Professional Documents

Culture Documents

PQR For

PQR For

Uploaded by

Akash Singh Tomar0 ratings0% found this document useful (0 votes)

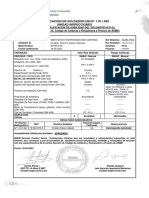

65 views3 pagesThis document is a Procedure Qualification Record that summarizes the welding parameters and test results for a gas tungsten arc welding procedure using a single pass on a 1.5mm thick AISI 316L stainless steel coupon in the 5G position. Visual and radiographic non-destructive testing indicated satisfactory results. The record was prepared by EF Site Technologies and witnessed by Tata Consulting Engineers in accordance with ASME Section IX requirements.

Original Description:

Original Title

PQR for

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a Procedure Qualification Record that summarizes the welding parameters and test results for a gas tungsten arc welding procedure using a single pass on a 1.5mm thick AISI 316L stainless steel coupon in the 5G position. Visual and radiographic non-destructive testing indicated satisfactory results. The record was prepared by EF Site Technologies and witnessed by Tata Consulting Engineers in accordance with ASME Section IX requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

65 views3 pagesPQR For

PQR For

Uploaded by

Akash Singh TomarThis document is a Procedure Qualification Record that summarizes the welding parameters and test results for a gas tungsten arc welding procedure using a single pass on a 1.5mm thick AISI 316L stainless steel coupon in the 5G position. Visual and radiographic non-destructive testing indicated satisfactory results. The record was prepared by EF Site Technologies and witnessed by Tata Consulting Engineers in accordance with ASME Section IX requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

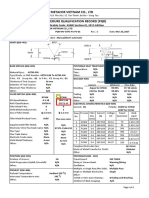

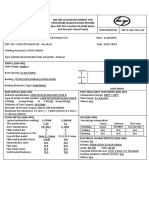

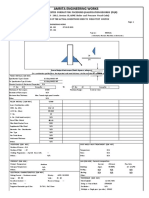

QW -483 PROCEDURE QUALIFICATION RECORDS (PQR)

(See QW-200.2, Section IX, ASME Boiler and Pressure vessel Code)

Company Name: M/s. EF Site Technologies Pvt Ltd.

Procedure Qualification Record No. EFSTPL/ PQR/F1 Rev-0 Dt: 22-01-2019

WPS No. EFSTPL/WPS/F1 Rve-0 Dt22-01-2019

Welding Process: Gas Tungsten Arc Welding (GTAW)

JOINT (QW-402)

Number of layers welded Single pass

BASE METALS (QW-403) POSTWELD HEAT TREATMENT (QW-407)

Material Specification : AISI 316L Temperature : NA

To AISI 316L Time : NA

P. No. __8__ Group No. __1__ To Other : NIL

P. No. __8__ Group No. __1__

GAS (QW -408)

Thickness of Test Coupon : 1.5mm Percentage Composition

Diameter of test coupon:1/2 inch Gas(es) Mixture Flow rate

Others : NA Shielding Argon 99.9995% NA 14-18 LPM

Trailing NA NA NA

Backing Argon 99.9995% NA 10-14 LPM

FILLER METALS (QW-404) ELECTRICAL CHARACTERSTICS (QW-409)

SFA Specification :NA Current : DC

AWS Classification : NA Polarity : Electrode Negative

Filler Metal F. No. : NA Amps : 63.4-69.5 Amp

Weld Metal Analysis A. No. : NA Volts : 19.4-19.5V

Size of Filler Metal : NA Tungsten Electrode size & type:2% Ceriated Tungsten,size

Other : NA 1.5mm dia

Weld Metal Thickness : NA Other : NIL

POSITION (QW-405) TECHNIQUE (QW-410)

Position of Fillet : 5G String or Weave Bead : String

Weld Progression : NA Multiple or Single Pass : Single Pass

Other : NIL Other : NIL

PRE HEAT (QW-406)

Preheat temperature :Atmospheric Temp 28ºC

Inter pass temperature : NA

Other : NIL

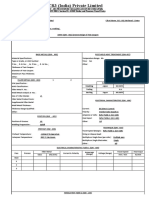

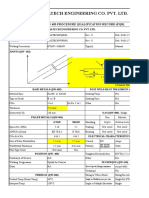

QW -483 (Back)

PQR No. EFSTPL/PQR/F1 Rev-0 Dt: 22-01-2019

TEST RESULT

Visual examination of completed weld (QW-302.4): Satisfactory

Guided Bend Test(QW-160)

Test Type Specimen No Result

Root Bend-1 - -

Root Bend-2 - -

Face Bend-1 - -

Face Bend-1 - -

Alternative volumetric examination result(QW-191) RT UT

RT Report No: RT/0025/2019

Other ______________________________ NA ______________________________________

Welder’s Name: Mr. Lakshmipathi Welder ID No. W72

Test conducted by: M/s. EF Site Technologies Pvt Ltd.

Test Witnessed by: Tata Consulting Engineers

We certify that the statement in this record are correct and that the welds were prepared, welded,

and tested in accordance with the requirements of ASME Section IX

Manufacturer

M/s. EF Site Technologies Pvt Ltd. TATA CONSULTING ENGINEERS

Examiner or Examining Body

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- PQRDocument2 pagesPQRHoangNo ratings yet

- ZIA Technical Handbook On Zirconium and Zirconium Compounds 2019 PDFDocument139 pagesZIA Technical Handbook On Zirconium and Zirconium Compounds 2019 PDFDannaIsabellaRey100% (2)

- Gmaw PQR SampleDocument5 pagesGmaw PQR SampleRakesh MenonNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- PRN005Document2 pagesPRN005beyNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)surjithkocherilNo ratings yet

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Document2 pagesBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyNo ratings yet

- PRN004Document2 pagesPRN004beyNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- JOINTS (QW-402) : Groove Design of Test CouponDocument2 pagesJOINTS (QW-402) : Groove Design of Test CouponbeyNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS PQR - P22 SS 18042024Document5 pagesWPS PQR - P22 SS 18042024mahesh kumarNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- PQR 005-50-NLG PWHT (Icas)Document2 pagesPQR 005-50-NLG PWHT (Icas)Atilio BarriosNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- Welder Qualification Record: Sub Contractor QC Lthe QC ClientDocument4 pagesWelder Qualification Record: Sub Contractor QC Lthe QC ClientZaidiNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- PQR FormatDocument2 pagesPQR FormatBE GNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Final PQRDocument130 pagesFinal PQRAhamed Naufal CaNo ratings yet

- Acfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Document6 pagesAcfrogdgjpoczzmyytfkwbkh0koiyebkjw2cygu7mcl7x89emnhqrr79 8h9g0sneqlza Asreuqopw V3yccnxf6wf4ssafjrpko6znwt9uci Enrtbyu8y I2ju68Daniel CamposNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiAR100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- QW483Document2 pagesQW483Sc TanNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Title: WQ 482 Welding Procedure Specification (WPS) : SupersedesDocument1 pageTitle: WQ 482 Welding Procedure Specification (WPS) : SupersedesdethamrnNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- 2 - WQT KPRDocument27 pages2 - WQT KPRSuryadev singhNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Rep PQR 02Document3 pagesRep PQR 02shaniraj BirajdarNo ratings yet

- 1.911.032 WPQ Smaw Astm A36Document1 page1.911.032 WPQ Smaw Astm A36Felipe Carrasco sepulvedaNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Piping Isometric Drawings - EnggCyclopediaDocument5 pagesPiping Isometric Drawings - EnggCyclopediaAkash Singh TomarNo ratings yet

- Updated QAQC FormatDocument16 pagesUpdated QAQC FormatAkash Singh TomarNo ratings yet

- Updated QAQC FormatDocument16 pagesUpdated QAQC FormatAkash Singh TomarNo ratings yet

- A961 PDFDocument7 pagesA961 PDFAkash Singh TomarNo ratings yet

- Lps and MpsDocument14 pagesLps and MpsAkash Singh TomarNo ratings yet

- A961 PDFDocument7 pagesA961 PDFAkash Singh TomarNo ratings yet

- Ibr Certificate Details-1Document5 pagesIbr Certificate Details-1Akash Singh TomarNo ratings yet

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (2)

- QAPDocument46 pagesQAPAkash Singh TomarNo ratings yet

- ATTENDANCE FormatDocument49 pagesATTENDANCE FormatAkash Singh TomarNo ratings yet

- Unit-4 CH 21 Phy SciDocument29 pagesUnit-4 CH 21 Phy SciCarlyn VarelaNo ratings yet

- A) B) B - Cos A) B, When A 90°: Material Charpy V Impact StrengthDocument3 pagesA) B) B - Cos A) B, When A 90°: Material Charpy V Impact StrengthsonuNo ratings yet

- Technical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaDocument6 pagesTechnical Information Sheet: General Information: ISO 12944 TI - G 9 / UsaBash MatNo ratings yet

- Astm C612Document5 pagesAstm C612GLADYS2714100% (2)

- Food and Beverage Services Week 7Document10 pagesFood and Beverage Services Week 7peter mendozaNo ratings yet

- 1 s2.0 S0378775320310120 MainDocument26 pages1 s2.0 S0378775320310120 MainRishabh KumarNo ratings yet

- SERIES 7000: Tolerances, Testing and Quality ControlDocument28 pagesSERIES 7000: Tolerances, Testing and Quality ControlM.GargoumNo ratings yet

- 13 - Economic, Environmental and Societal Issues in MSEDocument15 pages13 - Economic, Environmental and Societal Issues in MSEClarence Sulit QuijanoNo ratings yet

- Nike Catalog 2024 Football 01-05-24Document36 pagesNike Catalog 2024 Football 01-05-24Ethan AtchleyNo ratings yet

- CCTTC - SUP9 Datasheet, Chemical Composition: Item Standard Number DescriptionsDocument3 pagesCCTTC - SUP9 Datasheet, Chemical Composition: Item Standard Number DescriptionsAjeeth KumarNo ratings yet

- AkzoNobel Perkalite Processing in Polyolefins Pa Glo Eng TB tcm96-16534Document5 pagesAkzoNobel Perkalite Processing in Polyolefins Pa Glo Eng TB tcm96-16534huy.dicNo ratings yet

- Ahmad Hamidd IzomerizationDocument6 pagesAhmad Hamidd Izomerizationاحمد حمید کارسول عزیزNo ratings yet

- Sikadur 55 LP inDocument3 pagesSikadur 55 LP inRUDRA KARMAKARNo ratings yet

- Gear Pump For Polymer ProcessingDocument6 pagesGear Pump For Polymer ProcessingRodolfo Manuel Alarcón TroncosoNo ratings yet

- Improvement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesDocument9 pagesImprovement of Delamination and Energy Absorption Behavior in GLARE Using NanoparticlesTavo MuñizNo ratings yet

- D5329 PDFDocument7 pagesD5329 PDFIndira BanerjeeNo ratings yet

- Hazardous Areas - Explosionproof Solenoids: Some HistoryDocument5 pagesHazardous Areas - Explosionproof Solenoids: Some HistoryShahram GhassemiNo ratings yet

- Baxxodur EC 201: Technical InformationDocument2 pagesBaxxodur EC 201: Technical Informationpetersom 93100% (1)

- New Members Apr2004Document9 pagesNew Members Apr2004johnNo ratings yet

- Case Studies in Construction MaterialsDocument12 pagesCase Studies in Construction MaterialsSithesh RNo ratings yet

- D and F Block Elements With AnswersDocument5 pagesD and F Block Elements With AnswersFool TheNo ratings yet

- DYSTAR Cadira INDIGO Brochure March 2019 - AnsichtDocument2 pagesDYSTAR Cadira INDIGO Brochure March 2019 - AnsichtkwatbNo ratings yet

- Processing - Options - For - Gold-Tellurides VIE 21 JUL 2017Document9 pagesProcessing - Options - For - Gold-Tellurides VIE 21 JUL 2017Erick EscalanteNo ratings yet

- API 570 - Refresh - CB - 18 June 2014Document14 pagesAPI 570 - Refresh - CB - 18 June 2014nathan zacky ardamaNo ratings yet

- Boundary WallDocument1 pageBoundary WallgohilnarendraNo ratings yet

- Class: 6: Paper Code: UN479Document20 pagesClass: 6: Paper Code: UN479virajNo ratings yet

- ChemDocument34 pagesChemAaghash A SNo ratings yet

- William Corbett, SSPC PCS KTA-Tator, IncDocument23 pagesWilliam Corbett, SSPC PCS KTA-Tator, InccocorruoNo ratings yet

- Pouring & SolidificationDocument19 pagesPouring & SolidificationTanmay KothiwalNo ratings yet