Professional Documents

Culture Documents

Ur3569 TDS (En)

Ur3569 TDS (En)

Uploaded by

Alexandre GoulartOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ur3569 TDS (En)

Ur3569 TDS (En)

Uploaded by

Alexandre GoulartCopyright:

Available Formats

UR 3569

SURFACE CASTING RESIN

HARDNESS 70 – SHORE A –COLD CURING

DESCRIPTION

Polyurethane surface casting resin designed for foundry tools (patterns, core boxes) on aluminium preforms,

concrete resin etc.

PROPERTIES

• Good abrasion resistance • Excellent impact and shock resistance

• MDA free (Methylene-bis Aniline) • Quick hardening

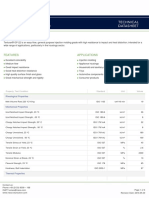

PHYSICAL PROPERTIES

Composition ISOCYANATE POLYOL MIXED

Mix ratio by weight 100 40

Mix ratio by volume at 25°C 100 39

Aspect liquid liquid liquid

Colour colourless beige to yellow beige to yellow

Viscosity at 25°C (mPa.s) BROOKFIELD LVT 7.500 190 3.500

Specific gravity at 25°C ISO 1675 : 1985 1.03 1.05 -

Specific gravity of cured product at 23°C ISO 2781 : 1996 - - 1.07

Pot life at 25°C on 100 g (min) 20

MECHANICAL PROPERTIES at 23°C (1)

Hardness ISO 868 :2003 Shore D1 / D15 70 / 65

Tensile modulus ISO 527 : 1993 MPa 300

Tensile strength ISO 527 :1993 MPa 30

Elongation at break ISO 527 :1993 % 160

Tear strength

ISO 34 :1994 kN/m 120

Unnotched angular specimens

Impact strength (CHARPY) 2

ISO 179/1eU : 1994 kJ/m Non breakable

Unnotched specimens

BASHORE resilience ASTM 2632 : 1992 % 55

Abrasion resistance (TABER 1000 revs / H22) ISO 5470: 1999 mg / 100U 33

PROCESSING CONDITIONS

Before use Polyol must be mixed until both colour and aspect become homogeneous. Both parts (polyol and

isocyanate) have to be mixed at a temperature equal or higher than 18°C according to the mixing ratio indicated

on the technical data sheet. In order to obtain a bubble-free product, UR 3569 should be degassed after mixing.

This operation do not last more than 8 minutes to avoid gel in the vacuum machine. Before casting ensure that

parts or moulds are free of any trace of moisture.

nd

Page 1/2-TDS10F0016 – September 02 , 2010

GERMANY SPAIN & PORTUGAL SLOVAKIA NORTH AMERICA JAPAN INDIA

+49 60 74 40 71 10 +34 93 225 16 20 +421 37 642 25 26 +1 517 663 8191 +81 564 26 25 91 +91 20 25510710/11

AXSON TECHNOLOGIES verkauf@axson.de axson@axson.es office@axson-ce.sk info@axson-na.com sales@axson.jp info.india@axson.com

Head Office France axson.de axson.es axson-ce.sk axson-na.com axson.jp axson.com

+33 1 34 40 34 60

axson@axson.fr ITALY U.K. MEXICO CHINA MIDDLE EAST

axson.fr +39 02 96 70 23 36 +44 1 638 66 00 62 +52 55 52 64 49 22 +86 21 58 68 30 37 +971 433 532 81

axson@axson.it sales@axson.co.uk axson@prodigy.net.mx china@axson.cn info.middleeast@axson.com

axson.it axson.com axson.com.mx axson.cn axson.com

UR 3569

SURFACE CASTING RESIN

HARDNESS 70 – SHORE A –COLD CURING

THERMAL AND SPECIFIC PROPERTIES (1)

Working temperature - °C -40 / +80

Glass transition temperature (Tg) ISO 11357 : 1999 °C 105

Coefficient of thermal expansion (CTE) -6 -1 140

ISO 11359 : 1999 10 K

(+0° to +40°C)

Linear shrinkage (specimen 250x50x3mm) - mm/m 3.5

Maximal casting thickness - mm 20

Demoulding time

-at 23°C - hours 16

-at 80°C 4

Complete hardening time

-

-at 23°C - days 6

-at 80°C (curing after gel) min 80

(1) : Average values obtained on standard specimens / Hardening conditions 16 hr at 70°C

HANDLING PRECAUTIONS

Normal health and safety precautions should be observed when handling these products :

Ensure good ventilation

Wear gloves, safety glasses and protective clothes.

For further information, please consult the product safety data sheet.

STORAGE CONDITIONS

Shelf life is 12 months in a dry place and in original unopened containers at a temperature between 15 and 25° C.

Any open can must be tightly closed under dry nitrogen blanket.

PACKAGING

ISOCYANATE POLYOL

1 x 5 kg 1 x 2 kg

6 x 1 kg 6 x 0.4 kg

GUARANTEE

The information of our technical data sheet are based on our present knowledge and the result of tests conducted under precise conditions. It

is the responsibility of the user to determine the suitability of AXSON products, under their own conditions before commencing with the

proposed application. AXSON refuse any guarantee about the compatibility of a product with any particular application. AXSON disclaim all

responsibility for damage from any incident which results from the use of these products. The guarantee conditions are regulated by our

general sale conditions.

nd

Page 2/2-TDS10F0016 – September 02 , 2010

GERMANY SPAIN & PORTUGAL SLOVAKIA NORTH AMERICA JAPAN INDIA

+49 60 74 40 71 10 +34 93 225 16 20 +421 37 642 25 26 +1 517 663 8191 +81 564 26 25 91 +91 20 25510710/11

AXSON TECHNOLOGIES verkauf@axson.de axson@axson.es office@axson-ce.sk info@axson-na.com sales@axson.jp info.india@axson.com

Head Office France axson.de axson.es axson-ce.sk axson-na.com axson.jp axson.com

+33 1 34 40 34 60

axson@axson.fr ITALY U.K. MEXICO CHINA MIDDLE EAST

axson.fr +39 02 96 70 23 36 +44 1 638 66 00 62 +52 55 52 64 49 22 +86 21 58 68 30 37 +971 433 532 81

axson@axson.it sales@axson.co.uk axson@prodigy.net.mx china@axson.cn info.middleeast@axson.com

axson.it axson.com axson.com.mx axson.cn axson.com

You might also like

- Epolam2040 2042 2047 GBDocument6 pagesEpolam2040 2042 2047 GBEduardo JoseNo ratings yet

- Adekit H9952Document4 pagesAdekit H9952José Antonio CuberoNo ratings yet

- Adekit A257 BK / H6257 BK: DescriptionDocument2 pagesAdekit A257 BK / H6257 BK: DescriptioneryNo ratings yet

- Epolam2500 GBDocument2 pagesEpolam2500 GBMcFlyNo ratings yet

- Epolam2500 GB PDFDocument2 pagesEpolam2500 GB PDFMcFlyNo ratings yet

- Epolam2500 GB PDFDocument2 pagesEpolam2500 GB PDFMcFlyNo ratings yet

- Adekit A 170 BK: Structural Thixotropic Epoxy AdhesiveDocument3 pagesAdekit A 170 BK: Structural Thixotropic Epoxy AdhesivesantiagoNo ratings yet

- Adekit A 140Document3 pagesAdekit A 140José Antonio CuberoNo ratings yet

- Styrolution PS 485N: High Impact Polystyrene (HIPS)Document2 pagesStyrolution PS 485N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Lexan™ Exell™ D - Sheet DatasheetDocument3 pagesLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNo ratings yet

- (Jay Shoemaker) Moldflow Design Guide 'A ResourcDocument3 pages(Jay Shoemaker) Moldflow Design Guide 'A ResourcFahri ibişoğluNo ratings yet

- Tekasil Neutral Profi enDocument2 pagesTekasil Neutral Profi enEzeval GráficaNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- Styrolution PS 495N: High Impact Polystyrene (HIPS)Document3 pagesStyrolution PS 495N: High Impact Polystyrene (HIPS)Inês MorgadoNo ratings yet

- General Information: 9.6 PP 100 / 20 PP 1.2Document3 pagesGeneral Information: 9.6 PP 100 / 20 PP 1.2vijayNo ratings yet

- ECOLAY Brochure NOX OutlineDocument14 pagesECOLAY Brochure NOX OutlinemishelleNo ratings yet

- BT - Absortex Eg - 346919 - Rev 120719 enDocument1 pageBT - Absortex Eg - 346919 - Rev 120719 enDEIVISON SILVANo ratings yet

- Advaboard TDSDocument1 pageAdvaboard TDSMohammed AbugharbiehNo ratings yet

- Compressor Oils: DIN 51506 VDL (Only For 32, 46, 68, 100, 150) DIN 51506 VBL (Only For 150-M, 220, 320, 460)Document2 pagesCompressor Oils: DIN 51506 VDL (Only For 32, 46, 68, 100, 150) DIN 51506 VBL (Only For 150-M, 220, 320, 460)Majed DawaNo ratings yet

- Lexan™ Exell D STP - Sheet DatasheetDocument2 pagesLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesNo ratings yet

- TSE2323 Series: Heat Resistant Silicone ElastomerDocument2 pagesTSE2323 Series: Heat Resistant Silicone Elastomercuenta_descarga88No ratings yet

- Datasheet Cawiton PR13635 - 002Document1 pageDatasheet Cawiton PR13635 - 002Fred HahnNo ratings yet

- Datasheet Cawiton PR13630 - 004Document1 pageDatasheet Cawiton PR13630 - 004Fred HahnNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- Tasnee LD 4025as Polyethylene: DescriptionDocument2 pagesTasnee LD 4025as Polyethylene: Descriptiontrần hải namNo ratings yet

- SABIC® PPcompound_2606_Global_Technical_Data_SheetDocument2 pagesSABIC® PPcompound_2606_Global_Technical_Data_SheetFahri ibişoğluNo ratings yet

- PS 416 N - F.T.Document2 pagesPS 416 N - F.T.Inês MorgadoNo ratings yet

- Omega Amide Nylon Pa CatalogueDocument5 pagesOmega Amide Nylon Pa Cataloguesoni10483No ratings yet

- Luran S 777K: Acrylonitrile Styrene Acrylate (ASA)Document3 pagesLuran S 777K: Acrylonitrile Styrene Acrylate (ASA)Leonardo DguezNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- Riblene FC 30Document2 pagesRiblene FC 30Josevi Jiménez MerinoNo ratings yet

- Datasheet Cawiton PR13675 - 002Document1 pageDatasheet Cawiton PR13675 - 002Fred HahnNo ratings yet

- Datasheet Cawiton PR13665 - 002 PDFDocument1 pageDatasheet Cawiton PR13665 - 002 PDFFred HahnNo ratings yet

- Styrolution TDS300600621530Document2 pagesStyrolution TDS300600621530seguridadehigieneseguridadehigNo ratings yet

- Styrolution 3 G55Document3 pagesStyrolution 3 G55John EduardoNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- Tasnee 1925ASDocument1 pageTasnee 1925ASpolymeianNo ratings yet

- Makrolon UV: Solid Polycarbonate SheetDocument2 pagesMakrolon UV: Solid Polycarbonate SheetKIMIKA Industrial CorporationNo ratings yet

- Sabic® Ldpe 2201H0Document2 pagesSabic® Ldpe 2201H0Berkosan BalkansNo ratings yet

- Datasheet Cawiton PR13610 - 002Document1 pageDatasheet Cawiton PR13610 - 002Fred HahnNo ratings yet

- Epoxy System LR620 Laminating: DescriptionDocument3 pagesEpoxy System LR620 Laminating: DescriptionFarzad LotfalipourNo ratings yet

- SABIC® HDPE - P6006AD - Global - Technical - Data - SheetDocument1 pageSABIC® HDPE - P6006AD - Global - Technical - Data - SheetNaren RawatNo ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- Luran 368R: Technical DatasheetDocument3 pagesLuran 368R: Technical DatasheetVictor PuertoNo ratings yet

- Datasheet Cawiton PR13650 - 004 PDFDocument1 pageDatasheet Cawiton PR13650 - 004 PDFFred HahnNo ratings yet

- Luran HH-120: Please SelectDocument3 pagesLuran HH-120: Please SelectDavid Costi da RosaNo ratings yet

- Terluran GP-35: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-35: Acrylonitrile Butadiene Styrene (ABS)DiegoTierradentroNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Estar 4030 HT PDFDocument1 pageEstar 4030 HT PDFhendrik kNo ratings yet

- Dacnis SEDocument1 pageDacnis SEironite100% (1)

- Dacnis SE PDFDocument1 pageDacnis SE PDFironiteNo ratings yet

- Styro Lution Tds 200400070620Document3 pagesStyro Lution Tds 200400070620gv_ScribdNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- TCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetDocument1 pageTCS-Geotechnics-Terram-T Series-Standard Nonwoven Geotextile-Data SheetBerat DalyabrakNo ratings yet

- Disola M3015-4015-5015Document2 pagesDisola M3015-4015-5015DriptoNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNo ratings yet

- Terlux 2802 TRDocument2 pagesTerlux 2802 TRDouglas AndradeNo ratings yet

- Small Volume Parentrals: Dr.Y.Anand KumarDocument25 pagesSmall Volume Parentrals: Dr.Y.Anand Kumarsaloni patelNo ratings yet

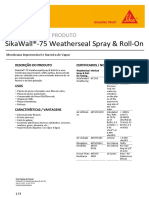

- Sikawall®-75 Weatherseal Spray & Roll-On: Ficha Técnica de ProdutoDocument3 pagesSikawall®-75 Weatherseal Spray & Roll-On: Ficha Técnica de ProdutoJaime Pinn RegliNo ratings yet

- Astm C311 - C311M 22Document11 pagesAstm C311 - C311M 22Diego RochaNo ratings yet

- Full Download Book Practical Guide To Rotational Moulding PDFDocument41 pagesFull Download Book Practical Guide To Rotational Moulding PDFmark.king621100% (28)

- Best Questions On Chemical Equilirbium FDocument8 pagesBest Questions On Chemical Equilirbium Flakshit singhalNo ratings yet

- Sodium Chloride: Standard Specification ForDocument4 pagesSodium Chloride: Standard Specification Forsebastian novoaNo ratings yet

- Copper Alloy Datasheet - AmericanDocument58 pagesCopper Alloy Datasheet - Americanyw_oulalaNo ratings yet

- Iso 6332 1988Document8 pagesIso 6332 1988Jim FrenkenNo ratings yet

- Plant CholesterolDocument13 pagesPlant Cholesterolrnd labNo ratings yet

- HN1530 L-2 Control Lot-1665UN MethodDocument18 pagesHN1530 L-2 Control Lot-1665UN MethodBenn BasilNo ratings yet

- Construction and Building MaterialsDocument15 pagesConstruction and Building MaterialsZakaria MohdNo ratings yet

- EAS 81 - 1 Milk Powders - Determination Ash and AlkalinityDocument7 pagesEAS 81 - 1 Milk Powders - Determination Ash and AlkalinityJocilene DantasNo ratings yet

- N Vasilesco-Karpen - Pile Permanente - FR577087A en PDFDocument3 pagesN Vasilesco-Karpen - Pile Permanente - FR577087A en PDFAlexandru DragomirNo ratings yet

- Chemical Engineering Journal: A B C D e e CDocument10 pagesChemical Engineering Journal: A B C D e e CHemanth Peddavenkatappa GariNo ratings yet

- Electrolysis Notes For SdaDocument13 pagesElectrolysis Notes For Sdatmoatshe96No ratings yet

- Poster 230 The Space Group List Project 230 Dina0 CDocument2 pagesPoster 230 The Space Group List Project 230 Dina0 CrataburguerNo ratings yet

- A Review of Biogas Utilisation, Purification and Upgrading TechnologiesDocument17 pagesA Review of Biogas Utilisation, Purification and Upgrading TechnologiesXavier OrtizNo ratings yet

- Part I: Trade Name Reference: AmfineDocument119 pagesPart I: Trade Name Reference: AmfineMoawiya HaddadNo ratings yet

- Polypropylene Natural Data SheetDocument1 pagePolypropylene Natural Data SheetsribachaNo ratings yet

- CHM 334 Colour Chem Part 1 - 2021Document27 pagesCHM 334 Colour Chem Part 1 - 2021Kelly ZimmermanNo ratings yet

- Chem Principles 7e ISM Focus 01 Even FINALDocument26 pagesChem Principles 7e ISM Focus 01 Even FINALSelma MeloNo ratings yet

- Neighbouring Group Participation PPT by Faiza ShahDocument17 pagesNeighbouring Group Participation PPT by Faiza Shahsweety_syed93% (14)

- Grade 4 Science Weeks 5-8 Worksheets - Term 2Document31 pagesGrade 4 Science Weeks 5-8 Worksheets - Term 2LamThiCamThuyNo ratings yet

- Additional English Sharp Notes PDFDocument1 pageAdditional English Sharp Notes PDFOm SonawaneNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data Sheetshyamdas38892853No ratings yet

- Trinity International School (Cbse) : A. Ni + and Cu B. Sc3+ and Ti3+Document5 pagesTrinity International School (Cbse) : A. Ni + and Cu B. Sc3+ and Ti3+Vishal M. VNo ratings yet

- Mondo Plexi-Tite BrochureDocument2 pagesMondo Plexi-Tite BrochureRonie Mae CalayoNo ratings yet

- Certificate of Analysis: 17α-Hydroxy Progesterone AcetateDocument2 pagesCertificate of Analysis: 17α-Hydroxy Progesterone Acetatewindli2012No ratings yet

- Metal Clusters:: Structure and Bonding in Higher BoranesDocument48 pagesMetal Clusters:: Structure and Bonding in Higher BoranesAnujNo ratings yet

- Ethylene MSDS (OPaL)Document5 pagesEthylene MSDS (OPaL)Viral PatelNo ratings yet