Professional Documents

Culture Documents

Engineering and Ship Production Technology For Lightweight Structures

Engineering and Ship Production Technology For Lightweight Structures

Uploaded by

Josua Sahat Parulian SinagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering and Ship Production Technology For Lightweight Structures

Engineering and Ship Production Technology For Lightweight Structures

Uploaded by

Josua Sahat Parulian SinagaCopyright:

Available Formats

Engineering and Ship Production Technology for Lightweight Structures

Engineering and Ship Production Technology for

Lightweight Structures

T.D. Huang

Northrop Grumman Ship Systems

Dennis D. Harwig

Edison Welding Institute

Pingsha Dong

Battelle Memorial Institute

Lawrence A. DeCan

University of New Orleans, Gulf Coast Region Maritime Technology Center

Shipboard applications of lightweight structures have increased over recent

years in both military and commercial vessels. Buckling distortion of complex

lightweight panels has historically had a significant negative effect on manu-

facturing cost and production throughput, limiting shipbuilders’ ability to

produce innovative ship designs. To tackle the distortion problems, in 2002

Northrop Grumman Ship Systems initiated a multiyear program to develop

distortion-control technology for complex panels. Such structures have

thickness transitions from multiple inserts ranging from 5 to 45 mm for weight

and structural optimization. Complex panel mock-ups were used to determine

how best to transition a modern shipbuilding facility designed for thick-plate

construction into a lightweight panel production facility. The objectives

focused on detailed solutions for numerical finite-element modeling; preferred

cutting, welding, and fabrication processes; and optimal assembly methods for

distortion control. This article describes the processes and procedures used to

develop a preferred manufacturing plan. When implemented, the preferred

manufacturing plan produced thin conventional panels with no buckling

distortions and complex panels with some buckling near manually welded

inserts. The successful implementation of the process techniques recommended

from this program will lead to a higher quality ship for the U.S. Navy, while

realizing significant savings by reducing rework. Northrop Grumman, the

states of Louisiana and Mississippi, and the U.S. Navy have jointly committed

to major investments to support the implementation of these processes as part

of the new capital improvement initiative at Northrop Grumman Ship Systems.

Introduction

In recent years, ship designers have been forced to incorporate lighter, thinner steel

structures to reduce topside weight, improve fuel economy, and enhance mission capabil-

ity. Over the past decade, the production ratio of thin-steel (10 mm or less) to thick-plate

structures for vessels built at Northrop Grumman Ship Systems rose to over 90% per

vessel. At the same time, both military and commercial owners have tightened the design

requirements in strength, stiffness, and fitness to meet more stringent performance

specifications [1–4].

Technology Review Journal • Spring/Summer 2005 1

Engineering and Ship Production Technology for Lightweight Structures

Significant problems due to distortion have emerged as shipyards work to meet the new

requirements. For the most part, the infrastructure, design methodologies, and construc-

tion techniques in U.S. shipyards are not designed to support such lightweight fabrica-

tions. Thin steel is more likely to deform and production is more difficult, because the

panels lack rigidity until integrated into a structural unit. Material-handling systems

require different tooling that facilitates accurate cutting, layout, and welding processes.

Residual stress and distortion induced by steel mill processing, material handling, and

manufacturing processes, such as cutting, tacking, and welding, result in progressive

manufacturing problems in downstream operations. Overwelding in excess of 200% is

common in the industry to compensate for fit-up gaps [5]. Distortion-repair costs are

significant, based on man-hours for difficult unit fit-ups, flame straightening, and rework.

Ship panels are made as large as possible to minimize the number of erection joints.

Typical panels are about 16 × 16 m and require butt welding of several plates to achieve

the design shape and dimension. To meet design requirements and optimize vessel

stability and weight, ship panels are tailored with multiple inserts of different thickness.

When stiffeners are attached, the large plate panels exhibit low buckling strength, because

of their size and the large aspect ratio of the length of the stiffeners relative to the spacing

between them.

In 2002, Northrop Grumman Ship Systems initiated a multiyear program to develop

distortion-control technology for complex lightweight ship structures. Data from the first

part of the study, presented in a previous article [6], were used to benchmark panel fabri-

cation processes. The second part of the study, discussed here, conducted a detailed

assessment of design and manufacturing processes for complex panels, including eval-

uation of material handling and tooling, cutting processes, welding processes, panel

assembly sequence, and repair statistics. A series of test panel mock-ups was used to

benchmark the combined effects of panel complexity and current production methods.

Lidar dimensional analysis was used to profile distortion before and after cutting, tacking,

and welding of panel butt seams and panel stiffeners. Distortion numerical modeling was

used to establish the capability of that engineering tool and its potential for optimization

of design and production methods.

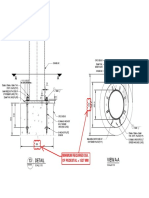

The first test panel mock-ups, using three designs of increasing complexity shown in

Figure 1, were built using the methods developed for heavy plate:

• Panel 1 was simply two 5-mm base plates butt-welded together with eight equally

spaced T-stiffeners.

• Panel 2 was identical to panel 1, except that a 10-mm insert plate with typical trans-

verse reinforcing stiffeners was added “in way of”—i.e., to support—a circular

penetration.

• Panel 3 was identical to panel 2, except that two additional thickness transitions were

added at both ends to simulate the improved joint connections of ship structures [6].

Significant distortion—primarily buckling distortion—was observed on all three designs

when processed through the traditional heavy-plate-panel manufacturing line. Distortion

severity increased with panel complexity. Findings from the initial manufacturing-process

assessments and panel mock-ups [6] can be summarized as follows:

• The sources of distortion included residual stress and shape in incoming materials,

material-handling damage, cutting accuracy, intrinsic deflection in tooling and found-

ations, fit-up accuracy, overwelding, assembly sequence, panel design complexity,

and excessive rework.

2 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

4876 (16 ft nominal) 4876 (16 ft nominal)

2438 2438 2438 2438

WT WT

100 x 7.5 100 x 7.5

AH-36 AH-36

(TYP) 152 (TYP)

6096 (20 ft nominal)

6096 (20 ft nominal)

R

229

5 mm

610 DH-36

(TYP)

5 mm 1753 914-mm-

DH-36 Diameter

(TYP) Penetra-

3048

tion

10 mm

EH-36

1525

610 610 610 610 610 610

5 305 305 5 305 305

TYP TYP

a. Test panel design 1 b. Test panel design 2

Note:

4876 (16 ft nominal)

Unless otherwise specified, all dimensions

2438 2438 are in millimeters.

10 mm

EH-36

610

229 152 914-mm-

Diameter

6096 (20 ft nominal)

R

Penetra-

tion

610

5 mm

Weld size varies

DH-36

10 mm EH-36 WT d. Butt weld

100 x 7.5

1753 AH-36

(TYP)

3048

5 mm

DH-36

10 mm

EH-36 610

1525

610 610 610

5 305 305

TYP Weld size varies

c. Test panel design 3 e. Fillet weld

Figure 1. Lightweight test panel mock-up designs 1 through 3

Technology Review Journal • Spring/Summer 2005 3

Engineering and Ship Production Technology for Lightweight Structures

• The dominant distortion mechanism in lightweight panels was local buckling, which

promoted severe edge waviness that interfered with downstream unit erection.

• Manual welding of inserts introduced severe distortions because of the high heat

inputs and overwelding procedures used by welders.

• A fit-and-weld assembly sequence promoted excessive buildup of distortion, which

interfered with subsequent fit-up and in turn promoted further distortion.

• Mechanized seam tracking used with conventional double-sided fillet welders

promoted overwelding, because that seam-tracking technology did not cope with T-

stiffener web waviness and fit-up errors. The fillet-weld area was typically twice that

required to ensure minimum weld (leg) size and dissolve large manual tacks.

Multiple process and manufacturing changes were proposed to measure, assess, and

control the variables that cause distortion. This article describes the results of testing an

additional 12 panel mock-ups, four of each design, and shows how those results led to a

combination of processes that constitute the new, preferred manufacturing plan.

Experimental Approach

A process improvement plan was developed to study the variables, listed in Table 1, that

cause distortion in complex lightweight steel panels. Four fabrication panel mock-ups were

made for each panel design (1, 2, and 3) shown in Figures 1a–c. The panel mock-ups were

used to study the effects of the cutting process (plasma or laser), weld size (Figures 1d

and 1e), assembly sequence (i.e., fitting, tacking, welding sequence, and two-half

assembly), transient thermal tensioning, and reverse arching.

The four test panels were designated A, B, C, and D for each design. All A and B panel

pieces were plasma-cut to size. All C and D panel pieces were laser-cut to size. The laser

had a cutting accuracy of 0.1 mm/m. The target dimensional tolerance, ±0.5 mm, was met

by the laser but not by the plasma cuts for all dimensions shown in Figure 1. The high

energy used in plasma cutting, designed for cutting thick plates, causes greater distor-

tions than laser cutting in the thin plates addressed by this study.

All panel pieces were assembled using double-sided submerged arc welding (SAW) for

the butt welds along the longitudinal and transverse seams. That procedure involved

fitting all plate pieces into the panel, tack welding, seal welding of gaps larger than 1.5 mm,

SAW welding of side 1, flipping the panel, and, finally, SAW welding of side 2. In general,

all longitudinal seams were submerged-arc-welded before the transverse seams. The SAW

Table 1. Variables for panel distortion experiment and numerical analysis

Design 1 Design 2 Design 3

Variable 1A 1B 1C 1D 2A 2B 2C 2D 3A 3B 3C 3D

Cutting method Plasma Laser Plasma Laser Plasma Laser

Weld size (mm) 5 5 4 5 5 5 5 5 4 4 3 3

Two-half assembly – – – – – – X – – – – –

Assembly sequence 1 1 1 1 2 2 3 1 4 1 4 1

Thermal tensioning – X – – – – – – – X – X

Reverse arching – – – – – X – – X – X –

4 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

parameters ensured overlapping full-penetration welds. Transverse SAW weld reinforce-

ment was ground off in the location of T-stiffeners.

Three fillet-weld sizes were studied—3-, 4-, and 5-mm—using optimized (i.e., preferred)

flux-cored arc welding (FCAW) parameters for a 1.2-mm-diameter E71T-1 electrode and CO2

shielding gas. Table 2 lists the parameters used for each fillet-weld size. The welds were

made using a double-sided machine with mechanical seam-tracking wheels. To maximize

weld quality, two operators crawled on each side of the panels and manually adjusted the

welding torch tool-point to achieve first-time quality—i.e., the preferred parameters for

precision fillet welding (Table 2)—in accommodating the errors due to T-stiffener web

waviness.

All stiffeners were clamped approximately every meter, using hydraulic rams provided by

the double-sided welding system. Under the clamps and panel was a solid mandrel that

provided continuous bearing support. The clamping was able to remove small gaps

between the tack welds. All tack welds were made manually and ground (if necessary) to

be smaller than the target fillet weld. The goal was to dissolve the tacks into the double-

sided fillet welds smoothly, so as to avoid generating the lack-of-fusion defects so

common near poor tacks.

In traditional manufacturing, the T-stiffeners are assembled using an incremental fit-and-

weld approach. However, that procedure was found to cause a progressive buildup of

distortion, making the subsequent stiffener assembly in lightweight structures more

difficult to fit and weld. For this study, therefore, all stiffeners were pretacked to maximize

panel rigidity. That assembly method was found to inhibit distortion.

In addition, two-half assembly was found to improve the panel rigidity for the SAW-panel

longitudinal-seam welds. The longitudinal residual stresses after welding the T-stiffeners

were modeled and found to be more favorable in each half. The modeling showed that a

significant increase in buckling strength can be achieved during the butt-seam welding of

the two halves. That procedure involved tacking and then welding all stiffeners before

applying the SAW longitudinal-seam weld. Two-half assembly was studied on panel

mock-up 2C.

Several different assembly sequences were studied with panel designs 1, 2, and 3. All

sequences were studied on panel mock-ups on which all stiffeners had been pretacked

before fillet welding to maximize rigidity. The assembly sequences are defined as follows:

Table 2. Preferred flux-cored arc welding parameters for three fillet weld sizes:

3, 4, and 5 mm

Parameter

Weld size WFSa TSb Arc Length CTWDc Voltage Current Heat Input

(mm) WFS/TS a,b (m/min) (m/min) (mm) (mm) (V) (A) (J/s)

3 5.8 5.8 1.0 1 11 21 215 4.515

4 10.4 7.8 0.75 1 14 25 265 8.833

5 15.6 7.8 0.5 2 17 27 225 12.15

a WFS: Wire feed speed

b TS: Travel speed

cCTWD: Contact tip to work distance

Technology Review Journal • Spring/Summer 2005 5

Engineering and Ship Production Technology for Lightweight Structures

• Assembly sequence 1, used on panel mock-ups 1A through 1D, 2D, 3B, and 3D, is

a right-to-left procedure applied after all stiffeners are tacked. It simulated a preferred

production flow during which the panel keeps moving down the assembly line.

• Assembly sequence 2, used on panel mock-ups 2A and 2B, welded the stiffeners from

the center, starting near the SAW longitudinal-seam weld. Then the stiffener-welding

sequence alternated from side to side. Again, all stiffeners were prefitted and tacked.

Sequence 2 was believed to split the distortion that develops when welding from edge to

edge, especially if a traditional fit-and-weld assembly sequence is used in the

manufacturing process.

• Assembly sequence 3, used on panel mock-up 2C, split the panel into two halves.

Each half was prefitted with stiffeners and double-sided fillet-welded. The panel was

completed with the SAW longitudinal-seam weld. That approach was believed to

reduce seam-welding distortion by increasing panel rigidity and simplifying stiffener

fit-up, as no seam-weld distortion was present to interfere.

• Assembly sequence 4, used on panel mock-ups 3A and 3C, was the same as

sequence 2, except reverse arching was used after welding to mitigate distortion.

Transient Thermal Tensioning. Thermal tensioning techniques have been under

development at Edison Welding Institute (EWI) since mid-1990. They were first tested in

1999 at Northrop Grumman Ship Systems for lightweight ship panel application on U.S.

Navy vessel class DDG-51 in the Department of Defense’s Manufacturing Technology

(MANTECH) program, Distortion and Accuracy Control project (S0916). Since March

2003, EWI has been working with Ship Systems on the U.S. Navy’s Office of Naval

Research’s Shipboard Applications of Lightweight Structures program, which has tested

thermal tensioning on a series of full-scale ship panels and found it to be partially

successful. The current approach, called transient thermal tensioning (TTT), has been

chosen from among several alternative approaches as one that is particularly easy to

apply during panel fabrication.

As shown in Figure 2, TTT uses local heat sources that move along the plate to induce

local plate tension. Precise application of local plate tension is used to remove welding-

induced compressive stress in panel membranes. Though analogous to preventive flame

straightening, TTT is performed before straightening is required. It can be particularly

valuable in adding tensile stress adjacent to free edges, where even minimal compressive

stress can cause buckling. In fact, TTT is advantageous in any area where buckling would

be likely to create severe plate deformation.

TTT can be more useful than flame straightening because it can effectively prevent the

initiation of thin-steel buckling distortion in an earlier stage of the manufacturing process

than can flame straightening, which is applied at the end. Flame straightening causes

stress redistributions not only in the longitudinal stiffener direction, but also in the

transverse direction. TTT, on the other hand, redistributes stresses in the longitudinal

stiffener direction, but it allows the transverse residual stresses to be released by plate

shrinkage at the panel line, while the panel is still free to contract in the tranverse direc-

tion. Thus, TTT can alleviate the problems of structural crippling that result from repeti-

tive straightening of adjacent areas in the deck and bulkhead structures at the final unit

assembly stage of ship construction using flame-straightening methods.

TTT was used on panel mock-ups 1B, 3B, and 3D. The numerical models were developed

to help choose the most beneficial sequence and pattern of when and how the thermal

tensioning is applied.

6 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

Side

Weld Heater

Electrode

Offset

Side

Heater

Tensioning

Weld Dimensions

Electrode Tensioning

Dimensions

Figure 2. TTT tooling setup

Reverse Arching. A new technique, reverse arching, developed after extensive numerical

modeling, can effectively remove distortion immediately after the welding of T-stiffeners.

The process is based on removing the high-longitudinal residual stresses that develop

under the T-joint. The high-magnitude compressive residual stress along the weld

direction serves as the driving force for buckling distortion. With the proposed reverse-

arching technique, a bending action is imposed as each T-stiffener fillet is completed, to

subject the plate and fillet weld to tension. On release of the bending action, the longitudi-

nal residual stresses should be significantly reduced, thus alleviating buckling distortion.

In the current shipyard process environment, it was not feasible to perform the reverse-

arching technique immediately after each T-stiffener was completed. Instead, the tech-

nique was evaluated by performing the reverse arching after all T-stiffeners were welded.

Bending supports were placed under the test panel, and hydraulic rams at the double-

sided fillet welder provided the force. Reverse arching was performed on panel mock-ups

2B, 3A, and 3C.

Hard Deck Foundation. A major problem at Northrop Grumman Ship Systems’ New

Orleans Operations was the work foundations, which are caster beds with the casters

staggered on a 2-m spacing. Thin-steel panels are relatively flexible and were found to

significantly bow between the casters, making assembly, fit-up, and welding difficult. To

evaluate a best-case condition for work support, a hard deck foundation (HDF) was

proposed and built. The objective was to eliminate work-foundation-induced distortions

by using the HDF as much as possible, so that other variables could be evaluated.

Technology Review Journal • Spring/Summer 2005 7

Engineering and Ship Production Technology for Lightweight Structures

An HDF was designed using two 25-mm plates that were separated and reinforced with

a grid of I-beams. Surveyed using lidar, the HDF was found to be extremely flat after fabri-

cation. The HDF was used to build all 12 test panel mock-ups in the improved manufactur-

ing process—which included fit-up and double-sided SAW welding of butt seams, fit-up

of stiffeners, and double-sided fillet welding.

Lidar Distortion Measurements. Distortion measurements (out-of-plane dimensional

variations) at various stages of fabrication were performed using a lidar system. In

principle, lidar is analogous to radar. Radar functions using radio waves, whereas lidar

uses much higher-frequency light waves. The lidar system emitted a series of near-infrared

laser pulses through a range of motion, and it measured the time required for each pulse to

be returned to the detector. The system collected 1000 point measurements per second

over a range of 2 to 100 m. A contour map illustrating out-of-plane distortions in the test

panels was generated, with an accuracy of ±2 mm at 10 m. To facilitate the lidar measure-

ments, a dedicated steel-frame platform was built for positioning both the part to be

measured and the lidar equipment above the test panels. The results for each variable

evaluated in Table 1 were compared using lidar distortion topography data, as shown in

Figures 4, 6, 10, 11, and 12 below (pages 11, 13, 16–18).

Numerical Modeling. Numerical models using ABAQUS, a commercial nonlinear finite-

element software package, were performed for panel mock-ups 1, 2, and 3, shown in

Figure 3. The panels were fabricated using the current panel line. All models were scaled

to magnify distortions with a multiplication factor of 20. All three panels showed distor-

tion, combining edge waviness with oil canning. The oil-canning distortion is a periodic

buckled wave between the stiffeners that relates to a frequency proportional to the

stiffener half-spacing. Such combinations of buckling modes were observed on mock-ups

of all three panel designs. Oil-canning distributions were very well predicted by the

numerical modeling techniques.

We developed new models to predict the distortion for some of the test panel mock-ups

listed in Table 1. The models were also used to measure the effects of the variables listed

in Table 1.

a. Mock-up using design 1 b. Mock-up using design 2 c. Mock-up using design 3

Figure 3. Numerical models of out-of-plane buckling in panels built in initial study [6]

8 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

Discussion of Experimental and Numerical Results

In the initial manufacturing process [6], nine panel mock-ups were built using the current

panel line, which was designed to fabricate plate panels greater than 12 mm thick. A caster

bed provided material support. Panels were moved by means of chain pullers that grip the

panel edges. Double-sided SAW welds were used to build designs 1 through 3 with

square groove joints.

The nine panels were assembled with the flat side up, i.e., the stiffener side. No clamping

was available for the SAW seam welds. The seam weld was made on the flat side after

assembly and seam tacking. Then the panel was flipped and welded from the opposite

side to provide overlapping weld beads that ensure complete groove penetration [7].

The original panel mock-ups used an average of 6.5-mm fillet welds with an incremental fit-

and-weld assembly sequence [6]. The mock-ups, which were made using current panel-

line technology, resulted in large buckling distortions.

All 12 panel mock-ups built in the improved manufacturing processes used the HDF.

The improved processes were found to significantly increase fit-up ease and dimensional

accuracy. Shims were used to fit the panel pieces flat side up. The HDF was used for each

panel mock-up from panel assembly through double-sided SAW, prefitting of stiffeners,

and completion of double-sided stiffener fillet welds.

Before building the 12 panel mock-ups, precision fillet-welding parameters were developed

for the FCAW process. The preferred parameters—listed in Table 2 and selected via the

ARCWISE™ parameter development method [5]—yielded fillet welds that offered the best

combination of face and underbead profile, as well as travel speed. The preferred param-

eters maximized travel speed but avoided high-weld-penetration parameters, which pro-

moted burn-through when traveling over fit-up gaps larger than 1 mm. The gap limit was

the target tolerance for the preferred manufacturing plan for lightweight structures.

The tooling used for double fillet welding employed mechanical seam tracking. A wheel

was positioned 150 to 200 mm in front of each welding torch. During welding, the opera-

tors controlled the fillet weld shape by manually adjusting the position of the arc at the

weld start. As the weld size was reduced from 5 mm to 3 mm, the operators could not rely

on mechanical seam tracking. The thin-steel T-stiffeners were observed to have some

waviness. Any beam waviness or large gap (>1 mm) in fit-up would have caused unequal

fillet-weld legs. In those tests, the operators crawled and steered the weld pool to maximize

first-time weld quality. The goal was to measure the distortion effects of the Table 1

variables with no repair. Overall, the operators were able to make welds as small as 3 mm

on our panel mock-ups. Such precision welding was made possible by the HDF, prefitting

of all stiffeners, contour grinding tacks for dissolvability, hydraulic clamping during

double-sided fillet welding, and real-time seam tracking via operators.

Panel Mock-ups 1A through 1D. Panel mock-ups 1A through 1D were built as shown in

design 1 in Figure 1—a design that simulated panels of constant thickness and uniform

beam length and spacing. Panels 1A and 1B were plasma-cut, as specified in Table 1.

They were built with the same processes, except that TTT was used concurrently with

double-sided fillet welding on panel 1B. Panel 1C had laser-cut pieces and smaller fillet

welds, 4 mm instead of 5 mm. Panel 1D was also made using laser-cut pieces and the

remainder of the panel variables were essentially the same as those of 1A.

Technology Review Journal • Spring/Summer 2005 9

Engineering and Ship Production Technology for Lightweight Structures

In general, the laser-cut pieces were found to produce nearly perfect fit-ups. As the panel

mock-ups were assembled, no visible gaps were observed along seam welds. The nearly

perfect fit-up allowed consistent double-sided SAW welds. The plasma-cut pieces pro-

duced an hourglass fit-up profile along each weld seam when viewed from above. The

gaps exceeded the 1.5-mm welding criterion and required complete seal welding at both

ends of the SAW seam. Such excessive gaps promoted overwelding and panel distortion

before stiffener fitting.

For simplicity of description, the discussion of the lidar data on and numerical models of

these panels is divided into two sections. Here, we will consider models of panels without

TTT. The following section will deal with panel 1B and the application of TTT.

Some aspects of the panel mock-ups were not modeled, because the weld thermal cycle

did not change. The ABAQUS buckling model considered only weld heating cycles and

the original stiffener curvatures. The effects of fit-up gap and plate residual stress from

cutting were excluded to simplify the analysis procedures. Thus, the differences in edge

condition between laser and plasma cutting were not observed in the ABAQUS models,

nor were differences due to welding sequence changes or reverse bending.

Panel mock-up 1C was visually observed to have far less buckling distortion and panel

arching than panels 1A and 1D. Panel 1C was welded with 4-mm fillets instead of 5-mm.

The smaller weld size reduced the compressive residual stresses in the panel that lead to

buckling. Numerical models were performed to evaluate the case where the fillet-weld size

had been reduced to 4 mm from the previous average measurement of 6.5 mm produced by

the initial manufacturing process. Both the lidar measurement and the numerical model

results showed more than a 50% decrease in buckling distortion.

Panel Mock-ups 2A through 2D. Panel mock-ups 2A through 2D were similar to those for

design 1 (Figure 1), except that a 10-mm insert was placed along one side of the SAW

seam weld. The 10-mm insert plate material was plasma-cut with a 3-to-1 bevel edge-

transition. The SAW process was capable of welding the linear portions of both the

longitudinal and transverse seams of the insert.

The corner radius joint area of the insert was welded with a manual FCAW. The corner

radius welds were larger than the SAW seam welds. The SAW weld reinforcement was

removed for stiffener fit-up and welding, and the transverse stiffeners were added after the

completion of all fillet welds on the longitudinal stiffeners. A manual FCAW was used to

make the fillet welds on the transverse beam stiffeners and intersection joints. All manual

FCAW fillet welds used for the stiffener intersections were about 8 mm or larger—

significantly greater than the required 5-mm weld size specified by the Navy contract for

LPD-17-class vessels.

Panel mock-ups 2A and 2B were plasma-cut and were more difficult to assemble. The

laser-cut panel pieces were easy to fit up for panels 2C and 2D, but the insert was slightly

oversized and caused some panel buckling before SAW welding. Panels 2A through 2D all

had 5-mm fillet welds, and several different assembly sequences were performed. Panel 2D

used the conventional right-to-left assembly sequence after all stiffeners were prefitted

and tacked, as shown in Figure 4a. That assembly method was much better than the fit-

and-weld assembly sequence in the intial manufacturing process, which permitted

distortion to build into the fit-up of subsequent stiffeners [6]. In the initial fit-and-weld

assembly sequence, each subsequent stiffener was found more difficult to fit to the panel,

and the fit-up and buckling distortion increased as welding progressed from the first

stiffener to the last.

10 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

Assembly

Sequence Effects

a. Panel mock-up 2D: b. Panel mock-up 2B:

Conventional welding sequence Before reverse arching

Out-of-Plane Reverse-

Distortion Arching

Value (mm) Effects

70

65

60

55

50

45

40

35

30

Support

25 Collapsed

20 during

15 Arching

10

5

c. Panel mock-up 2B:

0 After reverse arching

Figure 4. Lidar comparison of panel mock-ups 2B and 2D: Effectiveness of reverse-

arching technique with preferred T-stiffener assembly sequence

Panel mock-up 2B used a center-out welding sequence after all stiffeners were prefitted

and tacked, as shown in Figure 4b. That approach produced the least distortion of any

assembly method and was slightly better than welding sequence 1 when all stiffeners were

prefitted and tacked before fillet welding. Good clamping is used to iron gaps out of the

stiffener-to-panel T-joint.

Two-half assembly (sequence 3) was performed on panel mock-up 2C. That assembly

technique was found to reduce SAW seam distortion, with the peak distortion at the ends

of the SAW welds. Overall, however, two-half assembly is not currently recommended for

implementation, because material clearance made it incompatible with dedicated SAW

seam welders. In addition, two-half assembly interfered with the preferred material flow,

panel welding productivity, and accuracy control of stiffener location. For the long term,

Technology Review Journal • Spring/Summer 2005 11

Engineering and Ship Production Technology for Lightweight Structures

however, the benefits cited earlier for two-half assembly warrant reconsideration if the

construction requirements become more exacting. At that point, the ability of two-half

assembly to meet stricter requirements might justify the cost of revising the material flow

process.

Panel Mock-ups 3A through 3D. Panel mock-ups 3A through 3D were similar to those for

design 2 (Figure 1), except 10-mm transverse plate transitions were placed along both

edges of each panel. The transverse plates were 610 mm wide and created significant

restraint. The transverse SAW welds were made after the longitudinal SAW seam welds

on side 1, and again after the longitudinal seams on side 2, but only after the panel had

been flipped. Panel assembly was performed without clamping near the plate and adjacent

to the seams. Some panel buckling distortion was observed after all SAW welds were

completed. Stiffener fit-up was achieved, though more clamping and tacking work was

required before double-sided fillet welding.

Panels 3A and 3B were built from plasma-cut pieces; 4-mm T-stiffener fillet welds were

used. Panels 3C and 3D were constructed from laser-cut pieces, with 3-mm fillet welds.

TTT was applied concurrently with fillet welding on panels 3B and 3D. Reverse arching

was used after fillet welding on panels 3A and 3C to remove buckling distortion and edge

waviness. Both distortion-mitigation techniques showed promise but require further

development to optimize the process for complex panels with thickness transitions and

inserts.

Transient Thermal Tensioning. Three panel mock-ups from the second round, designated

1B, 3B and 3D, were chosen for application of TTT. The heating process was modeled in

ABAQUS using an approach similar to the modeling of welding:

• First, the heating pattern was modeled to get the heat distribution around a single

heating line.

• Second, the residual stresses generated by that heating line were modeled.

• Third, the heating lines were placed where needed on the final panel design using

truss elements that created equivalent forces, as shown in Figure 5.

The numerical analysis identified the most beneficial tensioning pattern by comparing the

eigenvalues from the buckling analysis. The largest eigenvalue corresponds with the

smallest magnitude of buckling distortion.

2 in. from Edge Midway between Stiffeners

(10 in. from stiffener) (12 in. from either stiffener)

1 2 3 4 5 6 7 8

Pass

Fillet-weld lines Numbers

Butt-weld line 1 through 8

Auxiliary heat lines

Figure 5. Sequence of transient thermal tensioning for panel mock-ups 1B, 3B,

and 3D

12 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

The following rules of thumb were used to select the tensioning pattern:

• Heating lines are most effective near edges or halfway between stiffeners.

• Heating lines should total no more than twice the number of stiffeners.

• Heating lines should be separated from other bands, edges, and welds by at least 2 in.

The burners used for TTT were 6 in. long and oriented parallel to the direction of travel, as

shown in Figure 2. The fuel used was natural gas (methane), and the oxygen flow rate was

set to provide an oxidizing flame. While this process was under development, all welding

was done at 0.5 m/min travel speed. For the welding of the lightweight panels in the

preferred processes, travel speeds ranged from 0.5 to 1.0 m/min, and gas flow rates were

scaled proportionally to the travel speed.

Figure 6 presents a lidar comparison of transient thermal tensioning results. Figure 6a

shows the lidar scan of panel 1A, fabricated with the same variables, except with an

improved process of TTT for panel 1B. We found that stiffened panels of uniform thick-

ness are best improved by heating lines parallel to the fillet welds. That experience was

applied to panel mock-up 1B; a flat, smooth panel was produced after T-stiffener fillet

welding with TTT, as shown in Figure 6b. However, the complex panels in tests 3B and 3D

required nontraditional tensioning patterns to accommodate the buckling force produced

by the transverse seam welds between different thicknesses of the panel and the insert.

The tensioning pattern for panel mock-up 1B was one line located 2 in. from each edge

parallel to the stiffeners, along with one line between each adjacent pair of stiffeners,

except the center two stiffeners, as shown in Figure 5. Here, the longitudinal butt weld

provided tension and no line heating was required.

The predicted distortion of panel mock-up 1B is shown in Figure 7, with a multiplication

factor of 20. The results agree well with the final lidar scan for panel 1B, as shown in

Figure 6b. No buckling is visible, and the panel had smooth edges with some arch along

the length of the panel. Some arching was expected from the longitudinal-weld residual

stress, but the smooth edges would make subsequent fit-up easy. Arching was minimized

by the application of smaller precision fillet welds.

Out-of-Plane

Distortion

Value (mm)

70

65

60

55

50

45

40

35

30

25

20

15

10

5

a. Lidar mock-up panel 1A: b. Lidar mock-up panel 1B:

Without transient thermal With transient thermal 0

tensioning tensioning

Figure 6. Lidar comparison of transient thermal tensioning results for panel

mock-ups 1A and 1B

Technology Review Journal • Spring/Summer 2005 13

Engineering and Ship Production Technology for Lightweight Structures

Figure 7. Numerical prediction of transient thermal tensioning results for panel

mock-up 1B

Panel mock-ups 3B and 3D both used smaller fillet welds than had been used previously in

the first round of panels with design 3. The smaller precision welds reduced the buckling

distortion by more than 50%, as shown in panel mock-ups 1C and 1D. However, even with

precision fillet welds, the manually welded insert and transverse SAW seams caused

enough additional stress that some buckling was observed. TTT eliminated all buckling,

except at the corners of the inserts, where oversized welds were placed. Panels 3B and 3D

did have more arching in the longitudinal plane, but their edges were smooth. We believe

that, with some additional development, TTT combined with precision welding could be

used to ensure the fabrication of smooth, lightweight, complex panels.

The TTT for panel design 3 used thermal tension lines parallel to the fillet welds, as shown

in Figure 8. Although two groups of lines are depicted, only the fillet-welding heat lines

were implemented. The butt-welding heat lines could not be applied after the stiffeners

had been tacked to the plate. Figure 9 shows the predicted buckling distortion of panel

mock-ups 3B and 3D after application of the fillet-welding heat lines.

Thermal tensioning was applied concurrently with welding, as shown in Figure 2. That

procedure was first applied on panel mock-up 1B (Figure 5) and produced a panel with no

buckling distortion (Figure 6b). Similar procedures were used in panel mock-ups 3B and

3D, as shown in Figure 8. They were among the first full-size complex panels with multiple

thickness transitions ever tested for TTT. Panel 3B was welded first. TTT caused minimal

buckling between stiffeners. The edges of panel 3B had more arching than those of panel

1B, whose edge near the insert had more distortion. The edges of panel 3B started to

buckle as soon as the heat was applied during double-sided fillet welding. Although in

simple panels such as 1B the edges flatten out after cooling, the waviness remained in

both edges of the more complex panel 3B after it cooled. The presence of the thicker

transverse plates on each end exacerbated the buckling. The thick-to-thin transition

appeared to behave like a hinge. Expansion of the thick and thin plates at different rates

caused local plastic deformation.

14 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

Pass 1

12 in.

Pass 2

12 in.

Pass 3

20 in. 20 in. 20 in. 20 in.

12 in.

Pass 4

Pass 5

2 in. Pass 9

11 in. (12 other side)

11 in. Pass 8

(11 other side)

Pass 10

(13 other side)

12 in. Pass 6

Pass 7

Fillet welds (2 per line)

2 in.

Butt welds (2 per line)

Butt-welding heat lines

Fillet-welding heat lines

Figure 8. Thermal tensioning pattern and sequence for panel mock-ups 3B and 3D

Figure 9. Numerical prediction of transient thermal tensioning results for panel

mock-ups 3B and 3D

Technology Review Journal • Spring/Summer 2005 15

Engineering and Ship Production Technology for Lightweight Structures

Figure 10 shows lidar comparison of transient thermal tensioning results for panel mock-

ups 3B and 3D. Panel mock-up 3B was repaired by reheating the edge, but with proper

clamping added: a piece of 75-mm C-channel was used as a clamping device by tacking it

along each longitudinal edge of the panel. As a result, the heating line was about 2 in.

inboard from the original heating line. The TTT procedures were performed in-situ with

no support from numerical models. The reheated TTT edge with restraint produced a

significant reduction in local waviness, although the edges were arched more from the

additional TTT heat input, as Figure 10a shows.

Panel 3D was also welded with a C-channel tacked along each edge to serve as a clamping

device when the first and last T-stiffeners were welded. The clamping was needed to

inhibit local deformation at the thin-to-thick transition along the edge. The C-channel was

tacked along the first edge, and local out-of-plane movements were observed between the

tack welds as the stiffener welding progressed. The C-channel was tacked atop the last

edge and provided additional stiffness, minimizing out-of-plane movement as the welding

progressed. Using C-channel as clamping resulted in minimal local waviness, although, as

shown in Figure 10b, both edges had some arching, which was aggravated near the

manually welded insert.

The use of lower TTT heat input along the edges should reduce the arching. TTT heat

parameters were estimated based on experiments on 5-mm fillet welds made at 0.5 m/min

travel speed. Panel 3D had 3-mm fillet welds made at 1 m/min travel speed. The TTT heat

input was increased proportionally to the travel speed. That logic resulted in excess

arching with the faster, smaller fillet welds. New numerical models are needed for TTT of

precision fillet welds made at high speeds.

Reverse Arching and T-Stiffener Assembly Sequence. Reverse arching was first inves-

tigated on panel mock-up 2B. In addition to that technique, the T-stiffener assembly

sequence was also explored for panel mock-up 2B. The panel distortion resulting from

assembly sequence 2 was compared with that from sequence 1 using a progressive

sequence—that is, stiffener fillet welds were made sequentially from the bottom edge to

Out-of-Plane

Distortion

Value (mm)

70

65

60

55

50

45

40

35

30

25

20

15

a. Panel mock-up 3B: b. Panel mock-up 3D: 10

4-mm fillets, with double transient 3-mm fillets, with transient 5

thermal tensioning thermal tensioning 0

Figure 10. Lidar comparison of transient thermal tensioning results for panel

mock-ups 3B and 3D

16 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

the top after the stiffeners were prefitted and tacked, as shown in Figures 4a and 4b. For

panel mock-up 2B, the T-stiffener assembly sequence was from the inside out. The final

distortion after the completion of all welding was less than that produced with assembly

sequence 1. Reverse arching further decreased the final distortion, as shown in Figure 4c.

The experiment demonstrated that assembly from the inside out tended to reduce buckling

distortion. After reverse arching was applied, most of the buckling distortion was recov-

ered. If reverse arching were applied after completion of each T-stiffener weld, the

technique would be even more effective.

Among all test panel designs (1, 2, and 3), design 3 was the most complex, because it

included a thicker insert and transverse end plates. As a result, the buckling distortion in

panel design 3 was the most severe, as observed from the first group of test panels in the

initial manufacturing conditions [6]. In the current study of preferred processes for com-

plex panels, reverse arching was evaluated on panel mock-ups 3A and 3C. The technique

was implemented in the same manner as that for panel mock-up 2B.

The lidar measurements of the buckling distortions are shown in Figure 11 for panel mock-

up 3C before and after reverse arching. Panel 3C used 3-mm fillet welds and had little panel

buckling on the side opposite the insert. Significant distortion and panel arching were

observed on the insert side. Reverse arching was able to remove most of the arching from

the panel and recover the small buckles between stiffeners. Though much improved, the

distortion near the panel edge on the insert side still had several edge waves after reverse

arching. Unfortunately, the lack of effective tooling impedes the implementation of reverse

arching under the current production environment. With proper tooling, the reverse

arching could be very effective and would provide an optimal solution for complex panel

fabrication, if applied with the preferred manufacturing plan.

Out-of-Plane

Distortion

Value (mm)

70

65

60

55

50

45

40

35

30

25

20

15

10

a. Panel mock-up 3C: b. Panel mock-up 3C:

Before reverse arching After reverse arching 5

0

Figure 11. Comparison of lidar distortion topography for panel 3C before and after

reverse arching

Technology Review Journal • Spring/Summer 2005 17

Engineering and Ship Production Technology for Lightweight Structures

New, Preferred Manufacturing Plan

Key changes to the current manufacturing processes and procedures brought dramatic

improvements that led to the new, preferred manufacturing plan. When implemented, the

preferred manufacturing plan produced thin conventional panels with no buckling distor-

tions and complex panels with some buckling near manually welded inserts. Smooth edges

were consistently produced; they had some arching but would significantly improve unit

erection.

Figure 12 compares lidar scans of panel mock-ups made in the initial and improved

manufacturing conditions. The applications of the preferred FCAW welding parameters

shown in Table 2 were able to control the precision fillet-weld size of 5 mm, in accordance

with the design specification. That weld size reduction from an average 6.5-mm overweld

in the initial manufacturing process [6] resulted in a 40% reduction of welding volume and

heat input. The results with the reduced weld size and preferred assembly sequence

showed buckling primarily located around the insert plate welds in panels made with

designs 2 and 3. The deformations appear to be caused more by the butt welds, which did

not change for the SAW seams; and the manual welds, which were especially large at the

radius corners of the inserts.

Based on the results obtained with our panel mock-ups, the following recommendations

were made as part of the preferred manufacturing plan:

• Modify incoming material-handling and -storage processes to prevent permanent

deformation.

• Precision-mill or laser-cut panel pieces to control accuracy and distortion before

assembly.

• Design and deploy an effective panel-handling and -processing system.

• Build a hard deck foundation and provide a material-clamping capability for panel

fabrication.

• Develop narrow-groove SAW or hybrid seam-welding procedures for panel blanket

assembly.

Out-of-Plane

Distortion

Value (mm)

70

65

60

55

50

45

40

35

30

25

20

15

a. Initial production process b. Improved (preferred) 10

production process 5

0

Figure 12. Lidar comparison of initial and improved production processes

18 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

• Prefit and tack all stiffeners before panel fillet welding to improve restraint and fit-up.

• Optimize tack-weld size or grind to ensure blending into stiffener fillet welds.

• Deploy precision high-speed fillet-welding parameters and procedures with through-

the-arc or laser seam tracking.

• Develop and deploy TTT distortion-prediction computer-aided engineering tools and

production hardware for panel-welding systems.

• Develop best practices for manual welding of inserts and transverse stiffeners to

minimize overwelding.

Work is in progress to further develop and deploy this technology on full-size production

panels as large as 16 m × 16 m. Designed with the preferred manufacturing plan, new panel

manufacturing lines are being procured to replace the current production lines at Northrop

Grumman Ship Systems’ Pascagoula and New Orleans Operations. More than 200 million

dollars in capital investments have been planned to implement most of the technology

developed from this research program and deploy the preferred manufacturing plan at

Ship Systems.

Subsequent downstream operations receiving flatter material should see a reduction in the

number of man-hours needed for fitting and welding assembly of ship panel structures. In

addition, ship-fitting costs for unit/block assembly should see a significant improvement

as well. The successful implementation of the process techniques developed from this

program will lead to a higher quality ship for the U.S. Navy, while realizing significant

savings by reducing rework.

Summary

A series of tests was conducted on candidate measures to improve the manufacturing

quality of thin panels for ship structures. The tests built on the results of previous work

that demonstrated the problems with manufacturing thin-steel ship structures [6]. The new

tests concentrated on material-handling and -storage processes, precision cutting of panel

pieces, a new material-handling foundation system, new welding procedures for panel

assembly, prefitting of stiffeners, precision high-speed welding, use of transient-thermal-

tensioning-based distortion-prediction tools and hardware, and improved manual welding.

Those procedures and tools were found to significantly improve the quality of the panel

construction process, lower production time, and reduce ship-fitting costs. The results are

sufficiently good to initiate the implementation of the improved processes and attract

commitments of hundreds of millions of dollars in capital investments by Northrop

Grumman, the U.S. Navy, and the states of Louisiana and Mississippi for improving

lightweight shipbuilding technology at Ship Systems.

Acknowledgments

The authors acknowledge all project team members from Northrop Grumman Corporation’s

Ship Systems and Newport News sectors, the University of New Orleans, Edison Welding

Institute, Battelle Memorial Institute, Dimensional Control Systems, the University of

Michigan, and Pennsylvania State University’s Applied Research Laboratory. Special

thanks go to John Carney, director of the MANTECH program for the U.S. Navy’s Office

of Naval Research.

Technology Review Journal • Spring/Summer 2005 19

Engineering and Ship Production Technology for Lightweight Structures

References

1. T.D. Huang, L.A. DeCan, D.D. Harwig, P. Dong, and R. Kumar, “Plate Process

Improvements at Northrop Grumman Ship Systems, Avondale Operations,” Proc.

2002 Automation in Shipbuilding Conf., New Orleans, La., December 11–13, 2002,

http://www.usashipbuilding.com/USASB/masters/Events/2003/QTR2//7992.pdf.

2. T.D. Huang and D.F. Niolet, SafeHull Analysis of ARCO 125,000 DWT Crude

Carrier, Northrop Grumman Ship Systems, Avondale Operations, New Orleans, La,

Technical Report SD97-01-09, November 1997.

3. T.D. Huang, SafeHull Analysis of American Heavy Lift Double Hull Product Tanker,

Northrop Grumman Ship Systems, Avondale Operations, New Orleans, La, Technical

Report DS-AHL-001, June 1995.

4. A. Treaster, Effects of Material Handling and Plate Distortion on Lightweight Steel

Structures, Northrop Grumman Ship Systems, Avondale Operations, New Orleans,

La., Six Sigma Black Belt Project, March 2003.

5. D.D. Harwig, “A Wise Method for Assessing Arc Welding Performance and Quality,”

Welding J., Vol. 79, No. 12, December 2000, pp. 35–40.

6. T.D. Huang, P. Dong, L.A. DeCan, and D.D. Harwig, “Residual Stresses and Distor-

tions in Lightweight Ship Panel Structures,” Technology Review Journal, Vol. 11,

No. 1, Spring/Summer 2003, pp. 1–26.

7. T.D. Huang, P. Dong, L.A. DeCan, D.D. Harwig, and R. Kumar, “Fabrication and

Engineering Technology for Lightweight Ship Structures, Part 1: Distortions and

Residual Stresses in Panel Fabrication,” J. Ship Production (published by the

Society of Naval Architects and Marine Engineers), Vol. 20, No. 1, February 2004,

pp. 43–59.

Author Profiles

T.D. Huang is a senior scientist and project manager at

Northrop Grumman Ship Systems. A licensed professional

engineer with over 25 years of marine and shipbuilding

experience, he specializes in finite-element applications in the

fatigue and fracture of marine structures. He has developed

plans for and overseen engineering system developments, in

addition to setting criteria for specifications and standards

for numerous programs. As an expert in structural engineer-

ing, Dr. Huang has established many teams of qualified

personnel, as well as provided leadership and oversight to

team personnel. His current interests are focused on imple-

menting engineering/production procedures optimized for

unit construction by incorporating distortion-control

technologies and computer-aided distortion-prediction finite-

element tools developed by his team. Dr. Huang has served

as the principal investigator of the Shipboard Applications

of Lightweight Structures program since it began in January

2002. He is now leading the third phase of the program,

investigating engineering/production process techniques

20 Technology Review Journal • Spring/Summer 2005

Engineering and Ship Production Technology for Lightweight Structures

and distortion-mitigation implementations in thin-steel

unit construction. Dr. Huang holds a BS from National

Chunghsing University, Taiwan; an MS from Ohio State

University; and a PhD from Tulane University, all in civil/

structural engineering.

td.huang@ngc.com

Dennis D. Harwig is the technology leader for the Arc

Welding, Materials, and Automation team at the Edison

Welding Institute (EWI). He has 20 years of experience in

heavy manufacturing technology, including the development

of adaptive and precision welding systems; synergic-fill

technology and procedures; high-deposition welding

processes; waveform optimization of advanced power

supplies; custom narrow-groove torches; robust engineering

of welding processes, including invention of the ARCWISE™

method; shipbuilding erection-beam cutting and clamping

tools and intelligent welding tractors; diffusible hydrogen

testing of electrodes; and titanium welding technology for

combat and ship structures. Before joining EWI in 1994,

Dr. Harwig worked on a design team at BWX Technology.

He holds seven patents related to welding technology. He

is active in the American Welding Society, where he serves

on the technical papers committee, the titanium filler materials

committee, and the structural welding code committee for

titanium. He is currently chairman of the titanium welding

committee. Dr. Harwig has a BS and an MS in welding

engineering from Ohio State University, as well as a PhD

in welding engineering from Cranfield University, UK.

dennis_harwig@ewi.org

Pingsha Dong serves as the technical director of the Center

for Welded Structures Research at Battelle Memorial Institute,

headquartered in Columbus, Ohio. His research interests

include design and analysis methods for welded structures,

advanced computational procedures for welding/joining

process simulations, fatigue/fracture behavior of welded

structures, and residual stress and distortion-mitigation

techniques. Dr. Dong has published more than 160 papers in

peer-reviewed conference proceedings and archive journals

and has received numerous awards, such as the American

Welding Society’s (AWS’s) Best Paper Award (1998) and the

American Society of Mechanical Engineers’ G.E. Widera

Literature Award (2002). He serves as a member of the

editorial board of the international journal Science and

Technology Review Journal • Spring/Summer 2005 21

Engineering and Ship Production Technology for Lightweight Structures

Technology of Welding and Joining and as a principal

reviewer of AWS’s Welding Journal Research Supplement.

Dr. Dong received a BS and an MS in welding engineering

from Harbin Institute of Technology, China, as well as a PhD

in computational mechanics from the University of Michigan.

dongp@battelle.org

Lawrence A. DeCan is a research engineer for the University

of New Orleans’ Gulf Coast Region Maritime Technology

Center. His recent research experience includes key roles in

the development and deployment of production automation

tooling, focusing on the application of robotics to shipbuild-

ing. He also serves the University’s College of Engineering as

an adjunct professor to the School of Naval Architecture and

Marine Engineering, teaching the Introduction to Naval

Architecture. Mr. DeCan holds a BS and an MS in naval

architecture from the University of New Orleans. He is

currently pursuing a doctorate in engineering at the same

institution.

ldecan@gcrmtc.org

22 Technology Review Journal • Spring/Summer 2005

You might also like

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Turbotorque™: Lightning Fast Torque On DemandDocument16 pagesTurbotorque™: Lightning Fast Torque On DemandDileep KumarNo ratings yet

- PSK GET 9th v2Document827 pagesPSK GET 9th v2Luis PozoNo ratings yet

- Gets InglesDocument1,088 pagesGets InglesKjatunMayu Gutierrez100% (6)

- Driveshaft Lorries2Document12 pagesDriveshaft Lorries2Alex BancilaNo ratings yet

- 2006-2007 Varel FixedCutterBitsCatalogDocument24 pages2006-2007 Varel FixedCutterBitsCatalogAndrzej KonopkaNo ratings yet

- Design of Thin-Film Coater BladeDocument24 pagesDesign of Thin-Film Coater BladeNtuthuko ZuluNo ratings yet

- C Dodge s2000Document56 pagesC Dodge s2000lyorhitmaNo ratings yet

- Tubing Cutter Replacement WheelsDocument1 pageTubing Cutter Replacement WheelsKTNo ratings yet

- Esteelde Steel Decking Sheets Safe LoadDocument54 pagesEsteelde Steel Decking Sheets Safe LoadfraantoineNo ratings yet

- Base Plate DWGDocument1 pageBase Plate DWGSiddharth TiwariNo ratings yet

- Yamato Steel Profiles PDFDocument51 pagesYamato Steel Profiles PDFויליאם סן מרמיגיוסNo ratings yet

- P200 RJ3.Document4 pagesP200 RJ3.YeraVersaillesNo ratings yet

- X BT GR X BT MR Data Sheet Technical Information ASSET DOC 9536692Document11 pagesX BT GR X BT MR Data Sheet Technical Information ASSET DOC 9536692anminsungNo ratings yet

- Permalex CatalogDocument24 pagesPermalex CataloggbricksphNo ratings yet

- Machine Drawings For Haas TM-1 Milling MachineDocument2 pagesMachine Drawings For Haas TM-1 Milling MachineJawana FucsumNo ratings yet

- GFHGHDocument1 pageGFHGHVarunn VelNo ratings yet

- Stress Check and Casing SeatDocument19 pagesStress Check and Casing Seatمحمد كريم زهير حبيب 49100% (1)

- BAR-US SimGrip Product Brochure EnglishDocument19 pagesBAR-US SimGrip Product Brochure EnglishBarusRebarCouplersNo ratings yet

- Gasket Calculator 6.0 - 2Document20 pagesGasket Calculator 6.0 - 2HUGO ALBERTO BARROS URZOLANo ratings yet

- CatalogDocument56 pagesCatalogBahman DaeeNo ratings yet

- Instruction 6x16 Float DockmakerDocument1 pageInstruction 6x16 Float DockmakerJose MelloNo ratings yet

- PEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoDocument20 pagesPEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoHECTOR ESCALLONNo ratings yet

- Gatesfacts™ Technical Information Library: Synchronous Belts - Part I Pa NoteDocument4 pagesGatesfacts™ Technical Information Library: Synchronous Belts - Part I Pa NoteMohanraj Sundaramoorthy SundaramoorthyNo ratings yet

- Nucor Yamato Steel Catalog 2008Document50 pagesNucor Yamato Steel Catalog 2008David D'AgostinoNo ratings yet

- Design Problem #2: 16.20 Handed Out: DueDocument4 pagesDesign Problem #2: 16.20 Handed Out: DueHendri HermawanNo ratings yet

- Keyless BushingsDocument52 pagesKeyless BushingsDC ProyectosNo ratings yet

- 1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Document8 pages1 2 2 System Description 2 3 Material and Identification 4 4 Load Capacity 4 5 Production 4 6 Installation 7 7 Quality Assurance 7 8 Applications 8Vagany7No ratings yet

- PVC Material Tube Settlers: Materials and FabricationsDocument2 pagesPVC Material Tube Settlers: Materials and FabricationsKaushalya WeerasingheNo ratings yet

- Undercarriage: Information Release MemoDocument10 pagesUndercarriage: Information Release MemochakrouneNo ratings yet

- VARGUS - Gear Milling Catalog - MetricDocument12 pagesVARGUS - Gear Milling Catalog - MetricGilberto ManhattanNo ratings yet

- 3 8 2 Spence StrainersDocument132 pages3 8 2 Spence StrainerszayerirezaNo ratings yet

- UK Commutator Maintenance CatalogueDocument9 pagesUK Commutator Maintenance CatalogueCarlosNo ratings yet

- Spence StrainersDocument132 pagesSpence StrainersRahul LavandNo ratings yet

- Wave Solder Pallet Design GuidelinesDocument11 pagesWave Solder Pallet Design GuidelinesThe HoangNo ratings yet

- Drill Bits - Taurex PDFDocument14 pagesDrill Bits - Taurex PDFCarlos Antonio Padra PerezNo ratings yet

- Catalog Gratare StacoDocument36 pagesCatalog Gratare StacoionutbranNo ratings yet

- Introduction Fischer A - C - T: The Key To Modern Facade AestheticsDocument74 pagesIntroduction Fischer A - C - T: The Key To Modern Facade AestheticsFALwilliamsNo ratings yet

- Ventilated Facade System For BuildingsDocument118 pagesVentilated Facade System For BuildingsClaudia Alagarda FuertesNo ratings yet

- 111 1400 Simon Black Jaguar Land RoverDocument29 pages111 1400 Simon Black Jaguar Land RoverseehariNo ratings yet

- Cat Wear PlateDocument4 pagesCat Wear PlateRoss WaringNo ratings yet

- POLEASengineered Class PulleysDocument4 pagesPOLEASengineered Class Pulleysmaxneiker13No ratings yet

- Dex Stainless Steel Undermount Kitchen Sinks: Installation ManualDocument18 pagesDex Stainless Steel Undermount Kitchen Sinks: Installation ManualRrsc RamsNo ratings yet

- Gasket CalculatorDocument24 pagesGasket Calculatorवैभव धुरीNo ratings yet

- Tokyo SympDocument13 pagesTokyo Sympkirt wirk skythomasNo ratings yet

- Viking Q4195 1Document14 pagesViking Q4195 1arbiNo ratings yet

- MOULDMACHINEACCESSORIESDocument19 pagesMOULDMACHINEACCESSORIESDhimas KLSNo ratings yet

- Catalog Profile PDFDocument57 pagesCatalog Profile PDFTănase FlorianNo ratings yet

- X M8H Data Sheet PDFDocument6 pagesX M8H Data Sheet PDFBogdan Constantin-BabiiNo ratings yet

- SHEF30 SalesDocument2 pagesSHEF30 Salesallen_worstNo ratings yet

- Tabla Ondulata Cat - Steeldeck PDFDocument48 pagesTabla Ondulata Cat - Steeldeck PDFMonica Adriana PopescuNo ratings yet

- Durable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceDocument12 pagesDurable, Long-Lasting Punches & Punch Blanks: Heads-Above-The-Rest PerformanceCristhian Graef100% (1)

- Experimental and Theoretical Analyses of First Ply Failure - 2000 - Composite SDocument7 pagesExperimental and Theoretical Analyses of First Ply Failure - 2000 - Composite SAhmed HassanNo ratings yet

- 275/290//carbon - Exploded DiagramDocument2 pages275/290//carbon - Exploded DiagramNicky KiloNo ratings yet

- 2018 2019 Mega-275-290-Carbon-MY2018 Exploded DiagramDocument2 pages2018 2019 Mega-275-290-Carbon-MY2018 Exploded Diagramsvaleev846fNo ratings yet

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- Understanding ANSI Z359 PDFDocument12 pagesUnderstanding ANSI Z359 PDFJosua Sahat Parulian SinagaNo ratings yet

- Piping Shop ExxonDocument12 pagesPiping Shop ExxonJosua Sahat Parulian Sinaga100% (1)

- As 1666.2-1995Document22 pagesAs 1666.2-1995Josua Sahat Parulian SinagaNo ratings yet

- As 2319-2001Document21 pagesAs 2319-2001Josua Sahat Parulian SinagaNo ratings yet

- Super Strong Shackles: Alloy - Stainless Steel - Long Reach - Government - DNV - TrawlingDocument16 pagesSuper Strong Shackles: Alloy - Stainless Steel - Long Reach - Government - DNV - TrawlingJosua Sahat Parulian SinagaNo ratings yet

- AS Round Sling 4497.1-1997Document21 pagesAS Round Sling 4497.1-1997Josua Sahat Parulian SinagaNo ratings yet

- KatalogDocument3 pagesKatalogJosua Sahat Parulian SinagaNo ratings yet

- APPEA Lifitng and Rigging Guidelines PDFDocument109 pagesAPPEA Lifitng and Rigging Guidelines PDFJosua Sahat Parulian SinagaNo ratings yet

- Flamingo Rendering: 12.1 Materials and Their EditingDocument7 pagesFlamingo Rendering: 12.1 Materials and Their EditingJosua Sahat Parulian SinagaNo ratings yet

- Watertight IntegrityDocument3 pagesWatertight IntegrityJosua Sahat Parulian SinagaNo ratings yet

- Flamingo Cheat SheetDocument6 pagesFlamingo Cheat SheetJosua Sahat Parulian SinagaNo ratings yet

- Hanwha Q Cells Data Sheet q6lmxp3-g3 2013-04 Rev01 enDocument2 pagesHanwha Q Cells Data Sheet q6lmxp3-g3 2013-04 Rev01 enJosua Sahat Parulian SinagaNo ratings yet