Professional Documents

Culture Documents

Used Drill Pipe Buggy

Used Drill Pipe Buggy

Uploaded by

John DolanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Used Drill Pipe Buggy

Used Drill Pipe Buggy

Uploaded by

John DolanCopyright:

Available Formats

Section : Rotary Shoulder 4/7 Approval : Date:1st June 2000

Subject : Used Drill pipe Inspection Revision No : 3 PTSCOS/06-2000

SUBJECT : USED DRILL PIPE INSPECTION.

1.0 This procedure is applicable to the inspection of used ferromagnetic drill

pipe and tubing with the Drilcolog portable pipe inspection unit. This

procedure is designed to detect transverse service- induced discontinuities

and wall reduction in order to classify the tube and tool joints in accordance

with API RP7G.

2.0 Interpretation of results from this procedure shall be performed only by

certified PTSC OS driil pipe technicians.

3.0 The PTSC OS technician in charge of the inspection job should have a pre-

inspection meeting with the customer representative at the job site. This

meeting is designed to discuss inspection standards and procedures. The

inspection standards used on the job should be denoted in the tally book

and on the inspection summary form.

4.0 Before inspection begins, set up and adequate inspection area and

determine an area for placement of rejected and accepted pipe . The

customer representative should approve these areas prior to use.

5.0 Roll out an appropriate amount of pipe depending on available rack space

and check for straightness. It is recommended

6.0 Steel stencil the following information on the 35 o pin shoulder of each joint :

6.0.1 One or two digits for month of inspection

6.0.2 One digit for year of inspection(last digit)

6.0.3 Drilco stamp – D in oval

6.0.4 One dot for pipe classification

6.0.5 Sequencial joint number

EXAMPLE : 2 4 D . 1

On flush OD joints stamp information on pin nose or other suitable low

stress area. Sequencial joint number should restart at 1 for each change of

size, weight or grade of pipe unless pipe is mixed on the rack.

7.0 Calibrate OD gage and check pipe full length for OD wear. Mark areas of

maximum wear on tube. Visually inspect tube for dents, gouges, washes or

other damage and mark areas on tube. Recalibrate OD gage every 25 pipe.

8.0 Calibrate ultrasonic wall thickness gage and check for minimum remaining

wall in middle of tube or at areas of maximum OD wear. A minimum of four

readings 90o apart should be taken in the centre of the tube. Record

Item No : PTSCOS, ROTARY-4/07-6/2000 Page 1 of 4

Section : Rotary Shoulder 4/7 Approval : Date:1st June 2000

Subject : Used Drill pipe Inspection Revision No : 3 PTSCOS/06-2000

minimum remaining wall thickness on pipe and on work copy of Inspection

Results Form.

9.0 If dry magnetic particle inspection of the end areas is included in the

inspection order, it should be done at this time. Magnetize each end with a

10,000 amp-turn DC coil and apply dry magnetic particles to the pipe OD.

Mark any indications on the pipe.

10.0 Set up Jacks and calibrate Drilcolog unit on calibration standard.

Recalibration should be performed every time the unit turned on and after

50 pipe have been run continuously. Calibration runs should be made in the

forward direction only.

11.0 The following information should be recorded at the start and end of each

chart :

11.0.1Customer name

11.0.2Location

11.0.3Size, weight, grade, range, & quantity of pipe

11.0.4Inspector name and date

11.0.5Invoice number

11.0.6Report number

Each run must identify the pipe number, pin end and box end. The cause of

significant indications should be denoted on the chart. Significant work

stoppages or changes in inspectors should also be denoted. At the end of

each chart, roll up the chart and denote customer name, invoice number,

inspector’s name, date and joint numbers on outside of roll. At the end of

the job, charts should be sent to the Inspection Manager along with copies

of all reports.

12.0 Perform full length electro-magnetic inspection of each tube. Verify joint

number versus chart number on every 10 pipe. Any discontinuities detected

should be verified at the time of detection. Verification will include as

required :

12.0.1 Visual or dry magnetic particle inspection

12.0.2 Probing of discontinuities if approved by the owner of pipe.

12.0.3 Measurement of depth with pit gage

12.0.4 Ultrasonic wall measurement

12.0.5 Optiscope inspection of ID

Record all discontinuities on chart and on work copy of Inspection Result

Form.

Item No : PTSCOS, ROTARY-4/07-6/2000 Page 2 of 4

Section : Rotary Shoulder 4/7 Approval : Date:1st June 2000

Subject : Used Drill pipe Inspection Revision No : 3 PTSCOS/06-2000

13.0 If discontinuities are not rejectable, blemish should be blended into the

surrounding area by grinding. Rejectable defects should have a red paint

band around the tube on each side of the defect. Longitudinal red lines

between the red bands above and below the defect should be applied to

highlight the defect.

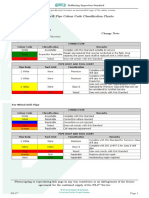

14.0 Apply paint band color code on OD of tube 2 to 4 feet from pin end per API

RP7G. Bands should be 2 inches wide.

Color code shalll be as follows :

Premum Class - 2 white bands

Class 2 - 1 yellow band

Class 3 - 1 orange band

Scrap - 1 red band

If the tube is not premium grade, additional dots will have to be added to

the steel stencils on the 35o pin shoulder to indicate appropriate

classification.

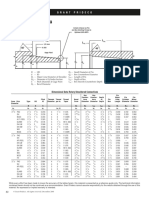

15.0 If a Type I Inspection is being performed, caliper tool joint OD 1 inch from

shoulder. Measure minimum shoulder width. If the measure minimum

shoulder width or the tool joint OD is below the A.P.I. minimum, record the

reading on the Inspection Results Form.

15.0.1 Visually inspect threads and shoulder for damage. Use appropriate

profile gage to check thread form. If joints are suspected of

stretch, verify with calibrated lead gage. If reading exceeds .006”

in 2”, reject joint for stretch.

15.0.2 If tool joint classification is different than pipe classification, apply

paint band color code per API RP7G to tool joint OD. Band should

be 2” wide.

Color code shall be as follows :

Permium Class - 2 white bands

Class 2 - 1 yellow band

Item No : PTSCOS, ROTARY-4/07-6/2000 Page 3 of 4

Section : Rotary Shoulder 4/7 Approval : Date:1st June 2000

Subject : Used Drill pipe Inspection Revision No : 3 PTSCOS/06-2000

Class 3 - 1 orange band

Scrap - 1 red band

15.0.3 If tool joints are not inspected, apply “Not Inspected” stencil on

OD in yellow paint.

15.0.4 If tool joints are rejected, indicate reason for rejection, i.e.

shoulder, thread, cracked, on OD in red paint on yellow

background. Paint red band around end of rejected joint.

16.0 Record all inspection results on Drill Pipe Inspection Results Form. A

separate Drill Pipe Inspection Results and Drill Pipe Inspection Summary

Form should be used for any change of size, weight or grate of pipe unless

the pipe is mixed on the rack.

17.0 If RSC inspection is included on inspection job, it should be done at this

time. If refacing is required and included, it should be done at this time.

Record results on Drill Pipe Inspection Results and Damage Evaluation

forms.

18.0 Present results and discuss with customer representative.

19.0 Dope threads and re-install thread protectors. Move finished pipe to

designated areas. Repeat procedure until all pipe have been inspected.

20.0 Clean up work area.

21.0 Complete Drill Pipe Inspection Summary form and Inspection Services

Invoice.

Item No : PTSCOS, ROTARY-4/07-6/2000 Page 4 of 4

You might also like

- DP Acco. To DS1 PDFDocument58 pagesDP Acco. To DS1 PDFMajdi JerbiNo ratings yet

- Min - TJL API RP 7G-2 - For MSDocument1 pageMin - TJL API RP 7G-2 - For MSQuality controllerNo ratings yet

- Inspection Procedures On Ds 1Document2 pagesInspection Procedures On Ds 1Chaerul Anwar100% (1)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Bear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARDocument5 pagesBear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARGabriel Ibarra100% (2)

- RP Insp Rep 01Document8 pagesRP Insp Rep 01advantage025No ratings yet

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- Tenaris Running Manual 01Document20 pagesTenaris Running Manual 01advantage025No ratings yet

- HT and XT Running and Handling SeminarDocument38 pagesHT and XT Running and Handling SeminarNhoj AicragNo ratings yet

- NS-1-141. Internal Coating and Inspection Specifications For Drill PipeDocument2 pagesNS-1-141. Internal Coating and Inspection Specifications For Drill PipeWHWENNo ratings yet

- BVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsDocument8 pagesBVM Corporation Maintenance Manual: "C", "T", & "MP" Series Safety ClampsRakefs100% (1)

- 10 37 00 1110 NS 1 A4 WatermarkedDocument7 pages10 37 00 1110 NS 1 A4 Watermarkedislam atif100% (1)

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- Sara Sae Hammer UnionsDocument16 pagesSara Sae Hammer UnionsFabricio100% (1)

- Make and Break NS2A4Document2 pagesMake and Break NS2A4islam atif100% (2)

- Facts & Myths of HardbandingDocument3 pagesFacts & Myths of Hardbandingsdb158No ratings yet

- Techsonic End Are Inspection ManualDocument57 pagesTechsonic End Are Inspection Manualriazhosein77No ratings yet

- VFP - Vam Eis - en PDFDocument30 pagesVFP - Vam Eis - en PDFZed ZedNo ratings yet

- Mckissick RJ Style Drilling BlocksDocument1 pageMckissick RJ Style Drilling BlocksRichard EVNo ratings yet

- Drilco Spiral Drill Collar PsDocument1 pageDrilco Spiral Drill Collar Psyojan35No ratings yet

- 01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFDocument5 pages01 - Field Inspection Procedure For Used uLTIMATE™ Extreme™ Torque Connections (uXT™) PC-17 PDFKarla HernandezNo ratings yet

- Drill Pipe Inspection Tally Sheet: International LimitedDocument1 pageDrill Pipe Inspection Tally Sheet: International LimitedMichael OkwuwaNo ratings yet

- Sub-Spec 023 - Tenaris DSTJ, WT™Document4 pagesSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNo ratings yet

- Visual SL APEXDocument3 pagesVisual SL APEXOscar Gomez Gonzalez100% (1)

- T4 Drill Pipe Colour Code Classification Chart NS2Document1 pageT4 Drill Pipe Colour Code Classification Chart NS2Josue Fish100% (2)

- 2012 Thread Profile Data SheetDocument2 pages2012 Thread Profile Data Sheetflasher_for_nokiaNo ratings yet

- TechScope EZT-IIDocument2 pagesTechScope EZT-IIMIS WORKSHOPNo ratings yet

- Choke ManifoldDocument30 pagesChoke Manifoldjamil voraNo ratings yet

- API Spec 10D Committee Working Draft 11072013 JH CJDocument20 pagesAPI Spec 10D Committee Working Draft 11072013 JH CJAquiles CarreraNo ratings yet

- TSH Ip 53.0070 - 01Document4 pagesTSH Ip 53.0070 - 01Cong BuiNo ratings yet

- API 8 Round ConnectionsDocument8 pagesAPI 8 Round Connectionsi oNo ratings yet

- Lift Caps: General RequirementsDocument2 pagesLift Caps: General Requirementsislam atif100% (1)

- Bha & Drill ColarsDocument6 pagesBha & Drill Colarswasim78622No ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- 003 Casing & Tubing Hanger PDFDocument4 pages003 Casing & Tubing Hanger PDFalaliali88No ratings yet

- Prem ConnectionDocument2 pagesPrem ConnectionJan Arild SkappelNo ratings yet

- Mud Gas Separator InfoDocument2 pagesMud Gas Separator InfoHIPAPNo ratings yet

- Hole Openers NS 1 A4 WatermarkedDocument13 pagesHole Openers NS 1 A4 Watermarkedislam atifNo ratings yet

- TMK Up™: Field ManualDocument84 pagesTMK Up™: Field Manualcorsini999No ratings yet

- Fox Public Fox-Tp-M-101 Field InspectionDocument5 pagesFox Public Fox-Tp-M-101 Field InspectionJoseph MidouNo ratings yet

- GP Tool Joint Dimensional Value PDFDocument2 pagesGP Tool Joint Dimensional Value PDFamerNo ratings yet

- Cementing Tools: General RequirementsDocument4 pagesCementing Tools: General Requirementsislam atifNo ratings yet

- Extreme CasingDocument1 pageExtreme CasingEleonora LetorNo ratings yet

- 106.11 - Sucker RodsDocument35 pages106.11 - Sucker RodsHassan GDOURANo ratings yet

- Hammer UnionsDocument5 pagesHammer UnionsiljicsNo ratings yet

- Casing and Tubing Crossovers: ScopeDocument4 pagesCasing and Tubing Crossovers: Scopeislam atifNo ratings yet

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageDavid OrtegaNo ratings yet

- AEPL NPT Thread Data SheetDocument2 pagesAEPL NPT Thread Data Sheetmechmohan07No ratings yet

- Used Sucker Rod GuidelinesDocument2 pagesUsed Sucker Rod Guidelinesluisfilippini3No ratings yet

- Manual Manual Power TongDocument13 pagesManual Manual Power TongJAVIER EDUARDO MANTILLA BUITRAGONo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationSAKDA MAPRADITKULNo ratings yet

- API Searchable IndexDocument7 pagesAPI Searchable IndexArtur FrancoNo ratings yet

- Product Information Bulletin: Handling ToolsDocument7 pagesProduct Information Bulletin: Handling ToolsghanNo ratings yet

- Iv-0778-20 Junk Mill A02002aDocument1 pageIv-0778-20 Junk Mill A02002aivan dario benavides bonilla100% (1)

- API 4G - E5 Addendum 2Document4 pagesAPI 4G - E5 Addendum 2KATHERINE RIVERANo ratings yet

- BHNK Drill Pipe CatalogDocument12 pagesBHNK Drill Pipe CatalogivertianNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Procedure For Rectification of Repair Pipes OriginalDocument6 pagesProcedure For Rectification of Repair Pipes OriginalMohammad Sazid AlamNo ratings yet

- Scrib 2Document2 pagesScrib 2zunain naumanNo ratings yet

- IPS Brief Profile PresentationDocument22 pagesIPS Brief Profile PresentationJohn DolanNo ratings yet

- MPI - DPI Report NewDocument2 pagesMPI - DPI Report NewJohn DolanNo ratings yet

- Ultrasonic Inspection: Part 1 IntroductionDocument172 pagesUltrasonic Inspection: Part 1 IntroductionJohn DolanNo ratings yet

- Ddaily Drift Calibration Procedure: 1. ScopeDocument1 pageDdaily Drift Calibration Procedure: 1. ScopeJohn DolanNo ratings yet

- Index: Daily, 6 Monthly and Yearly Equipment Calibration ChecksDocument1 pageIndex: Daily, 6 Monthly and Yearly Equipment Calibration ChecksJohn DolanNo ratings yet

- Ac Yoke and Coil Check Log: Thailand Industrial Proforma FormDocument1 pageAc Yoke and Coil Check Log: Thailand Industrial Proforma FormJohn DolanNo ratings yet

- Daily Drift Calibration LogDocument1 pageDaily Drift Calibration LogJohn DolanNo ratings yet

- Black Light Daily Check Log: Thailand Industrial Proforma FormDocument1 pageBlack Light Daily Check Log: Thailand Industrial Proforma FormJohn DolanNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- MPI Report 002 Mast 002 R.1Document1 pageMPI Report 002 Mast 002 R.1John DolanNo ratings yet

- MPI Report 004 Mast Axis 002Document1 pageMPI Report 004 Mast Axis 002John DolanNo ratings yet

- MPI Report 006 Swivel 531-12-19Document1 pageMPI Report 006 Swivel 531-12-19John DolanNo ratings yet

- MPI Report 005 Monkeyboard 001Document1 pageMPI Report 005 Monkeyboard 001John DolanNo ratings yet

- MPI Report 012 5inch DP Elevator A109-1Document1 pageMPI Report 012 5inch DP Elevator A109-1John DolanNo ratings yet

- MPI Report 013 5inch DP Elevator A109-2Document1 pageMPI Report 013 5inch DP Elevator A109-2John DolanNo ratings yet

- INDIN 078 - HWDP Proforma R.1Document2 pagesINDIN 078 - HWDP Proforma R.1John DolanNo ratings yet

- MPI Report 009 Sub Structure B668Document1 pageMPI Report 009 Sub Structure B668John DolanNo ratings yet

- Exhibit I - SOWDocument5 pagesExhibit I - SOWJohn DolanNo ratings yet

- Daily Drift Calibration Procedure: 1. ScopeDocument1 pageDaily Drift Calibration Procedure: 1. ScopeJohn DolanNo ratings yet

- Sales Call Report: Date Salesme N Country Person (S) Contacted: Position Contact Number/AddressDocument1 pageSales Call Report: Date Salesme N Country Person (S) Contacted: Position Contact Number/AddressJohn DolanNo ratings yet

- EYC 00278 EMA ApplicationDocument16 pagesEYC 00278 EMA ApplicationJohn DolanNo ratings yet

- Sales Flyer MSPEC Rev 1Document3 pagesSales Flyer MSPEC Rev 1John DolanNo ratings yet

- Field Inspection Procedure For Used GPDS Connections Revision 03 PDFDocument3 pagesField Inspection Procedure For Used GPDS Connections Revision 03 PDFJohn Dolan0% (1)

- LEEA-072 Roles and Resposibilities For Ensuring The Continued Safety of Lifting Equipment Version 1 Aug 2017 PDFDocument7 pagesLEEA-072 Roles and Resposibilities For Ensuring The Continued Safety of Lifting Equipment Version 1 Aug 2017 PDFJohn DolanNo ratings yet

- Mcas Magnetism ElectricityDocument27 pagesMcas Magnetism ElectricityBea GonzalesNo ratings yet

- Theremino Spectrometer Sample SpectrumsDocument16 pagesTheremino Spectrometer Sample SpectrumsjvcNo ratings yet

- I. Basic BJT Application & DC BiasingDocument20 pagesI. Basic BJT Application & DC BiasingNaim NizamNo ratings yet

- Turbo Supervisory Instruments: Presenter: Chona (C & I)Document25 pagesTurbo Supervisory Instruments: Presenter: Chona (C & I)Morassa Chona100% (1)

- Ordering Guide & Technical Information: Absolute Process Control Know Where You Are... RegardlessDocument56 pagesOrdering Guide & Technical Information: Absolute Process Control Know Where You Are... RegardlessEduard RamosNo ratings yet

- PLM Schneider Hoja de DatosDocument3 pagesPLM Schneider Hoja de DatosALEJANDRO MENDOZANo ratings yet

- CH 28Document29 pagesCH 28ameer kindalNo ratings yet

- 800kVUltra HVDC Transformer-A New Dimension of DCTransmissionDocument11 pages800kVUltra HVDC Transformer-A New Dimension of DCTransmissionA. HassanNo ratings yet

- AP Physics 1 - Test 09 - Rotational Dynamics Score:: A B C D EDocument9 pagesAP Physics 1 - Test 09 - Rotational Dynamics Score:: A B C D ESTNo ratings yet

- Sheet 1 InductanceDocument2 pagesSheet 1 Inductancemoustafa mouhammedNo ratings yet

- Polarization Is A Property of Transverse Waves That Specifies TheDocument16 pagesPolarization Is A Property of Transverse Waves That Specifies TheAbhishekNo ratings yet

- New Century Physics For Queensland Units 12 3Rd Edition Richard Walding Full ChapterDocument67 pagesNew Century Physics For Queensland Units 12 3Rd Edition Richard Walding Full Chapterlawrence.harding409100% (15)

- WS Module 3Document92 pagesWS Module 3sebastian vindro jude PanimayamNo ratings yet

- Physics: Pearson EdexcelDocument22 pagesPhysics: Pearson EdexcelmiltonNo ratings yet

- Jones Matrices & Mueller MatricesDocument20 pagesJones Matrices & Mueller MatricessulienNo ratings yet

- PHYSICS - (Paper - 1) (13th)Document7 pagesPHYSICS - (Paper - 1) (13th)Raju SinghNo ratings yet

- Bu 3109Document4 pagesBu 3109george tacheNo ratings yet

- Modul 2 Operasi GeneratorDocument50 pagesModul 2 Operasi Generatorika yuliyani murtiharjonoNo ratings yet

- Zhonghua Secondary Prelim 2021 PhysicsDocument50 pagesZhonghua Secondary Prelim 2021 PhysicsFadly RamliNo ratings yet

- MCQ-Ch-1-Electric Fields and ChargesDocument4 pagesMCQ-Ch-1-Electric Fields and ChargesPragati RathoreNo ratings yet

- Units and Measurement - Assignment 2Document6 pagesUnits and Measurement - Assignment 2dhivya shreeNo ratings yet

- Sample NEETDocument13 pagesSample NEETShloka LeleNo ratings yet

- Schedule of Loads LPA: Circuit Description LO Va/Lo VA Volts Amps CB Pole Switch NO AT AF S1 S2 S3Document4 pagesSchedule of Loads LPA: Circuit Description LO Va/Lo VA Volts Amps CB Pole Switch NO AT AF S1 S2 S3Samantha BolanteNo ratings yet

- Gerador Stamford Pm7d-28-Td-En - Rev - A 690vDocument7 pagesGerador Stamford Pm7d-28-Td-En - Rev - A 690vNirleison TelesNo ratings yet

- B.1 Thermal Energy Questionbank W - Out AnswersDocument18 pagesB.1 Thermal Energy Questionbank W - Out AnswersgjermenimegiiNo ratings yet

- Formula SheetDocument7 pagesFormula SheetFelipe RincónNo ratings yet

- Intensive Program For Neet-2022: Test - 3Document37 pagesIntensive Program For Neet-2022: Test - 3Umapathi mupNo ratings yet

- Data Sheet 3RF2150-1AA04: 3RF2900-3PA88 3RF2950-0HA16 3RF2900-0EA18 3RF2950-0GA16 3RF2920-0FA08Document6 pagesData Sheet 3RF2150-1AA04: 3RF2900-3PA88 3RF2950-0HA16 3RF2900-0EA18 3RF2950-0GA16 3RF2920-0FA08Ahmad AbdelrazekNo ratings yet

- Easy Start Guide LS Ic5 PDFDocument15 pagesEasy Start Guide LS Ic5 PDFMarina Cecilia TorresNo ratings yet

- Zelio Control Relays - RM4UB35Document8 pagesZelio Control Relays - RM4UB35Variya DharmeshNo ratings yet