Professional Documents

Culture Documents

I Girder Prestressing Methodology DRN

I Girder Prestressing Methodology DRN

Uploaded by

Akarsh KorishettarCopyright:

Available Formats

You might also like

- Method Statement For Prestressing I-Girder CastingDocument6 pagesMethod Statement For Prestressing I-Girder CastingArifur Rahman Apu90% (10)

- Productscatalog2023 DLDocument84 pagesProductscatalog2023 DLRaul TamayoNo ratings yet

- Girder Casting MethodologyDocument5 pagesGirder Casting MethodologyAkhilesh Dwivedi67% (3)

- MoRTH Pile Section - 1100Document23 pagesMoRTH Pile Section - 1100avisek_basu100% (1)

- Staging Load CalculationDocument12 pagesStaging Load CalculationRavi Rajan100% (1)

- Staging System (Cribs)Document5 pagesStaging System (Cribs)Surya Gowtham80% (5)

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- Methodology For Stressing of PSC GirdersDocument8 pagesMethodology For Stressing of PSC GirdersHegdeVenugopal100% (1)

- DBM Mix Design No.-1Document81 pagesDBM Mix Design No.-1pujan patel100% (1)

- Lesson 10 Cutting Length of Haunch BarDocument2 pagesLesson 10 Cutting Length of Haunch Barsibendu33% (3)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- Methodology For Filter Media Behind The Structure MaterialDocument5 pagesMethodology For Filter Media Behind The Structure MaterialKunal Paul100% (2)

- Methods Statement For Minor Bridges SUPER STRUCTUREDocument5 pagesMethods Statement For Minor Bridges SUPER STRUCTUREPrasanna S KulkarniNo ratings yet

- Paper Presented at CRRI On Bottom Plug in Well FoundationsDocument11 pagesPaper Presented at CRRI On Bottom Plug in Well FoundationskishoredataNo ratings yet

- Morth 1600 ReinforcementDocument7 pagesMorth 1600 ReinforcementRameshNo ratings yet

- Methodology For Well FoundationDocument8 pagesMethodology For Well Foundationjitendra100% (1)

- PSC GirderDocument73 pagesPSC GirderHegdeVenugopal100% (1)

- Method Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly OverDocument8 pagesMethod Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- Load Test For 17.136m span-ROB PDFDocument9 pagesLoad Test For 17.136m span-ROB PDFbrajeshNo ratings yet

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Stressing & GroutingDocument20 pagesStressing & GroutingPRATIK ATWAL100% (1)

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)VB665No ratings yet

- Post Tensioning SystemDocument13 pagesPost Tensioning SystemAbhijit JadhavNo ratings yet

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- PC Girder Post Tensioning MethodologyDocument16 pagesPC Girder Post Tensioning Methodologyd_ko_alam2169100% (3)

- MethodologyDocument42 pagesMethodologyCIVIL ENGINEERING100% (1)

- Methodology For DBMDocument10 pagesMethodology For DBMvivekNo ratings yet

- Methodology Well Foundation (R3)Document14 pagesMethodology Well Foundation (R3)jitendra100% (3)

- Methodology For PSC GirdersDocument5 pagesMethodology For PSC GirdersvnilNo ratings yet

- Prestressing of H.T.S Strands: Cable Fabrication & LayingDocument3 pagesPrestressing of H.T.S Strands: Cable Fabrication & LayingAnish Panchal100% (1)

- AASHTO PC Girder Post Tensioning MethodologyDocument16 pagesAASHTO PC Girder Post Tensioning MethodologyKiryaki FrancisNo ratings yet

- Staging DesignDocument8 pagesStaging DesignAbhinandan Jasrotia0% (1)

- Kentledge DetailsDocument3 pagesKentledge DetailsAbir Sengupta100% (2)

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- Irc - SP-35Document60 pagesIrc - SP-35Deven Patle25% (4)

- CTB Specification MORTH V RevDocument4 pagesCTB Specification MORTH V RevL V Laxmipathi Rao100% (1)

- Pier Cap Staging Analysis - 1Document6 pagesPier Cap Staging Analysis - 1Saiarpan V Joshi67% (3)

- Staging Design For Bridge SlabDocument10 pagesStaging Design For Bridge SlabRajarathinam RajamanickamNo ratings yet

- Irc SP 139-2023Document41 pagesIrc SP 139-2023anant11235No ratings yet

- M40 Piles Concrete Mix Design (Ambuja)Document4 pagesM40 Piles Concrete Mix Design (Ambuja)Samdhani Strikes100% (1)

- BC Mix Design SqmeDocument39 pagesBC Mix Design SqmePrasanna S Kulkarni0% (1)

- Morth 3100 Reinforce EarthDocument5 pagesMorth 3100 Reinforce EarthRamesh67% (3)

- Maintenance of PSC GirdersDocument10 pagesMaintenance of PSC GirdersradhakrishnangNo ratings yet

- Source: Summary of CTSB Mix DesignDocument20 pagesSource: Summary of CTSB Mix DesignAbhishek pathakNo ratings yet

- IS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)Document17 pagesIS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)bala subramanyam100% (2)

- Codes List For BridgesDocument6 pagesCodes List For Bridgesagsanghani100% (6)

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- IS 2911 Part 4 - 2013 PDFDocument17 pagesIS 2911 Part 4 - 2013 PDFAnshuman SinghNo ratings yet

- IS 2911 Part 1 Sec 2 - 2010Document26 pagesIS 2911 Part 1 Sec 2 - 2010lokesh aggarwalNo ratings yet

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Irc 78 2014 PDFDocument100 pagesIrc 78 2014 PDFRajen KoleyNo ratings yet

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- Methodology of PSC Girder StressingDocument8 pagesMethodology of PSC Girder StressingRavikant TyagiNo ratings yet

- 1 Method Statement For Barapullah Post Tensioning Rev-CDocument20 pages1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhNo ratings yet

- Methodology Well Foundation at Yamuna RiverDocument18 pagesMethodology Well Foundation at Yamuna RiverSambit NayakNo ratings yet

- C11 2Document44 pagesC11 2Digambar JadhavNo ratings yet

- SddsaDocument11 pagesSddsaAllswell ElleNo ratings yet

- Flush Valve: Jeevan Bhar Ka Saath..Document2 pagesFlush Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Vulcathene Technical BrochureDocument78 pagesVulcathene Technical BrochurekprasannanNo ratings yet

- SAP Nos Description PDFDocument40 pagesSAP Nos Description PDFSapana MallaNo ratings yet

- Eccentric Swage NippleDocument3 pagesEccentric Swage NipplebondsivamaniNo ratings yet

- Handtool AigoDocument10 pagesHandtool AigoDennis SetiawanNo ratings yet

- Corrosion Rate and Remaining Life - 6 Problems 2 QuestionsDocument3 pagesCorrosion Rate and Remaining Life - 6 Problems 2 Questionsnathaniel ekaikoNo ratings yet

- Comparison of EN ISO 15614-1 - 2012 Vs 2017Document6 pagesComparison of EN ISO 15614-1 - 2012 Vs 2017Swiss CIS AGNo ratings yet

- Review de Tecnologias de Robots en InspeccionDocument6 pagesReview de Tecnologias de Robots en InspeccionEsteban RodriguezNo ratings yet

- 000000000001001849Document544 pages000000000001001849Dante Filho100% (1)

- Welding Forum - Heat Input CalculationDocument11 pagesWelding Forum - Heat Input CalculationMatthew BallardNo ratings yet

- MVIP Catalog - 2013 - r2 - WsDocument34 pagesMVIP Catalog - 2013 - r2 - WsjjescuderoNo ratings yet

- V10 12d NZ - W02 Network EditorDocument15 pagesV10 12d NZ - W02 Network EditorrenandNo ratings yet

- Gmv5 Mini Heat Pump Owner S Manual 24 28Document32 pagesGmv5 Mini Heat Pump Owner S Manual 24 28Dmitriy DmitriyNo ratings yet

- ASTM UT StandardsDocument3 pagesASTM UT StandardsChoy De VillaNo ratings yet

- Ronak India PVT LTD New 1Document34 pagesRonak India PVT LTD New 1Ronak FireNo ratings yet

- Pipes and Pipelines (Wella)Document4 pagesPipes and Pipelines (Wella)WellaNo ratings yet

- Fevicol CatalogueDocument11 pagesFevicol CatalogueSonu SimonNo ratings yet

- TH42-VO #13 Service Toilet - R1Document11 pagesTH42-VO #13 Service Toilet - R1Adi SunardiNo ratings yet

- Brochure Cable GlandDocument180 pagesBrochure Cable GlandshahrialifizaniNo ratings yet

- Compressor For OILDocument74 pagesCompressor For OILRana BiswasNo ratings yet

- 2013.03.11 Ssi2000 2010 HDDocument28 pages2013.03.11 Ssi2000 2010 HDdanko826No ratings yet

- RotametroDocument2 pagesRotametroCarlos Gallardo SanchezNo ratings yet

- ASME B16.5 - 2009 (Parcial)Document27 pagesASME B16.5 - 2009 (Parcial)Cristiano Martinez100% (1)

- 720G 08182003Document66 pages720G 08182003Rodolfo YanaNo ratings yet

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingRichard Nixon Nalli100% (5)

- Design Os Sewers (Blue Book)Document388 pagesDesign Os Sewers (Blue Book)savanotrebor100% (1)

- SP-P-005 - Rev 1 - Specification For Underground PipingDocument12 pagesSP-P-005 - Rev 1 - Specification For Underground Pipingvishal bhamreNo ratings yet

- Pipe Flow Expert Software HelpDocument4 pagesPipe Flow Expert Software Helpbog1danNo ratings yet

I Girder Prestressing Methodology DRN

I Girder Prestressing Methodology DRN

Uploaded by

Akarsh KorishettarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I Girder Prestressing Methodology DRN

I Girder Prestressing Methodology DRN

Uploaded by

Akarsh KorishettarCopyright:

Available Formats

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

M/S. DRN INFRASTRUCTURE PVT LTD.

PROJECT : BRIDGE WORK AT SOLAPUR-BIJAPUR ROAD PROJECT OF NH-13

(NEW NH-52) FROM KM 0.000 TO KM 110.542 IN THE STATE OF MAHARASTRA

AND KARNATAKA

METHODOLOGY FOR PRESTRESSING & GROUTING

OF POST TENSIONED I-GIRDERS..

PROJECT DETAILS:

OWNER NATIONAL HIGHWAY AUTHORITY OF INDIA

INDEPENDENT

L.N.MALVIGA INFRA PROJECT PVT.LTD

CONSULTANTS

CONCERSIONAIRE VIJAYAPURA TOLLWAY PRIVATE LTD.

EPC CONTRACTOR IJMC (INDIA) INFRASTRUCTURE LIMITED

WORK CONTRACTOR DRN INFRASTRUCTURE PRIVATE LIMITED

DYNAM IC P R ES TR ESS P R OJ EC TS & SER V IC ES P VT.

PRESTRESSING LTD.

AGENCY ADD : 72, Mahavi r C ent re, S ect or – 17, Vashi , Navi Mum bai

– 400 705, Maharasht r a S t at e, IND IA.

REFERENCE DOCUMENTS/CODES/DRAWINGS

1. IS: 1343 Prestressed Concrete

2. IS: 14268 Stress Relieved Low Relaxation 7 Ply Strands for

Prestressed Concrete.

3. IS: 210 Grey Iron Casting – specification

4. BS: 970 Specifications for Wrought Steels for Mechanical &

Allied Engineering Purposes.

5. IRC: 18-2000 Design Criteria of Prestressed Concrete Road Bridges

(Post-tensioned Concrete)

6. Relevant Prestressing Drawings (Latest Revisions)

7. Specifications Related to Prestressing Work

PRESTRESSING MATERIALS

High Tensile Strands

Following are the properties of 12.7 mm Ø Low Relaxation High Tensile Strands. Oiled strand

shall be used –

Dia of H.T Strand - 12.7mm

Nominal Area of Strand - 98.7 mm2

Minimum Breaking Strength - 183.7 KN

Nominal Weight of Strand - 0.775kg/mtr.

Prepared by: (Dynamic) 1 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

SHEATHING PIPES

84 mm ID & 98 mm OD Corrugated HDPE Sheathing pipe Having 2.3mm thick for

19DP13Anchorages System

75 mm ID & 90 mm OD Corrugated HDPE Sheathing pipe Having 2.3mm thick for

12DP13Anchorages System

Dynamic 19DP13 / 12DP13 Live end Anchorage System

*Tube Unit (Anchor Cone)

The basic raw material for manufacture of tube unit is gray cast iron. It allows the transfer

of prestressing force from the bearing plate to the concrete. The Tube Unit is embedded in

concrete and can be easily fixed to the MS cone box by means of bolts and nuts. The design of

Tube Unit allows uniform flaring of H. T. Strands while stressing and free access to the

injection of grout.

*Anchor Head (Bearing Plate)

The basic raw material for manufacture of bearing plate is Steel casting / forged steel. The

conical holes facilitate the seating of wedges and holding the strands in stressed condition.

*Wedges

The basic raw material for manufacture of wedges is alloy steel. The individual high tensile

strands passing through the bearing plate is anchored by the wedges. The 3 segments of the

wedges are held together around the strand by means of special wire circlips for better

functioning, easy placement and storage

Prestressing and Grouting is broadly divided into following activities, viz.,

1. Layout & Profiling of the cables/sheathing.

2. Fixing of tube unit/end block.

3. Cable cutting and threading.

4. Fixing of Bearing plate & Wedges.

5. Stressing.

6. Cutting and end Sealing.

7. Grouting.

1. LAYOUT & PROFILING OF SHEATHING PIPES

After completion of alignment of bottom shuttering & bottom reinforcement of girder, layout

& Profiling of cables shall be carried out in following steps :

Layout of cables is carried out as per given ordinates & related reference drawings.

After all ordinates are plotted, tie bars of 10 mm. dia. shall be installed as per ordinates

to place the sheathing pipe wherever required. Installation of sheathing pipe is carried

out over the tie rods.

Sheathing pipe shall be supported in the bottom by tie rods & shall be cross bound

using double binding wire. It should be ensured that the sheathing pipes are fixed firmly

Prepared by: (Dynamic) 2 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

in position so as to prevent displacement during concreting by weight of concrete,

vibration or by floatation.

Connect the sheathing with the help of couplers provided at the end of each pipe.

Sealing of sheathing joints will be done using PVC tapes. It will be ensured that no

joints are remaining unsealed.

Cable profile shall be checked. Vertical ordinates shall be check from soffit of the

bottom shutters. Horizontal ordinates shall be check from the face of the side shutters,

which has been already checked for verticality or as in drawing.

2. FIXING OF TUBE UNIT

Fixing of tube unit shall be carried out after installation of end shuttering plate.

Fix tube unit to End plate with the help of 4 nos. of bolts.

Bursting reinforcement shall be fixed according to the drawing.

Connecting the tube unit to sheathing pipe.

Joint shall be sealed with the help of PVC tape.

The face of the tube unit shall be truly perpendicular to the axis of the cable and about

1.5m of cable before trumpet should be in straight alignment.

After the fixing of tube unit and cable layout, insert the HDPE pipes Or HTS Strand

inside all ducts to avoid the damage of sheathing pipe & ingress of cement slurry inside

the duct at the time of concreting.

3. CONCRETING

Although concreting is not a part of stressing, but it plays a vital role in successful

stressing of structure.

It shall be noted that the needle vibrator is not placed directly on sheathing pipe, which

may damage the sheathing pipe.

HDPE pipe Or HTS Strands in all the cables should be moved in both directions during

the period of concreting.

Due care should be taken while concreting in the end block portion. Proper compaction

of concrete should be ensured to avoid honeycombing.

4. CABLE CUTTING & THREADING

After completion of concreting & removing end block shuttering, cable threading shall be

done.

H. T. Strands shall be threaded manually.

For cutting strands, a portable grinding wheel shall be used.

H. T. Strands shall be cut as given in drawings, considering site conditions & gripping

length of jack.

5. FIXING OF BEARING PLATES & WEDGES

Fixing of bearings plates & wedges is done before stressing. It is ensured that the

tapered holes in bearing plates & wedges are free of rust.

Prepared by: (Dynamic) 3 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

Insert the strands into the tapered holes provided in the bearing plate.

Install the wedges over the strands and push them with a pipe into the tapered holes of

the bearing plate.

6. STRESSING

Prestressing of the girder is done as required by the system of prestressing and design.

Following points will be observed while carrying out the stressing operation.

The required strength of the girder concrete as mentioned in drawings/specifications

shall be ensured by cube testing before starting the stressing work.

Stressing of cables shall be done as per the sequence mentioned in the

drawings/specifications.

Elongation mentioned in the drawings must be modified for actual value of modulus of

elasticity ‘E’ and the area of c/s of strands ‘A’ of the cables as per the results unless

otherwise mentioned in the drawings/specifications.

Actual pressure shall be calculated after applying Jack efficiency factor.

Stressing shall be done using Multi-pull jacks only.

Stressing shall be done from both ends, care will be taken to achieve almost equal

readings of elongation at both the ends in each step of increment of pressure.

Readings will be taken preferably at incremental steps of 50 kg/cm 2 up to the final

pressure.

After locking the wedges the pressure in the jack will be released very slowly to avoid

transfer of prestressing force by impact.

In every cable instantaneous slip of anchorages must be recorded. It will be within

limits prescribed by the designer or by the prestressing agency.

The pressure applied and elongation achieved will match within the prescribed limits.

Normally, this limit is 5% of pressure and elongations.

No person will be allowed to stand behind the anchorages in any circumstances during

the process of tensioning.

6.1 THE FOLLOWING STEPS SHOULD BE PREFERED FOR JACK MOUNTING :

Fix the bearing plates at both the ends of the tensions.

Prepared by: (Dynamic) 4 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

Insert the bearing collar & fix it on tube unit with the help of screws.

Insert the lock-off plate as per the orientation the bearing plate.

A rigid runaway beam (ISMC/ISMB) structure shall be made at the end of the bridge

girder from where the Jack is to be suspended by means of a chain pulley block. The

arrangement will give full flexibility of movement of Jack both transversely and

longitudinally.

Push the Jack over the strands. The axis of the Jack must coincide with the tendon axis.

Insert the strand in to the Jack.

Apply “wax” inside the holes of pulling plate as well as outside of master grip.

Install the 3-piece wedge (master grip) over the strand into the pulling plate inside the

rear of the Jack. Push the grips with a piece of hollow hammering pipe to seat tightly

inside the pulling plate holes.

Ensure all connection of Jack with pump is correct and flexibility of hose pipe for

movement of the Jack at the time of stressing.

It is important that the supporting chain or hook shall be slackened off as soon as the

Jack starts to carry load, but they must be ready to support the Jack again when the

pressure is released.

Locking pressure should be maintained approximately 70-80 % of the stressing pressure.

6.2 Calibration and maintenance

i Pressure Gauges

Gauges shall be calibrated either against a master gauge or preferably by a

dead weight tester at regular intervals. Calibration of all gauges shall be done

at an interval so that satisfying the following conditions:

a. At least once in every three months

b. At least once for every 400 stressing operations

c. In case observed elongations are varying more than 10% from the

expected elongations.

d. At any sign of malfunctioning.

ii All the jacks shall be tested for their efficiencies in all the possible

combinations for jack calibration procedure. At least once in every year

7. CUTTING AND END SEALING

Cutting should be carried out after checking the 24 hrs. slip loss. Strand should be cut

approximately 40 mm. from the face of bearing plate. End sealing should be done with the help

of GROUT CAP or Epoxy & cement Mortar (Mounting the ends) .

7.1 GROUT CAP :

The advantages of using Dynamic Grout Cap are used for speedy grouting and saving of

sealing material i.e. cement mortar.

7.2 FIXING OF GROUT CAP

Prepared by: (Dynamic) 5 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

The stressed strands are cut to the required length i.e. 40 mm. from the face of bearing

plate.

On the inner surface of cap, grease should be applied.

‘O’ ring should be placed in the slot provided along the periphery of the cap, which

maintains the pressure and prevents the leakage of grout.

Grout cap is fixed by 4 nos. of allen key bolts by keeping the air vent nut in top

position.

8. GROUTING

Neat cement slurry should be filled in the annular spaces between sheathing duct & high tensile

(H.T.) steel/strands.

8.1 OBJECTIVES OF GROUTING :

a) To protect the steel against corrosion.

b) Effective bond between the Prestressing steel and concrete.

8.2 MATERIALS FOR GROUTING :

(A) CEMENT:

Ordinary Portland cement should be used for the preparation of the grout. It should be as fresh

as possible and free of any lumps. The cement shall have no false setting phenomenon and

shall be at a temperature less than 40 C at the time of production of grout. The cement should

be free from chemical impurities like chloride and sulphate, which leads to corrosion of steel.

(B) WATER:

Clean potable water, free from impurities shall be used. Sea or Creek water shall be strictly

avoided.

(C) ADMIXTURE (PLASTISIZER):

Suitable, qualified admixtures approved and recommended by client/consultant shall be used to

increase the workability or to reduce shrinkage of grout.( Sika Intraplast NN 0.5 % by weight of

cement OR Cebex 100 0.225 kg per bag)

8.3 WATER – CEMENT RATIO

The water to cement ratio to be maintained while grouting shall be 0.40 to 0.45 (depending on

site conditions). The precise water quantity/bag of cement shall be determined & shall be

approved from the client/consultants.

8.4 GROUT TEMPERATURE

Generally, the temperature of the grout must be 25 C. It is likely to change depending upon

the site conditions. When the ambient temperature during the day is likely to exceed 40 C,

grouting shall be done in the early morning or late evening hours.

8.5 GROUTING PROCESS

Following points will be observed while doing the grouting.

Prepared by: (Dynamic) 6 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

Grouting of cables shall be done as early as possible, after completion of stressing.

All cables that are to be grouted shall be cleaned thoroughly with water & compressed

air.

The grout mix is prepared in the agitator by thoroughly mixing it for 2 to 3 min.

The agitator must be placed at a height such that mortar can flow directly in top second

tank placed beneath the outlet of agitator.

Before flowing in to the second tank mortar must be passed through a 2 mm. mesh

screen so as to eliminate impurities and lumps which otherwise cause choking of the

pump at the time of grouting process.

Connect the suction hose of grout pump to the second drum.

Operate the pump to drain off water from the pump and hoses.

Allow discharge of a small quantity of grout from delivery hoses to check the correct

functioning of pump.

Connect the delivery hoses to the tube unit’s grout inlet opening and begin grouting.

Ensure that there is always enough grout in tank so that air is not sucked in to the pump.

When the grout flows out of the dead end tube unit’s grout opening, open the air vent

nut of the grout caps of both the ends.

Block the outlet of the other end after being assured that the air has been completely

bleeded and the duct is filled with grout.

Close the air vent nut and operate the pump until the desired pressure is achieved.

After the design pressure is achieved, stop the pump and maintain the pressure of 3-5

Kg/cm2 for 1 min. and close the valve of inlet connector.

Release the pressure in hose. The pump runs idle and returns grout to the tank.

Clean the grout pump & agitator with clean water to avoid clogging.

8.6 END PROTECTION OF ANCHORAGES

Tendons shall be protected against corrosion by a plug at each end to prevent passage of

air. After grouting is over the anchorages will be protected for corrosion as under –

1. Clean the exposed anchorage parts for rust and dirt with wire brush manually.

2. Clean the surface with cotton waste & apply a coat tar epoxy (solvent free araldite)

9 SAFETY PRECAUTIONS

9.1 Safety Precautions While Concreting

Although concreting is not a part of prestressing, it plays a vital role in successful stressing of

structure. Following points should be considered while concreting

Main contractor should ensure that vibration is to be supervised. It should be noted that

needle is not directly placed on sheathing pipe, which may damage the duct & thereby

blocking the path of strands.

The portion of the end block of the girder should be properly concreted. Weak concrete

leads to puncture of tube unit & hence stressing should be done only if concrete is

capable of taking the load.

Prepared by: (Dynamic) 7 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

It should be ensured that the bursting reinforcement in the end block zone is adequately

& properly installed.

9.2 Safety Precautions While Stressing

Very large forces are introduced into the tendons during stressing and the equipment is under

high hydraulic pressure. Hence, careful working can avoid accidents.

Only trained and experienced personnel, under the guidance of Dynamic technical

Staff, should perform stressing.

The equipment, especially the high pressure hoses and the adaptors must be in perfect

condition. Damaged hoses must be replaced immediately. Protection caps must always

be placed over unused connections (electric as well as hydraulic).

Jack should never be handled by hoses.

Stressing should be done according to specified data. The allowed maximum pressure

should never be exceeded.

During stressing, nobody should be allowed behind or underneath the jack, since failure

of a strand can cause fatal accidents.

For stressing close to traffic areas, the jack must be secured by ropes or chain hoist.

All bars, wires and strands should be stored carefully. Ensure that they are not damaged

in any way and should be checked for rust and corrosion before they are used.

Care should be taken while handling coils of high tensile steel strand as they may ‘whip

back’ with force, if not securely bound.

Do not permit welding near high tensile Prestressing steel. A drop of molten metal, if

applied to the strand, will change its mechanical properties and promote the

possibilities of premature failure.

Hogging of the girder during stressing operation should be observed & recorded.

9.3 Safety Precautions While Grouting

Protective glasses must be worn during grouting operation.

Do not start the pump while valves are closed, it may cause damage to the pressure

gauge.

Place the grout tank preferably at the same level of grout pump.

In case of a longer stoppage (more than 5 min), ensure that the grout does not get set in

the pump, if necessary empty the grout and flush the pump with water.

10 FORMATS

PREPARATION SHEET FOR PRESTRESSING

STRESSING RECORD SHEET

RECORD SHEET FOR GROUTING.

Prepared by: (Dynamic) 8 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

PREPARATION SHEET FOR PRESTRESSING

PROJECT :- PRESTRESSING WORK FOR FLYOVER AT SOLAPUR-BIJAPUR

CLIENT :- NATIONAL HIGHWAY AUTHORITY OF INDIA .

IND.CONSULTANT :- L.N.MALVIGA INFRA PROJECT PVT.LTD.

CONCERSIONAIRE : - VIJAYAPURA TOLLWAY PRIVATE LIMITED

EPC CONTRACTOR :- IJMC (INDIA) INFRASTRUCTURE LIMITED

WORK CONTRACTOR :- DRN INFRASTRUCTURE PRIVATE LIMITED

PRESTRESSING :- DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

Structure Location No:________________

P.S.C I-Girder No.__________ Date:________

Prestressing System: 19DP13 / 12DP13

Coil No : Dated:________

Supplier of HTS :

HTS TEST REPORT NO :

Therotical Area 'A' Value : 98.7 mmsq

Theoritical Moduless of Elasticity 'E' Value = 195000Mpa

Actual Area 'A' Value :_______ mmsq.

Actual Moduless of Elasticity 'E' Value = __________Mpa

Therotical Jacking Force : _______ Ton

Jack Ram Area : ___________cm2 CG 30/200 JACK

Jack Efficiency : ______ %

Prestressing Calculation:

1. Modified Guage Pressure = Jacking Force (Ton) X 1000

Ram Area X Jack Efficiency

= ______ Kg/cm2

= Say _______ Kg/cm2

-5%' Minimum = _________ kg/cm2 +5%' Maximum = ________ kg/cm2

2. Revised Extension (EX) = Theo. Elongation X Theo. 'E' Value X Theo. 'A' Value

Actual 'E' Value X Actual 'A' Value

-5%' Minimum = mm +5%' Maximum = mm

Checked by :

For DYNAMIC For DRNIPL For LNMIPPL

Prepared by: (Dynamic) 9 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

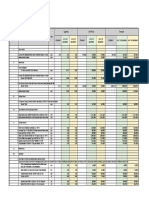

STRESSING RECORD SHEET

PROJECT :-

PRESTRESSING WORK FOR FLYOVER AT SOLAPUR-BIJAPUR

CLIENT :- NATIONAL HIGHWAY AUTHORITY OF INDIA

ND,CONSULTANT .L.N.MALVIGA INFRA PROJECT PVT.LTD.

CONCERSIONAIRE :- VIJAYAPURA TOLLWAY PRIVATE LIMITED

EPC CONTACTOR :- IJMC (INDIA) INFRASTRUCTURE LIMITED

WORK CONTACTOR DRN INFRASTRUCTURE PRIVATE LIMITED

PRESTRESSING :- DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

Date: Starting Time : Finishing Time :

Structure Location No :

P.S.C I- Girder No Cable No:

Prestressing System

Modified Extension Modified Guage Pressure

-5%' Minimum = -5%' Minimum =

+5%' Maximum = +5%' Maximum =

1 End 2 End

Load

Pressure applied Pump No. Jack No. Gauge No. Pump No. Jack No. Gauge No.

applie

Kg/cm2

d KN Reading Difference Cumulative Reading Cumulative

Difference mm.

mm. mm. mm. mm. mm.

Zero Correction = Zero Correction =

Slip @ 50 kg/cm2

Before Locking

After Locking

Slip mm. mm.

Checked by :

For DYNAMIC For DRNIPL For LNMIPPL

Prepared by: (Dynamic) 10 Approved By : (Consultants)

DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

PRESTRESSING WORK PROCEDURE FOR BRIDGE AT SOLAPUR - BIJAPUR

RECORD SHEET FOR GROUTING

.PROJECT :- PRESTRESSING WORK FOR FLYOVER AT SOLAPUR-BIJAPUR

CLIENT :- NATIONAL HIGHWAY AUTHORITY OF INDIA .

IND.CONSULTANT :- L.N.MALVIGA INFRA PROJECT PVT.LTD.

CONCERSIONAIRE : - VIJAYAPURA TOLLWAY PRIVATE LIMITED

EPC CONTRACTOR :- IJMC (INDIA) INFRASTRUCTURE LIMITED

WORK CONTRACTOR :- DRN INFRASTRUCTURE PRIVATE LIMITED

PRESTRESSING :- DYNAMIC PRESTRESS PROJECTS & SERVICES PVT. LTD.

Structure Location No :

P.S.C I- Girder No . Date

Prestressing System :19DP13/ 12DP13

Cable Grouting Consumed material Grout Achived

No. Start time Finish time Cement Admixture Water temp. pressure Remarks

Checked by :

For DYNAMIC For DRNIPL For LNMIPPL

Prepared by: (Dynamic) 11 Approved By : (Consultants)

You might also like

- Method Statement For Prestressing I-Girder CastingDocument6 pagesMethod Statement For Prestressing I-Girder CastingArifur Rahman Apu90% (10)

- Productscatalog2023 DLDocument84 pagesProductscatalog2023 DLRaul TamayoNo ratings yet

- Girder Casting MethodologyDocument5 pagesGirder Casting MethodologyAkhilesh Dwivedi67% (3)

- MoRTH Pile Section - 1100Document23 pagesMoRTH Pile Section - 1100avisek_basu100% (1)

- Staging Load CalculationDocument12 pagesStaging Load CalculationRavi Rajan100% (1)

- Staging System (Cribs)Document5 pagesStaging System (Cribs)Surya Gowtham80% (5)

- PSC Girder MethodologyDocument12 pagesPSC Girder MethodologySaurabh KumarNo ratings yet

- Methodology For Stressing of PSC GirdersDocument8 pagesMethodology For Stressing of PSC GirdersHegdeVenugopal100% (1)

- DBM Mix Design No.-1Document81 pagesDBM Mix Design No.-1pujan patel100% (1)

- Lesson 10 Cutting Length of Haunch BarDocument2 pagesLesson 10 Cutting Length of Haunch Barsibendu33% (3)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- Methodology For Filter Media Behind The Structure MaterialDocument5 pagesMethodology For Filter Media Behind The Structure MaterialKunal Paul100% (2)

- Methods Statement For Minor Bridges SUPER STRUCTUREDocument5 pagesMethods Statement For Minor Bridges SUPER STRUCTUREPrasanna S KulkarniNo ratings yet

- Paper Presented at CRRI On Bottom Plug in Well FoundationsDocument11 pagesPaper Presented at CRRI On Bottom Plug in Well FoundationskishoredataNo ratings yet

- Morth 1600 ReinforcementDocument7 pagesMorth 1600 ReinforcementRameshNo ratings yet

- Methodology For Well FoundationDocument8 pagesMethodology For Well Foundationjitendra100% (1)

- PSC GirderDocument73 pagesPSC GirderHegdeVenugopal100% (1)

- Method Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly OverDocument8 pagesMethod Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- Load Test For 17.136m span-ROB PDFDocument9 pagesLoad Test For 17.136m span-ROB PDFbrajeshNo ratings yet

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- Aws d1.5 PQRDocument2 pagesAws d1.5 PQRjacquesmayolNo ratings yet

- Stressing & GroutingDocument20 pagesStressing & GroutingPRATIK ATWAL100% (1)

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)VB665No ratings yet

- Post Tensioning SystemDocument13 pagesPost Tensioning SystemAbhijit JadhavNo ratings yet

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- PC Girder Post Tensioning MethodologyDocument16 pagesPC Girder Post Tensioning Methodologyd_ko_alam2169100% (3)

- MethodologyDocument42 pagesMethodologyCIVIL ENGINEERING100% (1)

- Methodology For DBMDocument10 pagesMethodology For DBMvivekNo ratings yet

- Methodology Well Foundation (R3)Document14 pagesMethodology Well Foundation (R3)jitendra100% (3)

- Methodology For PSC GirdersDocument5 pagesMethodology For PSC GirdersvnilNo ratings yet

- Prestressing of H.T.S Strands: Cable Fabrication & LayingDocument3 pagesPrestressing of H.T.S Strands: Cable Fabrication & LayingAnish Panchal100% (1)

- AASHTO PC Girder Post Tensioning MethodologyDocument16 pagesAASHTO PC Girder Post Tensioning MethodologyKiryaki FrancisNo ratings yet

- Staging DesignDocument8 pagesStaging DesignAbhinandan Jasrotia0% (1)

- Kentledge DetailsDocument3 pagesKentledge DetailsAbir Sengupta100% (2)

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- Irc - SP-35Document60 pagesIrc - SP-35Deven Patle25% (4)

- CTB Specification MORTH V RevDocument4 pagesCTB Specification MORTH V RevL V Laxmipathi Rao100% (1)

- Pier Cap Staging Analysis - 1Document6 pagesPier Cap Staging Analysis - 1Saiarpan V Joshi67% (3)

- Staging Design For Bridge SlabDocument10 pagesStaging Design For Bridge SlabRajarathinam RajamanickamNo ratings yet

- Irc SP 139-2023Document41 pagesIrc SP 139-2023anant11235No ratings yet

- M40 Piles Concrete Mix Design (Ambuja)Document4 pagesM40 Piles Concrete Mix Design (Ambuja)Samdhani Strikes100% (1)

- BC Mix Design SqmeDocument39 pagesBC Mix Design SqmePrasanna S Kulkarni0% (1)

- Morth 3100 Reinforce EarthDocument5 pagesMorth 3100 Reinforce EarthRamesh67% (3)

- Maintenance of PSC GirdersDocument10 pagesMaintenance of PSC GirdersradhakrishnangNo ratings yet

- Source: Summary of CTSB Mix DesignDocument20 pagesSource: Summary of CTSB Mix DesignAbhishek pathakNo ratings yet

- IS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)Document17 pagesIS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)bala subramanyam100% (2)

- Codes List For BridgesDocument6 pagesCodes List For Bridgesagsanghani100% (6)

- Dynamic Load Test 1200mm DiaDocument6 pagesDynamic Load Test 1200mm DiaVB665100% (1)

- Cast-In-Situ Bored Piling Works by ConventionalMethod1Document11 pagesCast-In-Situ Bored Piling Works by ConventionalMethod1jitendraNo ratings yet

- IS 2911 Part 4 - 2013 PDFDocument17 pagesIS 2911 Part 4 - 2013 PDFAnshuman SinghNo ratings yet

- IS 2911 Part 1 Sec 2 - 2010Document26 pagesIS 2911 Part 1 Sec 2 - 2010lokesh aggarwalNo ratings yet

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Irc 78 2014 PDFDocument100 pagesIrc 78 2014 PDFRajen KoleyNo ratings yet

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- Methodology of PSC Girder StressingDocument8 pagesMethodology of PSC Girder StressingRavikant TyagiNo ratings yet

- 1 Method Statement For Barapullah Post Tensioning Rev-CDocument20 pages1 Method Statement For Barapullah Post Tensioning Rev-CJkkhyhNo ratings yet

- Methodology Well Foundation at Yamuna RiverDocument18 pagesMethodology Well Foundation at Yamuna RiverSambit NayakNo ratings yet

- C11 2Document44 pagesC11 2Digambar JadhavNo ratings yet

- SddsaDocument11 pagesSddsaAllswell ElleNo ratings yet

- Flush Valve: Jeevan Bhar Ka Saath..Document2 pagesFlush Valve: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Vulcathene Technical BrochureDocument78 pagesVulcathene Technical BrochurekprasannanNo ratings yet

- SAP Nos Description PDFDocument40 pagesSAP Nos Description PDFSapana MallaNo ratings yet

- Eccentric Swage NippleDocument3 pagesEccentric Swage NipplebondsivamaniNo ratings yet

- Handtool AigoDocument10 pagesHandtool AigoDennis SetiawanNo ratings yet

- Corrosion Rate and Remaining Life - 6 Problems 2 QuestionsDocument3 pagesCorrosion Rate and Remaining Life - 6 Problems 2 Questionsnathaniel ekaikoNo ratings yet

- Comparison of EN ISO 15614-1 - 2012 Vs 2017Document6 pagesComparison of EN ISO 15614-1 - 2012 Vs 2017Swiss CIS AGNo ratings yet

- Review de Tecnologias de Robots en InspeccionDocument6 pagesReview de Tecnologias de Robots en InspeccionEsteban RodriguezNo ratings yet

- 000000000001001849Document544 pages000000000001001849Dante Filho100% (1)

- Welding Forum - Heat Input CalculationDocument11 pagesWelding Forum - Heat Input CalculationMatthew BallardNo ratings yet

- MVIP Catalog - 2013 - r2 - WsDocument34 pagesMVIP Catalog - 2013 - r2 - WsjjescuderoNo ratings yet

- V10 12d NZ - W02 Network EditorDocument15 pagesV10 12d NZ - W02 Network EditorrenandNo ratings yet

- Gmv5 Mini Heat Pump Owner S Manual 24 28Document32 pagesGmv5 Mini Heat Pump Owner S Manual 24 28Dmitriy DmitriyNo ratings yet

- ASTM UT StandardsDocument3 pagesASTM UT StandardsChoy De VillaNo ratings yet

- Ronak India PVT LTD New 1Document34 pagesRonak India PVT LTD New 1Ronak FireNo ratings yet

- Pipes and Pipelines (Wella)Document4 pagesPipes and Pipelines (Wella)WellaNo ratings yet

- Fevicol CatalogueDocument11 pagesFevicol CatalogueSonu SimonNo ratings yet

- TH42-VO #13 Service Toilet - R1Document11 pagesTH42-VO #13 Service Toilet - R1Adi SunardiNo ratings yet

- Brochure Cable GlandDocument180 pagesBrochure Cable GlandshahrialifizaniNo ratings yet

- Compressor For OILDocument74 pagesCompressor For OILRana BiswasNo ratings yet

- 2013.03.11 Ssi2000 2010 HDDocument28 pages2013.03.11 Ssi2000 2010 HDdanko826No ratings yet

- RotametroDocument2 pagesRotametroCarlos Gallardo SanchezNo ratings yet

- ASME B16.5 - 2009 (Parcial)Document27 pagesASME B16.5 - 2009 (Parcial)Cristiano Martinez100% (1)

- 720G 08182003Document66 pages720G 08182003Rodolfo YanaNo ratings yet

- Method Statement Pressure TestingDocument15 pagesMethod Statement Pressure TestingRichard Nixon Nalli100% (5)

- Design Os Sewers (Blue Book)Document388 pagesDesign Os Sewers (Blue Book)savanotrebor100% (1)

- SP-P-005 - Rev 1 - Specification For Underground PipingDocument12 pagesSP-P-005 - Rev 1 - Specification For Underground Pipingvishal bhamreNo ratings yet

- Pipe Flow Expert Software HelpDocument4 pagesPipe Flow Expert Software Helpbog1danNo ratings yet