Professional Documents

Culture Documents

DC Drives Catalogue

DC Drives Catalogue

Uploaded by

rajan_2002eee0 ratings0% found this document useful (0 votes)

24 views4 pagesKirloskar Drive

Original Title

Dc Drives Catalogue

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKirloskar Drive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

24 views4 pagesDC Drives Catalogue

DC Drives Catalogue

Uploaded by

rajan_2002eeeKirloskar Drive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

KIRLOSKAR

DIGITRAK MK II

me |

s

DIGITRAK

ae

QO=A50Mmrm

DIGITAL DC DRIVE

25A-3200A

STANDARD FEATURES

+ Parameter editing and drive programming,

Fully Digital Controller

Sel Commissioning,

Adaptive pulse triggering and gain switching with

avery [ast sampling rate tloachieve fast response,

Phase Locked Loop (PLL) technique for

synchronized zero crossing signal

Compensation for inpul line voltage and

frequency variation

Auto mains synchronization,

Common controller for single, woor four cuaalrant

operations

32 character alphanumeric display with backlite

and keypad for parameter / satus display

+ Seven segment display for viewing of crive status

Fess

and parameters trom a distance.

EEPROM for parameter storage.

Butensive self diagnostics

Faulk discrimination

Fault history.

Analog / Digital speed reference setting

Encoder /Tacho / Armature feedback faxility

Multiple isolated programmable digital input

outputs far system logic

Multiple isolated analog input / outpu

sgnal inter!

Bo isolated PWM outputs for meeting

Start / Stop facility through keypad with LED

indication

far drive

Galvanic isolation of controller ground.

Four layer printed circuit board (PCB) for compact

packaging, increased reiabilily and better noise

immunity

Fasy serviceability with hinged construction and

front accessibility

Large number of programmable featuess such as

selection of regenerative / non-regenerative

operation, bypassing ramp, selection of reference

and feedback types, selection of application

modules bypassing speed loop, bypassing inch

ramp, programmable digital outpuis for output

faulls and status, programmable analog outputs:

for diferent signals, bypassing of ramp for auxiliary

input, bypassing of ramp during stop, selection

of encoder as reference or feedback, selection of

current limit control, current control, ratio control,

thumbwheel ratio setting, crawl to run changeover

rive status on LED display ete

OPTIONAL FEATURES

+ Speed ramp rate control through analog signal

+ Curent reference control through analog signal

+ Current limit control through analog signal (40 20,

mA oF 01D)

+ Auxiliary speed reference setting with adjustable

gain and ramp time,

+ Raise / Lower operation

Inch/Cravel operation

+ Local / Remote reference selection

+ Master follower operation

+ Automatic feedback changeover.

From Encoder to Jacho feedback

From encoder to Armature feedback

From Tacho to Armature feedback

From Encoder to Tacho to Armature feedback.

+ Adjustable rate of rise of current reference signal

+ Ratio cantiol

+ Stretch control

+ RS 232485 Senal Communication

BASIC HARDWARE

+ Control PCB containing 16 bit microprocessors

assoviated interface and firing logic:

+ Signal interface circuit containing signal

conditioning, conversion circuits and status

indication LEDS for digital “0

+ Display boned containing 32.character LCD display

and 4 character, seven segment display with

keypad,

+0 tenmination Pee,

+ Switch mode power supply PCB

+ Power beard with pulse transformers andl other

interface companents,

ELECTRICAL SPECIFICATIONS

‘AC Input Voltage : 415, +/ 10F%

3 Phase, 3 wire

Frequency 47 Hz 10 63 Ue

De ourPUT

‘Armature Voltage : 400 / 440 / 460V

current Upto 32008,

Field Voltage 220 V ar 180 ¥ typical

ENVIRONMENTAL SPECIFICATIONS

Ambient temp. 0 to 50 Deg .

Humidity 0 to 85% RH

Non-condensing

altitude Uplo 100M above MSL

Storage Temperature | 10 to+ 65 Dey C

SAFETY AND PROTECTION

+ PLL circuit for providing immunity from line

transients and distortion

+ Automatic electronic trip and high speed pulse

inhiition under faults stich as

Phase fail

Field fail

© Instantaneous over current

AC under voltage

» DC over voltage

+

+

*

Mains under /” over frequency

Motor overspeed

Feedback fail / reverse

» DC loop open

» Inverse time overload

» Motor siall

© PLL Unlock

© Hardware watch dog trip

» Extemal fault

+ Software security for drive parameters,

A programming mocle key with LED indication

Prevents changes being made to parameters

unintentionally

Larthing stud for sale operation of equipment.

Calvanically sobted controland sgnal interface cards.

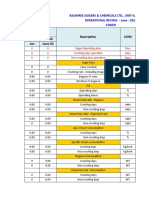

RATING CHART

TYPICAL DC MAX. CONT.

a hee MOTOR RATING DC CURRENT| COOLING TYPE

te AT 440V RATING.

10 40 HP KW AMPS |

Lo SNH) oR =r 12 9 NATURAL

2 SNIN-15 RII 15 7 8 NATURAL

3 | aN 11-22 SRIT-22 33 B NATURAL

4 | 3ni1-40 | 3R11-40 40 20 NATURAL

5 fant aR 11 ~ 55, 60 45 120 FORCE COOLED

6 |ann BR 11-70 65 9 130 NATURAL

z | antt-t30 | aR 11-130 | 138 104 28 FORCE COOLED

a fanit-165 | 3R11-165 | 158 re a1 FORCE COOLED

9 | ant1-200 | ar11-200 | 200 120 woo | FORCE cooLED

io | 3N11- 250 | BR 11-250 | 250 187 500 TORCE COOLED

1, | aN 11-300 | 3R11- 290 | 357 266 6 FORCE COOLED

12 | aN 11-350 | BR 11-350 | 450 326 850 TORCE COOLLD

13 aNLL-40 | BRIT Mo 518 386 FORCE COOLED

14, an 11-s20 | aRit-s20 610 465 1150 TORCE COOLED

15, aN11- 660 | 3R11- 660 | 854 636 1607 FORCE COOLED.

16. 3N 11-800 | 3R11- 800 | 1055 785, 1900 FORCE COOLED

IZ 3N11- 2200 | aR 11-2200) 1235 920 2200 FORCE COOLED

18 3N 11-2560 3R11- 2600) 1402 1045 2500 FORCE COOLED

19 3N11-3200 aR 11-3200] 1800 1341 3200 FORCE COOLED

NOTES

1. Module rating are for IP 00 degree protection

2. For IP 30 protection of panel derate the current ratings by 10%.

3. For IP 40 protection of panel derate the current ratings by 20%.

4, For IP 50 protection of panel derate the current ratings by 20%. However, please note, [P 50 protection can

be offered for range of modules 11-40, 70 which are natural cooled. For requirements of IP 58 protection for

other ratings, please refer to. manufacturing unit

APPLICATIONS

+ SUGAR + TESTRIG

1D Fan, FD Fan, Cane Crushers, GRPF drives, TRPF

crives, Centrifuges, Fibrisers, Mills etc.

+ MATERIAL HANDLING

Gear box test rig, Engine test tig, Turbine test tig,

Clutchtest rig, Helicopter blade test rig etc

+ PAPERMILL

Wagon Tippler, Stacker Reclimers, Conveyors,

Weigh heeders etc Line shaft or Sectional drives, Rewinders, Sitters,

Cuttersete

4 TRE & RUBBER

Extrucer, Conveyor, Mixer,Calender, Fabric dip units 4 STEEL

S Hot Rolling, Cold Rolling, Casters, Process line,

CEMENT Finishing line, Stretch Mill, Forming Mill, Tube

Kilns, Classifiers, Prebeaters, Fans, Cooling Mill Draw Bench, Pinch Roils, Colers, Kiln Main

Conveyors, Weigh Feeders, Grate Coolersetc Delve; Pete Mill ete

4 PLASTIC + CABLE &WIREDRAWING

Blow Film line, Extrusion line, Kneader etc. Winders, Rewinders, Coiler, Excentiic Binder,

TEXTILE Drawing, Spoolers, Concentric Binders, Takeup

Webwinder, Draw Texturisingete

KIRLOSKAR ELECTRIC COMPANY LTD.

WORKS Belavadi industrial Area, Mysore 570.018, Phone 0821 2402522 26, Dir: 2402179 Fax ; 2402266

mail infovkeed.com

CORP OFFICE : PBNo. S855, Malleshwaram West, BANGALORE-560055. Phone O80-24374865, 23378735 Fax: 23377706

Sales Offices (Telephone Nos.)

New Delhi 01126233788 Ludhiana, D161 2773985

Lucknow — 0522-2789035 Jaipur 0141-5108212

Kolkata 033-24861370 ‘Bhubaneswar 674-2555774 For more deatils, please contact

Jamshedpur 0657-2226326 Guwahati 0361-2668736

Mumbai 022-24912585, Ahmedabad — 079-27541428 z

Pune 020-27011025 ‘Surat 10261-2687920

Nagpur 0712-2545901 Indoor 9731-2827750

Chennai (044-26614785, Durg, 0788-4050383, |

Coimbatore 0422-2238263. Raipur 0771-5092693,

Madurai 0452-2700651 —Hyderabeel__040-23310497 5

Cochin 0484-2356709 Vizag 0891-2729693 gE

Bangalore 080-22270075

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SL - Crane HoistDocument1 pageSL - Crane Hoistrajan_2002eeeNo ratings yet

- Handbook PDFDocument168 pagesHandbook PDFrajan_2002eeeNo ratings yet

- Or Report 2021Document24 pagesOr Report 2021rajan_2002eeeNo ratings yet

- 403-3200-00-C5 MFD-FSD OmDocument31 pages403-3200-00-C5 MFD-FSD Omrajan_2002eeeNo ratings yet

- Policy For 24x7 Power To Industrial Consumers 24x7 Power To Industrial Consumers 24x7 Power To Industrial ConsumersDocument3 pagesPolicy For 24x7 Power To Industrial Consumers 24x7 Power To Industrial Consumers 24x7 Power To Industrial Consumersrajan_2002eeeNo ratings yet

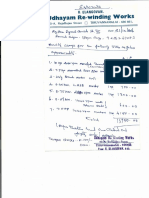

- Am Re-Winding Works: UdhayDocument1 pageAm Re-Winding Works: Udhayrajan_2002eeeNo ratings yet

- ASR StarterDocument2 pagesASR Starterrajan_2002eee100% (3)

- Mitigate VFD Harmonic - Encon EngineersDocument4 pagesMitigate VFD Harmonic - Encon Engineersrajan_2002eeeNo ratings yet

- TGP - 45 - R0Document1 pageTGP - 45 - R0rajan_2002eeeNo ratings yet

- PMG PDFDocument6 pagesPMG PDFrajan_2002eeeNo ratings yet

- Sx460 Automatic Voltage Regulator (Avr)Document4 pagesSx460 Automatic Voltage Regulator (Avr)rajan_2002eee100% (1)

- Matrimonial Bureaus in and Around Villupuram - SouthsearchDocument5 pagesMatrimonial Bureaus in and Around Villupuram - Southsearchrajan_2002eeeNo ratings yet

- Abb Acs550-01-012a-4Document2 pagesAbb Acs550-01-012a-4rajan_2002eeeNo ratings yet