Professional Documents

Culture Documents

Torque Table en PDF

Torque Table en PDF

Uploaded by

MichalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Torque Table en PDF

Torque Table en PDF

Uploaded by

MichalCopyright:

Available Formats

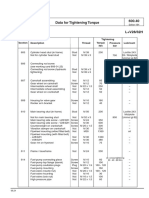

Torque settings for wheel nuts and bolts

on commercial vehicles

Important ! Vehicle make

Auwärter

Tread Torque setting ( Nm )

Bolt centering Hub centering Trilex

Check torque settings regularly! M 20 × 1.5

M 22 × 1.5

350

350

450

600

Bedford

M 22 × 1.5 510 – 580 550 – 600

7/8 ˝ – 11 BSF 510 – 580 550 – 600

To ensure wheel nuts/bolts are correctly tightened on DAF

truck wheels, please note the following: M 18 × 1.5 340 – 400 270 – 300

M 20 × 1.5 280 – 350 450 – 520 320 – 350

M 22 × 1.5 700

Torque value Daimler

It is imperative to adhere to the torque values specified by the Atego M 18 × 1.5 400

vehicle manufacturers. On steel rims the wheel nuts should Atego M 20 × 1.5 500

always be tightened crosswise. Actros M 22 × 1.5 600

Axor M 22 × 1.5 600

Faun

Torque wrench

M 18 × 1.5 290 – 320

For reasons of operational safety, the use of a torque wrench M 20 × 1.5 370 – 400

is recommended as this ensures the specified torque values M 22 × 1.5 430 – 460

are adhered to exactly. Iveco

M 18 × 1.5 335 – 410

M 20 × 1.5 440 – 540

Impact wrench

M 22 × 1.5 380 – 450 580 – 650

With serial fittings, electric- or air-powered single or multiple EVO-Bus, Setra

impact wrenches are frequently used for reasons of efficiency. 450 ± 45 600 ± 60

Unless these wrenches are designed for a single nut size using MAN

the maximum torque permitted by the machine, adhering to M 18 × 1.5 390 ± 20

M 20 × 1.5 475 ± 25

the correct torque value is usually difficult and depends more

M 22 × 1.5 575 ± 25

or less on the skill of the fitter. Regular checks using a torque RVI

wrench are recommended under all circumstances. M 22 × 1.5 450 – 550

Scania

Other 7/8 ˝ – 11 BSF 600

Steyr-Daimler-Puch

Hubs and wheels on all vehicles are coated with primer and

M 20 × 1.5 450 – 500

usually with a top coating to protect them from rust. These M 22 × 1.5 550 – 600

coatings tend to give after the first few miles. Nuts and bolts Volvo

also need time to settle. It is therefore essential that the wheel M 18 × 1.5 375 ± 65

nuts are checked after the first 30 miles and tightened, where M 20 × 1.5 525 ± 75

M 22 × 1.5 670 ± 30

necessary. Regular checks are also important later, because if

7/8 ˝ – 14 UNF 670 ± 30

the wheels are loose, the bolt holes wear ovally and damage VW

the wheel bolts. Transporter T 2, T 5 M 14 × 1.5 180

Transporter T 4 to 12 / 95 M 14 × 1.5 160

Use the specified wheel mounting elements. Transporter T 4 from 01/ 96 M 14 × 1.5 180

LT 28, 31 M 14 × 1.5 200

LT 35, 40, 45, 50 M 18 × 1.5 320

Exchange nuts and bolts which are rusty or hard to move. Trailer

M 14 × 1.5 110 – 120

Before fitting, remove rust and dirt from the contact area M 18 × 1.5 270 320

around the wheel, axle hub and brake drum. M 20 × 1.5 350 450

M 22 × 1.5 450 – 500 630 – 650

M 22 × 2 430

An alloy wheel is approximately twice the thickness of a steel

* ) with spring washer and flat collar nut All information given without guarantee.

one, which means that longer wheel bolts are required. 10 Nm = 1 Kpm Status: January 2011

66C34.en 2011.01

www.continental-truck-tires.com

www.continental-corporation.com

You might also like

- BMW X6 2010 N63 4.4l - Torques de ApertoDocument16 pagesBMW X6 2010 N63 4.4l - Torques de ApertoBruno SantosNo ratings yet

- Mitsubishi Canter Service Manual 4d34 Mi 1b3pujDocument6 pagesMitsubishi Canter Service Manual 4d34 Mi 1b3pujEndyHarisNasution38% (13)

- Torque Settings For Wheel NutsDocument1 pageTorque Settings For Wheel NutsTh NattapongNo ratings yet

- Torque Table enDocument1 pageTorque Table enArun KumarNo ratings yet

- Runmax Catalog PDFDocument118 pagesRunmax Catalog PDFMijhaelNo ratings yet

- Catalogue1 Pieces Hinomoto PDFDocument69 pagesCatalogue1 Pieces Hinomoto PDFWotimeil100% (1)

- Project Concept Statement Template - Final (5130)Document5 pagesProject Concept Statement Template - Final (5130)hamdanNo ratings yet

- Parker Fitting AssemblyDocument16 pagesParker Fitting AssemblyMechanical2022No ratings yet

- Gas Hedaer Chain Grate FurnaceDocument1 pageGas Hedaer Chain Grate FurnaceBambang HMNo ratings yet

- MZ45 MZ45GDocument2 pagesMZ45 MZ45GSalpa AdenugrahaNo ratings yet

- TorquesDocument2 pagesTorquesCRISTIANNo ratings yet

- Data Sheet USB5 05 2019 05 ENDocument1 pageData Sheet USB5 05 2019 05 ENJanne LaineNo ratings yet

- CE-Katalog ENDocument100 pagesCE-Katalog ENAhmad Fahmi IrfandaNo ratings yet

- Data K EDocument1 pageData K ErodrigomessiasNo ratings yet

- 9812/7600 F5-1-2 Transmission, 4WD 4WD, Permanent, PS750Document2 pages9812/7600 F5-1-2 Transmission, 4WD 4WD, Permanent, PS750heroskNo ratings yet

- 2022-2023cacheng CatalogueDocument2 pages2022-2023cacheng Catalogueinme3400No ratings yet

- RD-TY300: TOURNEY Rear DerailleurDocument1 pageRD-TY300: TOURNEY Rear Derailleurkavin bhagavathyNo ratings yet

- Voss Brochure Assembly-Notes enDocument32 pagesVoss Brochure Assembly-Notes enQuyềnNo ratings yet

- DEORE SIDE SWING Front Derailleur: (3x10-Speed)Document1 pageDEORE SIDE SWING Front Derailleur: (3x10-Speed)Marcos ZanelliNo ratings yet

- Service: Machine Type 600 GroupDocument12 pagesService: Machine Type 600 GroupSzilárd SNo ratings yet

- JCB EPC2Document3 pagesJCB EPC2chrideerNo ratings yet

- Catalogo Sellos MecanicosDocument2 pagesCatalogo Sellos MecanicoseduardoNo ratings yet

- Dessin Moteur 3kw 1500 B5Document1 pageDessin Moteur 3kw 1500 B5oussama bvbNo ratings yet

- Standard Tables For Wind Moment ConnectionDocument18 pagesStandard Tables For Wind Moment ConnectionAce LowNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- MAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueDocument1 pageMAN Diesel & Turbo 600.40 L+V28/32H Data For Tightening TorqueAntonioNo ratings yet

- Standard Dokumentation + SD SB28.3 En1 - 1 - 00Document126 pagesStandard Dokumentation + SD SB28.3 En1 - 1 - 00Andres GarcíaNo ratings yet

- Catalog12 - CompletoDocument2 pagesCatalog12 - CompletoWalter FormigoniNo ratings yet

- Catalogo X10R - 33Document2 pagesCatalogo X10R - 33Walter FormigoniNo ratings yet

- Surub Si Piulita Pe Bile 1-THKDocument2 pagesSurub Si Piulita Pe Bile 1-THKNicu TruicaNo ratings yet

- E9x 3-Series (Non-M) Wheel & Tire Fitment GuideDocument9 pagesE9x 3-Series (Non-M) Wheel & Tire Fitment GuideJBNo ratings yet

- NANO 160 NANO 200: CNC AutomationDocument2 pagesNANO 160 NANO 200: CNC AutomationRajesh S Pande - AURA AutomationsNo ratings yet

- Glenair - M39029-58 (D38999 Pin)Document2 pagesGlenair - M39029-58 (D38999 Pin)Rafael BorbaNo ratings yet

- Eurocargo PTODocument7 pagesEurocargo PTOHoang PhanNo ratings yet

- 2016 Motorbases MB27 38Document4 pages2016 Motorbases MB27 38jonbilbaoNo ratings yet

- Evinru 1Document3 pagesEvinru 1JSMarine Parts ChinaNo ratings yet

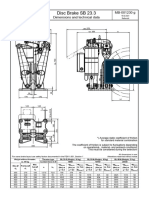

- Disc Brake SST 10: Dimensions and Technical DataDocument1 pageDisc Brake SST 10: Dimensions and Technical DataLukaNo ratings yet

- 8041M08 00Document6 pages8041M08 00D43dalusNo ratings yet

- 05-Axle ShaftsDocument7 pages05-Axle ShaftsGuillaume HaddadNo ratings yet

- Dellner Bubenzer SB 23.3Document2 pagesDellner Bubenzer SB 23.3AKA jeanNo ratings yet

- Standard Dokumentation + SD SB16 En1!1!00Document175 pagesStandard Dokumentation + SD SB16 En1!1!00Andres GarcíaNo ratings yet

- ER-6000-AT: In-Line PCB Separator Cut MachineDocument1 pageER-6000-AT: In-Line PCB Separator Cut Machinebet52wNo ratings yet

- IVECO 8210SRi40.00Document6 pagesIVECO 8210SRi40.00jvega_534120No ratings yet

- 8040SRM16 10Document6 pages8040SRM16 10Roberto MammolaNo ratings yet

- BMW 5 Series VII (G30G31) (2016 .. 2020) - WheelDocument2 pagesBMW 5 Series VII (G30G31) (2016 .. 2020) - WheelGabriel TintarescuNo ratings yet

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- 8041i06.55 8041i40.55Document6 pages8041i06.55 8041i40.55Roberto MammolaNo ratings yet

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- 9812/7600 F5-4-1 Mainshaft, Clutch Components, PS750 449/13160,449/13100Document2 pages9812/7600 F5-4-1 Mainshaft, Clutch Components, PS750 449/13160,449/13100heroskNo ratings yet

- CR Manual enDocument2 pagesCR Manual endenisNo ratings yet

- Instrucciones Bastidor Inodoro Suspendido Es - 8297Document5 pagesInstrucciones Bastidor Inodoro Suspendido Es - 8297BRENDA HERNANDEZ LOPEZNo ratings yet

- Evinru 1Document3 pagesEvinru 1JSMarine Parts ChinaNo ratings yet

- Versatilely Usable Grinding Machine For Burins and Tools For Different Tool GeometriesDocument1 pageVersatilely Usable Grinding Machine For Burins and Tools For Different Tool GeometriescarrubaNo ratings yet

- Engineering Mechanics STATICS J.L.Meriam and L.G.Kraige 7th EditionDocument1 pageEngineering Mechanics STATICS J.L.Meriam and L.G.Kraige 7th Editiontarzaa007xNo ratings yet

- Drive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredDocument21 pagesDrive Pinion and Hollow Shaft, Disassembling and Assembling: Special Tools, Testers and Auxiliary Items RequiredTIGANA 15No ratings yet

- Catalogo X10R - 30Document3 pagesCatalogo X10R - 30Walter FormigoniNo ratings yet

- Sauer Danfoss TMT Orbital Motor Service ManualDocument40 pagesSauer Danfoss TMT Orbital Motor Service ManualPolavarapu Sreedhar100% (1)

- Fiat 8065 PDFDocument6 pagesFiat 8065 PDFigorkov100% (1)

- SMF DSF DTF 200 Parts BookDocument81 pagesSMF DSF DTF 200 Parts BookMartin GodoyNo ratings yet

- United Motors SMF DTF DSF 200cc PDFDocument83 pagesUnited Motors SMF DTF DSF 200cc PDFjair ospinaNo ratings yet

- PDF TD 393 01 D TDI-En-0-TecDocPdfResourceDocument1 pagePDF TD 393 01 D TDI-En-0-TecDocPdfResourcengochai15061991No ratings yet

- Lewis Shiner - Dirty WorkDocument16 pagesLewis Shiner - Dirty WorkGiovanni Di FrancescoNo ratings yet

- Ejc 110 - 112 - 212 - enDocument187 pagesEjc 110 - 112 - 212 - enporter1980No ratings yet

- TBS Company Profile 2023Document19 pagesTBS Company Profile 2023steventsunjayaNo ratings yet

- AppendicesDocument102 pagesAppendicesJared MakoriNo ratings yet

- No-01 M.S NLC Final Check List Standard PDI For 40 Ft-Half Body Trailer....Document4 pagesNo-01 M.S NLC Final Check List Standard PDI For 40 Ft-Half Body Trailer....Syed Ali Raza NaqviNo ratings yet

- Dhaka Metro NewDocument1 pageDhaka Metro NewAdib AhmedNo ratings yet

- Prefix CATERPILLAR OFF-HIGHWAY TRUCK Manuals & Parts CatalogsDocument7 pagesPrefix CATERPILLAR OFF-HIGHWAY TRUCK Manuals & Parts CatalogsLeonardo GomesNo ratings yet

- Dodge Journey 3.6L 2010 - Controle Do Motor - Diagrama ElétricoDocument6 pagesDodge Journey 3.6L 2010 - Controle Do Motor - Diagrama ElétricoAndré Sartori100% (1)

- Heavy Duty 4WD Filter Kits WebDocument5 pagesHeavy Duty 4WD Filter Kits Webarnel gonzalesNo ratings yet

- There Is A Light That Never Goes OutDocument2 pagesThere Is A Light That Never Goes OutMarcelo DonatiNo ratings yet

- Volvo RC Caliper Brochure V11 Single Pages 1476178707Document12 pagesVolvo RC Caliper Brochure V11 Single Pages 1476178707ВЛАДИМИРNo ratings yet

- Steering SystemDocument12 pagesSteering Systemmayur_lanjewarNo ratings yet

- HD9-sheet-chassis-euro3-8x4-GB Camión PDFDocument4 pagesHD9-sheet-chassis-euro3-8x4-GB Camión PDFAlonso Fernando Magallanes PalominoNo ratings yet

- Kia Seltos Vs Creta 2020 Dimensions - Google SearDocument1 pageKia Seltos Vs Creta 2020 Dimensions - Google SearADITYA RANJANNo ratings yet

- Quotation of Backhoe Loader (2022.04.25)Document8 pagesQuotation of Backhoe Loader (2022.04.25)Nicolau Tech0% (1)

- TM 9-4910-496-10Document31 pagesTM 9-4910-496-10ONTOS66No ratings yet

- Title: Lowboy Trailer SafetyDocument12 pagesTitle: Lowboy Trailer SafetyPrimelift Safety Resources LimitedNo ratings yet

- Us Army Vehicle Recovery ManualDocument10 pagesUs Army Vehicle Recovery ManualJoeNo ratings yet

- Copy of Copy of Mumbai DataDocument36 pagesCopy of Copy of Mumbai DataKarthick ANo ratings yet

- EXD SF 20 EN ManualDocument150 pagesEXD SF 20 EN ManualHidromix 2003 SRL HidromixNo ratings yet

- Price-List 20231102 083327 0000Document1 pagePrice-List 20231102 083327 0000gege nurdiansyahNo ratings yet

- WasimanDocument2 pagesWasimanHermanto Al-banaNo ratings yet

- Employee Name Designation Size Sr. No. Emp CodeDocument3 pagesEmployee Name Designation Size Sr. No. Emp CodejanhavijagdhaneNo ratings yet

- Montgomery Fleet Equipment Inventory FA PART 1 ENDDocument4 pagesMontgomery Fleet Equipment Inventory FA PART 1 ENDNayan Moni KalitaNo ratings yet

- NOTA Copy PrintDocument31 pagesNOTA Copy Printanna kendrickNo ratings yet

- Reparacion Directa InventarioDocument18 pagesReparacion Directa InventarioMercedes MontillaNo ratings yet

- HD Factory Direct USADocument5 pagesHD Factory Direct USAsurtipartesNo ratings yet

- Arb 4x4 Accessories 1 Old Man Emu International Application Catalogue Edition 36Document180 pagesArb 4x4 Accessories 1 Old Man Emu International Application Catalogue Edition 36Marco Antonio Marin HernandezNo ratings yet