Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

50 viewsHammerMills Brochure

HammerMills Brochure

Uploaded by

djenanHammer_Mills_Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Impact MasterDocument5 pagesImpact Masterdjenan0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Basic HydraulicDocument129 pagesBasic Hydraulicdjenan100% (29)

- Cone - Crushers PARKERDocument4 pagesCone - Crushers PARKERdjenan50% (2)

- Belimo Aktuator Klapni Za Koja FutureDocument5 pagesBelimo Aktuator Klapni Za Koja FuturedjenanNo ratings yet

- Stuffing Box Valve: Data Sheet 006001 Englisch (English)Document16 pagesStuffing Box Valve: Data Sheet 006001 Englisch (English)djenanNo ratings yet

- Tollok CatalogDocument49 pagesTollok CatalogdjenanNo ratings yet

- Ventur - en - Compact HCFT B HCBT BDocument32 pagesVentur - en - Compact HCFT B HCBT BdjenanNo ratings yet

- AC Axial Fans Catalogue NewDocument140 pagesAC Axial Fans Catalogue NewdjenanNo ratings yet

- KSB - Range of Valves DataDocument68 pagesKSB - Range of Valves DatadjenanNo ratings yet

- Taper LockDocument10 pagesTaper LockdjenanNo ratings yet

- Terex Gladiator GTH3007 Parts ManualDocument110 pagesTerex Gladiator GTH3007 Parts ManualdjenanNo ratings yet

- PED 2014-EU Design and Inspection Requirements On HL-LHC Cold MassDocument21 pagesPED 2014-EU Design and Inspection Requirements On HL-LHC Cold MassdjenanNo ratings yet

- Impact Hammer CrusherDocument4 pagesImpact Hammer Crusherdjenan100% (2)

- GC Series Hydraulic PumpsDocument10 pagesGC Series Hydraulic PumpsdjenanNo ratings yet

- Craelius Drill BitsDocument7 pagesCraelius Drill BitsdjenanNo ratings yet

HammerMills Brochure

HammerMills Brochure

Uploaded by

djenan0 ratings0% found this document useful (0 votes)

50 views8 pagesHammer_Mills_Brochure

Original Title

HammerMills_Brochure

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHammer_Mills_Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

50 views8 pagesHammerMills Brochure

HammerMills Brochure

Uploaded by

djenanHammer_Mills_Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 8

UP RUNNING Broshor an,

ei 20" x18" a

Zee

a

wand

o

ope BY i

EXCLU

This is the most effective method yet developed for crushing,

grinding or pulverizing. This unique principle operates with a

Fain of hammer or ring blows which shalter and disintegrate

the material being reduced.

Materials are reduced 2 ways: (1) shattered upon entry by tho

revolving hammers, (2) further disintagrated by forcetul impact

against the heavy breaker plates in the cover.

This dual mechanical reduction, plus the effect of particles im-

pinging against each other in the air, causes most materials to

be sufficiently reduced to pass through the adjustable grinding

plate.

Finished product size depends on: (1) the size of openings in

perforated screens or spacing between the heavy duty grates;

(2) the number, size and type of hammers or rings: (3) the setting

of the adjustable grinding piate, and (4) the speed of the rotor.

ROTORS

The material to be reduced determines the rotor construction

of a Stedman Hammer Mill. A series of tough armor plated steel

disks or spacer plates is keyed to the extra heavily constructed

rolor shaft. Long bolts pass through their outer diameters. From

these, sets of hammers or rings are suspended. The rotor re-

volves within a substantial housing of exclusive cast design

Insuring maximum return on investment.

All Stedman Type “A” 2-Stage Hammer Mills are fully adjust-

able, the rotor can be made with adjusting holes for setting

out hammers or rings compensating for wear.

SHAFTS

Shafts for all Stedman Hammer Mills are made of forged alloy

steel, Machined to very close tolerances from 50% to 100%

oversize to prevent whipping and vibration,

PERFORATED EE

Punched from tough, high carbon, woar-tosistant or stainloes

steel, perforated metal screens are used in Stedman Type “A’

Cross Section of Stedman 2-Stage Swing Hammar Machine

ON

PRINC

machines for sizing and medium hard materials like tankage,

pressed cake, grain or shavings. Screens are mounted in a sub-

stantial frame and the entire assembly slides into machined

grooves in the side housing, Perorations run from Ye" to 2%

Gamoters. Wom perforated screens can be removed easily

The cage adds materially to the screen's life, holding it in per-

fect alignment and preventing bending or sagging.

aS AND RINGS

Important to consider when deciding whether to equip a

‘machine with hammers or rings are the materials to be reduced,

teed size, whether hard, sot, tibrous, tough, frabie or abrasive

‘Also equally important are finished product specifications. The

{ype of hammers or rings selected depends also upon whethor

the sized product is fo be uniform with a minimum of fines or

pulverized with a maximum of fines. Stedman, with over 60 years

| practical operating experience is well qualified to recom-

‘mend the proper size anc type of hammers or rings for the

reduction to be eccomplished. The hammers end rings ore

made of high grade manganeso or alloy steel, alloy steel parts

being heat-treated to resist abrasive wear... Carbice tip

hammers are available,

E BARS

savy auly grate bars are furnished when sizing hard and

‘abrasive materials like limestone, brick bats, raw or junk bone,

fertilizer tailings and the like. These bars are of the “rapid

discharge” type. Openings between the bers from Yieinch 10

4:inch are maintained by spacing blocks socuroly rivotod to

the bars. The bars are so constructed that they can be shifted

around in the machine distributing the wear and getting the

maximum service from each set. When complete set of bars

is installed in the machined recesses on the housing sides or

bar presses against the spacing blocks of the next bar. Th

maintains tho proper spacing. When the cover is lowered the

grate bars are locked into position,

207 3 12", 20" x 18Mounied on

‘Unit Base with Dirve! Ove Blower Fan

‘ane Direct Motor Brive.

IDEAL FOR MANY MATERIALS

Animal Tankage * Bark » Bauxite Ore » Bentonite

Bones * Bone & Meat Scraps* Bumed Lime Cake = Cal-

cium Carsonate ~ Carbon - Chomicale Clays = Coal

* Corn Cracklings » Dolomite » Stone » Dross » Ex-

eller Cake Fertilizer Materials » Fibre Board Scrap

* Fish Scrap * Foundry Cores = Garbage = Garbage

Tankage - Glue * Graphite - Green Bone = Gypsum

Hard Rubber * Hog Chips » Hydrated Lime » Junk Bone

‘Limestone * Magnesite « Meat Cake» Mica Nitrates

* Gil Sand Cores = Phosphate Rock * Potash * Quick

Lime Flaw Fish = Aesin= Rosin Salt Cake Salts Saw.

ust = Shellac + Shelled Corn » Soap Powder = Sodium

Fluoride » Sodium Sulphate * Steam Bone * Tan Bark

‘Tankage * Urea Crystals * Vermiculite » Whey > Yeast

Zine Oxide

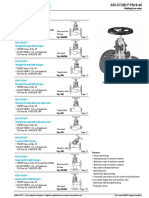

A Smooth ring large feed and hard

B Shredded ring mmaterale

© Double-ond, two-cornor | Assembled disc type

rotor for 20” x 18”"size

type, Carbide tipped UOf FOr 2x 18 size

hammer for special triewbie counting)

purpose mati °

4 Complete plate type

B Doudlewnd. tour | Foto lor kx 20" size

fight duty'service iene ee

E Doubled chisel type four rows of double-end

hammer for ough and, reversible hemmers

torous mtenais K From left, perforated

metal screen only; the

F Double-end fourcorner fetal screen only: tt

type, medium duty

pe fh) pororated screen

a: Dovbesia eurccomar: Sippel partway ita

type, heavy duty Secs capeane

servis ‘screen

H Hoary duty yoke ype L Ato fhe ies anc

Used insmalfoire fees ct ga ban

tmachincsr handling a notin Stedman mls

ee A el ee |

Tet)

Ce?

he special combination of features found in the Stedman Type

B" Hammer Millis the result of over 50 years experience in

etme required to reverse the hamm

has rounded, the tips

struction coupled

'a superior machin

xtreme simplicity of design METHOD OF REDUCING MATERIALS:

imple to maintain and

efficient machine

can be made

tools or highly skilled labor.

'B" Hammer Mill ut

rial

distribut

10 compen

Phosphate R

Refractory Material Quartz

a Flock Salt Sand Stone

Brick Bats Glass Cullet Steel Tunings Iron Or Shale

3 Iron Borings Gypsum Terra Cotta Limestone agers

Sem

Serie

ACCESSIBILITY

The Stedman Hammer Mills designed to allow

3 without removing the feed chute or auxiliary hoppe:

ine back hat of

easy access for adjustments and/or replacements. 8y remov

Capacities and Specifications: STEDMAN Type “B" Heavy Duly Coal Hammer Mills

| rs [Lt | | [ese

Capacities and Specifications: STEDMAN Type °B” Heavy Duty Steel Tumnings Hammer Mills

| I

STEDMAN'S TYPE “BX” HAMMER MILL

DOWN RUNNING

ultin

Large Feed Opening

Extra Heavy

Houring Liners

& Breaker Pistes

‘Adjustabio

‘aringing Plate

Sectional Construction

SUCCESSFULLY USED FOR CRUSHING AND HOGGING A WIDE VARIETY OF NON FRIABLE MATERIALS.

Stedman Type BX Medium-Duty Crushers are recommended for reductions which

do not require the use of heavy-duly machines. In construction and design,

they are similar, including practically all features as offered in Stedman Type "B

Heavy-Duty Crushers.

Unusually large feed openings simplify the feeding of medium hard lumpy or

bulky materials—difficult to feed the average crusher.

Type 8X" Hammar Mills are recommended for hogging and crushing Metal

Turnings, Wood Waste, Bark, Cark and similar materials.

BUILT-IN METAL TRAP

Positive, Gravity type. Trap contents will discharge by gravity

by simply raising the hinged clean-out coor.

EXTRA HEAVY HOUSING LINERS AND

BREAKER PLATES

The entire crusher housing is protected from wear by heav

liners of maximum thickness, in the 20” x 12” and 20” x 18)

i209, liners are provided below the sereen bars and at

the lower back end,

RADIAL ADJUSTING SPACER PLATES

Full hammer or ring coverage is provided at every fractional

partot the crushing chamber through the use of alternating

spacer plates,

Radial adjusting holes can be providedin the spacer plates for

setting oul the hammers of rings to compensate for wear—

‘maintaining a uniform clearance between revolving and

stationary forces,

A partial list of materials:

LARGE FEED OPENING

The feed openings in all Type “BX” machines are unusually

large—simplitying the feeding of large lumpy or bulky materials.

EXTREME SECTIONAL CONSTRUCTION

[As accessibility is very important in equipment of this kind—

considerable thought has been given to this subject.

By raising the back half of he coverin the larger machines,

oF the one-piece hinged cover of the smaller machines—the

interior is immodiatoly accossibls for inepection, adjustments,

cleaning or replacements,

ADJUSTABLE GRINDING PLATE

The grinding plate against which materials are reduced, is of

the fully adjustable type. By adjusting, proper clearance can

be maintained between hammers or rings and grinding plate

face—controlling size of finished product.

The adjusting mechanism s positive and simple in operation—

located at the outer side of the crusher and readily accessible,

"5.12" Crusher.

Fear view showin

clout Soot and hinged cover.

SeEcirIGATIONS

Sai “tise (ot

- Bett or Direct Horse Feed

Inches Die Brive Power Shehest

2x8 a | &, 1020 exon | 7

wee |, 0 15:90 Wen aH" 1200

ay" 2" 98 ge, |(e-40 wrx” | 2600 4400

[aon 18” a, Ey 40-60 19" x 19 "3680 6000

20" x20" 10 20 50.75 tr x at" 6670 8:00

Dimensions and weights as listed are approximate. Weights

apply to slandard machines when equipped with hammers,

rings, perforated metal screens or screen bars most commonly

Used) Weights and gimensions of direct motor driven machines

IN vary with horsepower, typo and epoed of motor requirod,

‘oper operating speeds for specified reductions will be recom

mended by our Engineering Department, Speeds as listed are

‘minimum and maximum.

Rolling rings are not available in the 12” x 9" size.

Flywheels are not standard equipment and are furnished only

when required,

Unless otherwise specified, all machines are built for right

hand drive— determined when facing the machine at the teed

end

Cortiiod foundation plane and accurate chipping weighte will

be furnished on request

eee

‘Sine Togo dm Crater

See Guaiog no 613

See Catalog No 80°F ScoGmaognose oor

ecto Duty Cage Mi

Sieminoatue toe

us ik Type" teay/ Day Hammary" Down Rung Hager M—Type BX Low Pe Hana My “T

‘See Cuming No. 600 ‘Soe Gatsoy No. 800, Cawloghte oor = Seeaaegre ss

TEST PLANT - Select the perfect crusher for your application

Stedman has one of the finest testing faciliies available. With

‘over 175 years of experience, many materials already have test INDIANA \ OHIO

reports on fie. Whether hard granite, gravel, imestone, coal, ®

‘metal or raw garbage, callus for a comparison report or 10

schedule testing with our selection of fullsize equipment

For a full-scale test, 800-1200 ibs. of your feed material will be

required. 55 gallon drums are the most suitable container for

‘shipment and should be clearly marked with your company name

Best routing sto Cincinnat, Ohio, and then through Aikins Lines,

Inc. to Aurora, Indana. Ship prepaid to: Stedman Machine

‘Company, c/o Test Centar, 108 Indiana Ave., Aurora, IN 47001,

Originater of the Cage Mit SINCE 1834

1-800-262-5401

STEDMAN MACHINE COMPANY + P. 0, BOX260 + AURORA, INDIANA 47001 + PHONE (812)926-0038 + FAX (812) 926-2482

E-Mail: sales@stedman-machine.com + Web Site: http://www-stedman-machine.com

Printed in USA {catalog No, 600-R ‘© Canytaht 1996, Stecman Machine Compary

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Impact MasterDocument5 pagesImpact Masterdjenan0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Basic HydraulicDocument129 pagesBasic Hydraulicdjenan100% (29)

- Cone - Crushers PARKERDocument4 pagesCone - Crushers PARKERdjenan50% (2)

- Belimo Aktuator Klapni Za Koja FutureDocument5 pagesBelimo Aktuator Klapni Za Koja FuturedjenanNo ratings yet

- Stuffing Box Valve: Data Sheet 006001 Englisch (English)Document16 pagesStuffing Box Valve: Data Sheet 006001 Englisch (English)djenanNo ratings yet

- Tollok CatalogDocument49 pagesTollok CatalogdjenanNo ratings yet

- Ventur - en - Compact HCFT B HCBT BDocument32 pagesVentur - en - Compact HCFT B HCBT BdjenanNo ratings yet

- AC Axial Fans Catalogue NewDocument140 pagesAC Axial Fans Catalogue NewdjenanNo ratings yet

- KSB - Range of Valves DataDocument68 pagesKSB - Range of Valves DatadjenanNo ratings yet

- Taper LockDocument10 pagesTaper LockdjenanNo ratings yet

- Terex Gladiator GTH3007 Parts ManualDocument110 pagesTerex Gladiator GTH3007 Parts ManualdjenanNo ratings yet

- PED 2014-EU Design and Inspection Requirements On HL-LHC Cold MassDocument21 pagesPED 2014-EU Design and Inspection Requirements On HL-LHC Cold MassdjenanNo ratings yet

- Impact Hammer CrusherDocument4 pagesImpact Hammer Crusherdjenan100% (2)

- GC Series Hydraulic PumpsDocument10 pagesGC Series Hydraulic PumpsdjenanNo ratings yet

- Craelius Drill BitsDocument7 pagesCraelius Drill BitsdjenanNo ratings yet