Professional Documents

Culture Documents

Welding Procedure Specification Sample PDF

Welding Procedure Specification Sample PDF

Uploaded by

Albertus Widiatmaka SOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification Sample PDF

Welding Procedure Specification Sample PDF

Uploaded by

Albertus Widiatmaka SCopyright:

Available Formats

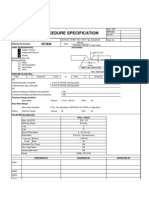

Sheet 1 of 2

Welding Procedure Specification (WPS)

Code: AWS D1.1

Company Name: www.WPSAmerica.com Identification #:

Address: info@WPSAmerica.com, 1 (877) 977-9353 GMAW-DEMO

Is WPS Prequalified?

Yes

Welding Process: Process Type: Position: Supporting PQR No.(s):

GMAW Semi-Automatic Flat Prequalified

Base Metal Part I (Material Spec., type or grade): Base Metal Part II (Material Spec., type or grade):

Group I and II of Table 3.1-AWS D1.1 Group I and II of Table 3.1-AWS D1.1

Thickness*/Pipe Diameter: Filler Metals:

Groove or Fillet Range: AWS Classification*/AWS Specification:

T>=6 mm (1/4 in.) E70C-6M H4

* If Prequalified, qualified range as shown in Sketch A5.18

* Electrode-Flux Class. (SAW)

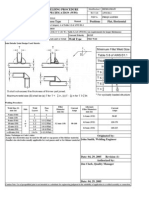

Joint Details/Sketch:

Joint Design Used (Design information for Prequalified WPS as shown in Sketch):

Root Opening G: mm (in) 0 Root Face RF: >=3 mm (1/8 in.) Groove Angle: 60 Radius (J-U): n/a

Weld Type: Joint Type:

Partial Joint Penetration Groove Weld Butt Joint Corner Joint

Backing Option: Backing Material: Back Gouging Method:

Welded without backing n/a n/a

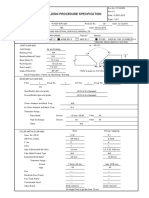

Identification #: GMAW-DEMO Sheet 2 of 2

Electrical Characteristics: Shielding:

Current Type/Polarity: DCEP Gas Composition (Flux for SAW): Ar + 5 to 15% CO2

Transfer Mode (GMAW): Spray

Gas Flow Rate: 40 to 50 CFH

Tungsten Electrode (GTAW):

Gas Cup Size: 5/8 in.

Type: N/A

Size: n/a

Welding Procedure

Filler

Current Wire Feed

Weld Pass Filler Metal Metal Current Travel

Process Type& Speed Volts Remarks or Heat Input

Layer(s) No. Classification

Diameter Amps Speed (in/min)

Polarity (in/min)

mm(in)

1 1 GMAW E70C-6M H4 1.4 mm (0.052) 200-250 DCEP 200-250 25-27 10-14 Root Pass

1 to 2 2 to 3 GMAW E70C-6M H4 1.4 mm (0.052) 200-250 DCEP 200-250 25-27 10-14 Fill Pass

2 to n 3 to n GMAW E70C-6M H4 1.4 mm (0.052) 270-300 DCEP 270-320 26-28 12-18 Weld Size >= 10 mm (3/8 in.)

Technique:

Stringer or Weave Bead: Stringer Bead Contact Tube to Work Distance: 1 to1-1/8 in.

Initial/ Interpass Cleaning: Wire Brush, Grind Peening: n/a

Number of Electrodes: Single

Electrode Spacing: Longitudinal: n/a Lateral: n/a Angle: n/a

Heat Treatment:

Preheat Temp., Min C (F): 0 to 10 (C)-Table 3.2 of AWS D1.1 Interpass Temp., Min/ Max C (F): 0 to 10 (C)-Table 3.2 of AWS D1.1

Postweld Heat Treatment: Temp. C (F): n/a Time: n/a

Additional Notes:

The end of contact tube recommended to be recessed in the cup nozzle at least 6 mm (1/4 in.)

Manufacturer/ Contractor Authorized by:

Welding Engineer:

Name: Weld Guy Name: John Smith

Title: Welding Engineer Title: QA Manager

Date: 12/12/2005 Date: 12/12/2005

You might also like

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Aws B2.1-B2.1m-2014-Amd1-PvDocument11 pagesAws B2.1-B2.1m-2014-Amd1-PvMc Harold Mari18% (11)

- Typical Welder Qualification CertificateDocument1 pageTypical Welder Qualification CertificateSatish Keskar100% (3)

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- Weld MapDocument4 pagesWeld MapSatish Keskar33% (3)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Machine Design ProblemsDocument32 pagesMachine Design ProblemsMark Lucriana Mariscotes76% (17)

- Welding Procedure SpecificationDocument101 pagesWelding Procedure SpecificationOsman Gone Rana70% (10)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Figure 1-Sample Welding Procedure Specification FormDocument2 pagesFigure 1-Sample Welding Procedure Specification Formahmad fikrieNo ratings yet

- lLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Document14 pageslLEEA Academy Foundation Course Revision Test 1 - V 1.0 Jan 2019Muaz MuhammedNo ratings yet

- Astm A709Document9 pagesAstm A709Jose Rueda100% (3)

- Welding Procedure Specification - TemplateDocument2 pagesWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (4)

- Welding Procedure Specification (WPS)Document31 pagesWelding Procedure Specification (WPS)Cui Xiao92% (13)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WpsDocument6 pagesWpsabhishek198327No ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRKiukStaks100% (6)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- WPS PQR WPQ PeiplDocument16 pagesWPS PQR WPQ PeiplKrishnamurthy Panchapakesan100% (4)

- WPS, PQR, WPQ (Si007)Document5 pagesWPS, PQR, WPQ (Si007)Suresh RathodNo ratings yet

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- Concentrating Table Wifley-1Document4 pagesConcentrating Table Wifley-1felixsamuelalvarado100% (2)

- ASTM KS-JIS-DIN Material Comparison TablesDocument28 pagesASTM KS-JIS-DIN Material Comparison TablesHongHaiDuong100% (2)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Qualification of Welding Procedure Specification FCDocument14 pagesQualification of Welding Procedure Specification FCmister pogi100% (4)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Welding QualificationDocument45 pagesWelding QualificationeswarNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Welder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationDocument1 pageWelder Continuation Log: Welder Name: Welder ID: Date of Initial QualificationPerminder Singh100% (1)

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocument1 pageASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliNo ratings yet

- Weld Map & TracebilityDocument2 pagesWeld Map & TracebilityvinothNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure SpecificationDocument21 pagesWelding Procedure Specificationboypardede100% (9)

- Welder Qualification Tests WQT DL QC 001 2019Document24 pagesWelder Qualification Tests WQT DL QC 001 2019adelNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- Welding Procedure SpecificationDocument6 pagesWelding Procedure SpecificationJorge SanchezNo ratings yet

- AL Wps PDFDocument4 pagesAL Wps PDFprem nautiyalNo ratings yet

- Guide To Writing A Welding Procedure Specification - December 2015Document23 pagesGuide To Writing A Welding Procedure Specification - December 2015arnoldbatista55100% (3)

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Approved Welding Procedures List RegioDocument2 pagesApproved Welding Procedures List Regiogabriel__regio100% (1)

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessDocument1 pageInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiNo ratings yet

- PQR Form (Welding)Document2 pagesPQR Form (Welding)jasmineammaNo ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- WPS - D1.1Document1 pageWPS - D1.1Nam_HitechNo ratings yet

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- ESL School OF WeldingDocument1 pageESL School OF WeldingesltrichyseoNo ratings yet

- Astm A781 2020 PDFDocument11 pagesAstm A781 2020 PDFCristhian Camilo Quiroga Walteros100% (1)

- Edd Fuel Tank ApplicationDocument11 pagesEdd Fuel Tank ApplicationZubair AhmadNo ratings yet

- Study and Operation of Tempering ProcessDocument11 pagesStudy and Operation of Tempering ProcessMostafizur Rahman SobujNo ratings yet

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- 316 316l Data SheetDocument2 pages316 316l Data SheetDiman Aditya KardiNo ratings yet

- GB090 2614 250 CS DB 0001 - 0 - Design Basis For Steel StructureDocument25 pagesGB090 2614 250 CS DB 0001 - 0 - Design Basis For Steel StructuretanujaayerNo ratings yet

- ColdHeadingForFastenerManufactureDocument40 pagesColdHeadingForFastenerManufactureKeerthi Kumar100% (1)

- American Welding Soceity 5.9Document33 pagesAmerican Welding Soceity 5.9Hư VôNo ratings yet

- Welding Notes 0Document70 pagesWelding Notes 0Azmeer Mohamed100% (1)

- Oxy Acetylene Flame - A Simple Guide To The Different TypesDocument2 pagesOxy Acetylene Flame - A Simple Guide To The Different TypesBalamurugan PNo ratings yet

- Part I Preboard 2022Document7 pagesPart I Preboard 2022Jovelyn NanguilamNo ratings yet

- Welding of Ferritic Cryogenic SteelsDocument2 pagesWelding of Ferritic Cryogenic SteelsMuhammed SulfeekNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenMytzy Godoy TapiaNo ratings yet

- Sec 05 KTZ4 67.5-63 (Angle Discharge)Document1 pageSec 05 KTZ4 67.5-63 (Angle Discharge)Gustavo HuertasNo ratings yet

- Welding Consumable For Piping Work (UAIL Project)Document7 pagesWelding Consumable For Piping Work (UAIL Project)Karthik100% (1)

- Critical Review of The LiteratureDocument2 pagesCritical Review of The LiteratureskluxNo ratings yet

- PriceList - 020 - Stainless Steel Pipe and FittingsDocument32 pagesPriceList - 020 - Stainless Steel Pipe and FittingsOgochukwuNo ratings yet

- RAFTIntroduction 101Document35 pagesRAFTIntroduction 101Abraham Dominguez SandovalNo ratings yet

- Zyg Anodic Index PDFDocument3 pagesZyg Anodic Index PDFRay FaiersNo ratings yet

- 01 01 10Document13 pages01 01 10brains26No ratings yet

- Structural Steels: High-Quality Steels For Construction ApplicationsDocument3 pagesStructural Steels: High-Quality Steels For Construction Applicationsmaheshmalaichamy007No ratings yet