Professional Documents

Culture Documents

IS 10810-57 (1987) - Methods of Test For Cables, Part 57 - Flexing Test

IS 10810-57 (1987) - Methods of Test For Cables, Part 57 - Flexing Test

Uploaded by

Standards IndiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IS 10810-57 (1987) - Methods of Test For Cables, Part 57 - Flexing Test

IS 10810-57 (1987) - Methods of Test For Cables, Part 57 - Flexing Test

Uploaded by

Standards IndiaCopyright:

Available Formats

UDC 621-315.21: 620.

174 ( Second Reprint AUGUST 1997 ) IS : 10810 ( Part 57 ) - 1987

Indian Standard ( Reaffirmed 2002 )

MET-HODS OF TEST FOR CABLES

APART 57 FLEXING TEST

1. Scope- Covers thetest procedure to determine the flexibility of flexible cable.

1.1 Flexible cables having conductors with nominal cross-sectional area exceeding 4 mm2 and all single

core cables are not subjected to this test.

2. Significance -The flexible cables are subjected to frequent flexing in service. This test is done

to ascertain the capability of cable to withstand flexing and other mechanical stresses occurring in

normal use.

3. Terminology -As given in IS: 1885 ( Part 32)-1971 ‘Electrotechnical vocabulary : Part 32 Cables,

conductors and accessories for electricity supply’.

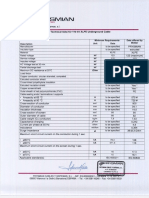

4. Apparatus -AS shown in Fig. 1. This apparatus has a carrier C supporting two Pulleys A and B

arranged so that the cable is horizontal between the pulleys. The pulleys have a semi-circular shaped

groove for circular cables and a flat groove for flat cables. The carrier makes a backward and forward

movement over a distance of 1 m at an approximately constant speed of 0.33 m/s. The mass of the

weight for loading the end of the test specimen and the diameter of the pulleys A and B are as given

below:

e______

FIG. 1 FLEXING APPARATUS

Type of Cable Mass of Weight Diameter of Pulleys

kg mm

Braided cord or light PVC sheathed cords 1.0 80

Ordinary PVC sheathed or tough rubber sheathed

cord and ordinary polychloroprene or other equi-

valent synthetic elastomer sheathed cord with

a nominal cross-sectional area of conductors:

a) Net exceeding 1 mm2 I.0 80

b) 1.5 and 2.5 mm‘J I.5 120

Heavy polychloroprene or other equivalent

synthetic elastomer sheathed cable with a

nominal cross sectional area of conductor:

a) Not exceeding 25 mm2 15 120

b) 4 mm1 2.0 200

PVC insulated parallel twin unsheathed cords 1.0 60

The restraining clamps D shall be fixed so that the pull isalways applied by the weight from

which the carrier is moving away.

Adopted 3 April 1987 @ October 1987, BIS Gr 1

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

IS : 10810 ( Part ~57 ) - 1987

5. Material - No material other than the test specimen is required.

6. Test Specimen

6.1 A cable sample of approximately 5 m length shall be taken.

6.2 Number of Specimens - One.

7. Conditioning --No conditioning is required.

8. Procedure

8.1 The test specimen shall be stretched over the pulleys as shown in Fig. 1, each end being loaded

with a weight as given in 4.

8.2 Each conductor of the test specimen shall be loaded with the current specified below:

Nominal Cross-Sectional Current

Area of Conductor

mm% A

0.75 9

1 11

1.5 14

2.5 20

4 25

For two-core cables, fhe voltage between the conductors shall be 240 V (ac). For all other

cables having free or more cores, a three-phase ac voltage of about 415 V shall be applied to the three

conductors, any additional conductors being connected to neutral. The carrier shall make 15 000 back-

ward and 15 000 forward movements, that.is, 30 000 single storkes, during which neither interruption of

current not short-circuit between the conductors shall occur.

After this test, the sheath, if any, of cables with three or more cores shall be removed. The

cable or cores shall then withstand the (ac) voltage test carried out in accordance with relevant

standard on cable, as appropriate, but with a test voltage not exceeding 2 000 volts.

9. Tabulation of Observations

Specimen Cable Mass Current ac Test Duration Observation

NO. Description Voltage min

kc A v

16. Calculation - No calculation is involved.

11. Report

11.1 Flexing Test

Cable Type

Cable No./Drum No.

11.2 Results

Reference Specification

Specimen Description Mass Ccirrent ac Test Duration Observation

No. of Specimen Voltage min

b A v

11.3 Conclusion -The specimen meets/does not meet the requirement of the specification.

Printed at Dee Kay Printers, New Delhi, India

You might also like

- BC Science 9 Chemistry Unit Study GuideDocument2 pagesBC Science 9 Chemistry Unit Study Guideerinyth100% (2)

- A Report On Structural Analysis and Design OF Industrial BuildingDocument20 pagesA Report On Structural Analysis and Design OF Industrial BuildingRoshan KejariwalNo ratings yet

- 220 KV Xlpe Insulated Power CableDocument25 pages220 KV Xlpe Insulated Power CablePrasad Pawar - ERO PowerNo ratings yet

- ABB No.26 - RemovedDocument8 pagesABB No.26 - RemovedDaniNo ratings yet

- 2.1 References: 2.0 HV Sheath DC Test Protocol: (For Reference Only)Document2 pages2.1 References: 2.0 HV Sheath DC Test Protocol: (For Reference Only)SeguNo ratings yet

- HV Outer Sheath TestDocument2 pagesHV Outer Sheath TestSegu100% (2)

- General Sheath Test Procedure HV CableDocument2 pagesGeneral Sheath Test Procedure HV CableSegu100% (6)

- Texas AM MV SpecificationDocument11 pagesTexas AM MV SpecificationDavid BurgessNo ratings yet

- ACSR Test ProcedureDocument4 pagesACSR Test ProcedurePuneet ChaurasiaNo ratings yet

- Technical Specification Control Xlpe CablesDocument28 pagesTechnical Specification Control Xlpe Cablesashish.bhattNo ratings yet

- CABLES - Nexans - Lov Voltage CablesDocument112 pagesCABLES - Nexans - Lov Voltage CablesCET INGENIERIANo ratings yet

- ABB No.26 - RemovedDocument8 pagesABB No.26 - RemovedDaniNo ratings yet

- Submarine Solutions 2015 B3 6 Extension of Qualification Applied On A MV Extruded Submarine Cable in France PDFDocument4 pagesSubmarine Solutions 2015 B3 6 Extension of Qualification Applied On A MV Extruded Submarine Cable in France PDFcskkrakenNo ratings yet

- PVC U ConduitDocument2 pagesPVC U ConduitkkkhattabbbNo ratings yet

- PVC U ConduitDocument2 pagesPVC U Conduitahmed khattabNo ratings yet

- Discharging Characteristics of A HVDC Test-CableDocument6 pagesDischarging Characteristics of A HVDC Test-CableAnonymous xr5vXthNo ratings yet

- Testing of CablesDocument8 pagesTesting of CablesDiwakar DiwakarNo ratings yet

- ANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEDocument7 pagesANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEsajjad_pirzadaNo ratings yet

- 1.10 Commissioning Procedures (Site Test Manual)Document14 pages1.10 Commissioning Procedures (Site Test Manual)hesby vbNo ratings yet

- 20kV Transformer Feeder Cable: Current Carrying Capacity Short Circuit Rating Voltage Drop Earth Loop ImpedanceDocument6 pages20kV Transformer Feeder Cable: Current Carrying Capacity Short Circuit Rating Voltage Drop Earth Loop ImpedanceNalex GeeNo ratings yet

- Technical Specification For 3C XPLE CableDocument9 pagesTechnical Specification For 3C XPLE Cableramana3339No ratings yet

- Medium Voltage CableDocument16 pagesMedium Voltage Cablewamiq wasiNo ratings yet

- Kelani Cable Book SL PDFDocument60 pagesKelani Cable Book SL PDFShami MudunkotuwaNo ratings yet

- PsDocument8 pagesPsAlluri Appa RaoNo ratings yet

- How To Test An RF Coaxial Cable Using A VNADocument5 pagesHow To Test An RF Coaxial Cable Using A VNAStefanvnvNo ratings yet

- Telecommunication Lab ManualDocument34 pagesTelecommunication Lab ManualYADAVAMITKUMAR007No ratings yet

- Operation & Maintenance Manual LV & MV CablesDocument12 pagesOperation & Maintenance Manual LV & MV CablesE.E. / Mayurakshi E & M Division, SuriNo ratings yet

- Power Transmission Over Long Distances With CablesDocument8 pagesPower Transmission Over Long Distances With CablesramsesiNo ratings yet

- 5-LV Service Drop CablesDocument10 pages5-LV Service Drop CablesapranaguptaNo ratings yet

- More Than Just A Phase: Understanding Phase Stability in RF Test CablesDocument5 pagesMore Than Just A Phase: Understanding Phase Stability in RF Test CablesMartin Antonio Castro PerezNo ratings yet

- Xlpe Cable Commissioning Test Procedure Following Iec StandardDocument5 pagesXlpe Cable Commissioning Test Procedure Following Iec StandardAkd Deshmukh100% (3)

- Testing: Service LineDocument2 pagesTesting: Service LineVerónicaNo ratings yet

- Is 1554Document14 pagesIs 1554Pardeep KhosaNo ratings yet

- MODEL PAPER Ps-1saquibDocument3 pagesMODEL PAPER Ps-1saquibKaize JbNo ratings yet

- 110kv Ehv Cable - GtpsDocument2 pages110kv Ehv Cable - GtpsBijaya Kumar MohantyNo ratings yet

- Medium Voltage CableDocument5 pagesMedium Voltage CableNaveenNavabNo ratings yet

- 694Document13 pages694Naresh MudaniNo ratings yet

- Guidelines of Electricity ConstructionDocument26 pagesGuidelines of Electricity ConstructionPhool Mohammad Rayeen100% (1)

- Model Questions of Electrical Power Transmission & DistributionDocument1 pageModel Questions of Electrical Power Transmission & DistributionAchinta Malik - EENo ratings yet

- Part 9Document5 pagesPart 9pravishnNo ratings yet

- Is 7098Document17 pagesIs 7098ASPRAN INDIANo ratings yet

- Section Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Document56 pagesSection Four - Medium Voltage Tr-Xlpe Cables: Explanatory Information 2-13Terex14253No ratings yet

- For HT PVC Cable PDFDocument12 pagesFor HT PVC Cable PDFAnonymous Gg6z0u9IBzNo ratings yet

- Httpsbescom - Karnataka.gov - Instoragepdf filesQSandS DrawingsTechnical Specification LT AB Cable PDFDocument12 pagesHttpsbescom - Karnataka.gov - Instoragepdf filesQSandS DrawingsTechnical Specification LT AB Cable PDFhr saimsonlineNo ratings yet

- Sizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableDocument9 pagesSizing Calculations For 20/3.3 KV, 12.5 MVA Transformer Feeder CableNeomax BuildersNo ratings yet

- 4/11/2021 /conversion/tmp/scratch/518123760Document10 pages4/11/2021 /conversion/tmp/scratch/518123760DenyNo ratings yet

- Test On 110kV Power Cable After InstallationDocument9 pagesTest On 110kV Power Cable After InstallationKate Catherine RamosNo ratings yet

- IS-7098 PT - 1.Document17 pagesIS-7098 PT - 1.Rishi PalNo ratings yet

- On Electromagnetic Field Simulation SoftwareDocument2 pagesOn Electromagnetic Field Simulation SoftwareAnurag JaiswalNo ratings yet

- IEC 60708 SummaryDocument6 pagesIEC 60708 SummaryAdnan Khan0% (1)

- SECTION 26 05 13 Medium-Voltage CablesDocument10 pagesSECTION 26 05 13 Medium-Voltage Cablesjesus marquez arvaezNo ratings yet

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalNo ratings yet

- Anixter Minimum Bending Radius Wire Wisdom en PDFDocument1 pageAnixter Minimum Bending Radius Wire Wisdom en PDFAndrew Ixara AribowoNo ratings yet

- Mediumvoltage 2 PDFDocument41 pagesMediumvoltage 2 PDFesoares1990No ratings yet

- LV and HV Cable SizingDocument7 pagesLV and HV Cable Sizingelectrifier_suren100% (1)

- Inspection Procedure For Electrical Cables: Prepared by SatheeshDocument3 pagesInspection Procedure For Electrical Cables: Prepared by SatheeshSatheesh KumarNo ratings yet

- Development of The Next Generation Battery Cell Isolation SwitchDocument6 pagesDevelopment of The Next Generation Battery Cell Isolation Switch구자춘No ratings yet

- Loadbreak Products: Experience & ReliabilityDocument8 pagesLoadbreak Products: Experience & ReliabilityCbdtxd PcbtrNo ratings yet

- Cable TestingDocument19 pagesCable Testingyohannes GelanNo ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Feugen PO 06 2020-21Document2 pagesFeugen PO 06 2020-21Standards IndiaNo ratings yet

- Mil STD 2223Document96 pagesMil STD 2223Standards IndiaNo ratings yet

- Height of Water ColumnDocument2 pagesHeight of Water ColumnStandards IndiaNo ratings yet

- Quotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateDocument2 pagesQuotation M/S. Sensors India Quotation No.: Q00205 09/07/2020: Quotation DateStandards IndiaNo ratings yet

- Operating Manual Operating Manual: Sensors Ndia Vacuum Oven Ndia Vacuum OvenDocument21 pagesOperating Manual Operating Manual: Sensors Ndia Vacuum Oven Ndia Vacuum OvenStandards IndiaNo ratings yet

- Sensor's BrochureDocument18 pagesSensor's BrochureStandards IndiaNo ratings yet

- Is 9873 P-7 2017Document60 pagesIs 9873 P-7 2017Standards India100% (2)

- IS 302-2-3 (2007) - Safety of Household and Similar Electrical Appliances, Part 2 - Particular Requirements, Section 3 - Electric IronDocument12 pagesIS 302-2-3 (2007) - Safety of Household and Similar Electrical Appliances, Part 2 - Particular Requirements, Section 3 - Electric IronStandards IndiaNo ratings yet

- Is - 00191 - 2007 PDFDocument14 pagesIs - 00191 - 2007 PDFSangita GhaisasNo ratings yet

- BTS Products Introduction 2016Document35 pagesBTS Products Introduction 2016ridwanwidyantaraNo ratings yet

- 28-11-22 JR - Iit Star Co-Sc Model-A Jee Adv 2018 P-II Cat-8 Key & Sol FDocument11 pages28-11-22 JR - Iit Star Co-Sc Model-A Jee Adv 2018 P-II Cat-8 Key & Sol Fzaid khanNo ratings yet

- Simulación Optimizada Del Tiempo de La Parte Superior Del Cuerpo en La Producción de La Velocidad de La Cabeza Del Bate en El Bateo deDocument9 pagesSimulación Optimizada Del Tiempo de La Parte Superior Del Cuerpo en La Producción de La Velocidad de La Cabeza Del Bate en El Bateo dejhonattan sandovalNo ratings yet

- Cat Dcs Sis ControllerDocument2 pagesCat Dcs Sis Controllerroestatom50% (2)

- Underwing Nozzles: Carter Ground FuelingDocument54 pagesUnderwing Nozzles: Carter Ground FuelingHenryNo ratings yet

- Polyethylene Glycol-Salt PDFDocument14 pagesPolyethylene Glycol-Salt PDFlauraNo ratings yet

- Review PDFDocument140 pagesReview PDFBLa ProductionNo ratings yet

- Topic 9 First Year MCAT (Electrochemistry)Document39 pagesTopic 9 First Year MCAT (Electrochemistry)Khubaib KhanNo ratings yet

- Basics of Non-Ideal FlowDocument32 pagesBasics of Non-Ideal FlowKavali Koteswar ReddyNo ratings yet

- E MAX TIR Trip Indication Relay 2015Document4 pagesE MAX TIR Trip Indication Relay 2015Ryan McMaster0% (1)

- Lecture 4Document16 pagesLecture 4Vivek ChikkalaNo ratings yet

- Chapter 3-3 Signal Processing Elemnt Part ThreeDocument43 pagesChapter 3-3 Signal Processing Elemnt Part Threedan gNo ratings yet

- Shigleys Mechanical Engineering Design 10th Edition Budynas and Nisbett Solution ManualDocument26 pagesShigleys Mechanical Engineering Design 10th Edition Budynas and Nisbett Solution Manualmark100% (33)

- Ijert Ijert: Structural Analysis of A Multi-Storeyed Building Using ETABS For Different Plan ConfigurationsDocument5 pagesIjert Ijert: Structural Analysis of A Multi-Storeyed Building Using ETABS For Different Plan ConfigurationsPachaKhanKhogyaniNo ratings yet

- CEM ManualDocument127 pagesCEM ManualSeemplify100% (1)

- Wheels and Castors Guide: We Innovate MobilityDocument58 pagesWheels and Castors Guide: We Innovate MobilityArjun GoudNo ratings yet

- Lecture On CompressorDocument72 pagesLecture On CompressorYan ManurungNo ratings yet

- Free Vibration of Thin Film Cantilever Beam: Mohammad ZannonDocument13 pagesFree Vibration of Thin Film Cantilever Beam: Mohammad ZannonerpublicationNo ratings yet

- JIS G3106-SM400 - SM490 - SM520 - SM570 Structural Steel PlateDocument7 pagesJIS G3106-SM400 - SM490 - SM520 - SM570 Structural Steel PlateAbhishek BhargavNo ratings yet

- Chapter 02Document12 pagesChapter 02Βασίλης ΝούσηςNo ratings yet

- Laird Macomber Cde Solid-Polymerium-Alu-CapacitorDocument8 pagesLaird Macomber Cde Solid-Polymerium-Alu-CapacitorKrzyszto FPNo ratings yet

- Third Space Learning - Fluent in Five GCSE - Progress Tracker GCSE FoundationDocument44 pagesThird Space Learning - Fluent in Five GCSE - Progress Tracker GCSE FoundationZoonieFRNo ratings yet

- Mass and Balance - Keys NotesDocument4 pagesMass and Balance - Keys NotesArnav KapoorNo ratings yet

- Famous PhysicistsDocument11 pagesFamous PhysicistsPaul Mark PilarNo ratings yet

- Polymer: Berkant Yetiskin, Oguz OkayDocument10 pagesPolymer: Berkant Yetiskin, Oguz OkayKhaled Al GhaebNo ratings yet

- Chapter 3 Manipulator KinematicsDocument101 pagesChapter 3 Manipulator KinematicsKeith wongNo ratings yet

- 3250 ds054 4 Light GateDocument9 pages3250 ds054 4 Light GateMarcosH911No ratings yet

- University of Southern Philippines Foundation. College of Engineering and ArchitectureDocument12 pagesUniversity of Southern Philippines Foundation. College of Engineering and ArchitectureJason OwiaNo ratings yet