Professional Documents

Culture Documents

Cumene - Process, Technology, Applications, Patent, Consultants, Company Profiles, Reports, Market, Projects

Cumene - Process, Technology, Applications, Patent, Consultants, Company Profiles, Reports, Market, Projects

Uploaded by

Mmmmoh0 ratings0% found this document useful (0 votes)

8 views6 pagesOriginal Title

Cumene - Process , Technology, Applications, Patent, Consultants, Company Profiles, Reports, Market, Projects

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views6 pagesCumene - Process, Technology, Applications, Patent, Consultants, Company Profiles, Reports, Market, Projects

Cumene - Process, Technology, Applications, Patent, Consultants, Company Profiles, Reports, Market, Projects

Uploaded by

MmmmohCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

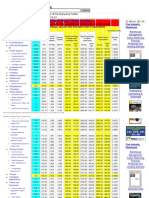

Cumene

Process , Technology, Applications, Patent, Consultants,

Company Profiles, Reports, Market, Projects

Primary Information

Services Home. Ordering

Information. Contact

Search PrimaryInfo

Information @ a Contents on the CD Rom

Glance

Cumene is the General Consultant &

common name for Information Plant

isopropylbenzene,

an organic Cumene (1‑ Consultant from

compound that is methylethylbenzene) U.S

an aromatic fact sheet Consultant UK

hydrocarbon. Cumene US Consultant

It is a constituent Cumene FAQ from Minnesota

of crude oil and About Cumene Consultant from

refined fuels. It is California

a flammable Company Profiles Consultant from

colorless liquid New Jersey

that has a boiling Company from USA Consultant

point of 152 °C. Georgia Plant from South

Cumene is a India Company Carolina

colorless, from Kolkata

flammable liquid International Patent

that has a sharp, Company

penetrating, Company from Cumene

gasoline‑type Korea Oxidation

odor. Cumene is Company from Italy Process

insoluble. Company from Process for the

Commercial Saudi Arabia preparation of a

production of Company from cumene feed for

cumene is carried India cumene oxidation

out through the Company from USA Process for

catalytic Producing

alkylation of Production Cumene

benzene, with the Purification of

addition of Problems at the Cumene Recycle

propylene. Solid Cumene Production Streams

phosphoric acid Facility, Unit 800 Method of

(SPA) supported Cumene Production Recovering

on alumina can – Change in Reactor Cumene

also be used as a Conditions Removal of

catalyst. Design of a New, Methyl Styrene

Most of the 100,000 Metric Ton from Cumene

current cumene Per Year, Cumene Separation of

plant production Production Facility Cumene from 3‑

processes utilize a Material Balances Ethyl Touluene

patented Design Problem by Azeotropic

supported Cumene Production Distillation

phosphoric acid Energy Balances and

catalyst, with a Numerical Methods Projects

few using a Design Project

Friedel‑Crafts Production of Reactors and

reaction with Cumene Separations

aluminum Fluid Mechanics, Design Project

trichloride. Heat Transfer, Production of

Benzene and Thermodynamics Cumene

propylene are Design Project Critical

compressed Production of Properties of

together to a Cumene Pure Compounds

Chevron

pressure of 30

standard

Process Announces

atmospheres at Approval of

Crystal Structure of Cumene

250 °C (482° F) in

the Terminal Modernization

presence of a

Oxygenase Project at Port

catalytic Lewis Component of Arthur, Texas,

acid. Phosphoric Cumene Plant

acid is often Dioxygenase from Phenol / Acetone

favored over Pseudomonas Cumene

aluminum fluorescens

halides. Cumene Cumene with Material Safety

is formed in the proprietary catalyst Data Sheet

gas‑phase Friedel‑ PBE‑1 zeolite based

Crafts alkylation Proprietary process Cumene

of benzene by technology Isopropylbenzene

propylene. Cumene process Safety Data for

Cumene is with drag (purge) Isopropylbenzene

oxidized in streams [Cumene]

slightly basic Cumene Overview Benzene, (1‑

conditions in Cumene Oxidation methylethyl)‑

presence of a process Cumene 99%

radical initiator, Process Marathon

which removes Intensification in Cumene

the tertiary Alkylation Process Demand CS

benzylic Cumene process

hydrogen from Energy Efficient Safety Issues

cumene and Catalytic Reaction

hence forms a and Production of Concise

cumene radical. Cumene International

Cumene is used Chemical

to manufacture Applications Assessment

other chemicals Document for

such as phenol, Cumene Cracking Cumene

acetone, on Modi ed Cumene ‑ Hazard

acetophenone, Mesoporous Summary

and methyl Material Toxicological

styrene. Effect of Oxidative Review of

It is used as a Stress, Produced by Cumene

thinner in paints, Cumene Assessment

lacquers, and Hydroperoxide, on Report on

enamels. It is a the Various Steps of Cumene for

component of Protein Synthesis Developing

Propranolol Ambient Air

oxidation by human

high octane motor liver microsomes ‑ Quality

fuels. the use of cumene Objectives

Cumene in used hydroperoxide to Thermal hazard

in the probe isoenzyme assessment on

manufacture of specificity and regio‑ hydroperoxides

rubber, iron and and stereoselectivity -examples on

steel, and pulp cumene

and Technology hydroperoxide

paper.Modern

phenol Analysis of Cumene Market & Report

technology (Isopropylbenzene)

involves Degradation Genes Cumene

oxidation of from Pseudomonas Polypropylene

cumene with air fluorescens Upgrading

at high efficiency Extraction of Prospects

to produce benzene, toluene, Cumene Uses

cumene ethyl benzene, and Market Data

hydroperoxide xylene and cumene Cumene Prices

(CHP). from soil using and Pricing

A high efficiency methanol at elevated Information

oxidation system temperature and World

has been pressure Consumption of

developed which Regioselective Cumene

improves yield by nitration of cumene Phenol / Acetone

lowering the to 4‑nitro cumene & Derivatives

formation of using nitric acid over Market

byproducts. An solid acid catalyst PERP Program‑

advanced Conventional New Report Alert

cleavage system Technology ‑Cumene

produces Phenol/Acetone Via Cumene Capacity

improved Cumene Oxidation Expansion

selectivity of Study on Green Strengthens

phenol from CHP. Process Design of Petrochemical

Modern process Cumene Production Operations

Raytheon licenses

technology is

based on the Cumene Technology Suppliers

reaction of for Ertisa plant in

Spain Cumene Selling

propylene and

Leads

benzene either in Suppliers of

the liquid or gas Cumene

phases. These Cumene

processes initially Exporters

used solid Manufacturer /

phosphoric acid Suppliers of

or aluminium Cumene

chloride catalysts Chemical

but in recent years Suppliers of

there has been a Cumene

shift to using Cumene

zeolite catalysts. Suppliers

Cumene is the

main feedstock Order the CD

for ROM Today

phenol/acetone

production and

demand is driven

by market growth

for the derivatives

of phenol and

acetone such as

bis‑phenol A,

phenolic resins

and caprolactam.

Global cumene

demand grew by

over 5%/year.

Cumene demand

growth is

expected to be

slightly below

phenol’s growth

rate of just over

4%/year in the

2006‑2011 period.

Around 98% of

cumene is used to

produce phenol

and its co‑product

acetone.

However, the

outlook for

cumene is largely

dependent on the

performance of

phenol’s

derivatives which

have resulted in

healthy growth

rates for cumene.

Primary Information Services

21 Murugappan St, SwamyNagar Ext2,

Ullagaram, Chennai 600091, India.

Phone: 91 44 22421080 Email : informer@eth.net

Mobile numbers:9940043898, 9444008898 Fax : 91 44 22423753

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Double Pipe Heat Exchanger - Excel CalculationsDocument4 pagesDouble Pipe Heat Exchanger - Excel CalculationsMmmmohNo ratings yet

- Engineers Guide - Equipment Wise Material and Energy Balance For Cumene Production From Benzene and PropyleneDocument3 pagesEngineers Guide - Equipment Wise Material and Energy Balance For Cumene Production From Benzene and PropyleneMmmmoh100% (2)

- Credentials - APIs & Services - Libya-Arcadier - Google API ConsoleDocument1 pageCredentials - APIs & Services - Libya-Arcadier - Google API ConsoleMmmmohNo ratings yet

- Design and Analysis of Pressure Vessel: October 2019Document13 pagesDesign and Analysis of Pressure Vessel: October 2019MmmmohNo ratings yet

- Steam Tables Pressure Heat of VaporizatioDocument5 pagesSteam Tables Pressure Heat of VaporizatioMmmmohNo ratings yet

- Kaspersky Internet Security 2020 Crack + Activation Code (Latest Version)Document1 pageKaspersky Internet Security 2020 Crack + Activation Code (Latest Version)MmmmohNo ratings yet

- 03 Chapter 04 - Part 1 - 05Document41 pages03 Chapter 04 - Part 1 - 05MmmmohNo ratings yet

- Sketchup 2016 Pro Download With Crack 32 and 64 Bit - YouTubeDocument3 pagesSketchup 2016 Pro Download With Crack 32 and 64 Bit - YouTubeMmmmoh0% (1)

- Kurd Live - Pastebin PDFDocument2 pagesKurd Live - Pastebin PDFMmmmohNo ratings yet

- Benzene, (1-Methylethyl)Document7 pagesBenzene, (1-Methylethyl)MmmmohNo ratings yet

- Kurd Live - PastebinDocument2 pagesKurd Live - PastebinMmmmohNo ratings yet