2011Document3 pagesASTM E937 - 93 Reapproved 2011Trà Trần SơnNo ratings yet

ASTM E761 - 92 Reapproved 2011 PDF

ASTM E761 - 92 Reapproved 2011 PDF

Uploaded by

Trà Trần SơnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM E761 - 92 Reapproved 2011 PDF

ASTM E761 - 92 Reapproved 2011 PDF

Uploaded by

Trà Trần SơnCopyright:

Available Formats

Designation: E761 – 92 (Reapproved 2011)

Standard Test Method for

Compressive Strength of Sprayed Fire-Resistive Material

Applied to Structural Members1

This standard is issued under the fixed designation E761; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E605 Test Methods for Thickness and Density of Sprayed

1.1 This test method covers a procedure for measuring the Fire-Resistive Material (SFRM) Applied to Structural

compressive strength of sprayed fire-resistive material (SFRM) Members

applied to a rigid substrate. These fire-resistive materials 3. Summary of Test Method

include sprayed fibrous and cementitious materials applied

directly in contact with these structural members. The test 3.1 The compressive strength of SFRM applied to a steel

method is applicable to laboratory procedure. sheet is determined by applying a crushing load normal to the

1.2 The values stated in SI units are to be regarded as surface of the specimen. This test method measures the stress

standard. The values given in parentheses are mathematical at 10 % deformation or at failure, whichever is smaller.

conversions to inch-pound units that are provided for informa- 4. Significance and Use

tion only and are not considered standard.

1.3 This standard does not purport to address all of the 4.1 The intent of this test method is to determine properties

safety concerns, if any, associated with its use. It is the of direct-applied SFRM that may be used to provide an

responsibility of the user of this standard to establish appro- indication of serviceability. Satisfactory performance of fire-

priate safety and health practices and determine the applica- resistive material applied to structural members and assemblies

bility of regulatory limitations prior to use. depends upon its ability while in place to withstand the various

influences that may occur during the life of the structure, as

2. Referenced Documents well as upon its satisfactory performance under fire tests.

2.1 ASTM Standards:2 4.2 This test method measures the compressive strength of

D2092 Guide for Preparation of Zinc-Coated (Galvanized) SFRM and is a measure of the resistance to deformation under

Steel Surfaces for Painting3 a compressive load. It is an indication of the ability of SFRM

E84 Test Method for Surface Burning Characteristics of to remain in place and resist removal during anticipated service

Building Materials conditions.

E119 Test Methods for Fire Tests of Building Construction 5. Apparatus

and Materials

5.1 Testing Machine—Any form of standard hydraulic or

mechanical compression testing machine accurate to 0.005 kg

1

This test method is under the jurisdiction of ASTM Committee E06 on

(0.01 lb) and 0.25 mm (0.001 in.).

Performance of Buildings and is the direct responsibility of Subcommittee E06.21 5.2 Spherical Bearing Block Assembly, having a plane

on Serviceability. bearing surface of 150 mm (6 in.) square. The upper bearing

Current edition approved April 1, 2011. Published August 2011. Originally shall be a spherically seated, hardened metal block firmly

approved in 1980. Last previous edition approved in 2005 as E761 – 92 (2005).

DOI: 10.1520/E0761-92R11. attached at the center of the upper head of the machine. The

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or center of the sphere shall lie at the center of the surface held in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM its spherical seat, but shall be free to turn in any direction, and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

its perimeter shall have at least 6-mm (1⁄4-in.) clearance from

3

Withdrawn. The last approved version of this historical standard is referenced the head to allow for specimens whose bearing surfaces are not

on www.astm.org. exactly parallel (see Fig. 1).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,`,``,`,,,```,,`,`,,`,,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 10:43:07 MST

E761 – 92 (2011)

7.4 Testing may be performed after it has been determined

that the specimen has reached constant weight.

7.5 Where necessary, even the surface of the specimen at

two areas 150 mm (6 in.) square at opposite ends of the

specimen with an appropriate capping material such as poly-

urethane, epoxy, polyester, or other similar materials. The top

plane of the capping material shall not exceed the thickest point

of the test area of a test specimen with an irregular surface by

FIG. 1 Spherical Bearing Block for Compressive Strength Test

more than 1.3 mm (0.05 in.).

7.6 Make two compression tests at opposite ends of the test

specimen. Make one density test on the specimen.

5.3 Drying Oven, capable of maintaining temperature and

7.7 Other types of non-compressible backing may be used if

humidity conditions during the specimen curing cycle, in

specified.

accordance with the SFRM manufacturers’ published require-

ments. 8. Procedure

6. Materials and Manufacture 8.1 Apply the load perpendicular to the face of the test

specimen, with the bearing block on top of the specimen. The

6.1 This test method requires the application of SFRM in

initial thickness of the test specimen for deformation calcula-

accordance with manufacturers’ published instructions. The

tions shall be the distance between the plane bearing surface of

apparatus, materials, and procedures used to apply the SFRM

the block assembly and the steel (backing) plane, after an

for this test shall be representative of application in the field.

initial load of 0.7 kPa (0.1 psi) has been applied to the

6.2 The density of the prepared sample shall be similar to

specimen.

the density tested and reported during the Test Methods E119

8.2 The speed of the moving head of the testing machine

and Test Method E84 fire exposure tests or as required by the

shall be not more than 1.3 mm (0.05 in.)/min. Compress the

sponsor of the test.

specimen until either a deformation of 10 % or ultimate load is

6.3 Determine the density and thickness of each of the

reached, whichever occurs first.

laboratory-prepared specimens. Report in accordance with Test

Methods E605. 9. Report

7. Test Specimen 9.1 Report the following information:

9.1.1 Compressive strength in kilopascals (or pounds-force

7.1 The test specimen shall be SFRM applied to galvanized

per square inch), including weight of spherical test block

steel sheet, 1.5 mm (0.060 in. (16 ga.)) minimum thickness,

assembly at 10 % deformation or at ultimate load, whichever is

175 by 600 mm (7 by 24 in.). Clean with solvent to remove

the smaller,

any oil on the surface to be sprayed, in accordance with Guide

9.1.2 Mode of failure, and

D2092.

9.1.3 Thickness in millimetres (or inches) and the density in

7.2 Apply the fire resistive material to the galvanized steel

kilograms per cubic metre (or pounds per cubic foot) of the

sheet at a minimum thickness of 19 mm (3⁄4 in.). Individual

SFRM.

thickness measurement shall be +3.0 mm (+0.125 in.) with no

measurement less than 19 mm (3⁄4 in.). 10. Precision and Bias

7.3 Condition the prepared specimen for a period of not less 10.1 Precision—The precision of the test method is being

than 72 h at room temperature (20 6 10°C (68 6 18°F)) and at developed and will be added when available.

relative humidity not greater than 60 %. After 72 h, the 10.2 Bias—The procedure in this test method has no bias

specimen may be force dried in a drying oven at 43 6 6°C because the value of the compressive strength can be defined

(110 6 10°F), and at a relative humidity not greater than 60 % only in terms of a test method.

until reaching constant weight.4

11. Keywords

4

Although mass is being determined, the term weight is used in this test method 11.1 compressive strength; sprayed cementitious; sprayed

as a field-accepted substitute. fibrous; sprayed fire resistive materials (SFRMs)

--`,,`,``,`,,,```,,`,`,,`,,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 10:43:07 MST

E761 – 92 (2011)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

--`,,`,``,`,,,```,,`,`,,`,,,``-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Committee on Institutional Cooperation/5967164001

No reproduction or networking permitted without license from IHS Not for Resale, 02/13/2012 10:43:07 MST

You might also like

- Astm C1180-10Document3 pagesAstm C1180-10LydiaNo ratings yet

- Inspection & Testing Plan For AggregatesDocument2 pagesInspection & Testing Plan For Aggregatesjerin sam kurianNo ratings yet

- Astm e 1745Document2 pagesAstm e 1745Zahoor Ahmed Mohsan100% (1)

- Rebound Hammer Test Procedure For Concrete HardnessDocument4 pagesRebound Hammer Test Procedure For Concrete HardnessSite Engineer.2p2No ratings yet

- Concrete Batch Plants CommentsDocument2 pagesConcrete Batch Plants CommentsShoaib SafdarNo ratings yet

- DCPT TestDocument10 pagesDCPT TestMonirul Islam BadalNo ratings yet

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyNo ratings yet

- D806-11 Standard Test Method For Cement Content of Hardened Soil-Cement MixturesDocument4 pagesD806-11 Standard Test Method For Cement Content of Hardened Soil-Cement MixturesRony YudaNo ratings yet

- D 4718 - 87 R94Document3 pagesD 4718 - 87 R94Joseph LinajaNo ratings yet

- Concrete Protective CoatingDocument10 pagesConcrete Protective CoatingShabbar Abbas MalikNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanKhurram ShehzadNo ratings yet

- Deviation Approval FormDocument3 pagesDeviation Approval FormMv PatelNo ratings yet

- Earth WorksDocument14 pagesEarth WorksJam100% (1)

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

- Aashto t23 FormDocument5 pagesAashto t23 FormTuan Do VanNo ratings yet

- Concrete Placement (Spec)Document18 pagesConcrete Placement (Spec)Vetrivel MuruganNo ratings yet

- Astm Codes For Paving TilesDocument2 pagesAstm Codes For Paving TilesrinjumathewNo ratings yet

- Early Cracking of Concrete PavementDocument25 pagesEarly Cracking of Concrete PavementRajesh KhadkaNo ratings yet

- C94C94M-15 Standard Specification For Ready-Mixed Concrete PDFDocument14 pagesC94C94M-15 Standard Specification For Ready-Mixed Concrete PDFdiego rodriguezNo ratings yet

- 02225Document6 pages02225uddinnadeemNo ratings yet

- Backfilling PDFDocument4 pagesBackfilling PDFAdjei BaldanNo ratings yet

- Ufgs 09 97 13.15Document43 pagesUfgs 09 97 13.15Tim KearneyNo ratings yet

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- Astm C1586Document3 pagesAstm C1586Lydia100% (1)

- Agencies Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Testing Agency EvaluationDocument9 pagesAgencies Testing Concrete and Concrete Aggregates For Use in Construction and Criteria For Testing Agency EvaluationCory BradleyNo ratings yet

- SSPC QS 1Document9 pagesSSPC QS 1FCTNo ratings yet

- TDS Nitocote EPU Saudi ArabiaDocument4 pagesTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- Renderoc TgxtraDocument2 pagesRenderoc TgxtratalatzahoorNo ratings yet

- ASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodDocument9 pagesASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodAdam Jones0% (1)

- 524r 16 PreviewDocument4 pages524r 16 Previewosama anterNo ratings yet

- Elcometer 266 DC Portable Holiday DetectorDocument3 pagesElcometer 266 DC Portable Holiday DetectorkhuramluckNo ratings yet

- Pull-Off Strength of Coatings Using Portable Adhesion TestersDocument16 pagesPull-Off Strength of Coatings Using Portable Adhesion TestersKok Keong TanNo ratings yet

- Cri 104 Standard For Installation of Commercial CarpetDocument48 pagesCri 104 Standard For Installation of Commercial Carpetbalan 16No ratings yet

- Pre-Grouting ChecklistDocument1 pagePre-Grouting ChecklistChukwuma OgbonnaNo ratings yet

- D 7167 Monitoring Performance of Safety Related Linings PDFDocument7 pagesD 7167 Monitoring Performance of Safety Related Linings PDFImmanuel100% (1)

- Saudi Aramco Inspection Checklist: Masonry Materials Receiving and Storage Inspection SAIC-M-1007 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Masonry Materials Receiving and Storage Inspection SAIC-M-1007 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Initial Concrete Batch Plant QC Surv (2002)Document6 pagesInitial Concrete Batch Plant QC Surv (2002)aslam.amb100% (1)

- Astm D5199-01Document4 pagesAstm D5199-01thaiduyduc123No ratings yet

- C938Document3 pagesC938jorgepitaNo ratings yet

- QCS 2014 - Section 2, Part 14 Appendix ADocument1 pageQCS 2014 - Section 2, Part 14 Appendix AJenna Mortel-DoligolNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- Asphalt ConcreteDocument132 pagesAsphalt ConcretePipim Pogi100% (1)

- Flood Testing Horizontal Waterproofing Installations: Standard Guide ForDocument5 pagesFlood Testing Horizontal Waterproofing Installations: Standard Guide ForCarlos Olivares ZegarraNo ratings yet

- ACI 301 - New Business - Whats Next - WilsonDocument33 pagesACI 301 - New Business - Whats Next - Wilsoneros100% (1)

- Chapter 9: Evalua On and Acceptance of Hardened ConcreteDocument9 pagesChapter 9: Evalua On and Acceptance of Hardened ConcreteGaneshNo ratings yet

- Astm C 32Document2 pagesAstm C 32yaseenNo ratings yet

- ASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsDocument10 pagesASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsMohammad Raihan MukhlisNo ratings yet

- Cold Weather ConcretingDocument2 pagesCold Weather ConcretingBoris DikovNo ratings yet

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Document7 pages1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNo ratings yet

- Civil Inspector For ARAMCO Interview-Question & Answers (1) CTSADocument6 pagesCivil Inspector For ARAMCO Interview-Question & Answers (1) CTSAmunirNo ratings yet

- Saic M 1031Document3 pagesSaic M 1031noor mohamedazeezNo ratings yet

- 09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteDocument7 pages09-SAMSS-068 Qualification Requirements For Coal Tar Epoxy in Buried or Immersion Services (APCS-3) For Steel and ConcreteAbdul HannanNo ratings yet

- Standard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFDocument7 pagesStandard Method For Making and Curing Cubes Made From Pre-Bagged Grouts and Polymer Modified Mortars PDFVCNo ratings yet

- C-CS-10-003 Inspection Testing Rev1Document13 pagesC-CS-10-003 Inspection Testing Rev1Johnny vargas suclupeNo ratings yet

- Water Tite 101Document2 pagesWater Tite 101Ruel Buntog100% (1)

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselNo ratings yet

- QCS 2010 Section 16 Part 5 WeldingDocument12 pagesQCS 2010 Section 16 Part 5 Weldingbryanpastor106No ratings yet

- E761 Gtqu3601Document3 pagesE761 Gtqu3601prasanth cpNo ratings yet

- Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling PanelsDocument6 pagesStrength Properties of Prefabricated Architectural Acoustical Tile or Lay-In Ceiling PanelsMina RemonNo ratings yet

- Astm E736 E736m 19 2023Document2 pagesAstm E736 E736m 19 2023Jorgen AertsNo ratings yet

- PSA MOB PF2 PS SPU Spec PDFDocument95 pagesPSA MOB PF2 PS SPU Spec PDFTrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption Thermobreak 140518 PDFDocument2 pagesASTM C1763 Water Absorption Thermobreak 140518 PDFTrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption Thermobreak 140518 PDFDocument2 pagesASTM C1763 Water Absorption Thermobreak 140518 PDFTrà Trần SơnNo ratings yet

- ASTM E 648 Test Class IDocument7 pagesASTM E 648 Test Class ITrà Trần SơnNo ratings yet

- ASTM C1763 Water Absorption ThermobreakDocument2 pagesASTM C1763 Water Absorption ThermobreakTrà Trần SơnNo ratings yet

- ASTM E937 - 93 Reapproved 2011Document3 pagesASTM E937 - 93 Reapproved 2011Trà Trần SơnNo ratings yet